Introduction: Navigating the Global Market for file sldprt

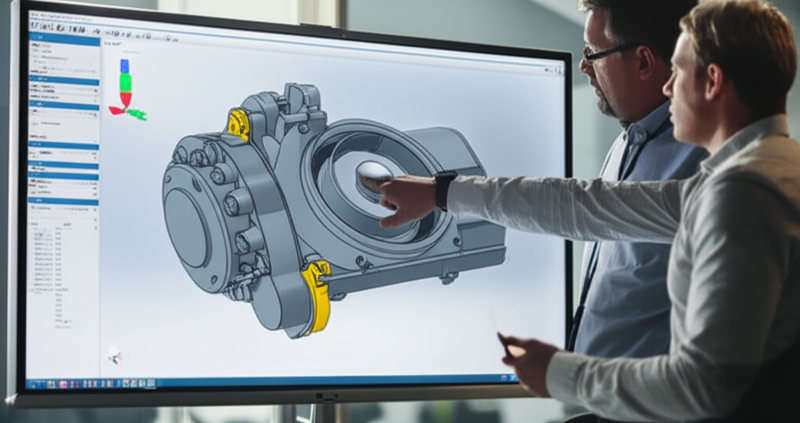

In today’s interconnected manufacturing landscape, the ability to efficiently source and utilize high-quality engineering files such as SLDPRT is a linchpin for international B2B success. SLDPRT, the proprietary part file format used by SolidWorks, enables detailed 3D modeling of individual components—critical for sectors ranging from automotive and aerospace to consumer goods and industrial machinery. For buyers in Africa, South America, the Middle East, and Europe, understanding how to navigate the complexities of SLDPRT files is essential not just for seamless collaboration with global partners, but also for meeting stringent quality, compatibility, and speed-to-market expectations.

SLDPRT files are much more than digital blueprints—they are the core of product development, enabling rapid prototyping, precise communication among supply chain partners, and smooth transitions from design to manufacturing. Their interoperability, support for conversions into universal CAD and manufacturing formats, and the robust ecosystem of software and service providers around them make SLDPRT files a preferred standard for cross-border collaborations.

This guide is designed for strategic B2B buyers seeking clarity and competitive advantage in their SLDPRT sourcing journeys. It covers:

- SLDPRT file types and compatibility: Understanding variants and essential software tools.

- Materials and manufacturing standards: From metals to polymers and quality benchmarks.

- Supplier selection and due diligence: Vetting, audits, and partnerships worldwide.

- Cost structures and negotiation insights: Price drivers, hidden costs, and benchmarking.

- Market trends and risk management: Evolving demand, regulatory influences, and digital transformation.

- FAQs and troubleshooting: Addressing common pain points in global SLDPRT procurement.

By equipping your team with these actionable insights, you can minimize risks, control costs, and secure reliable, high-quality part files—whether collaborating with design houses in Italy, manufacturers in Argentina, or upstream suppliers across Africa and the Middle East. This guide aims to turn complex sourcing decisions into clear opportunities for growth and innovation.

Understanding file sldprt Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Native SolidWorks SLDPRT | Fully-editable, high-fidelity SolidWorks part file | Engineering design, modifications | Best for collaboration and editing; requires SolidWorks license |

| Neutral Format Export (STEP/IGES) | SLDPRT exported as a widely-supported neutral 3D format | Cross-software compatibility, OEM supply | Highly versatile; some parametric data loss |

| Visualization/Viewer SLDPRT | Optimized for viewing only (.eprt, eDrawings) | RFQs, supplier-client communications | Secure, lightweight files; no direct editing possible |

| Mesh Conversion (STL/OBJ) | SLDPRT converted to mesh-based formats | 3D printing, prototype manufacturing | Essential for rapid prototyping; no native feature/parametric data |

| Batch/Bulk Converted SLDPRT | Multiple SLDPRTs processed simultaneously for standardization | Large project management, data migration | Streamlines workflows; risk of conversion inconsistencies with complex models |

Native SolidWorks SLDPRT

This variation retains the full parametric feature history, enabling engineers and designers to adjust dimensions, features, and tolerances with ease. It offers maximum flexibility for iterative design and collaboration, especially within organizations or partners who use SolidWorks. B2B buyers should consider the need for ongoing modifications, supplier design input, or localization as justifications to request native SLDPRT files. However, access requires a licensed version of SolidWorks, potentially increasing total project costs for companies lacking in-house CAD resources.

Neutral Format Export (STEP/IGES)

By exporting SLDPRT files to neutral formats like STEP or IGES, buyers gain broad interoperability across various CAD and PLM platforms. These are ideal for suppliers or manufacturers outside the SolidWorks ecosystem, ensuring the 3D design intent is preserved. B2B buyers should specify export standards compatible with their in-house systems. Despite high compatibility and reduced vendor lock-in, some advanced parametric or feature-based data might be lost, making future edits less efficient.

Visualization/Viewer SLDPRT

Files prepared for viewing (such as eDrawings, .eprt) strip editing capabilities, focusing on easy and secure sharing. These are highly effective for reviewing part geometry, validating quotes, or discussing modifications without risking IP leakage. B2B buyers benefit from lightweight files that can be opened in free viewers, facilitating decision-making among non-technical stakeholders. The main tradeoff is that such files cannot be directly altered or adapted, so communication with the file originator is necessary for changes.

Mesh Conversion (STL/OBJ)

Converted mesh formats represent the solid as discrete facets, suitable for additive manufacturing or 3D printing workflows. Common in prototyping and small-batch production across Africa, South America, and the Middle East, these files are machine-ready for most 3D printers and digital factories. Buyers must recognize that mesh files do not retain design features, making modifications challenging. It’s vital for B2B procurement teams to ensure final design signoff before mesh conversion to avoid costly revisions.

Batch/Bulk Converted SLDPRT

This approach involves exporting or converting multiple SLDPRT files simultaneously, aiding in managing large projects or standardizing part libraries. It accelerates data migration and multi-supplier collaboration by delivering files in required target formats efficiently. B2B buyers, especially those coordinating large assemblies with international suppliers (such as European automotive or Middle Eastern energy sectors), should emphasize robust QA procedures to verify conversion integrity and prevent downstream manufacturing errors. Streamlined, but vigilance is necessary to avoid inconsistent data or format-specific issues.

Related Video: SOLDIWORKS How to convert STEP files to SOLIDWORKS parts file (SLDPRT)

Key Industrial Applications of file sldprt

| Industry/Sector | Specific Application of file sldprt | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Automotive Manufacturing | 3D modeling of engine or chassis components | Accelerates prototyping, reduces development cycles | Software compatibility, IP protection, global collaboration support |

| Industrial Equipment | Custom parts and component engineering | Enables rapid iteration for complex machinery designs | File interoperability, supplier technical expertise, secure data exchange |

| Aerospace & Defense | Prototyping and simulation of critical parts | Ensures manufacturing accuracy, supports stringent QA | Compliance with industry standards, high-precision data, version control |

| Consumer Electronics | Design and testing of enclosures & assemblies | Enhances product aesthetics and fit, accelerates market entry | Protection of design IP, integration with multi-CAD workflows |

| Oil & Gas Engineering | Tooling and pipeline component design | Reduces risk of failure, improves operational efficiency | Robust encryption, on-site compatibility checks, rapid file conversion |

Automotive Manufacturing

In the automotive sector, SLDPRT files are indispensable for designing and iterating vehicle components such as engine blocks, suspension parts, and body panels. Engineers utilize these part files for 3D modeling, simulation, and virtual assembly, allowing rapid prototyping and easier modification. For buyers across regions like Europe and South America, having partners who can both receive and deliver SLDPRT files streamlines joint ventures and facilitates localization of vehicle models. It’s crucial to ensure vendor platforms are compatible with industry-standard CAD systems and support secure file exchanges, especially with global supply chains.

Industrial Equipment

Manufacturers of industrial machinery employ SLDPRT files to custom-engineer parts, refine existing designs, and validate assemblies in a virtual environment before fabrication. This enables buyers in Africa and the Middle East to source precision-engineered components tailored to local operational conditions. Interoperability with digital manufacturing workflows and the ability to handle multi-part assemblies are vital. Buyers should prioritize suppliers well-versed in CAD conversion and data integrity, ensuring SLDPRT files are accurately translated and securely handled during transactions.

Aerospace & Defense

Aerospace and defense contractors rely on SLDPRT files for detailed design, structural simulation, and production planning of safety-critical components. The file’s high level of detail supports regulatory compliance and quality assurance in environments with zero tolerance for error. International buyers, including those in Europe and the Middle East, must verify that design files conform to sectoral standards and that suppliers have robust version control and cybersecurity measures in place to safeguard sensitive designs and intellectual property throughout collaboration.

Consumer Electronics

For consumer electronics, SLDPRT files enable rapid prototyping of housings, connectors, and internal structures. Design teams can share and modify files seamlessly across continents, reducing the product development timeline and improving overall quality. In emerging markets like Africa and South America, the capacity to integrate SLDPRT with existing design systems or convert to neutral formats is important. B2B buyers should check that manufacturers can handle multi-file projects and protect proprietary data throughout the design-to-manufacture process.

Oil & Gas Engineering

SLDPRT files play a critical role in designing drilling tools, pipeline fittings, and safety equipment. Their precision modeling supports accurate stress simulations and ensures that components meet operational and regulatory standards. For buyers in regions such as the Middle East and Africa, it’s essential that suppliers guarantee secure file transfers, quick conversions into required standards (e.g., STEP or IGES), and have processes for on-site verification. This minimizes downtime and improves the reliability of highly engineered oil and gas infrastructure.

Related Video: Uses and Gratifications Theory

Strategic Material Selection Guide for file sldprt

Analyzing Common Materials for SLDPRT-Based Parts in B2B Applications

Selecting the optimal material for a component modeled in an SLDPRT file is fundamental to its commercial viability, lifecycle performance, and regulatory compliance—especially when sourcing or manufacturing internationally. Below is an analysis of four widely used industrial materials in SLDPRT-driven design and manufacturing: Stainless Steel, Aluminum Alloys, Engineering Plastics (such as ABS or Nylon), and Cast Iron. Each is evaluated to assist B2B buyers, factoring in key properties, typical benefits and limitations, and application-specific considerations across Africa, South America, the Middle East, and Europe.

Stainless Steel (e.g., 304, 316 Grades)

Key Properties:

Stainless steels, particularly 304 and 316 grades, offer high corrosion resistance, robust temperature tolerance (-200°C to ~800°C depending on grade), and excellent mechanical strength. 316 provides superior resistance to chlorides and aggressive environments.

Pros:

– Exceptional durability in corrosive or high-humidity environments

– Broad compliance with international standards (ASTM, DIN, EN, JIS)

– Suitable for hygienic or food-grade applications

Cons:

– Higher material and machining cost versus carbon steel

– Can be susceptible to stress corrosion cracking in some cases

Application Impact:

Ideal for parts exposed to chemicals, marine climates, or sanitation-critical sectors (e.g., food processing in Italy; water infrastructure in the Middle East). For African and South American buyers, 304 may suffice for general exposure, while 316 is often specified for harsher environments.

International Considerations:

Widespread adherence to recognized stainless grades ensures smoother cross-border procurement. Buyers must confirm compatibility with regional standards (ASTM A240, EN 10088, JIS G4304, etc.), which are often requested by EU and Middle East partners.

Aluminum Alloys (e.g., 6061, 7075)

Key Properties:

Aluminum alloys deliver low density, good corrosion resistance, and moderate mechanical strength, making them highly suitable for weight-sensitive applications. 6061 is known for versatility and ease of machining; 7075 is stronger but costlier.

Pros:

– Lightweight (1/3 the density of steel) for reduced shipping costs

– Good corrosion resistance and non-magnetic properties

– Often less expensive to machine due to softness

Cons:

– Lower strength and wear resistance compared to steel

– Not suitable for highly abrasive or high-temperature environments

Application Impact:

Common in parts where weight reduction is critical, such as in automotive or packaging machinery, especially relevant for European exporters. Aluminum is also valued in Africa and South America where logistics costs are significant. Not recommended for heavily loaded or severe wear applications.

International Considerations:

Aluminum alloys are standardized globally; major grades conform to ASTM B209 (USA), EN 573/485 (Europe), and JIS H4000 (Japan). Specifications and supply quality may vary, so careful supplier vetting is needed, particularly in regions with variable metal processing infrastructure.

Engineering Plastics (e.g., ABS, Nylon)

Key Properties:

Engineering plastics like ABS (Acrylonitrile Butadiene Styrene) and Nylon offer chemical resistance, light weight, and electrical insulation. They tolerate moderate temperatures (ABS: –20°C to 80°C; Nylon: up to 120°C).

Pros:

– Highly versatile with complex geometries possible via injection molding or additive manufacturing

– Resistant to many chemicals, lightweight, and low cost

– Excellent for prototyping and non-structural parts

Cons:

– Limited load-bearing and temperature range compared to metals

– Can degrade with prolonged UV exposure (ABS especially)

Application Impact:

Suitable for enclosures, housings, and components in consumer electronics or light-duty mechanical systems. For exporters to Africa or South America, these materials offer a cost-effective path for rapid market penetration, though suitability for harsh sun-exposed outdoor use may be limited.

International Considerations:

Plastic grades may have local variants; buyers should check compliance with IEC or UL standards and match environmental resistance to local climate conditions. Availability of recycling streams can be a key factor in the EU.

Cast Iron (e.g., Grey Iron, Ductile Iron)

Key Properties:

Cast irons are valued for excellent vibration damping, high compressive strength, and good machinability. While relatively heavy, they remain cost-effective for mass production of stable parts.

Pros:

– High wear resistance and dimensional stability

– Cost-effective for high-volume, heavy-duty parts

– Suitable for applications with low to moderate corrosion risks

Cons:

– Brittle (grey iron), can crack under impact

– Heavy (complicates shipping to remote markets)

– Poor corrosion resistance compared to stainless steel or aluminum

Application Impact:

Dominant in machine bases, piping components, and agricultural machinery. In Africa and South America, cast iron’s robustness favors local machine-building, though careful logistics planning is crucial due to weight. In the EU, stricter regulations on foundry emissions might limit procurement options.

International Considerations:

Grades like ASTM A48 (grey iron) and ASTM A536 (ductile iron) are prevalent, but European standards (EN 1561, 1563) may differ. B2B buyers should confirm certification and, where necessary, negotiate for inspection reports or sample analysis.

Summary Table: Common Materials for SLDPRT-Based Components

| Material | Typical Use Case for file sldprt | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (304/316) | Corrosion-resistant mechanical parts, food-grade equipment | Excellent corrosion resistance, global standardization | Higher cost vs. carbon steel; can be hard to machine | High |

| Aluminum Alloy (6061/7075) | Lightweight structural parts, transport equipment | Low weight, easy to machine | Lower strength and wear resistance than steel | Medium |

| Engineering Plastics (ABS, Nylon) | Housings, prototypes, light-duty mechanical devices | Low cost, easily formed into complex shapes | Limited load/temperature; UV aging (esp. ABS) | Low |

| Cast Iron (Grey/Ductile) | Heavy-duty frames, machinery bases, piping | High stability, excellent machinability | Brittle (grey); heavy; moderate corrosion resistance | Low to Medium (varies by region) |

In-depth Look: Manufacturing Processes and Quality Assurance for file sldprt

SolidWorks SLDPRT files serve as a digital backbone for custom part manufacturing across a wide spectrum of industries—from automotive components in Italy to agricultural machinery in Argentina, industrial equipment in South Africa, and oil & gas applications in the Middle East. Understanding how these designs are transformed from 3D models to finished parts, as well as how quality is controlled throughout the process, is essential for international buyers seeking reliable partners and consistent results.

Manufacturing Process Overview

The journey from SLDPRT file to physical part typically follows a structured sequence, blending digital precision with rigorous shop-floor practices. While specific steps can vary depending on industry, material, and complexity, common stages include:

1. Material Sourcing and Preparation

- Material Selection: The SLDPRT file defines geometric attributes, but material—be it steel, aluminum, plastics, or composites—must be specified according to property requirements and international market norms.

- Material Certification: Especially for buyers in sectors with regulatory oversight (like energy or medical equipment), ensure suppliers provide mill certificates validating material grades and traceability.

2. Part Forming and Machining

- Computer-Aided Manufacturing (CAM): The SLDPRT file is transitioned into CAM software to generate tool paths for CNC machining, 3D printing (additive manufacturing), or other forming operations.

- Primary Manufacturing Methods:

- CNC Machining: For precise, subtractive fabrication from billets or plates; popular for low/mid-volume or highly complex parts.

- Injection Molding or Casting: For mass production and plastics/metals; mold design is often driven directly by the SLDPRT geometry.

- Additive Manufacturing: Rapid prototyping or production of complex geometries directly from SLDPRT via 3D printing.

- Process Validation: Critical for custom parts. Buyers should request initial samples (first article inspection or FAI) before bulk production proceeds.

3. Assembly (if applicable)

- When parts designed as SLDPRT files are incorporated into multipart assemblies, precision in fit and function is ensured by digital cross-checks during design and by physical validation during pilot assembly.

4. Finishing Operations

- Surface Treatment: Includes painting, coating, anodizing, or plating to meet functional or aesthetic requirements.

- Dimensional Inspection: Final checks to confirm that critical dimensions match those specified in the SLDPRT and accompanying technical drawings.

Key Quality Assurance (QA) and Quality Control (QC) Approaches

For international B2B buyers, a robust QC process is non-negotiable. The following frameworks and checkpoints are critical throughout manufacturing, regardless of origin market or production geography.

International and Industry-Specific QA Standards

- ISO 9001: The global benchmark for quality management systems—suppliers should be certified wherever possible.

- Industry Certificates: Depending on application, buyers may require:

- CE Marking: For European market entry, especially in machinery, electrical, or medical sectors.

- API: American Petroleum Institute, vital for parts used in oil & gas applications (common for Middle East or African buyers).

- AS9100: Aerospace, for buyers in advanced manufacturing.

- Other regional or sector-specific approvals, as dictated by law or best practice in your country/sector.

Quality Control Stages and Checkpoints

- Incoming Quality Control (IQC): Inspection of raw materials and components to verify conformity with purchase requirements and prevent defect propagation.

- In-Process Quality Control (IPQC): Ongoing monitoring during key production steps—measurement of critical features using CMMs (Coordinate Measuring Machines), visual inspections, and process audits to catch deviations early.

- Final Quality Control (FQC): Comprehensive review of finished parts prior to dispatch, including dimensional checks, functional tests, and surface finish evaluations.

Common Testing and Inspection Methods

- Dimensional Measurement: Using calipers, micrometers, or CMMs to verify geometric tolerances defined in the SLDPRT.

- Destructive and Non-Destructive Testing (NDT): For mission-critical items—UT (ultrasonic), X-ray, or magnetic particle inspection, as required.

- Functional Testing: Assembling parts to confirm fit, motion, or other operational parameters as specified by the buyer.

Ensuring Quality as an International B2B Buyer

Buyers from Africa, South America, the Middle East, and Europe each face specific procurement challenges—logistical, linguistic, and regulatory. Implementing a proactive QC oversight strategy can mitigate risk and assure product integrity.

Supplier Prequalification and Due Diligence

- Site Audits (Remote or In-Person): Arranging pre-production audits or walkthroughs helps confirm that the manufacturer follows best practices and maintains appropriate certifications.

- Sample Approvals and PPAP: Utilizing Production Part Approval Process (PPAP) and requiring documented sample approvals ensures the supplier’s process can consistently meet requirements.

Transparency and Documentation

- Quality Documentation: Insist on detailed inspection reports, material certificates, and where relevant, traceable process logs. These should be provided in your preferred language or with certified translations.

- Change Management: Any revisions to the SLDPRT (and thus the part design) must pass through formal change management with updated approvals.

Third-Party Inspection and Local Agents

- For buyers far removed from manufacturers, using independent QC agencies—such as SGS, TÜV, or Intertek—provides added confidence. These bodies can inspect goods pre-shipment on your behalf, referencing the SLDPRT and associated drawings as control documents.

QC and Certification Nuances by Region

- Africa and South America: While international certificates (ISO, CE) are valuable, local standards or customs-related documentation may also be required to facilitate import and resolve disputes.

- Middle East: Traceability and proof of origin are often demanded, especially for infrastructure or energy-related sectors.

- Europe (e.g., Italy): Compliance with CE and alignment to EU directives is critical; documentation must meet regional legal standards and often requires attestation by authorized bodies.

Key Action Points for B2B Buyers

- Establish QC Protocols Early: Ensure expectations for inspection, testing, and certification are defined before releasing the SLDPRT and purchase order.

- Verify Certificates: Request and verify up-to-date ISO, CE, or industry-specific certifications with official bodies where possible.

- Engage 3rd Parties Where Needed: Consider cost-effective third-party inspection for high-value, safety-critical, or first-time orders.

- Communicate Clearly: Use unambiguous language and, if needed, bilingual contracts to avoid misinterpretation across regions.

Conclusion

Turning an SLDPRT file into high-quality finished parts requires clear control of every manufacturing and QC stage. For international buyers, diligence in supplier vetting, documentation, and independent oversight bridges the gap between digital design and consistent, compliant results. By specifying requirements clearly and verifying supplier capabilities, you’ll confidently manage risk and secure high-value supplier relationships regardless of market region.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for file sldprt Sourcing

Understanding the True Cost of SLDPRT File Sourcing in International B2B Markets

When sourcing SLDPRT files (SolidWorks part files) in the global B2B context, buyers need to look beyond the initial quoted price. The costs inherent to engineering, manufacturing, and logistics can vary significantly based on supplier location, technical requirements, and market factors—especially for buyers in Africa, South America, the Middle East, and Europe. A comprehensive approach to cost analysis enables better negotiation power and a more accurate understanding of the Total Cost of Ownership.

Core Cost Components

1. Materials:

Whether the SLDPRT file defines a plastic, metal, or composite part, material selection directly affects cost. Prices fluctuate by region, material grade, and certification (e.g., REACH or RoHS compliance), and should be confirmed in writing.

2. Labor:

CAD modeling, engineering design, and potential validation are labor-intensive. Labor rates differ sharply worldwide: European and Middle Eastern suppliers usually charge premium rates, while African and South American suppliers can be more cost-competitive, though this may impact lead times or require extra project oversight.

3. Manufacturing Overhead:

This involves machine time, utilities, and facility costs, which can be embedded in SLDPRT file pricing when physical parts or prototypes are also sourced. Evaluate whether digital deliverables include costs for CAD software licenses or cloud-based collaboration tools.

4. Tooling and Setup (if physical prototyping or manufacturing is included):

Some SLDPRT-based projects require custom tooling for prototyping or later mass production. Request a breakdown between NRE (non-recurring engineering) charges and per-part pricing.

5. Quality Control (QC) and Testing:

Suppliers may charge additional fees for technical documentation, compliance reports, or third-party verifications. Clear communication on QC expectations is essential, particularly for highly regulated sectors.

6. Logistics and Data Transfer:

While digital transfer is typically low-cost, large files or secure transfer (with encryption) can incur extra charges. When physical deliverables or prototypes accompany the digital files, shipping costs (air, sea, incoterms) must be factored in.

7. Supplier Margin:

Suppliers apply profit margins based on project complexity, market demand, and competitive positioning. Margins tend to be more negotiable in high-volume or long-term partnership scenarios.

Key Price Influencers

-

Order Volume & Minimum Order Quantity (MOQ):

Larger orders or ongoing contracts can command discounted rates. For small-batch or low-MOQ requests, expect pricing premiums. -

Design Specifications & Level of Customization:

Custom features, tight tolerances, or unique file conversions (e.g., SLDPRT to STEP, STL, or IGES) can add cost. Providing clear, standardized requirements can reduce back-and-forth and avoid escalation of engineering fees. -

Material Quality and Certifications:

Demanding advanced materials or international certifications (CE, ISO, etc.) raises costs. Always verify which certificates are genuinely critical for your market. -

Supplier Capabilities & Location:

Suppliers with advanced CAD capabilities or those certified to serve regulated industries may charge more. African and South American suppliers often offer lower prices but may provide less extensive documentation unless specified. -

Incoterms:

DDP (Delivered Duty Paid), FOB (Free On Board), and EXW (Ex Works) radically affect landed cost. Ensure that any price comparison is based on consistent incoterms.

Actionable Tips for International B2B Buyers

-

Negotiate for Transparent Quotes:

Request itemized cost breakdowns—especially for labor, design changes, material, and QC. Transparent suppliers are generally more reliable partners. -

Leverage Volume and Partnerships:

Use anticipated repeat business or bundled projects to negotiate better rates, particularly if sourcing from Europe or the Middle East where MOQs and relationships matter. -

Total Cost of Ownership (TCO):

Calculate not just the quote but all ancillary costs: design revisions, currency fluctuations, regulatory compliance, and potential rework. TCO is especially relevant for African and South American buyers who may face higher logistics fees. -

Clarify Data Ownership and IP Rights:

Ensure your agreement specifies IP transfer or licensing, especially if third-party design input is involved. Mishandled IP can incur hidden legal costs. -

Understand Local Price Drivers:

In emerging markets (e.g., Africa, South America), engage with suppliers who support standard international payment methods, and clarify all taxes, duties, and data transfer issues upfront to avoid surprises. -

Prioritize Digital Collaboration:

Take advantage of online SLDPRT viewers, translators, and cloud-based project management to streamline working across time zones and regulatory environments.

Important Disclaimer

- All price figures and cost structures outlined are indicative only. Actual prices will vary by supplier, market conditions, technical complexity, and region. Always conduct thorough due diligence and seek multiple competitive quotes before making sourcing decisions.*

By adopting a holistic and transparent approach to SLDPRT file sourcing, international buyers can mitigate risk, unlock better value, and achieve smoother project execution in the global market.

Spotlight on Potential file sldprt Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘file sldprt’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Convert SLDPRT CAD Files With Our Free Online Converter (fabconvert.com)

Convert SLDPRT CAD Files With Our Free Online Converter (FabConvert) is a specialized digital solutions provider focused on CAD and 3D file format conversions, including the SLDPRT file type. They offer a user-friendly, web-based platform that enables global businesses to convert SLDPRT files to a wide range of industry-standard formats such as STL, STEP, OBJ, and FBX, supporting both single and batch operations (up to 20 files at once and 100MB per file). This tool is cost-effective and accessible, with no usage fees or artificial limits, making it well-suited for lean manufacturing workflows and widely distributed engineering teams across Africa, South America, the Middle East, and Europe.

Key strengths include rapid conversion turnaround, multilingual support, and strict privacy practices (automatic file deletion after 15 minutes). Their adaptable online approach removes barriers for B2B buyers who may lack powerful local hardware or proprietary CAD software, streamlining cross-border collaboration and design transfer. While no manufacturing certifications are indicated, FabConvert is recognized as a practical, cloud-based resource in the SLDPRT sector, supporting seamless interoperability for international supply chains.

4 Best Free SLDPRT Viewer Software For Windows (listoffreeware.com)

ListOfFreeware.com aggregates and reviews top free SLDPRT viewer solutions for Windows, making it a trusted resource for industrial sectors looking to streamline 3D part visualization. Their featured software specializes in handling SolidWorks file formats such as SLDPRT, SLDASM, and SLDDRW, as well as a broad range of other CAD models. B2B buyers benefit from advanced viewing functions: precise zoom, pan, rotate, multiple projection views, wireframe and solid modes, as well as cross-sectional analysis. Several tools offer configurable lighting, markups for better design communication, and integrated measurement features (length, angle, volume, weight) to support technical collaboration and pre-manufacturing analysis. While specific certifications or export markets are not detailed, the selection focuses on usability and compatibility, making it suitable for procurement, engineering, and collaborative teams across Africa, South America, the Middle East, and Europe seeking efficient, no-cost CAD visualization solutions.

Open SLDPRT Online & Free (docpose.com)

Open SLDPRT Online & Free, accessible at docpose.com, provides a streamlined solution for online viewing of SLDPRT files, the native 3D part format from SolidWorks. The company focuses on rapid, browser-based file viewing and ease of access—users simply drag and drop files to instantly display complex CAD models without downloads or software installation. This service appeals to B2B buyers who require cross-team file access, supplier collaboration, or client verification in distributed international projects, especially where desktop CAD solutions are impractical.

Key strengths include support for immediate, free SLDPRT viewing and a user interface designed for non-technical users or remote teams. While detailed public information on certifications or manufacturing capacity is limited, the platform is positioned for international workflow integration, making it a practical tool for partners in Africa, South America, the Middle East, and Europe seeking fast, barrier-free CAD file access.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Convert SLDPRT CAD Files With Our Free Online Converter | Online batch SLDPRT CAD file conversion tool. | fabconvert.com |

| 4 Best Free SLDPRT Viewer Software For Windows | Aggregator of top free SLDPRT viewer tools. | listoffreeware.com |

| Open SLDPRT Online & Free | Instant online SLDPRT viewing tool. | docpose.com |

Essential Technical Properties and Trade Terminology for file sldprt

Critical Technical Properties of SLDPRT Files

1. Native CAD Compatibility

SLDPRT files are created using SolidWorks, a leading parametric 3D CAD software. This means they hold comprehensive parametric data and metadata about a part, including feature history, design intent, and editable geometry. For B2B buyers, ensuring SLDPRT file compatibility is essential for seamless collaboration with manufacturers, effective design iteration, and minimizing loss of detail when importing into other CAD ecosystems.

2. Granular Geometric Detail

These files encapsulate precise 3D geometry, including curves, faces, features, and edge definitions. The fidelity and resolution of this geometry are critical when specifying parts for high-precision applications such as automotive components, aerospace fittings, or medical devices. Detailed geometry allows for accurate prototyping, manufacturability analysis, and simulation, ensuring final products meet stringent international standards.

3. Interoperable Export Options

SLDPRT files can be converted or exported into widely accepted formats such as STEP (.STEP), IGES (.IGS), STL (.STL), and DXF (.DXF). Each exports different levels of detail or data. For international B2B buyers, the ability to request or supply files in these alternative formats enhances supply chain agility, especially when partnering with suppliers using different CAD platforms in countries such as Italy, Brazil, Germany, or UAE.

4. Parametric and Feature History

Unlike neutral 3D formats, SLDPRT maintains a “feature tree” that outlines every design step, from initial sketches to final features. This traceability increases design transparency and makes engineering changes efficient. For buyers, access to editable parametric data ensures the easy adaptation of a part to various market requirements or localization needs without starting from scratch.

5. File Integrity and Size Constraints

The integrity of an SLDPRT file is crucial, as file corruption can disrupt production timelines. When transferring large files—often exceeding 10MB for complex parts—secure file transfer protocols and timely downloads are essential to protect business continuity, especially in global trade contexts with connectivity variability.

6. Version Control and Revision Management

As parts move through design iterations, maintaining clear versioning and revision history within SLDPRT files prevents confusion and manufacturing errors. Accurate revision management is particularly critical for regulated industries or across multi-lingual, multi-country trade relationships.

Common Industry and Trade Terms for SLDPRT-Based Procurement

OEM (Original Equipment Manufacturer)

Refers to a company that produces parts or assemblies to another company’s specifications for integration into their final products. When discussing SLDPRT files, OEMs often require the original file or a compatible export to ensure components precisely fit into their larger assemblies.

MOQ (Minimum Order Quantity)

The minimum quantity a supplier is willing to produce or sell in a given order. For engineered parts sourced from SLDPRT files, MOQ can impact price-per-unit, logistics, and supplier selection, especially for custom or limited-run projects in regions like Africa or South America.

RFQ (Request for Quotation)

A formal process where a buyer requests a detailed price quote from suppliers for a specific volume and specification—in this case, often submitting SLDPRT files as part of the technical documentation. Properly structured RFQs streamline negotiations and help buyers compare offers across multiple vendors globally.

Incoterms (International Commercial Terms)

A standardized set of trade terms defining responsibilities for shipping, insurance, and tariffs in cross-border transactions. Understanding Incoterms is essential when procuring physical parts manufactured from SLDPRT data, as it impacts cost, liability, and delivery times for buyers in the Middle East, Europe, and beyond.

CAD Interoperability

This term describes the ability of one CAD system to reliably open, interpret, or modify files from another. Since not all supply chain partners use SolidWorks, verifying CAD interoperability—via neutral formats or with conversion tools—is key to avoiding costly miscommunications or delays.

BOM (Bill of Materials)

A comprehensive list of raw materials, components, and assemblies (all often linked to individual SLDPRT files) required to construct a product. When placing international orders, clarity in the BOM ensures accurate part sourcing, inventory management, and reduces errors during assembly.

By mastering these key technical characteristics and trade terms, B2B buyers can make informed decisions, facilitate reliable supplier communications, and ensure smooth cross-border transactions involving SLDPRT files and SolidWorks-based 3D models. This approach supports cost-effective procurement, minimizes design risks, and streamlines the move from digital design to physical manufacturing.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the file sldprt Sector

Global Market Overview and Key Sourcing Trends

The demand for SLDPRT files—an essential format for 3D part modeling in modern manufacturing—continues to surge across global B2B sectors. Industrial digitization and rapid prototyping are principal drivers, with industries such as automotive, aerospace, manufacturing, and medical device production increasingly reliant on sophisticated CAD workflows. As manufacturers and suppliers expand operations beyond traditional strongholds, international buyers from Africa, South America, the Middle East, and Europe are presented with new opportunities and challenges in sourcing SLDPRT-compatible solutions.

A defining trend is the widespread adoption of cloud-based and collaborative CAD platforms. These technologies enable geographically dispersed teams to concurrently design, iterate, and approve parts, drastically accelerating time-to-market. Additionally, SLDPRT file interoperability is becoming critical: suppliers that can natively handle multiple formats (e.g., STEP, IGES, STL, DWG) stand out, as buyers routinely require flexible integration with existing engineering ecosystems.

Sourcing activity is shifting toward value-driven partnerships. International buyers seek suppliers offering not just file delivery, but also technical consulting, design optimization, and post-processing services like file conversion and error correction. This is particularly relevant in regions where CAD expertise may be unevenly distributed or where localized standards prevail, such as specific compliance requirements in the EU or regional certification in Latin America and Africa.

Cost efficiency remains important, yet buyers are increasingly weighing factors such as the supplier’s IP protection protocols, agility in high-mix low-volume manufacturing, and robust after-sales support. Platforms offering batch file processing, instant online file conversion (with secure deletion policies), and multi-language support are now preferred, especially for multinational operations in diverse regions such as Italy, Argentina, the UAE, and Nigeria.

Key Takeaways for Buyers:

– Prioritize third-party vetted suppliers with strong format compatibility and technical credentials.

– Seek value-added services such as consulting and rapid prototyping support.

– Evaluate supply partners on cybersecurity, IP protection, and compliance with local industry standards.

Sustainability and Ethical Sourcing Considerations

Sustainability is rapidly moving to the forefront of international procurement, including for CAD and digital manufacturing sectors. Buyers in Europe, the Middle East, South America, and Africa are increasingly held to stringent regulations around environmental impact and ethical sourcing, and the SLDPRT supply chain is no exception.

Progressive suppliers are adopting energy-efficient data processing centers for cloud-based CAD storage and simulation, reducing the carbon footprint associated with heavy 3D modeling workloads. Additionally, there is a rising preference for suppliers who can demonstrate a commitment to renewable energy usage and responsible digital infrastructure management.

On the physical production side, SLDPRT files often serve as the bridge to manufacturing—so sourcing from providers that prioritize recyclable materials, eco-friendly prototyping methods (such as low-waste 3D printing), and reduced material consumption delivers both cost and sustainability benefits. Many international buyers are now factoring in green certifications (such as ISO 14001, RoHS compliance, or region-specific ecolabels) when choosing their file and modeling service partners.

To ensure supply chain integrity, buyers should scrutinize partners for transparent labor practices and evidence of ethical digital asset handling, including secure data deletion and compliance with regulations such as GDPR. Ethical SLDPRT providers will often publish sustainability reports or ESG statements, giving buyers clear metrics and targets.

Sourcing Recommendations:

– Request documentation on a supplier’s data center energy mix and environmental certifications.

– Favor partners using sustainable materials and low-emission production techniques.

– Include clauses on ethical digital handling and data privacy in procurement contracts, particularly when exchanging proprietary SLDPRT files.

Brief Evolution and Historical Perspective

The rise of SLDPRT files reflects the global shift from manual drafting to digital manufacturing, beginning in the late 1990s with the emergence of robust CAD platforms like SolidWorks. Initially adopted in high-end sectors such as aerospace and automotive design, SLDPRT’s parametric and feature-based modeling capabilities have enabled a new era of part standardization and rapid customization.

As globalization accelerated, the format became a cross-border lingua franca for parts data exchange, increasingly supported by third-party viewers, converters, and collaborative tools. This evolution has made SLDPRT not merely a technical standard, but a strategic asset for companies competing in fast-evolving global markets—especially as digital manufacturing extends to previously underserved regions in Africa, South America, and the Middle East. Buyers equipped with an understanding of this evolution are better positioned to leverage the full potential of their sourcing relationships and digital transformation initiatives.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of file sldprt

-

How can I effectively vet international suppliers of SLDPRT files to ensure high-quality deliverables?

Prioritize suppliers with a proven track record in CAD file delivery, ideally with client references in your region or sector. Request sample SLDPRT files and verify them for integrity and compatibility with your workflows. Evaluate supplier credentials—including ISO certifications, experience with SolidWorks or relevant CAD software, and data security measures for intellectual property protection. Engage in a technical call to assess communication capabilities and clarify expectations before finalizing agreements. Consider working with suppliers that offer NDA agreements to safeguard your proprietary designs. -

Are SLDPRT files customizable to my unique product requirements, and how should I communicate specifications?

SLDPRT files can be tailored to your precise design, dimensional, and functional requirements. To facilitate customization, provide comprehensive technical drawings, sketches, or reference models, along with material and tolerance details. Clear communication of revision cycles, change requests, and design validation processes is critical—ideally, set up collaborative review stages using shared CAD platforms or live screen-sharing. Establish who retains authorship and update rights for modified files to avoid future disputes. -

What typical minimum order quantities (MOQ), lead times, and payment terms do suppliers expect for SLDPRT file projects?

MOQ is generally flexible for digital files like SLDPRT, but suppliers may implement a minimum project value or charge design/setup fees for complex requests. Lead times vary based on file complexity, ranging from a few hours for standard components to several days for intricate, custom designs. Common payment structures include 30–50% upfront, with balance paid upon delivery. Secure international payment channels—such as wire transfer or accredited payment platforms—are recommended to mitigate currency risk and ensure traceability. -

What quality assurance (QA) practices and certifications should I expect from SLDPRT file suppliers?

Expect robust QA processes such as peer review, digital file verification (to identify errors or missing features), and compatibility testing with your target CAD software versions. Reputable suppliers often possess ISO 9001 certification or equivalent, denoting standardized quality management. Ask for documentation on internal QA practices, version control policies, and file format integrity checks. You may require third-party verification or a pilot delivery for large-scale or mission-critical projects. -

How do I ensure that SLDPRT files are compatible with my CAD software and workflows internationally?

Before purchase, confirm the version of SolidWorks or alternative CAD platforms in use at both ends. Request a sample SLDPRT file and perform a compatibility check within your working environment. For cross-platform use (e.g., Fusion 360, Onshape), ask suppliers for secondary formats (STEP, IGES, STL) to minimize conversion challenges. For regions with variable internet reliability, opt for smaller, well-optimized files and clarify file transfer methods (secured cloud, encrypted email, etc.). -

What are the main logistics and delivery considerations when sourcing SLDPRT files across different continents?

While SLDPRT files are digital, secure and efficient delivery remains crucial. Specify preferred transmission modes—such as secure cloud platforms, encrypted email, or enterprise file-sharing solutions—with clear deadlines. Account for regional technology constraints, such as internet bandwidth or restrictions in certain countries. Clarify time zone differences for project milestones and support requests, and set protocols for urgent fixes, ensuring a responsive supply chain across Africa, South America, the Middle East, or Europe. -

How should disputes over SLDPRT deliverables—such as design errors or licensing issues—be handled contractually?

Your contract should define acceptance criteria, timelines for review, and mechanisms for rectifying errors or omissions in the delivered files. Stipulate dispute resolution methods (e.g., mediation, arbitration) and jurisdiction aligned with both parties’ legal frameworks. Clarify intellectual property ownership and licensing terms, especially if future modifications or redistribution are anticipated. Retain detailed correspondence and change logs to facilitate fact-based resolution. -

What best practices ensure data security and IP protection when sharing SLDPRT files with third-party suppliers?

Implement NDAs with all parties accessing your SLDPRT files, outlining limitations on use and strict confidentiality. Use password-protected archives, encrypted transfers, and platforms with granular user access controls. Regularly audit supplier security practices, particularly when dealing with cross-border transactions. For critical innovations or sensitive commercial projects, consider watermarking CAD files or using third-party escrow services to manage access until project milestones are met.

Strategic Sourcing Conclusion and Outlook for file sldprt

As global industries continue to accelerate digital transformation, SLDPRT files have become an essential cornerstone for agile, transparent, and precise product development. For B2B buyers across Africa, South America, the Middle East, and Europe, the ability to source, convert, and integrate SLDPRT files supports more dynamic supplier relationships, cross-border collaboration, and access to a wider network of partners. Understanding the technical nuances of SLDPRT compatibility, conversion options, and industry-standard workflows is vital for making informed decisions and minimizing risks in complex procurement cycles.

Key Takeaways for International Sourcing

- Interoperability Advantage: Utilizing SLDPRT files allows buyers to confidently share and adapt part designs across global supplier ecosystems, increasing efficiency in prototyping and production.

- Streamlined Collaboration: The flexibility to convert SLDPRT files into widely accepted CAD and 3D model formats (e.g., STEP, STL, IGES, OBJ) facilitates faster evaluation, supplier onboarding, and compatibility with local and international manufacturing standards.

- Risk Mitigation: Emphasizing secure handling and timely conversion of sensitive design data reduces exposure to intellectual property risks and ensures rapid responsiveness in competitive markets.

A Forward-Looking Opportunity

B2B organizations that prioritize strategic sourcing of SLDPRT files are positioning themselves at the forefront of manufacturing innovation, regardless of geography. By leveraging robust platforms, secure online converters, and clear file management practices, buyers can confidently engage with a broader supplier base and tap into high-value engineering expertise worldwide. Now is the time to strengthen your sourcing strategies, build trusted digital partnerships, and unlock new potential in global product development networks.