Introduction: Navigating the Global Market for cnc wood carving machine

In the competitive landscape of global woodworking and manufacturing, CNC wood carving machines have emerged as vital tools driving precision, efficiency, and scalability. For international B2B buyers—especially those operating in dynamic markets across Africa, South America, the Middle East, and Europe—these machines are not just equipment but strategic assets that enable rapid customization, superior product quality, and optimized production workflows. Whether you are a furniture manufacturer in Germany, a bespoke joinery specialist in South Africa, or an industrial supplier in Brazil, selecting the right CNC wood carving technology directly influences your ability to meet evolving customer demands and sustain profitable growth.

Navigating the diverse and rapidly evolving CNC wood carving machine market requires deep insight into machine types, material compatibilities, manufacturing standards, and supplier capabilities. This guide offers a comprehensive roadmap tailored to the unique challenges and opportunities faced by international buyers. It covers:

- Detailed analyses of CNC wood carving machine types and their ideal industrial applications

- Material selection strategies to maximize precision and durability

- Best practices for manufacturing quality assurance and compliance with international standards

- Guidance on vetting global suppliers, including evaluating after-sales support, lead times, and warranties

- Cost structures, logistics considerations, and region-specific procurement nuances

- Current market trends, emerging opportunities, and a practical FAQ addressing common buyer concerns

Armed with this knowledge, decision-makers can confidently assess risks, identify genuine value propositions, and forge resilient supplier partnerships. This empowers businesses to unlock new market potentials, enhance operational agility, and secure long-term success in the global CNC woodworking arena.

Understanding cnc wood carving machine Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Router for Wood | Large flatbed, high-speed spindle, interchangeable tooling | Furniture manufacturing, cabinetry, interior fit-out | Versatile and high throughput; moderate precision for fine details |

| CNC Wood Lathe | Rotating workpiece, automated shaping of cylindrical items | Stair parts, balusters, columns | Excellent for round components; limited use for flat or complex shapes |

| 5-Axis CNC Wood Carver | Multi-axis movement enabling complex 3D carving | Bespoke furniture, mold making, sculptural pieces | Enables intricate designs; higher cost and training requirements |

| CNC Laser Engraver | Non-contact laser cutting and engraving | Signage, detailed inlays, prototyping | Highly precise and clean cuts; limited to thinner or softer woods |

| CNC Oscillating Knife | Vibrating blade optimized for soft or laminated woods | Packaging, model making, softwood panels | Fast and clean on thin materials; unsuitable for hardwoods |

CNC Router for Wood

CNC routers are the most widely adopted machines in industrial woodworking, favored for their versatility and capacity to handle large flat panels efficiently. They accommodate a variety of tooling options, allowing businesses to perform cutting, carving, drilling, and profiling on wood and composites. For B2B buyers, especially in furniture and cabinetry sectors across Europe and South America, assessing bed size, spindle power, and software compatibility is critical to match production demands. Additionally, availability of local technical support and spare parts significantly impacts operational uptime and ROI.

CNC Wood Lathe

Specialized for shaping cylindrical wooden components, CNC wood lathes automate the turning process with high precision and repeatability. They are essential for manufacturers producing stair parts, balusters, and decorative columns, common in markets like South Africa and the Middle East where architectural woodwork is prominent. Buyers should consider spindle length and tooling flexibility to accommodate diverse profiles. While highly efficient for round parts, these machines are less versatile for flat or complex 3D shapes, making them ideal for businesses with focused product lines.

5-Axis CNC Wood Carver

Offering advanced multi-axis control, 5-axis CNC wood carving machines enable the creation of complex, three-dimensional shapes without repositioning the workpiece. This capability is invaluable for bespoke furniture makers, mold producers, and artisans targeting premium markets in Europe and upscale segments in Africa. However, the higher capital investment and operational complexity require buyers to ensure adequate training and supplier support. These machines open avenues for product differentiation but necessitate strategic planning to justify the total cost of ownership.

CNC Laser Engraver

CNC laser engravers utilize focused laser beams to cut or engrave wood with exceptional precision, ideal for detailed signage, intricate inlays, and rapid prototyping. Their non-contact process reduces mechanical wear and enables fine detail work, favored by businesses producing high-value decorative items or prototypes. However, their application is generally limited to thinner or softer wood types, which buyers should consider when evaluating machine fit for their product range. For buyers in regions with growing branding and design industries, laser engravers offer a competitive edge.

CNC Oscillating Knife

This type uses a rapidly vibrating blade to cut softwoods, laminates, and thin panels with clean edges and minimal dust. It is particularly suited for packaging manufacturers and model makers who require fast, precise cutting on delicate materials. While cost-effective for specific applications, oscillating knives are unsuitable for hardwood or thick materials, limiting their use in heavy woodworking sectors. B2B buyers should align machine capabilities with their material profiles and production volumes to avoid underutilization.

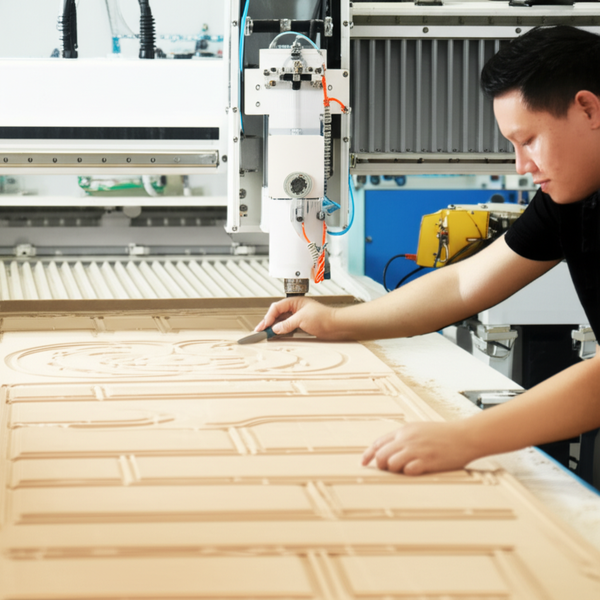

Related Video: Unbelievable 2.5D Wood Carving – CNC Router Perfection

Key Industrial Applications of cnc wood carving machine

| Industry/Sector | Specific Application of cnc wood carving machine | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Furniture Manufacturing | Intricate decorative paneling and custom furniture parts | Enables high-precision, repeatable designs with reduced lead times and labor costs | Machine precision, software compatibility with CAD designs, local technical support |

| Architectural Millwork | Production of detailed moldings, balusters, and columns | Enhances product differentiation through complex, high-quality carvings | Multi-axis capability, tooling versatility, durability for hardwoods |

| Signage and Branding | Custom wooden signage and engraved corporate logos | Delivers sharp, consistent branding elements with fast turnaround | Laser engraving integration, fine detail resolution, ease of design file import |

| Artisanal and Craft Industries | Sculptural and ornamental wood pieces for luxury markets | Allows bespoke, high-value craftsmanship with scalability for batch production | Machine flexibility, training availability, after-sales service in target markets |

| Interior Fit-Out and Joinery | Customized cabinetry and paneling for commercial and residential projects | Improves customization options and reduces manual finishing time | Bed size and spindle power, software interoperability, spare parts availability |

Furniture Manufacturing

In furniture manufacturing, CNC wood carving machines are widely used to produce intricate decorative panels, chair backs, and custom parts that require high precision and repeatability. This technology addresses the challenge of maintaining consistent quality while reducing manual labor and production time. For B2B buyers in regions such as South America and Europe, it is crucial to select machines with robust software compatibility to easily import CAD designs and reliable technical support to minimize downtime. Additionally, the ability to handle various wood types is essential to meet diverse market demands.

Architectural Millwork

Architectural millwork firms leverage CNC wood carving machines to create detailed moldings, balusters, columns, and other ornamental components for building interiors and exteriors. These machines allow for complex multi-axis carving that enhances product differentiation in competitive markets like Germany and the Middle East. Buyers must prioritize machines with tooling versatility and durability to handle hardwoods common in architectural applications. Access to local training and maintenance services also ensures smooth integration into existing workflows, especially where skilled labor shortages exist.

Signage and Branding

For businesses specializing in wooden signage and branding, CNC wood carving machines enable the production of custom logos, letters, and intricate engravings with precision and speed. This is particularly valuable for B2B buyers in fast-growing African markets like South Africa, where rapid brand deployment is critical. Machines with laser engraving capabilities or fine detail resolution are preferred to achieve sharp edges and consistent results. Ease of importing vector design files and compatibility with common graphics software are key sourcing considerations to streamline production.

Artisanal and Craft Industries

Artisanal producers and luxury craft businesses use CNC wood carving machines to create bespoke sculptural and ornamental wood pieces that command premium prices. These machines facilitate scalability without compromising the handcrafted aesthetic, a significant advantage for exporters in South America and Europe targeting high-end markets. Buyers should focus on equipment flexibility to handle diverse designs and materials, as well as comprehensive training programs and after-sales support to maximize machine utilization and product quality.

Interior Fit-Out and Joinery

In interior fit-out and joinery sectors, CNC wood carving machines are instrumental in delivering customized cabinetry, wall paneling, and decorative elements for commercial and residential projects. This application reduces manual finishing time and expands customization options, allowing businesses in regions like the Middle East and Africa to compete with international standards. Key considerations include selecting machines with adequate bed size and spindle power to accommodate large panels, software interoperability for design integration, and the availability of spare parts to ensure operational continuity.

Related Video: CNC Wood Carving Machine – Maverick 3×5 3-Workstation Demo – Legacy CNC Woodworking Machinery

Strategic Material Selection Guide for cnc wood carving machine

Common Materials for CNC Wood Carving Machines: A B2B Analysis

1. Aluminum Alloys

Key Properties: Aluminum alloys commonly used in CNC wood carving machines offer excellent strength-to-weight ratios, good corrosion resistance, and thermal conductivity. They typically withstand moderate mechanical stresses and temperature variations encountered during machining operations without deformation.

Pros & Cons: Aluminum’s lightweight nature reduces machine inertia, enabling faster acceleration and deceleration, which improves cycle times and precision. It also resists corrosion well, making it suitable for humid environments common in regions like South America and parts of Africa. However, aluminum is softer than steel, which may lead to faster wear in high-load components unless properly treated or alloyed. Manufacturing complexity is moderate, with good machinability but requiring careful handling to avoid surface damage.

Impact on Application: Aluminum frames and components are ideal for mid-to-high precision CNC routers and carving machines where speed and accuracy are prioritized. Its corrosion resistance benefits buyers in coastal or humid climates, such as the Middle East or South Africa.

International Buyer Considerations: Buyers in Europe (e.g., Germany) often require compliance with standards like DIN EN 573 for aluminum alloys, ensuring traceability and quality. In Africa and South America, sourcing aluminum components with certifications aligned to ASTM standards enhances reliability. Additionally, availability of local suppliers or nearby warehouses can reduce lead times and import costs.

2. Cast Iron

Key Properties: Cast iron is known for its excellent vibration damping, high compressive strength, and thermal stability. It maintains dimensional accuracy under heavy cutting loads and resists deformation under prolonged use.

Pros & Cons: The superior rigidity and damping characteristics of cast iron make it ideal for heavy-duty CNC wood carving machines that require minimal vibration for fine detail work. It is cost-effective and widely available globally. However, cast iron is brittle and can crack under impact or stress concentration. It is also heavier, which may increase shipping costs and complicate installation.

Impact on Application: Cast iron is favored for machine beds and structural frames in industrial-grade CNC routers used in furniture manufacturing hubs such as Germany and São Paulo, where precision and durability are paramount.

International Buyer Considerations: Compliance with international standards like ASTM A48 or EN-GJL-250 is critical for ensuring material quality. Buyers in the Middle East and Africa should verify corrosion protection measures, as cast iron is prone to rust without proper coatings. The heavier weight also necessitates logistics planning for import and local handling.

3. Steel (Carbon and Alloy)

Key Properties: Steel offers high tensile strength, toughness, and wear resistance. Alloy steels can be tailored for enhanced hardness and corrosion resistance. They perform well under mechanical stress and temperature fluctuations typical in CNC machining.

Pros & Cons: Steel components provide durability and longevity, especially for moving parts like spindles and tool holders. Carbon steel is cost-effective but requires surface treatment to prevent corrosion. Alloy steels, while more expensive, offer better performance in harsh environments. The manufacturing process is more complex due to heat treatment and finishing requirements.

Impact on Application: Steel is essential for high-wear components and structural parts where strength and precision are critical. Its adaptability suits diverse markets from Europe’s precision-driven industries to the more cost-sensitive markets of Africa and South America.

International Buyer Considerations: European buyers expect compliance with EN 10025 or DIN standards, while ASTM standards are prevalent in the Americas and parts of Africa. Surface treatments like galvanizing or powder coating are important for buyers in humid or coastal regions to extend component life.

4. High-Density Polymer Composites (Engineering Plastics)

Key Properties: High-density polymers such as UHMW (Ultra High Molecular Weight Polyethylene) or reinforced composites offer low friction, chemical resistance, and vibration dampening. They are lightweight and resistant to moisture and many chemicals.

Pros & Cons: These materials reduce noise and wear on moving parts like linear guides and bushings. They are easier to machine and replace but generally have lower load-bearing capacity than metals. Cost varies widely depending on composite formulation and reinforcement.

Impact on Application: Polymers are increasingly used in CNC wood carving machines for components requiring low friction and corrosion resistance, especially in humid environments like the Middle East and coastal Africa. They enable quieter operation and reduce maintenance frequency.

International Buyer Considerations: Buyers should verify compliance with material safety and environmental standards such as RoHS or REACH in Europe. Availability of certified polymer composites can be limited in some African and South American markets, so sourcing from reliable international suppliers with local distribution is advisable.

Summary Table: Material Selection for CNC Wood Carving Machines

| Material | Typical Use Case for cnc wood carving machine | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys | Machine frames, structural components | Lightweight, corrosion resistant, good machinability | Softer material, wear-prone under heavy load | Medium |

| Cast Iron | Machine beds, heavy structural frames | Excellent vibration damping, high rigidity | Brittle, heavy, prone to corrosion without coating | Low |

| Steel (Carbon and Alloy) | High-wear parts, spindles, tool holders | High strength, durable, customizable properties | Requires surface treatment, heavier than aluminum | Medium to High |

| High-Density Polymer Composites | Low-friction components, bushings, vibration dampening | Lightweight, corrosion resistant, low maintenance | Lower load capacity, variable cost depending on grade | Medium to High |

In-depth Look: Manufacturing Processes and Quality Assurance for cnc wood carving machine

Manufacturing Processes for CNC Wood Carving Machines

The manufacturing of CNC wood carving machines involves a series of meticulously controlled stages to ensure precision, durability, and operational efficiency. For B2B buyers, understanding these processes is crucial for assessing supplier capabilities, product quality, and long-term reliability.

1. Material Preparation

Material selection and preparation set the foundation for machine performance and longevity. Key components such as the machine frame, spindle, motors, and control systems require high-grade materials—typically steel or aluminum alloys for structural parts, and precision-engineered components for mechanical and electronic subsystems.

- Raw material inspection: Incoming materials undergo rigorous checks for mechanical properties, dimensional accuracy, and surface finish.

- Cutting and shaping: CNC laser cutting or water jet cutting is frequently used to achieve precise base plate and frame components.

- Surface treatment: Processes like sandblasting, anodizing, or powder coating enhance corrosion resistance and durability, critical for machines operating in diverse climates.

2. Component Forming and Machining

This stage involves transforming raw or semi-finished materials into functional parts with exact specifications.

- Machining: Milling, turning, and grinding operations produce high-precision parts such as lead screws, linear rails, and spindle housings.

- Welding and joining: Structural frames may be welded or bolted, depending on design requirements, with careful control to avoid warping or misalignment.

- Heat treatment: Critical for enhancing material hardness and wear resistance, especially for moving parts exposed to mechanical stress.

3. Assembly

Assembly is a highly skilled phase where mechanical, electrical, and software components are integrated.

- Mechanical assembly: Precise installation of linear guides, ball screws, and spindle units, ensuring alignment within micrometer tolerances.

- Electrical integration: Wiring of stepper or servo motors, installation of control panels, and integration of sensors for feedback and safety systems.

- Software installation: CNC control software and firmware are loaded and configured to match machine specifications and customer requirements.

4. Finishing and Calibration

Final finishing ensures aesthetic appeal and operational readiness.

- Painting and labeling: Machines receive protective coatings and are marked with serial numbers, certification labels, and safety warnings.

- Calibration: Comprehensive calibration of axes, spindle speed, and tool changers to guarantee machining accuracy.

- Packaging: Machines are carefully packed to protect against damage during international shipping, often including moisture-absorbing materials and robust crates.

Quality Assurance and Control (QA/QC) Framework

Robust quality assurance is indispensable for CNC wood carving machines, especially for international buyers who demand compliance with global standards and consistent machine performance.

Relevant International and Industry Standards

- ISO 9001: The foundational quality management standard that ensures suppliers maintain systematic processes covering design, production, and service.

- CE Marking: Mandatory for machines sold in the European Economic Area, indicating compliance with health, safety, and environmental protection legislation.

- RoHS and REACH: Environmental compliance standards relevant for electronic components and materials, increasingly important in Europe and some Middle Eastern markets.

- Industry-specific certifications: While not universally required, certifications like API for certain industrial applications or UL for electrical safety may apply depending on machine use.

QC Checkpoints in Manufacturing

Quality control is performed at multiple stages to catch defects early and maintain standards:

- Incoming Quality Control (IQC): Verification of raw materials and purchased components against specifications.

- In-Process Quality Control (IPQC): Continuous monitoring during machining and assembly, including dimensional checks, torque testing, and electrical continuity.

- Final Quality Control (FQC): End-of-line inspection encompassing full functional tests, accuracy verification, surface finish inspection, and safety feature validation.

Common Testing Methods

- Dimensional inspection: Use of coordinate measuring machines (CMM), laser scanners, and precision gauges to verify part tolerances.

- Performance testing: Dry runs and load tests simulate operational conditions, validating motor function, spindle speed stability, and tool change accuracy.

- Electrical safety and EMC testing: Ensures compliance with electrical safety regulations and electromagnetic compatibility, critical for uninterrupted machine operation.

- Vibration and noise analysis: Important for assessing machine stability and operator comfort.

Strategies for B2B Buyers to Verify Supplier Quality Control

International buyers, especially from Africa, South America, the Middle East, and Europe, must adopt proactive strategies to ensure supplier QC capabilities meet their stringent requirements.

1. Factory Audits and Inspections

- On-site audits: Engage third-party inspection firms or conduct in-person audits to assess manufacturing processes, equipment, and workforce competence.

- Process capability evaluation: Review the supplier’s process control charts, defect rates, and corrective action histories.

- Sample inspections: Request pre-shipment samples for independent testing or visit production lines to observe ongoing QC practices.

2. Documentation and Certification Review

- Quality management system certificates: Verify current ISO 9001 certification and any relevant CE, RoHS, or regional approvals.

- Test reports: Demand detailed inspection and testing reports, including raw material certificates, dimensional inspection data, and functional test results.

- Traceability: Ensure the supplier can provide batch and component traceability to manage recalls or warranty claims effectively.

3. Third-Party Verification

- Independent inspections: Utilize recognized inspection agencies (e.g., SGS, Bureau Veritas) for pre-shipment quality verification.

- Compliance testing: For European and Middle Eastern buyers, especially, insist on compliance testing aligned with local regulatory requirements.

- Long-term partnerships: Establish contractual quality agreements specifying inspection protocols, acceptance criteria, and penalties for non-compliance.

Quality Control Nuances for International Buyers by Region

Africa and South America

- Logistics and environmental factors: Buyers should ensure machines are robustly packaged to withstand long shipping times and variable climates.

- After-sales support: QC verification should include supplier capability to provide timely spare parts and technical assistance locally.

- Regulatory alignment: While ISO 9001 is widely accepted, local certifications may vary; buyers should clarify import and safety standards upfront.

Middle East

- Stringent safety standards: Compliance with CE and international electrical safety standards is critical due to strict regulatory enforcement.

- Environmental regulations: Increasingly, RoHS and REACH compliance are demanded for environmental stewardship.

- Supplier transparency: The region’s emphasis on quality and reputation necessitates thorough due diligence and supplier audits.

Europe (e.g., Germany)

- High precision and reliability expectations: European buyers prioritize advanced QC techniques and traceability.

- Compliance with EU directives: CE marking, EMC, and machinery directives are non-negotiable.

- Sustainability focus: Suppliers demonstrating eco-friendly manufacturing and materials handling gain competitive advantage.

Summary for B2B Buyers

For international B2B buyers investing in CNC wood carving machines, a deep understanding of manufacturing processes and rigorous quality assurance frameworks is essential. Evaluating suppliers based on their material sourcing, production methodologies, and QC checkpoints can significantly mitigate risks. Leveraging international standards like ISO 9001 and CE, combined with thorough audits and third-party inspections, equips buyers—whether in Africa, South America, the Middle East, or Europe—to secure machines that deliver precision, durability, and compliance. This strategic approach fosters confidence, reduces operational disruptions, and supports scalable growth in competitive woodworking industries worldwide.

Related Video: Top 5 Mass Production Techniques: Manufacturing Process

Comprehensive Cost and Pricing Analysis for cnc wood carving machine Sourcing

Cost Components in Sourcing CNC Wood Carving Machines

A thorough understanding of the cost structure is essential for international B2B buyers aiming to optimize procurement strategies. The primary cost components include:

-

Materials: High-quality components such as precision steel frames, linear guides, ball screws, and durable electronics significantly influence the base price. Lower-cost machines may compromise on these, affecting longevity and performance.

-

Labor: Manufacturing labor costs vary widely, especially between regions. In Europe (e.g., Germany), higher wages often translate into more advanced, meticulously assembled machines, whereas suppliers from regions like China or India might offer more competitive prices with streamlined labor costs.

-

Manufacturing Overheads: This encompasses R&D, quality assurance, tooling, and factory expenses. Premium brands with rigorous QC protocols tend to have higher overheads, which are reflected in their pricing but often guarantee better reliability and after-sales support.

-

Tooling and Accessories: Additional tooling such as specialized bits, dust collection systems, and software licenses can either be bundled or sold separately, impacting the overall cost.

-

Quality Control & Certifications: Machines meeting international standards (ISO, CE, UL) or industry-specific certifications often command premium prices but offer assurance of compliance, crucial for buyers in regulated markets.

-

Logistics & Import Duties: Shipping costs depend on the machine’s size, weight, and origin. Buyers from Africa and South America should factor in higher freight and customs duties, which can add 10-30% to the total cost. Incoterms like FOB, CIF, or DDP influence who bears these costs and risks.

-

Margins & Markups: Distributors and local agents apply margins based on regional market conditions, brand reputation, and after-sales service offerings. Premium brands may include higher margins for service and warranty coverage.

Price Influencers and Market Dynamics

Pricing for CNC wood carving machines is highly sensitive to several factors:

-

Order Volume & MOQ: Larger orders often unlock discounts, with MOQ thresholds ranging from 1 to 10 units. For startups or small enterprises, negotiating favorable terms for smaller quantities is critical.

-

Specifications & Customization: Machines with higher spindle power, multi-axis capabilities, or advanced software customization will be priced higher. Buyers seeking bespoke configurations should anticipate a premium of 15-30% over standard models.

-

Material Compatibility & Complexity: Machines optimized for dense hardwoods or complex carvings typically cost more due to enhanced tooling and structural robustness.

-

Quality & Certifications: Certified machines compliant with regional standards (e.g., CE for Europe, SABS for South Africa) tend to have a higher initial cost but reduce compliance risks.

-

Supplier Factors: Established brands with strong after-sales networks and comprehensive warranties often command higher prices. Conversely, emerging suppliers might offer lower upfront costs but could pose higher long-term risks.

-

Incoterms & Shipping: FOB (Free On Board) prices are common, but DDP (Delivered Duty Paid) includes all costs, simplifying logistics but increasing the initial quote. Buyers should evaluate total landed costs rather than just ex-works prices.

Buyer Tips for Effective Cost Management

-

Negotiate Beyond Price: Leverage volume, long-term partnerships, or regional exclusivity to negotiate better prices or favorable payment terms.

-

Focus on Total Cost of Ownership (TCO): Consider installation, maintenance, spare parts, and energy consumption. A cheaper machine may incur higher operational costs, eroding initial savings.

-

Understand Pricing Nuances: Prices can vary significantly based on regional market conditions, currency fluctuations, and import tariffs. For example, European suppliers might price machines higher but offer superior quality and support, whereas African or South American buyers might benefit from local or regional distributors with competitive rates.

-

Evaluate Supplier Reputation & Support: Prioritize suppliers with proven track records, reliable after-sales service, and accessible spare parts networks to avoid hidden costs and downtime.

-

Stay Informed on Regional Import Regulations: Different countries have unique import duties, VAT, and certification requirements. Engaging local agents or consultants can help clarify these costs upfront.

Indicative Price Range

As a general reference, standard CNC wood carving machines typically range from $10,000 to $50,000, depending on size, capabilities, and brand. High-end, fully customized or 5-axis systems can exceed $100,000. These figures are indicative and subject to regional variations, supplier negotiations, and evolving market conditions.

In summary, international B2B buyers must approach CNC wood carving machine sourcing holistically—balancing initial purchase costs with long-term operational expenses, regional logistics, and support services. Strategic negotiation and comprehensive cost analysis are key to securing optimal value and sustainable investment.

Spotlight on Potential cnc wood carving machine Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cnc wood carving machine’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cnc wood carving machine

Critical Technical Properties for CNC Wood Carving Machines

1. Working Area (Work Envelope)

This specifies the maximum dimensions of the material that the machine can accommodate. For B2B buyers, selecting a machine with an appropriate working area is crucial to match production needs—whether for small custom pieces or large panels. A larger workspace increases versatility but may also influence cost and footprint.

2. Spindle Power and Speed

The spindle is the motor that drives the cutting tool. Higher power (measured in horsepower or kilowatts) allows for efficient machining of dense hardwoods and thick materials. Spindle speed (RPM) impacts surface finish and cutting precision; higher speeds are essential for detailed engraving and fine carving. Ensuring compatibility with your target materials optimizes productivity and quality.

3. Precision and Tolerance

Precision defines the machine’s ability to produce parts within specified dimensional limits, typically measured in millimeters or microns. Tolerance indicates the acceptable deviation from the intended dimensions. For industries demanding high accuracy—such as furniture components or intricate decorative carvings—tight tolerances (e.g., ±0.05 mm) are vital to reduce finishing time and material waste.

4. Feed Rate and Axis Speed

The feed rate (mm/min) determines how quickly the machine moves during cutting, affecting productivity and surface quality. Axis speed (the movement speed of the machine’s axes) influences the overall cycle time and ability to handle complex geometries. B2B buyers should consider these specs to balance throughput with precision, especially for high-volume production.

5. Material Compatibility and Power Requirements

Different machines are optimized for specific materials—hardwoods, softwoods, MDF, plastics, etc. Confirming material compatibility ensures the machine can handle your typical production materials without unnecessary wear or downtime. Additionally, understanding the electrical requirements (voltage, phase, power consumption) is critical for seamless integration into regional facilities.

6. Software and Control System Compatibility

The control system governs how the machine interprets design files and executes cuts. Compatibility with popular CAD/CAM software (e.g., ArtCAM, Aspire, VCarve) streamlines workflow. For international buyers, ensuring that control interfaces support multiple languages and regional standards enhances usability and reduces training costs.

Essential Trade and Industry Terms

1. OEM (Original Equipment Manufacturer)

Refers to the company that designs and produces the CNC machine, which may be branded under a different company’s name. Knowing whether a supplier offers OEM or branded equipment helps assess customization options, quality control, and after-sales support.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell. For B2B buyers, understanding MOQ is vital for planning inventory, negotiating prices, and managing cash flow, especially when sourcing from overseas suppliers.

3. RFQ (Request for Quotation)

A formal process where buyers solicit detailed price proposals from multiple suppliers. An RFQ includes specifications, quantities, and delivery timelines. Responding effectively to RFQs ensures competitive pricing and aligns supplier capabilities with project requirements.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce, defining responsibilities for shipping, insurance, and customs clearance. Familiarity with Incoterms (e.g., FOB, CIF) helps B2B buyers clarify costs, risks, and delivery obligations in international transactions.

5. Lead Time

The period from placing an order to receiving the machine. Shorter lead times enable quicker project initiation, but they may come at a premium. Understanding lead times assists buyers in planning production schedules and inventory buffers.

6. After-Sales Support and Warranty

Refers to the technical assistance, maintenance, and spare parts provided post-purchase. Reliable after-sales support minimizes downtime and prolongs machine lifespan, which is especially important for international buyers managing logistics across regions with varying service infrastructure.

Familiarity with these technical properties and trade terms equips B2B buyers from Africa, South America, the Middle East, and Europe to make informed decisions, negotiate effectively, and ensure successful procurement aligned with regional market conditions and operational goals.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc wood carving machine Sector

Market Overview & Key Trends

The global market for CNC wood carving machines is experiencing robust growth driven by increasing demand for precision craftsmanship, customization, and automation across multiple sectors. Key industry drivers include the rising construction of bespoke furniture, architectural detailing, and decorative elements in interior design, especially in regions like Europe, Africa, South America, and the Middle East. In Europe, countries such as Germany lead with advanced manufacturing ecosystems emphasizing high-quality outputs and technological innovation, while in Africa and South America, rapid urbanization and a burgeoning artisanal sector foster demand for scalable, cost-effective solutions.

Emerging trends highlight a shift toward multi-axis and hybrid CNC systems that combine traditional routing with laser or engraving capabilities, offering versatility for diverse applications. Additionally, the integration of Industry 4.0 technologies—such as IoT connectivity, real-time monitoring, and AI-driven optimization—is transforming how B2B buyers source, operate, and maintain these machines. This technological evolution enhances productivity, reduces downtime, and improves quality control, making these tools more attractive for manufacturers aiming to meet international standards.

From a sourcing perspective, buyers are increasingly favoring suppliers who offer comprehensive after-sales support, flexible financing options, and region-specific service networks. The trend toward modular, scalable machines that can adapt to varying production volumes and material types is also gaining momentum. For Africa, South America, the Middle East, and Europe, understanding regional supply chain nuances, import regulations, and local technical expertise is crucial for optimizing procurement strategies and ensuring long-term operational resilience.

Sustainability & Ethical Sourcing in B2B

Sustainability is becoming a core criterion in sourcing CNC wood carving machines, driven by global environmental concerns and stricter regulatory frameworks. For B2B buyers, integrating eco-friendly practices can enhance brand reputation, meet customer expectations, and comply with international standards such as FSC (Forest Stewardship Council) or PEFC (Programme for the Endorsement of Forest Certification). These certifications validate the use of responsibly sourced timber, which is increasingly demanded in sectors like furniture manufacturing and interior design.

Environmental impacts of CNC machines extend beyond the raw materials; energy consumption, waste management, and emissions from manufacturing processes are critical considerations. Buyers are now prioritizing machines equipped with energy-efficient motors, dust collection systems, and sustainable lubricants. Additionally, sourcing from suppliers who adhere to ethical supply chain practices—ensuring fair labor conditions and transparency—is vital for mitigating risks associated with social responsibility.

The rise of ‘green’ certifications for machine components, such as low VOC (Volatile Organic Compounds) emissions and recyclable materials, further underscores this shift. Suppliers offering machines with eco-friendly features not only align with global sustainability goals but also provide a competitive edge in markets with strict environmental regulations, particularly in Europe and increasingly in emerging markets like South Africa and Brazil.

Brief Evolution/History

The evolution of CNC wood carving machines has been marked by continuous technological innovation since their inception in the late 20th century. Early models focused on basic routing and engraving capabilities, primarily serving industrial furniture manufacturers. Over time, advancements in computer-aided design (CAD), multi-axis movement, and laser integration have expanded their functionalities to include complex 3D sculpting, fine detailed engraving, and multi-material processing.

In recent decades, the proliferation of Industry 4.0 has driven the development of smarter, connected CNC systems. These innovations enable remote operation, predictive maintenance, and real-time quality assurance, significantly reducing downtime and operational costs. For international B2B buyers, understanding this historical trajectory helps in assessing the longevity, upgradeability, and technological maturity of potential machine investments, ensuring alignment with future industry standards and regional market demands.

By staying informed about market dynamics, technological trends, and sustainability practices, international B2B buyers—particularly from Africa, South America, the Middle East, and Europe—can make strategic sourcing decisions. These insights facilitate not only cost-effective procurement but also support long-term operational resilience and compliance with evolving environmental and social standards.

Frequently Asked Questions (FAQs) for B2B Buyers of cnc wood carving machine

1. How can I effectively vet CNC wood carving machine suppliers to ensure quality and reliability?

To vet international suppliers, start by requesting comprehensive company credentials, including business licenses, ISO or other relevant quality certifications, and detailed product catalogs. Check their track record through customer references, online reviews, and industry reputation. Request factory audits or virtual tours if possible. Evaluate their after-sales support, warranty terms, and spare parts availability. Confirm their compliance with regional safety and quality standards, especially for import regions like Europe (CE marking) or South Africa (SABS). Engaging with verified third-party inspection agencies before shipment can further mitigate risks and ensure the supplier’s credibility.

2. How customizable are CNC wood carving machines for different regional market needs and specific project requirements?

Most reputable suppliers offer customization options, including machine size, spindle power, software interfaces, and tooling compatibility, tailored to your project scope. You can specify features like multi-axis capabilities for complex carvings or enhanced dust extraction for regions with stricter environmental standards. Discuss your specific material types, production volumes, and design complexity to ensure the machine aligns with your operational goals. Some suppliers also provide custom training and software localization (language, units) to facilitate smoother integration into your regional workflow. Clear communication of your needs upfront ensures the final product meets your unique project demands.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for international purchases?

MOQs vary depending on the supplier and machine complexity, often ranging from one unit for small-scale machines to larger quantities for bulk orders. Lead times generally span from 4 to 12 weeks, influenced by customization, supplier location, and logistics. Payment terms are usually 30% upfront deposit with the balance payable before shipment or upon delivery, though some suppliers accept letters of credit or escrow arrangements for added security. Negotiating flexible payment options and understanding the production timeline upfront helps manage cash flow and planning, especially when coordinating with regional logistics and customs clearance.

4. What quality assurance standards and certifications should I look for in a CNC wood carving machine supplier?

Look for suppliers that adhere to internationally recognized standards such as ISO 9001 for quality management, CE marking for European safety compliance, and regional certifications like SABS (South Africa), UL (North America), or equivalent. These certifications indicate compliance with safety, environmental, and performance benchmarks. Request detailed test reports, calibration certificates, and quality control procedures. Suppliers with a robust QA system demonstrate consistent product quality and reliability, reducing downtime and maintenance costs. Ensuring compliance with your regional standards minimizes import complications and enhances operational safety.

5. How do I manage international logistics, customs, and import duties when sourcing CNC machines from abroad?

Partner with freight forwarders experienced in handling heavy machinery, and choose options like FOB or CIF incoterms to clarify responsibilities. Confirm the supplier can provide detailed shipping documentation, including commercial invoices, packing lists, and certificates of origin. Be aware of regional import duties, VAT, and compliance requirements—these vary significantly between Africa, South America, the Middle East, and Europe. Engaging customs brokers familiar with local regulations can streamline clearance. Additionally, consider the lead time for customs inspection and potential delays, and incorporate buffer periods into your project planning.

6. What are common dispute resolution mechanisms and warranty considerations for international CNC machine transactions?

Establish clear contractual terms specifying warranty duration, scope (parts, labor, software), and response times. Many suppliers offer standard warranties of 12 months, with options for extended coverage. Dispute resolution should ideally be via arbitration under internationally recognized frameworks like ICC or UNCITRAL, with jurisdiction clauses favoring neutral locations. Ensure your contract includes detailed service level agreements (SLAs) and escalation procedures. Pre-negotiated dispute mechanisms minimize risks of costly legal battles and ensure quicker resolution, protecting your investment and maintaining supply chain stability.

7. How can I ensure after-sales support and technical training are available in my region?

Choose suppliers with local or regional offices, authorized service centers, or partners who can provide timely technical support. Confirm whether they offer remote troubleshooting, on-site servicing, and spare parts supply within your region. Request detailed training programs—either onsite or virtual—that cover machine operation, maintenance, and safety protocols. Check if they provide comprehensive user manuals, software updates, and technical helplines. Establishing a strong support network ensures minimal downtime, maximizes machine uptime, and enhances your team’s operational competence, especially crucial in regions with limited local technical expertise.

8. What are key regional considerations I should keep in mind when sourcing CNC wood carving machines from Africa, South America, the Middle East, or Europe?

Regional factors include local standards, import tariffs, logistics infrastructure, and language barriers. In Europe, compliance with CE standards simplifies certification; in Africa and South America, regional certifications like SABS or INMETRO may be necessary. Infrastructure challenges—such as unreliable power supplies or limited transport routes—require robust, adaptable machines and reliable logistics partners. Language barriers can be mitigated by choosing suppliers offering localized technical support and documentation. Additionally, consider regional market trends and demand for specific features, ensuring your investment aligns with local industry needs and operational realities.

This set of FAQs offers actionable insights tailored to international B2B buyers, enabling strategic sourcing, risk mitigation, and operational success in acquiring CNC wood carving machines globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc wood carving machine

Conclusion and Future Outlook

Effective strategic sourcing of CNC wood carving machines is crucial for international B2B buyers seeking to enhance operational efficiency, precision, and scalability. By thoroughly evaluating supplier capabilities—such as technological expertise, after-sales support, and regional logistics—buyers can mitigate risks and secure long-term partnerships that drive sustainable growth. Emphasizing quality assurance, regional customization, and cost optimization ensures a competitive edge in diverse markets, from Africa’s burgeoning woodworking sector to Europe’s high-precision manufacturing hubs.

Looking ahead, rapid technological advancements—particularly in automation, AI integration, and IoT connectivity—will continue to reshape the CNC landscape. Buyers should stay informed about emerging innovations and regional market trends to capitalize on new opportunities and adapt swiftly to evolving demands. Now is the time for international B2B buyers, especially from Africa, South America, the Middle East, and Europe, to prioritize strategic sourcing as a means to unlock new markets, improve product quality, and foster resilient supply chains.

Proactive engagement with trusted suppliers, combined with continuous market intelligence, will position buyers to harness the full potential of CNC wood carving technology—driving competitive advantage in a dynamic global industry.