Introduction: Navigating the Global Market for al 7075 t6

Unlocking the Potential of 7075 T6 Aluminum in Global Supply Chains

In today’s highly competitive international market, sourcing high-performance materials like 7075 T6 aluminum is crucial for industries demanding exceptional strength, durability, and reliability. Recognized as one of the strongest aluminum alloys available, 7075 T6 offers a unique combination of tensile strength, fatigue resistance, and heat treatability—making it indispensable across aerospace, military, automotive, and sporting goods sectors worldwide.

This comprehensive guide is designed to empower B2B buyers from Africa, South America, the Middle East, and Europe—including key markets such as Nigeria and the UK—with in-depth insights into every facet of 7075 T6 aluminum. It covers the alloy’s technical properties, diverse forms and tempers, manufacturing processes, quality assurance standards, and leading suppliers. Additionally, it explores cost considerations, market trends, and frequently asked questions, enabling informed decision-making in complex procurement environments.

By understanding the alloy’s critical specifications and applications, international buyers can optimize their sourcing strategies, mitigate risks, and establish reliable supply chains for high-performance components. Whether you seek raw material in plates, bars, or extrusions, or need guidance on quality standards and cost optimization, this guide provides the actionable intelligence necessary to navigate the dynamic global market confidently. Ultimately, it positions you to secure the best value, quality, and supply stability for your demanding projects.

Understanding al 7075 t6 Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| 7075-T6 Plate | Thick, flat, solution heat-treated, artificially aged for high strength | Aerospace structural parts, tooling, marine hardware | Pros: Excellent strength-to-weight ratio; durable. Cons: Higher cost, limited formability. |

| 7075-T6 Extrusions | Long, continuous profiles with uniform properties after heat treatment | Aircraft frameworks, automotive components, industrial machinery | Pros: Precise dimensions, high strength. Cons: Limited complex shapes, higher tooling costs. |

| 7075-T6 Wrought Bars | Solid, machined-ready bars with consistent mechanical properties | Mechanical components, sports equipment, military hardware | Pros: High machinability, excellent fatigue resistance. Cons: Poor weldability, requires careful handling. |

| 7075-T6 Wires | Fine, high-strength wire forms suitable for precision applications | Electronics, springs, high-performance fasteners | Pros: Superior tensile strength, corrosion resistance with surface treatment. Cons: Costly, limited to specific applications. |

| 7075-T6 Forgings | Pre-shaped, high-strength forgings with superior toughness | Aerospace engine parts, military armor, high-stress automotive parts | Pros: Superior toughness, high fatigue life. Cons: Complex manufacturing process, higher lead times. |

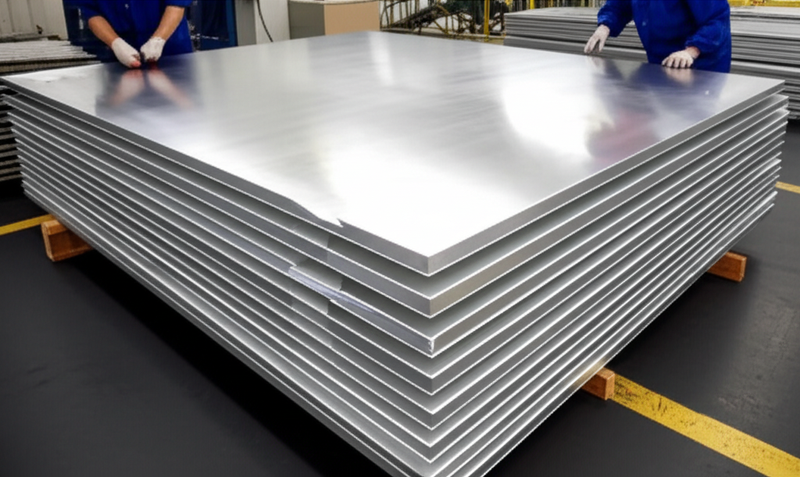

Plate Variations

7075-T6 plates are thick, flat sheets that undergo solution heat treatment and artificial aging, resulting in exceptional mechanical strength. These plates are ideal for structural aerospace components, marine hardware, and tooling where high load-bearing capacity is essential. B2B buyers should consider their required dimensions and tolerances, as plates often involve higher procurement costs and limited flexibility in forming. They are best suited for applications demanding maximum strength with less emphasis on complex shaping.

Extrusions

7075-T6 extrusions are continuous profiles that are extruded in specific cross-sectional shapes, then heat-treated for uniform properties. They are favored in aerospace and industrial sectors for their high strength and dimensional stability. For B2B buyers, extrusions offer predictable mechanical performance but can entail higher tooling and setup costs. They are suitable for applications where precision and high performance are critical, but less ideal for intricate or complex geometries that require extensive secondary processing.

Wrought Bars

7075-T6 wrought bars are solid, machined-ready forms that provide consistent mechanical properties across batches. They are widely used in manufacturing high-performance mechanical parts, sports equipment, and defense applications. Buyers benefit from their excellent fatigue resistance and machinability, making them cost-effective for high-precision components. However, their poor weldability necessitates mechanical fastening or adhesive bonding, which should be factored into assembly planning.

Wires

7075-T6 wires are high-strength, fine forms suitable for precision applications such as springs, fasteners, and electronic components. Their superior tensile strength combined with surface treatments for corrosion resistance makes them ideal for demanding environments. B2B buyers should anticipate higher costs and limited availability in larger quantities, focusing on niche applications where performance outweighs expense.

Forgings

7075-T6 forgings are pre-shaped, high-toughness components produced through forging processes that enhance fatigue life and impact resistance. They are critical in aerospace engines, military armor, and automotive high-stress parts. While offering superior toughness and durability, forgings involve complex manufacturing and longer lead times, making them suitable for high-value, mission-critical applications. Buyers should evaluate their supply chain capacity and lead time requirements when considering forgings.

Related Video: All Machine Learning Models Clearly Explained!

Key Industrial Applications of al 7075 t6

| Industry/Sector | Specific Application of al 7075 t6 | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace & Defense | Structural aircraft components, such as fuselage fittings and control surfaces | High strength-to-weight ratio reduces aircraft weight, improving fuel efficiency and payload capacity | Consistent alloy quality, traceability, and adherence to aerospace standards (e.g., AMS, ASTM) |

| Automotive & Motorsport | High-performance suspension parts and chassis components | Enhanced durability and load-bearing capacity for safety-critical parts | Certification for automotive standards, availability in specific tempers (T6, T651) |

| Sporting Goods & Recreation | Bicycle frames, rock climbing gear, and baseball bats | Superior strength ensures safety, longevity, and performance | Precise temper control, surface finish quality, and supply in various forms (plates, bars) |

| Marine & Offshore | Marine hardware, hardware fittings, and lightweight structural parts | Corrosion resistance with surface treatments, combined with high mechanical strength | Surface treatment options (anodizing, coating), compliance with marine standards, and corrosion resistance |

| Industrial Machinery & Equipment | High-stress machine parts, molds, and tooling | Excellent fatigue resistance and dimensional stability for precision applications | Consistent mechanical properties, formability in annealed states, and reliable supply chain |

Aerospace & Defense

7075 T6 aluminum is integral to aerospace and defense sectors due to its exceptional strength-to-weight ratio. It is used extensively in manufacturing structural components such as fuselage fittings, control surfaces, and gears. For international buyers from regions like Nigeria, the UK, or South America, sourcing aerospace-grade 7075 T6 requires strict compliance with industry standards (e.g., AMS, ASTM), ensuring material traceability and quality assurance. This alloy helps reduce aircraft weight, leading to fuel savings and increased payload capacity, which is critical for commercial and military applications. Buyers must prioritize suppliers with proven certification and consistent alloy composition to meet rigorous safety and performance standards.

Automotive & Motorsport

In high-performance automotive applications, especially racing or specialized vehicles, 7075 T6 aluminum provides the necessary strength and fatigue resistance for suspension components, chassis reinforcements, and drive train parts. For B2B buyers in Europe or the Middle East, sourcing reliable, high-grade 7075 T6 ensures durability under extreme stresses and enhances vehicle safety. The alloy’s excellent mechanical properties allow manufacturers to reduce weight without compromising strength, which is vital for competitive performance. Selecting suppliers that offer certified material with appropriate temper and surface finishes will facilitate compliance with automotive standards and improve product longevity.

Sporting Goods & Recreation

The demanding performance requirements of sporting goods such as bicycle frames, rock climbing hardware, and baseball bats make 7075 T6 aluminum an ideal choice. Its high strength and fatigue resistance ensure safety and durability, appealing to premium markets across Africa and South America. Buyers should focus on sourcing alloys with precise temper control and surface quality, as these influence product performance and aesthetics. Reliable supply chains that can deliver in various forms—plates, bars, or extrusions—are essential to meet production timelines and maintain consistent quality standards for international markets.

Marine & Offshore

7075 T6 aluminum, when combined with suitable surface treatments like anodizing or marine coatings, offers an excellent solution for lightweight marine hardware, fittings, and structural components. Its high strength ensures the durability of marine equipment exposed to dynamic loads, while surface treatments mitigate corrosion in saltwater environments. For buyers in the Middle East or coastal regions of Africa and South America, sourcing from suppliers with proven marine standards and corrosion-resistant options is critical. Ensuring material compliance and surface finishing quality helps extend the lifespan of marine assets and reduces maintenance costs, providing a competitive edge in harsh environments.

Industrial Machinery & Equipment

Heavy-duty machinery, molds, and tooling benefit from 7075 T6 aluminum’s fatigue resistance and dimensional stability. Its high strength allows for lighter, more efficient machine parts that can withstand cyclic stresses over extended periods. Buyers in Europe or South America should prioritize suppliers offering consistent mechanical properties and options for custom forms and sizes. Ensuring the alloy’s traceability and compliance with industry standards will facilitate smooth integration into manufacturing processes, reducing downtime and enhancing product reliability in demanding industrial applications.

Strategic Material Selection Guide for al 7075 t6

Comparative Analysis of Common Materials for al 7075 T6 Applications

When selecting materials to complement or substitute 7075 T6 aluminum in high-performance applications, B2B buyers from Africa, South America, the Middle East, and Europe must consider key material properties, manufacturing complexities, cost implications, and compliance standards. Here, we analyze four prevalent materials: Carbon Steel, 6061 Aluminum, Titanium, and Stainless Steel, focusing on their suitability for demanding environments and international trade considerations.

Carbon Steel (e.g., A216 WCB)

Key Properties:

Carbon steel is known for its excellent strength, durability, and cost-effectiveness. It can withstand high pressures and temperatures, making it suitable for structural and industrial applications. However, it exhibits poor corrosion resistance unless coated or treated, which can be a concern in marine or humid environments.

Pros & Cons:

Its primary advantage is low cost coupled with high tensile strength, making it ideal for heavy-duty structural components. The drawbacks include susceptibility to corrosion, requiring protective coatings, and higher weight compared to aluminum alloys. Manufacturing processes such as welding are straightforward, but the material’s weight can impact performance in weight-sensitive applications.

Impact on Application:

Carbon steel’s corrosion vulnerability necessitates surface treatments, especially in coastal or tropical climates common in Africa and South America. It is compatible with standard ASTM specifications, which are widely recognized internationally, simplifying procurement for European and Middle Eastern markets.

International Considerations:

Buyers should verify local standards and corrosion protection requirements. Steel is often favored in regions with less stringent environmental controls due to its cost advantage, but additional protective measures may be necessary to meet durability expectations.

6061 Aluminum

Key Properties:

6061 aluminum offers good strength, corrosion resistance, and ease of fabrication. It is less strong than 7075 T6 but provides excellent weldability and moderate temperature resistance, making it suitable for structural and general engineering purposes.

Pros & Cons:

Its main advantage is versatility—easy to machine, weld, and form—at a moderate cost. However, it has lower strength and fatigue performance compared to 7075 T6, limiting its use in high-stress applications. It is more resistant to corrosion, especially with anodized finishes, which is beneficial in marine and humid environments.

Impact on Application:

For applications requiring moderate strength and high corrosion resistance, 6061 is a practical alternative. It aligns well with international standards like ASTM B209 and JIS, easing compliance across regions.

International Considerations:

Buyers should consider local surface treatment capabilities and standards. In regions like Europe and the Middle East, 6061 is widely accepted for structural and architectural applications, while in Africa and South America, availability and cost are often decisive factors.

Titanium

Key Properties:

Titanium boasts an exceptional strength-to-weight ratio, outstanding corrosion resistance, and high-temperature stability. It is ideal for aerospace, military, and high-performance automotive components where weight savings and durability are critical.

Pros & Cons:

Its primary advantage is superior corrosion resistance and strength, even in aggressive media like seawater or chemical environments. The main drawbacks are high material and processing costs, and complex manufacturing requirements, including specialized welding techniques.

Impact on Application:

Titanium’s properties make it suitable for extreme environments, but its high cost limits widespread use. It is often used in niche applications where performance justifies expense, such as aerospace or offshore structures.

International Considerations:

Buyers must ensure compliance with international standards like ASTM F136 or ISO standards. Importing titanium involves navigating strict regulations, tariffs, and certification processes, especially in regions with evolving aerospace and defense sectors.

Stainless Steel (e.g., 17-4 PH)

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and good ductility. Variants like 17-4 PH can be heat-treated for enhanced mechanical properties, making it suitable for demanding environments.

Pros & Cons:

It provides durability and corrosion resistance without the need for coatings, suitable for marine, chemical, and food processing applications. However, it is significantly heavier than aluminum, and its higher cost can be a limiting factor.

Impact on Application:

Stainless steel’s corrosion resistance makes it ideal for applications exposed to harsh media, such as seawater or industrial chemicals. It complies with numerous international standards, facilitating global procurement.

International Considerations:

Buyers should verify standards like ASTM A276 or A240 and consider local manufacturing capabilities for welding and fabrication. Its higher cost and weight are balanced by its longevity and low maintenance needs.

Summary Table

| Material | Typical Use Case for al 7075 t6 | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Carbon Steel | Heavy-duty structural components, machinery frames | Cost-effective, high strength | Poor corrosion resistance, heavy weight | Low |

| 6061 Aluminum | Structural frames, marine components, general engineering | Good corrosion resistance, weldable | Lower strength than 7075, fatigue limited | Medium |

| Titanium | Aerospace, offshore, high-performance automotive | Superior strength-to-weight ratio, corrosion resistance | Very high cost, complex processing | High |

| Stainless Steel (17-4 PH) | Marine hardware, chemical processing, high-corrosion environments | Excellent corrosion resistance, durable | Heavy, more expensive than aluminum | High |

This comparative analysis equips international B2B buyers with a strategic understanding of material options aligned with application demands, environmental conditions, and regional standards. Selecting the optimal material depends on balancing performance requirements with cost and manufacturing capabilities, especially considering regional logistics, compliance, and environmental factors.

In-depth Look: Manufacturing Processes and Quality Assurance for al 7075 t6

Manufacturing Processes for 7075-T6 Aluminum Alloy

Material Preparation and Raw Material Sourcing

The journey of 7075-T6 begins with the procurement of high-quality raw billets or sheets, typically produced through extrusion, forging, or rolling processes. Reputable suppliers adhere to international standards such as ASTM B209 or AMS-QQ-A-250/12 to ensure chemical composition consistency, notably zinc, magnesium, and copper levels critical for achieving the desired mechanical properties. For B2B buyers, verifying the supplier’s adherence to these standards is essential, as it directly impacts the alloy’s performance in demanding applications.

Solution Heat Treatment and Artificial Aging

The defining characteristic of T6 temper involves solution heat treatment followed by artificial aging. This process entails heating the alloy to approximately 477–635°C to dissolve alloying elements uniformly, then quenching rapidly (often in water) to lock in a supersaturated state. Subsequent artificial aging at around 120–160°C precipitates fine particles that significantly enhance strength and hardness. Manufacturers with advanced heat treatment furnaces and controlled atmospheres can produce consistent T6 temper, which is critical for high-performance applications such as aerospace or military hardware.

Forming and Fabrication

While 7075-T6 offers excellent mechanical properties, its high strength imposes limitations on forming processes. Typically, initial forming is performed in the annealed (O) condition to facilitate bending, stretching, or shaping. After forming, components often undergo post-forming heat treatments to restore or enhance properties. Techniques such as machining, drilling, and milling are common, with manufacturers employing CNC equipment optimized for high-strength aluminum to ensure precision and surface integrity. For complex geometries, extrusion or forging may be used to produce near-net-shape parts, reducing waste and machining time.

Assembly and Joining

Due to its poor weldability, 7075-T6 is predominantly assembled using mechanical fastening methods such as rivets, bolts, or screws. Adhesive bonding is also gaining popularity, especially for applications requiring airtight or watertight seals. When welding is unavoidable, friction stir welding (FSW) or other solid-state welding techniques are preferred to minimize defects. B2B buyers should specify joint requirements clearly and ensure suppliers follow best practices to avoid compromising alloy integrity.

Finishing and Surface Treatment

Post-fabrication, surface finishing techniques such as anodizing, painting, or powder coating are employed to enhance corrosion resistance and aesthetic appeal. For marine or outdoor applications, additional surface treatments like chromate conversion or organic coatings are recommended. Suppliers should provide documentation on surface treatment processes, especially for buyers in regions with harsh environments like Nigeria or Middle Eastern countries, where corrosion resistance is paramount.

Quality Control (QC) in Manufacturing of 7075-T6

International and Industry Standards

Manufacturers producing 7075-T6 are expected to comply with internationally recognized standards such as ISO 9001, which emphasizes quality management systems, process consistency, and continuous improvement. Industry-specific standards like CE marking (for European markets) or API specifications (for oil and gas applications) further ensure compliance with regional regulatory requirements. B2B buyers should request copies of relevant certifications and audit reports to verify supplier adherence.

QC Checkpoints and Inspection Stages

– Incoming Quality Control (IQC): Raw materials are tested for chemical composition via spectrometry, ensuring alloy content aligns with specifications. Mechanical properties are often verified through tensile, hardness, and fatigue tests on sample billets or sheets before processing.

– In-Process Quality Control (IPQC): During heat treatment and forming, process parameters such as temperature, duration, and cooling rates are monitored and recorded. Dimensional inspections using coordinate measuring machines (CMM) or optical comparators verify tolerances. Non-destructive testing (NDT) methods like ultrasonic or dye penetrant inspection identify internal or surface defects.

– Final Quality Control (FQC): Completed parts undergo comprehensive testing, including tensile strength, hardness, and corrosion resistance (via salt spray tests). Surface finish and dimensional accuracy are inspected visually and with precision instruments. For critical applications, destructive testing on sample batches confirms mechanical integrity.

Testing Methods and Documentation

Advanced laboratories utilize methods such as ASTM E8 for tensile testing, ASTM B117 for salt spray testing, and ASTM D3359 for adhesion of surface coatings. B2B buyers should request detailed test reports, certificates of conformity, and traceability documents. Digital records and batch-specific certificates facilitate quality verification across international supply chains.

Verifying Supplier Quality for International B2B Buyers

Supplier Audits and Factory Visits

Conducting or commissioning audits is crucial for buyers from Africa, South America, the Middle East, and Europe. An on-site audit assesses the supplier’s quality management system, equipment calibration, personnel training, and process control. For remote buyers, engaging third-party inspection agencies like SGS, Bureau Veritas, or TUV can provide impartial verification and detailed inspection reports.

Third-Party Inspection and Certification

Third-party inspectors review manufacturing processes, perform sample testing, and verify documentation. Certificates such as ISO 9001, AMS, or ASTM compliance serve as initial quality indicators. For high-stakes applications, buyers should specify requirements for third-party testing of mechanical properties, corrosion resistance, and surface finish before shipment.

Product Traceability and Batch Control

Effective traceability systems enable buyers to track each batch or lot from raw material to finished product. Suppliers should provide detailed records including chemical analysis, heat treatment parameters, and inspection reports. This traceability is vital for warranty claims, product recalls, or certification audits in regulated industries.

Special Considerations for Regional B2B Buyers

Africa (e.g., Nigeria):

Buyers should prioritize suppliers with ISO 9001 certification and robust traceability systems. Given climate challenges, surface treatments like anodizing or protective coatings are essential for corrosion resistance. Conducting local or regional audits can help verify quality control practices, especially where infrastructure may vary.

South America:

Regional suppliers often cater to aerospace and automotive markets, requiring stringent QC. Buyers should verify compliance with ASTM or ISO standards and seek third-party inspection reports. Establishing clear communication channels and documentation standards mitigates risks of quality discrepancies.

Middle East:

Harsh environmental conditions necessitate high-quality surface treatments and corrosion-resistant finishes. Buyers should insist on detailed QC documentation, including salt spray test results and coating adhesion certificates. Engaging local inspection agencies familiar with regional standards enhances reliability.

Europe (e.g., UK):

European buyers typically demand compliance with CE marking and EN standards. They should verify that suppliers maintain ISO 9001 certification and provide comprehensive quality documentation. Regular audits and third-party testing are common practices to ensure ongoing compliance.

Conclusion

For B2B buyers sourcing 7075-T6 aluminum, understanding the manufacturing and QC landscape is vital to ensuring product performance and compliance across diverse markets. Emphasizing supplier transparency, rigorous inspection protocols, and adherence to international standards minimizes risks and guarantees the high-quality, high-performance components critical to demanding applications. Establishing clear communication, detailed documentation, and periodic audits fosters trust and long-term partnerships in the global supply chain.

Related Video: Lean Manufacturing: MIND-BLOWING Factory Tour! (Behind The Scenes)

Comprehensive Cost and Pricing Analysis for al 7075 t6 Sourcing

Cost Structure Breakdown for 7075-T6 Aluminum Sourcing

Understanding the comprehensive cost structure of 7075-T6 aluminum is crucial for international B2B buyers seeking optimal value. The primary components influencing the total cost include raw materials, manufacturing processes, labor, overhead, tooling, quality assurance, logistics, and profit margins.

Materials Cost:

7075-T6 aluminum is characterized by its high strength-to-weight ratio, zinc as the primary alloying element, and specific tempering requirements. The material cost is significantly influenced by global zinc and aluminum prices, which fluctuate based on market demand, geopolitical factors, and supply chain stability. Typically, material costs constitute 40-55% of the total product price, with prices ranging from approximately $4.50 to $8.50 per kilogram for bulk purchases, depending on volume and supplier location.

Manufacturing and Processing:

The heat treatment process (solution heat treating and aging) to achieve T6 temper adds to manufacturing costs. Additional processing such as extrusions, machining, or surface treatments (e.g., anodizing, coating) can elevate costs further. For high-volume orders, economies of scale reduce per-unit costs, but small or custom orders often incur premium charges due to setup and handling.

Labor & Overheads:

Labor costs vary widely across regions—lower in Africa or South America compared to Europe or North America. Overhead costs, including plant operations, quality control, and administrative expenses, also influence pricing. Efficient production facilities with advanced automation tend to lower labor-related costs, providing more competitive pricing for large orders.

Tooling and Equipment:

Initial tooling, especially for custom shapes or complex extrusions, involves significant upfront investment. Tooling costs can range from a few thousand to tens of thousands of dollars, amortized over the expected production volume. Buyers should negotiate tooling costs upfront, especially for long-term or large-volume projects, to mitigate per-unit price escalations.

Quality Assurance & Certifications:

International buyers, particularly from Europe and the Middle East, often require certifications such as AMS, ASTM, or ISO standards. These add to costs due to additional testing, documentation, and inspection procedures. Suppliers with established quality systems may charge a premium for certified products, but this ensures compliance and reduces downstream risks.

Logistics & Incoterms:

Transportation costs depend on shipment volume, destination, and mode (sea, air, land). FOB (Free on Board) or CIF (Cost, Insurance, Freight) terms are common, with FOB offering more control over logistics costs. Buyers from Nigeria, Brazil, or Europe should consider tariffs, import duties, and local taxes, which can significantly impact total landed cost.

Profit Margins:

Margins are typically 10-25%, depending on the supplier’s market positioning, order volume, and relationship. Competitive bidding and volume commitments can help negotiate better pricing.

Price Influencers and Market Dynamics

- Volume & MOQ: Larger orders generally reduce unit prices through economies of scale. MOQ requirements vary from 100 kg to several tons, depending on the supplier.

- Specifications & Customization: Tighter tolerances, special surface finishes, or specific certifications increase costs. Custom shapes or complex extrusions also entail higher tooling and processing expenses.

- Material & Grade Quality: Suppliers offering prime-grade 7075-T6 with full certifications command higher prices than secondary or ungraded stock.

- Supplier Reputation & Location: Established suppliers with extensive certifications and quality systems often charge a premium but offer reliability and consistency. Regional factors such as transportation infrastructure and import regulations also influence final pricing.

Buyer Tips for Cost Optimization

- Negotiate Pricing & Terms: Leverage volume commitments, long-term partnerships, or flexible delivery schedules to secure discounts.

- Focus on Total Cost of Ownership (TCO): Consider not just unit price but also logistics, lead times, quality assurance, and post-sale support.

- Explore Regional Suppliers: Sourcing from regional manufacturers or distributors can reduce shipping costs and lead times, especially for European or Middle Eastern buyers.

- Request Detailed Quotations: Ensure quotes specify all cost components, including tooling, certifications, and logistics, to avoid hidden charges.

- Plan for Fluctuations: Monitor raw material markets and currency exchange rates, which can impact prices, especially for buyers dealing in local currencies or with fluctuating tariffs.

Disclaimer

Indicative prices for 7075-T6 aluminum in bulk (over 1 ton) typically range between $4.50 and $8.50 per kilogram. Small or customized orders may attract higher premiums. Prices are subject to market volatility, supplier negotiations, and specific project requirements.

By understanding these cost components and influencing factors, international B2B buyers from Africa, South America, the Middle East, and Europe can better strategize their procurement, negotiate effectively, and optimize their total cost of ownership for 7075-T6 aluminum.

Spotlight on Potential al 7075 t6 Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘al 7075 t6’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

10 Leading 7075 Aluminum Plate Suppliers for 2024 (www.unionaluminium.com)

Manufacturer Profile

This leading supplier specializes in high-performance aluminum solutions, with a strong focus on 7075-T6 aluminum plates tailored for demanding industrial and aerospace applications. Established with advanced manufacturing capabilities, the company adheres to international quality standards such as ISO 9001, ensuring consistent product quality and traceability. Known for its precision-engineered products, it offers customized solutions that meet strict tolerances and surface finish requirements, making it a preferred choice for global B2B markets including Africa, South America, the Middle East, and Europe. Its strategic focus on high-strength, heat-treatable alloys positions it as a reliable partner for industries requiring durable, lightweight materials with superior mechanical properties. The company’s extensive logistics network and commitment to customer service facilitate seamless international procurement and supply chain integration.

**

7075-T6 Aluminum Market Size, Statistics Report 2025-2034 (www.gminsights.com)

The manufacturer specializing in 7075-T6 aluminum is recognized for delivering high-performance, aerospace-grade alloys tailored to demanding industries. With a focus on precision and quality, they operate advanced manufacturing facilities equipped with CNC machining, heat treatment, and rigorous testing to meet international standards such as ISO 9001. Their product portfolio includes custom-engineered solutions for aerospace, defense, automotive, and industrial applications, emphasizing high strength, lightweight, and durability. With extensive experience serving global markets—including Africa, South America, the Middle East, and Europe—they support B2B clients with reliable supply chains, technical expertise, and certifications aligned with industry requirements. Their strategic positioning enables them to cater to high-end projects demanding superior alloy quality and consistency.

**

7075 Aluminum Manufacturers (aluminummanufacturers.org)

7075 Aluminum Manufacturers specializes in producing high-performance aluminum alloys tailored for demanding aerospace, military, and industrial applications. Established with a focus on high-strength, lightweight materials, the company offers premium 7075-T6 aluminum in various forms, including sheets, plates, bars, and extrusions, meeting rigorous quality standards such as ISO 9001 and industry-specific certifications. Equipped with advanced CNC machining centers and in-house testing facilities, they ensure precise dimensional control and consistent material properties suitable for critical structural components. With extensive experience serving international markets—including Africa, South America, the Middle East, and Europe—they cater to buyers seeking durable, high-strength solutions for sectors like aerospace, automotive, and sporting goods. Their ability to customize alloys and surface treatments positions them as a reliable partner for complex, high-stress projects requiring superior performance.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Unionaluminium | High-quality, custom 7075-T6 aluminum plates for global markets | unionaluminium.com |

| GMI Insights | High-performance 7075-T6 aluminum supplier targeting international industries | gminsights.com |

| Aluminum Manufacturers | High-strength 7075-T6 aluminum for diverse global industrial applications | aluminummanufacturers.org |

Essential Technical Properties and Trade Terminology for al 7075 t6

Critical Technical Properties for 7075 T6 Aluminum in B2B Transactions

Material Grade and Temper

7075 T6 is a high-strength, heat-treated alloy within the 7000 series, primarily alloyed with zinc. The “T6” temper indicates the alloy has undergone solution heat treatment and artificial aging, resulting in maximum mechanical properties. Recognizing the specific grade and temper is vital for buyers to ensure the material meets strength, durability, and performance requirements for applications such as aerospace, automotive, or structural components.

Tensile and Yield Strength

7075 T6 exhibits exceptional tensile strength—up to approximately 572 MPa (83 ksi)—and yield strength around 503 MPa (73 ksi). These properties make it suitable for high-stress environments where material failure is unacceptable. For B2B buyers, understanding these figures helps in selecting a material capable of withstanding operational loads, vibration, and cyclic stresses, reducing risks of fatigue or structural failure.

Dimensional Tolerance

Tolerance specifications define permissible deviations in dimensions, critical for precision manufacturing and assembly. Common tolerances for 7075 T6 aluminum sheets and bars are typically within ±0.1 mm to ±0.5 mm, depending on the product form and size. Accurate tolerances ensure parts fit correctly, minimizing rework, and ensuring quality in mass production or critical assemblies.

Corrosion Resistance and Surface Finish

While 7075 T6 offers good mechanical strength, its corrosion resistance is moderate, especially in harsh environments like marine or industrial settings. Surface treatments such as anodizing or coating are often employed. For B2B buyers, specifying surface finish requirements upfront ensures longevity and performance, especially for outdoor or corrosive applications.

Formability and Machinability

Although 7075 T6 is highly strong, its formability is limited compared to softer alloys, especially after heat treatment. It machines well in its annealed (O) state but requires specialized tooling and techniques in T6. Recognizing these properties allows manufacturers to plan appropriate machining processes, select suitable tooling, and reduce production delays.

Heat Treatment and Certification

The T6 temper involves solution heat treatment and artificial aging, which must be certified for quality assurance. Buyers should request material certificates confirming compliance with standards like ASTM B209 or AMS-QQ-A-250/12. Such certifications are critical in high-stakes industries, ensuring traceability and adherence to quality protocols.

Essential Industry and Trade Terms for B2B Buyers

OEM (Original Equipment Manufacturer)

An OEM produces parts or entire products under their brand, often requiring high-quality, consistent materials like 7075 T6 aluminum. Understanding OEM standards helps buyers align their specifications with manufacturer expectations, ensuring compatibility and quality in end-use applications.

MOQ (Minimum Order Quantity)

This is the smallest quantity a supplier is willing to sell. For high-performance alloys like 7075 T6, MOQs can range from small batches to bulk orders. Clear MOQ knowledge helps buyers plan procurement budgets and inventory, avoiding delays caused by supply constraints.

RFQ (Request for Quotation)

A formal request sent by buyers to suppliers seeking price, lead time, and specification details. An RFQ ensures transparent communication, enabling buyers to compare offers and select suppliers that meet their technical and commercial criteria efficiently.

Incoterms (International Commercial Terms)

Standardized trade terms defining responsibilities for shipping, insurance, and customs between buyers and sellers. Familiarity with Incoterms such as FOB (Free on Board) or CIF (Cost, Insurance, Freight) ensures clear contractual obligations, minimizing misunderstandings and unexpected costs during international transactions.

Certifications and Standards

References to ASTM, AMS, or ISO standards are common in B2B transactions for materials like 7075 T6. These certifications assure buyers that materials conform to recognized quality and performance benchmarks, which is especially critical for aerospace or military applications.

Lead Time and Supply Chain Reliability

Lead time refers to the period from order placement to delivery. For high-demand alloys, reliable lead times are crucial for production planning. Establishing clear communication and understanding supplier capacity helps mitigate risks of delays, especially in international sourcing from regions like Africa, South America, or Europe.

By mastering these technical properties and trade terms, B2B buyers can make informed decisions, optimize procurement processes, and ensure the quality and performance of their aluminum components across global markets.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the al 7075 t6 Sector

Market Overview & Key Trends

The global market for 7075-T6 aluminum alloy is driven by its exceptional strength-to-weight ratio, fatigue resistance, and heat-treatability, making it indispensable across aerospace, defense, automotive, sporting goods, and industrial sectors. As demand for high-performance lightweight materials grows—particularly in aerospace and high-end automotive applications—buyers from regions like Europe, the Middle East, South America, and Africa are increasingly seeking reliable supply chains to meet stringent quality standards.

Emerging sourcing trends emphasize diversification and localization. For instance, European buyers are favoring suppliers with proven certifications (ISO, EN standards) and sustainable practices to comply with strict environmental regulations. Middle Eastern markets, driven by defense and infrastructure projects, prioritize suppliers offering tailored solutions and quick lead times, often through regional distribution centers or local partnerships.

Africa and South America, especially Nigeria and Brazil, are experiencing accelerated industrialization, prompting demand for high-grade alloys like 7075-T6 in sectors such as aerospace, transportation, and manufacturing. However, market dynamics are influenced by geopolitical factors, tariffs, and currency fluctuations, which can impact pricing and availability. International buyers are increasingly leveraging digital sourcing platforms, pre-qualification processes, and supplier audits to ensure quality and consistency.

Furthermore, technological advances in manufacturing—such as improved extrusion, machining, and surface treatment methods—are expanding the application scope of 7075-T6, prompting buyers to seek suppliers capable of providing tailored alloy forms (plates, sheets, extrusions) with specific temper conditions (e.g., T651, T7351). The overall trend points toward a more integrated, transparent, and sustainable supply chain, aligning high-performance requirements with evolving market and regulatory standards.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a critical criterion for international B2B buyers sourcing 7075-T6 aluminum, especially from regions with growing environmental awareness such as Europe and the Middle East. The environmental impact of aluminum production—particularly energy consumption and greenhouse gas emissions—has driven demand for greener supply chains. Buyers are increasingly requiring suppliers to demonstrate compliance with environmental standards through certifications like ISO 14001, and to adopt sustainable practices such as using renewable energy sources during smelting and processing.

Ethical sourcing is equally vital, with buyers scrutinizing supply chains for transparency and social responsibility. This includes verifying that raw materials are sourced without conflict minerals and that labor practices adhere to international standards. Traceability systems, blockchain, and third-party audits are becoming standard tools for ensuring compliance.

In terms of materials, there is a rising preference for suppliers offering ‘green’ or recycled aluminum options. Recycled 7075 aluminum significantly reduces energy consumption and carbon footprint, aligning with corporate sustainability commitments. Certifications such as LEED or Cradle to Cradle can provide additional assurance of a product’s eco-friendliness.

For B2B buyers in emerging markets, establishing partnerships with suppliers committed to environmental stewardship and ethical standards not only mitigates risks but also enhances brand reputation. Investing in suppliers with transparent supply chains and eco-friendly production processes can lead to long-term cost savings, regulatory compliance, and a competitive advantage in markets increasingly driven by sustainability imperatives.

Brief Evolution/History (Optional)

The development of 7075 aluminum alloy dates back to the early 1940s, initially designed for aerospace applications during World War II. Its exceptional strength and lightweight properties quickly made it a preferred choice for critical structural components. Over decades, advances in heat treatment processes and alloy refinement have expanded its applications into diverse sectors, including automotive, sporting goods, and military equipment.

Today, the evolution of 7075-T6 reflects a broader industry shift toward high-performance, sustainable materials. Modern production techniques prioritize not only mechanical excellence but also environmental responsibility, with many suppliers adopting recycled content and cleaner manufacturing practices. This historical progression underscores the alloy’s adaptability and the importance for B2B buyers to engage with suppliers who innovate responsibly, ensuring that high-quality standards are maintained in tandem with sustainability goals.

Related Video: The Inside Story of the Ship That Broke Global Trade

Frequently Asked Questions (FAQs) for B2B Buyers of al 7075 t6

1. How can I effectively vet suppliers of 7075 T6 aluminum to ensure quality and reliability?

Vetting international suppliers requires a multi-step approach. Start by requesting comprehensive certifications such as ISO 9001, ASTM, or AMS standards, which confirm quality management systems. Review their product datasheets, test reports, and third-party inspection certificates. Conduct virtual audits or site visits when feasible, especially in regions with emerging supply chains like Nigeria or South America. Seek references from previous clients in your industry or region. Additionally, evaluate their production capacity, lead times, and responsiveness. Reliable suppliers should provide transparent communication and verifiable quality documentation, minimizing risks of substandard material or supply disruptions.

2. What customization options are typically available for 7075 T6 aluminum, and how do I specify my requirements?

7075 T6 aluminum can be customized in various forms—sheets, plates, bars, extrusions, or tubes—according to your project needs. Specify alloy temper (T6), dimensions, surface finish (anodized, polished, coated), and any surface treatments like hard anodizing or coating for corrosion resistance. If you require specific mechanical properties, such as increased fatigue strength or stress corrosion resistance, communicate these explicitly. Work with suppliers who offer technical support to confirm that your specifications align with manufacturing capabilities. Providing detailed drawings, tolerances, and performance criteria upfront ensures accurate fulfillment and reduces costly rework.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for sourcing 7075 T6 aluminum internationally?

MOQs for 7075 T6 aluminum vary depending on supplier size and production capacity but generally range from 100 kg to several tons for standard products. Lead times typically span 2–6 weeks from order confirmation, influenced by stock availability, customization, and shipping logistics. Payment terms often include 30% upfront payment with the balance payable before shipment, or letters of credit for larger transactions. Negotiating flexible terms is common, especially for ongoing partnerships. Establish clear communication early on to align expectations and plan your procurement schedule accordingly, factoring in international shipping durations.

4. What quality assurance measures and certifications should I request from suppliers?

Request suppliers’ quality assurance documentation such as mill test reports (MTRs), certificates of compliance, and third-party inspection reports. Certifications like ISO 9001, ASTM B209, or AMS-QQ-A-250/12 confirm adherence to industry standards. For critical applications, demand detailed chemical composition and mechanical property test results aligned with ASTM or AMS standards. Consider requesting samples for independent testing if feasible. Suppliers with a track record of consistent quality and transparency in documentation reduce your risk of receiving non-conforming material, especially when sourcing from regions with variable quality standards.

5. How can I manage logistics and shipping effectively when importing 7075 T6 aluminum from overseas?

Effective logistics management involves choosing reliable freight forwarders experienced in handling metals and hazardous materials if applicable. Compare shipping options—sea freight for cost efficiency on large volumes, air freight for urgent needs. Clarify Incoterms (e.g., FOB, CIF) to understand responsibilities and costs. Ensure your supplier provides proper packaging to prevent damage during transit. Track shipments diligently and request documentation like bills of lading, packing lists, and customs clearance papers. Working with local customs brokers familiar with your country’s import regulations helps streamline clearance, minimizing delays and costs.

6. What common disputes or issues arise in international sourcing of 7075 T6 aluminum, and how can I prevent them?

Disputes often stem from quality inconsistencies, late deliveries, or payment disagreements. To prevent these, establish clear contractual terms covering specifications, inspection rights, and penalties for non-compliance. Use detailed purchase agreements that specify tolerances, certifications, and dispute resolution processes such as arbitration. Maintain open communication channels and document all agreements and changes. Conduct regular quality audits and insist on pre-shipment inspection reports. Building strong supplier relationships and choosing reputable, verified vendors reduces the likelihood of disputes and ensures smoother resolution if issues arise.

7. What should I consider regarding the environmental and regulatory compliance of 7075 T6 aluminum?

Ensure your supplier complies with environmental standards such as RoHS, REACH, and local regulations relevant to your market. Request documentation confirming that the material is free from hazardous substances and meets safety standards for your region. For regions like Europe and the Middle East, compliance with WEEE and other environmental directives is vital. Additionally, consider the supplier’s sustainability practices, including recycling and waste management. Verifying compliance reduces regulatory risks, potential delays, and liabilities associated with non-conforming imports, supporting your company’s commitment to environmental responsibility.

8. How do I handle potential quality disputes or product non-conformance after delivery?

Establish clear procedures in your purchase agreement for handling non-conformance, including inspection rights upon receipt. Conduct thorough incoming inspections against agreed specifications—chemical composition, mechanical properties, and surface quality. If discrepancies are identified, notify the supplier promptly with documented evidence. Request corrective actions such as rework, replacement, or refunds. Maintain good communication and keep detailed records of all correspondences and inspections. Building a trusted relationship with your supplier facilitates quick resolution. If necessary, involve third-party inspectors or testing labs to verify claims and support dispute resolution processes efficiently.

Strategic Sourcing Conclusion and Outlook for al 7075 t6

Conclusion and Future Outlook

Strategic sourcing of 7075 T6 aluminum offers B2B buyers a compelling combination of unparalleled strength, fatigue resistance, and versatility, making it ideal for high-performance applications across aerospace, military, automotive, and industrial sectors. By carefully selecting reputable suppliers and optimizing procurement processes, buyers can ensure consistent quality, competitive pricing, and reliable supply chains—crucial factors for manufacturing resilience and innovation.

Given the alloy’s moderate corrosion resistance and welding limitations, a strategic approach should include evaluating surface treatment options and forming capabilities aligned with specific project requirements. As global markets continue to evolve, leveraging local and regional suppliers—particularly in emerging markets like Nigeria, or established hubs within Europe, the Middle East, and South America—can reduce lead times, lower costs, and foster sustainable partnerships.

Looking ahead, the increasing demand for lightweight yet durable materials underscores the importance of proactive sourcing strategies. International B2B buyers from Africa, South America, the Middle East, and Europe are encouraged to deepen supplier relationships, explore new supply channels, and invest in quality assurance. Such initiatives will position them to capitalize on technological advancements and meet the rising global demand for high-strength aluminum solutions.