Introduction: Navigating the Global Market for best metal cutter tool

Navigating the global market for the best metal cutter tools is a strategic imperative for B2B buyers operating across diverse regions such as Africa, South America, the Middle East, and Europe. The choice of cutting tools—whether band saws, plasma cutters, laser systems, or angle grinders—directly influences project efficiency, safety, and overall cost management. In industries ranging from infrastructure development and manufacturing to energy and construction, having reliable, high-quality tools is essential to meet demanding specifications and ensure operational continuity.

This comprehensive guide equips international procurement teams with critical insights to make informed sourcing decisions. It covers a broad spectrum of topics, including the various types of metal cutters and their industrial applications, advanced materials and manufacturing processes, and rigorous quality assurance protocols. Additionally, it offers practical strategies for evaluating domestic and global suppliers, understanding pricing models, and navigating supply chain complexities—factors especially relevant amid fluctuating logistics and regional standards.

Designed to empower buyers with actionable intelligence, this resource helps mitigate risks, optimize costs, and ensure compliance with international standards. Whether sourcing in emerging markets or established industrial hubs, this guide enables you to identify the most suitable tools, select reputable suppliers, and build resilient supply chains. By mastering these insights, B2B buyers can secure the high-performance metal cutting tools necessary to drive growth, innovation, and competitive advantage in today’s interconnected global economy.

Understanding best metal cutter tool Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Band Saw | Continuous toothed blade; manual or automated operation | Structural steel fabrication, pipeline cutting, general steel processing | High accuracy and efficiency for bulk cuts; slower on very thick or hard steel, requires maintenance and blade replacement |

| Angle Grinder | Portable, handheld with interchangeable abrasive discs | Onsite repairs, maintenance, fabrication, field adjustments | Highly versatile and mobile; less precise, operator skill-dependent, consumable discs wear quickly |

| Plasma Cutter | Ionized gas jet; fast, clean cuts; suitable for thick and intricate shapes | Manufacturing, shipbuilding, automotive repair, heavy fabrication | Rapid cutting of thick or complex metals; high power consumption, safety precautions needed |

| Laser Cutter | Focused laser beam; high precision, minimal material waste | Electronics, automotive, high-end manufacturing, detailed fabrication | Exceptional accuracy and automation compatibility; high upfront cost and skilled operation required |

| Hydraulic Shear | Mechanical or hydraulic straight blade; high-force cutting of sheet metal | Mass production, HVAC, steel fabrication, sheet metal work | Efficient for straight cuts in large volumes; limited to simple, straight cuts, less flexible for complex shapes |

Band Saw

Band saws are distinguished by their continuous toothed blade loop, capable of making both straight and curved cuts with high repeatability. They are ideal for processing structural steel, pipes, and other profiles in high-volume environments. For B2B procurement, focus on blade quality, machine robustness, and aftersales support. Reliable spare parts and local service are critical, especially in regions with limited industrial infrastructure, ensuring minimal downtime and consistent productivity. Their suitability for bulk, precise cuts makes them a staple in large-scale fabrication and manufacturing.

Angle Grinder

Angle grinders are portable, versatile tools favored for onsite cutting, grinding, and polishing tasks. Their ability to operate in tight or remote locations makes them indispensable for field repairs and quick adjustments. When sourcing angle grinders, buyers should prioritize motor power, safety features, and compatibility with various abrasive discs. Consider the availability of consumables and local repair services, which influence long-term operational costs. Their flexibility and ease of use make them suitable for diverse applications, but operators require training to ensure safety and optimal performance.

Plasma Cutter

Plasma cutters utilize a high-velocity jet of ionized gas to swiftly and cleanly cut through electrically conductive metals, including thick steel plates. They excel in industries such as shipbuilding, heavy machinery manufacturing, and automotive repair, where speed and precision are paramount. Procurement considerations include the cutter’s power requirements, safety features, and technical support for installation and maintenance. Proper training for operators on safety protocols and operational procedures is essential, especially in regions with less regulatory oversight, to maximize efficiency and safety.

Laser Cutter

Laser cutters are distinguished by their ability to produce extremely precise cuts with minimal material wastage, making them suitable for high-value sectors like electronics, aerospace, and automotive manufacturing. They are ideal for intricate designs, small batch production, and automation integration. Buyers should evaluate the quality of laser sources, software compatibility, and aftersales services such as remote diagnostics and training. Although initial investment is high, laser cutters offer long-term savings through reduced waste and enhanced productivity, making them a strategic choice for organizations aiming for advanced manufacturing capabilities.

Hydraulic Shear

Hydraulic shears provide high-force, straight cuts on sheet metal, making them essential for mass production environments like HVAC manufacturing and steel fabrication. They are valued for their speed, accuracy, and low operating costs. When sourcing hydraulic shears, buyers should assess the shear’s capacity, precision, and durability, as well as the availability of replacement blades and maintenance support. Suitable for high-volume, straight-cut tasks, they are less adaptable for complex or curved cuts, so buyers should consider their specific application needs and potential for automation integration to maximize ROI.

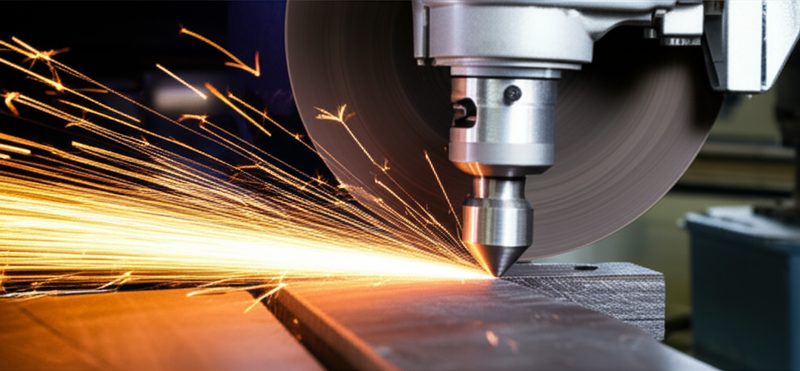

Related Video: 7 Common Metal Cutting Tools | for fast and easy cutting.

Key Industrial Applications of best metal cutter tool

| Industry/Sector | Specific Application of best metal cutter tool | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Construction & Infrastructure | Cutting structural steel beams and reinforcement bars for building frameworks | Ensures precise, clean cuts that improve safety and structural integrity | Tool durability for heavy-duty use, compatibility with steel grades, supplier reliability in remote regions |

| Manufacturing & Fabrication | Precision cutting of metal sheets and components for machinery assembly | Reduces waste, improves accuracy, and accelerates production timelines | High precision capabilities, automation options, availability of spare parts, aftersales support |

| Oil & Gas | Cutting and shaping pipes, pressure vessels, and industrial equipment | Ensures safety, compliance with standards, and high-quality welds | Material compatibility, safety certifications, ability to cut thick or high-strength steel |

| Automotive & Shipbuilding | Cutting complex shapes and large metal panels for vehicle and ship assembly | Facilitates intricate designs, reduces processing time, enhances quality | Versatility for different metals, safety features, technical support for complex cuts |

| Energy & Power Generation | Cutting large metal components for turbines, reactors, and infrastructure | High efficiency, precision cuts critical for operational safety and longevity | Power capacity, cutting accuracy, supplier expertise in large-scale projects |

Construction & Infrastructure

In large-scale construction projects, especially in regions like Africa and South America, metal cutters are essential for shaping structural steel beams, reinforcing bars, and other load-bearing elements. These tools must deliver high precision to ensure safety and compliance with engineering standards. International B2B buyers need to prioritize cutters that can handle heavy-duty steel, offer durability in rugged environments, and come with reliable aftersales support. Sourcing from reputable suppliers with local service capabilities can minimize downtime and ensure project continuity.

Manufacturing & Fabrication

Manufacturers involved in machinery production, metal furniture, or custom fabrication rely heavily on advanced metal cutters for cutting sheets, plates, and complex parts. These tools improve efficiency by providing accurate, repeatable cuts, reducing material waste, and enabling automation integration. For international buyers, especially in Europe and Asia, selecting cutters with high precision, consistent performance, and comprehensive technical support is crucial. Ensuring access to spare parts and maintenance services helps sustain long-term operational efficiency.

Oil & Gas

The oil and gas industry demands robust cutting tools capable of processing thick, high-strength steel pipes, pressure vessels, and industrial equipment. These applications require cutters that can operate reliably under demanding conditions, ensuring safety and compliance with stringent standards. Buyers in the Middle East and South America should evaluate tools for material compatibility, safety certifications, and capacity to cut through high-alloy steels. Reliable supply chains and technical expertise are vital for maintaining operational safety and minimizing delays.

Automotive & Shipbuilding

In automotive and shipbuilding sectors, cutting complex, large metal panels and components with high precision is essential for quality assembly and performance. Metal cutters used here must be versatile, capable of handling diverse metals, and support intricate shapes. International buyers should focus on tools that offer automation compatibility, safety features, and supplier expertise in large-scale, high-precision cuts. Sourcing from established brands with global support networks ensures consistent quality and reduces risk during critical manufacturing phases.

Energy & Power Generation

Large metal components for turbines, reactors, and infrastructure in energy projects require high-capacity, precise cutting tools. These applications benefit from cutters that combine efficiency with accuracy, ensuring components meet strict safety and performance standards. Buyers in Europe and the Middle East should prioritize tools with proven reliability for large-scale, high-stakes projects, along with suppliers offering comprehensive training and technical support. Ensuring the right tool specifications can significantly impact project timelines and operational safety.

Related Video: How to Select the Best Cutting Tool For Milling Operations – Basic Tutorial – SMITHY GRANITE 3-in-1

Strategic Material Selection Guide for best metal cutter tool

Material Analysis for Best Metal Cutter Tools

Selecting the optimal material for manufacturing metal cutter tools is crucial for ensuring performance, durability, and cost-efficiency. Different materials offer distinct advantages and limitations, which must be carefully considered in relation to the specific application, operational environment, and regional standards. Here, we analyze four common materials used in cutting tools—High-Speed Steel (HSS), Tungsten Carbide, Powder Metallurgy Steel, and Cermet—focusing on their properties, pros and cons, application impact, and considerations for international B2B procurement.

High-Speed Steel (HSS)

Key Properties:

HSS is renowned for its excellent toughness, moderate hardness, and ability to withstand high temperatures (up to 600°C). It maintains cutting edges well during prolonged use and is relatively easy to sharpen. Its corrosion resistance is moderate unless coated.

Pros & Cons:

HSS tools are cost-effective and widely available, making them suitable for a broad range of applications. They are easier to manufacture and repair, which is advantageous for regions with limited access to advanced manufacturing facilities. However, HSS has lower wear resistance compared to carbide, leading to shorter tool life in demanding applications involving hard or abrasive materials.

Impact on Application:

Ideal for general-purpose cutting, drilling, and machining of mild to medium-hard steels. Less suitable for high-volume, high-precision tasks involving very hard materials or high-speed operations.

International Buyer Considerations:

HSS conforms well to international standards like ASTM and DIN, facilitating compliance across regions. Buyers should verify coating specifications and heat treatment quality, especially in markets with variable manufacturing standards such as Africa or South America. Its affordability and ease of sharpening make it a popular choice in emerging markets.

Tungsten Carbide

Key Properties:

Tungsten carbide is extremely hard and resistant to wear, with a melting point exceeding 2,400°C. It offers high compressive strength and excellent corrosion resistance, especially when coated or alloyed.

Pros & Cons:

Carbide tools provide superior durability and cutting performance, especially in high-speed and high-volume operations. They are suitable for machining hard steels and abrasive materials. The primary drawbacks include higher manufacturing complexity, increased cost, and brittleness—prone to chipping if mishandled or used improperly.

Impact on Application:

Best suited for precision, high-speed cutting, and applications involving hardened steels or abrasive media. Its resilience reduces downtime and replacement frequency, making it cost-effective over the long term.

International Buyer Considerations:

Carbide tools often meet stringent international standards like ISO and JIS, aiding global procurement. Buyers in regions with less developed logistics should consider supplier reliability and the availability of spare parts. The higher initial investment is justified by longer tool life, especially in demanding sectors like aerospace or automotive manufacturing in Europe or the Middle East.

Powder Metallurgy Steel (PM Steel)

Key Properties:

Produced via powder metallurgy, this steel combines fine grain structure with uniform properties, resulting in high toughness, wear resistance, and good corrosion resistance. It can be tailored for specific applications through alloying and heat treatment.

Pros & Cons:

PM steel offers a balanced mix of toughness and wear resistance, making it versatile for various cutting tasks. Manufacturing complexity and cost are higher than traditional steels but lower than carbide. Its consistency and performance are highly valued in high-precision industries.

Impact on Application:

Suitable for complex cutting tools, inserts, and high-performance applications where durability and precision are critical. It performs well in automated CNC environments and high-volume production.

International Buyer Considerations:

Compliance with standards like ASTM A387 or DIN 1.2344 is common. Buyers should verify supplier certifications and quality control processes, especially in markets with varying standards like South America or Africa. Its adaptability makes it appealing for regions with diverse manufacturing needs.

Cermet

Key Properties:

Cermets are composite materials combining ceramic and metallic phases, offering high hardness, wear resistance, and chemical stability. They withstand high temperatures and are resistant to oxidation.

Pros & Cons:

Cermets excel in high-precision, high-speed cutting of hard materials, providing excellent surface finishes. Their brittleness makes them susceptible to chipping under impact or improper handling. Manufacturing and procurement costs are high, and they require specialized equipment.

Impact on Application:

Ideal for finishing operations, high-speed machining of hardened steels, and aerospace components. Their use is often limited to specialized sectors due to cost and handling considerations.

International Buyer Considerations:

Cermets often meet international standards like ISO 513 or JIS B 0406. Buyers should ensure proper training for handling and tool setup. In regions like Europe, where precision and high-speed machining are prioritized, cermets are increasingly favored despite their higher costs.

Summary Table

| Material | Typical Use Case for best metal cutter tool | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| High-Speed Steel (HSS) | General-purpose machining, drilling, low to medium hardness steels | Cost-effective, easy to sharpen, widely available | Lower wear resistance, shorter lifespan in demanding tasks | Low |

| Tungsten Carbide | High-speed cutting, machining hard steels, abrasive materials | Extremely durable, high precision, long tool life | Brittle, expensive, manufacturing complexity | High |

| Powder Metallurgy Steel | High-precision tools, complex cutting, automated CNC operations | Balanced toughness and wear resistance, versatile | Higher manufacturing cost, requires quality certification | Med |

| Cermet | Finishing, high-speed machining of hardened steels | High hardness, excellent surface finish, high-temperature stability | Brittle, costly, specialized handling required | High |

This comprehensive analysis enables international B2B buyers to make informed decisions aligned with their operational needs, regional standards, and budget constraints. Understanding the properties and limitations of these materials ensures the procurement of the most suitable, reliable, and cost-effective metal cutting tools for diverse industrial applications worldwide.

In-depth Look: Manufacturing Processes and Quality Assurance for best metal cutter tool

Manufacturing and Quality Assurance of High-Performance Metal Cutting Tools: A Deep Dive for International B2B Buyers

Understanding the manufacturing intricacies and quality assurance (QA) protocols of top-tier metal cutter tools is essential for procurement teams operating across diverse regions. For buyers from Africa, South America, the Middle East, and Europe—including Australia and Mexico—comprehending these processes enables informed supplier evaluation, risk mitigation, and assurance of product reliability. This section outlines the main manufacturing stages, industry-standard QA practices, and practical verification methods tailored to international procurement contexts.

Manufacturing Process of Metal Cutter Tools

The production of high-quality metal cutters involves multiple carefully controlled stages, each critical to ensuring performance, durability, and safety.

1. Material Preparation

Raw Material Selection:

The foundation of a durable cutter is the selection of premium raw materials. Commonly used materials include high-speed steels (HSS), tungsten carbide, and advanced alloy steels, chosen for their hardness, wear resistance, and toughness. Suppliers often source these from certified mills adhering to international standards such as ASTM, EN, or JIS.

Material Testing:

Before processing, incoming materials undergo rigorous testing to verify chemical composition, hardness, and microstructure. Techniques like spectrometry, hardness testing (Rockwell or Vickers), and non-destructive testing (NDT) ensure compliance with specified grades.

2. Forming and Machining

Forging and Casting:

For cutter bodies and critical components, forging is preferred due to its superior grain structure and mechanical properties. Casting may be used for certain parts but requires subsequent heat treatment to enhance strength.

Precision Machining:

High-precision CNC machining shapes the components to tight tolerances, often within ±0.01 mm, essential for tools like laser or plasma cutters. Techniques such as turning, milling, grinding, and wire EDM are employed to achieve complex geometries and fine surface finishes.

Heat Treatment:

Post-machining, parts undergo heat treatment processes—quenching and tempering—to optimize hardness and toughness. Advanced suppliers utilize controlled atmospheres or vacuum furnaces to prevent oxidation and achieve consistent results.

3. Assembly and Integration

Component Assembly:

Critical components—such as blades, inserts, and drives—are assembled using techniques like press-fitting, welding, or brazing, depending on the tool type. For instance, tungsten carbide inserts are often brazed onto steel bodies with high-temperature, high-strength solders.

Balancing and Alignment:

Dynamic balancing ensures the tool operates smoothly at high speeds, reducing vibration and extending service life. Precision alignment during assembly minimizes inaccuracies that could compromise cut quality.

4. Finishing and Surface Treatment

Surface Finishing:

Processes such as polishing, coating, or nitriding enhance surface hardness and corrosion resistance. Coatings like TiN, TiAlN, or DLC are applied via PVD or CVD methods to reduce wear and improve performance.

Final Inspection:

Visual and dimensional inspections are conducted to verify surface quality, coating adherence, and geometric accuracy before packaging.

Quality Control (QC) Framework for Metal Cutter Manufacturing

Robust QC protocols ensure that each batch of tools meets or exceeds international standards, reducing the risk of failures in demanding operational environments.

1. International Standards Compliance

ISO 9001:

Most reputable manufacturers operate under ISO 9001 certification, which mandates a comprehensive quality management system covering process control, documentation, corrective actions, and continuous improvement.

Industry-Specific Standards:

Depending on the application, additional standards may be required:

– CE Marking (Europe): Ensures compliance with safety and environmental directives.

– API Standards: For oil and gas industry tools, API Spec Q1 emphasizes quality in manufacturing critical equipment.

– ASTM and EN Standards: Cover material properties, testing methods, and product performance.

2. Inspection Stages and Checkpoints

Incoming Quality Control (IQC):

– Verifies raw material chemical composition, hardness, and microstructure.

– Uses spectrometers, hardness testers, and NDT methods.

In-Process Quality Control (IPQC):

– Monitors machining accuracy, dimensional tolerances, and surface finishes.

– Implements statistical process control (SPC) charts to track variations.

Final Quality Control (FQC):

– Conducts comprehensive inspections, including visual checks, dimensional verification, and surface integrity.

– Performs functional tests such as cutting performance, vibration analysis, and balance testing.

3. Testing and Validation Methods

- Hardness Testing: Ensures materials meet specified hardness levels, critical for wear resistance.

- Microstructural Analysis: Uses optical microscopy or SEM to confirm grain structure and absence of defects.

- Performance Testing: Bench tests simulate real-world operation, measuring cutting efficiency, heat generation, and tool longevity.

- Coating Adhesion Tests: Crosshatch or pull-off tests assess coating durability.

Verifying Supplier Quality for International B2B Buyers

For buyers in emerging markets or regions with varying regulatory environments, verifying the quality assurance systems of suppliers is vital.

1. Supplier Audits and Site Visits

- Pre-Audit Preparation: Review supplier certifications, previous audit reports, and production capacity.

- On-Site Inspection: Assess manufacturing facilities, cleanliness, equipment calibration, and process control measures.

- Process Observation: Witness key operations like heat treatment, machining, and coating application.

2. Documentation and Certification Review

- Quality Certificates: Request ISO 9001 certificates, material test reports (MTRs), and industry-specific compliance documents.

- Test Reports and Records: Examine QC logs, inspection reports, and performance test data.

- Traceability Records: Confirm that each batch can be traced back to raw material sources and process parameters.

3. Third-Party Inspection and Certification

- Engage accredited third-party inspection agencies (e.g., SGS, TÜV, Bureau Veritas) to conduct independent audits or product testing.

- Use these reports to validate supplier claims, especially when sourcing from regions with less mature quality infrastructure.

Special Considerations for International Buyers

- Cultural and Regulatory Differences: Understand regional standards and certification requirements, such as CE for Europe or API for oil and gas sectors.

- Language and Communication: Ensure documentation is available in accessible languages and that technical specifications are clearly translated.

- Logistics and Lead Times: Factor in inspection and certification lead times into procurement schedules to avoid delays.

Conclusion

For B2B buyers sourcing the best metal cutter tools globally, a thorough understanding of manufacturing and QA processes is indispensable. Recognizing the critical stages—from raw material selection through finishing—enables better supplier evaluation and risk management. Emphasizing adherence to international standards, rigorous inspection checkpoints, and third-party validation ensures that procurement decisions lead to reliable, high-performance tools capable of meeting diverse regional demands. By integrating these insights into their sourcing strategy, international buyers can secure tools that optimize operational efficiency, enhance safety, and deliver long-term value across their global operations.

Related Video: Most Satisfying Factory Production Processes And Heavy-Duty Factory Machines!

Comprehensive Cost and Pricing Analysis for best metal cutter tool Sourcing

Cost Components in Metal Cutter Tool Sourcing

Understanding the full cost structure behind top-tier metal cutting tools is essential for making informed procurement decisions. The primary cost components include:

-

Materials: High-quality cutting tools typically utilize advanced alloys such as tungsten carbide, high-speed steel, or composite materials. These materials influence both durability and performance but can significantly impact the price, especially when sourcing premium grades or specialized compositions.

-

Manufacturing and Labor: Precision manufacturing processes—such as CNC machining, heat treatment, and surface finishing—are labor-intensive and require skilled personnel. Countries with higher labor costs, like Germany or parts of Europe, may have elevated manufacturing expenses, whereas regions like China or Eastern Europe might offer competitive rates.

-

Overhead and Tooling: Investment in specialized tooling, molds, and quality control infrastructure adds to the overall cost. Mass production and automation can reduce per-unit costs, but initial setup expenses are substantial, influencing pricing especially for smaller order volumes.

-

Quality Control and Certifications: Compliance with international standards (ISO, ANSI, CE) and certifications (e.g., traceability, safety) can raise costs due to rigorous testing and documentation requirements. Buyers demanding certified quality must factor these into their budget.

-

Logistics and Importation: Shipping costs vary widely based on origin, destination, mode (air, sea, land), and current fuel prices. For buyers in Africa, South America, or remote regions, freight and customs duties may constitute a significant portion of total costs, especially for bulky or heavy tools.

-

Margins and Distribution: Suppliers typically include profit margins to sustain operations, which can differ based on market competitiveness, supplier reputation, and order volume. Negotiating bulk discounts or long-term partnerships can help reduce these margins.

Price Influencers and Market Dynamics

Several factors impact the final pricing of metal cutting tools in the international market:

-

Order Volume and MOQ: Larger orders or volume discounts are standard in B2B transactions. Suppliers often set minimum order quantities (MOQs) that influence unit prices—smaller buyers may face higher per-unit costs due to setup and handling expenses.

-

Customization and Specifications: Custom tools or specialized coatings (e.g., TiN, DLC) elevate costs due to additional R&D, tooling adjustments, and processing. Precise specifications demanded by high-performance sectors increase both manufacturing complexity and price.

-

Material Selection: The choice of cutting material directly affects cost—premium alloys and advanced composites cost more but offer longer lifespan and better performance, reducing lifecycle costs.

-

Supplier Reputation and Certification: Established suppliers with proven quality records and certifications often command premium prices but reduce risk of defects, delays, and non-compliance issues.

-

Incoterms and Delivery Terms: The chosen Incoterm (FOB, CIF, DDP, etc.) impacts landed costs. Buyers should carefully evaluate whether to handle freight themselves or rely on suppliers’ logistics, factoring in insurance, tariffs, and handling fees.

Buyer Tips for Cost Optimization

-

Negotiate Effectively: Leverage order volume, long-term commitments, or regional partnerships to secure better pricing. Clarify payment terms and seek bundled deals on related tools or services.

-

Focus on Total Cost of Ownership (TCO): Price alone is insufficient. Consider tool lifespan, maintenance costs, downtime, and operational efficiency. Higher upfront costs for premium tools may lead to savings through reduced replacement frequency and improved productivity.

-

Evaluate Lead Times and Flexibility: Longer lead times may enable better price negotiations, especially if suppliers have excess capacity. Flexibility on specifications can also open access to more cost-effective options.

-

Understand Pricing Nuances for International Buyers: Be aware of currency fluctuations, import duties, and regional taxes. Establishing local procurement channels or regional distributors can mitigate some logistics and customs costs.

-

Assess Supplier Reliability and Support: Cheaper options from less reputable sources may compromise quality, leading to higher costs over the lifecycle. Prioritize suppliers with robust aftersales support, training, and quality assurance programs.

Disclaimer

Indicative prices for high-quality metal cutting tools typically range from $50 to $500 per unit, depending on the type, size, and specifications. Custom or specialized tools can cost significantly more. These figures are approximate and subject to fluctuation based on market conditions, supplier negotiations, and logistical factors. Buyers should conduct thorough market research and supplier evaluations tailored to their specific needs and regional contexts.

By comprehensively analyzing these cost components and market influencers, international B2B buyers from Africa, South America, the Middle East, and Europe can develop strategic sourcing plans that optimize expenditure, reduce risks, and ensure the procurement of reliable, high-performance metal cutting tools.

Spotlight on Potential best metal cutter tool Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘best metal cutter tool’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for best metal cutter tool

Critical Technical Properties of Metal Cutter Tools

1. Material Grade and Composition

The quality and durability of a metal cutter are heavily influenced by the materials used in its construction, such as high-speed steel (HSS), tungsten carbide, or composite alloys. Higher-grade materials offer improved wear resistance, strength, and longevity, especially when cutting hardened or abrasive metals. B2B buyers should prioritize tools made from certified materials that meet industry standards (e.g., ASTM, ISO) to ensure consistent performance and reduce replacement costs.

2. Cutting Tolerance and Precision

Tolerance refers to the allowable deviation from specified dimensions during cutting operations. Precise tolerances (e.g., ±0.05mm) are essential for applications demanding high accuracy, such as aerospace or electronics manufacturing. Buyers should evaluate the tool’s manufacturing precision and calibration standards, as tighter tolerances directly impact product quality and reduce rework or scrap.

3. Cutting Capacity and Thickness Range

This property defines the maximum material thickness or cross-section the tool can handle efficiently. For instance, a band saw may cut up to 300mm thick steel, while a plasma cutter might process even thicker plates. Selecting a tool with appropriate capacity prevents overloading, enhances productivity, and minimizes equipment wear. It’s vital to match the tool’s specifications with project requirements for optimal results.

4. Speed and Power Ratings

Cutting speed (measured in meters per minute or surface feet per minute) and power consumption influence productivity and operational costs. Higher speeds can increase throughput but may require more robust machinery and safety measures. Power ratings (kW or HP) determine the tool’s ability to cut tough materials without overheating or failure. B2B buyers should consider their operational environment and future scalability when assessing these specs.

5. Tool Life and Wear Resistance

The lifespan of cutting tools depends on their ability to resist wear and maintain sharpness over time. Tools with superior wear resistance reduce downtime and procurement frequency, especially important in high-volume manufacturing. Buyers should look for tools with proven longevity, backed by manufacturer warranties and performance data.

6. Compatibility and Interchangeability

This includes the standardization of tool sizes, shank types, and mounting mechanisms to ensure compatibility with existing machinery. Using interchangeable parts simplifies maintenance, reduces inventory complexity, and accelerates setup times. It’s crucial for buyers to verify that tools conform to industry standards like ANSI, DIN, or ISO specifications.

Common Trade and Industry Terms

1. OEM (Original Equipment Manufacturer)

Refers to the original producer of a tool or component. OEM parts are typically designed to meet strict quality and performance standards, ensuring compatibility and reliability. B2B buyers often prefer OEM tools for critical applications to minimize risk and guarantee operational consistency.

2. MOQ (Minimum Order Quantity)

The smallest number of units a supplier is willing to sell in a single order. Understanding MOQ helps buyers plan procurement volumes, negotiate better prices, and avoid excess inventory, especially when sourcing from international suppliers.

3. RFQ (Request for Quotation)

A formal document issued by buyers to solicit price and delivery terms from potential suppliers. An RFQ helps compare offers, clarify specifications, and establish clear terms before committing to a purchase.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the International Chamber of Commerce that define responsibilities between buyers and sellers regarding shipping, insurance, and customs clearance. Common Incoterms like FOB (Free On Board) or CIF (Cost, Insurance, and Freight) specify who bears costs and risks at different stages of transit, critical for international procurement.

5. Lead Time

The period from placing an order to receiving the product. Shorter lead times improve supply chain responsiveness, especially for urgent projects or just-in-time manufacturing. B2B buyers should confirm lead times upfront, considering regional logistics constraints.

6. Certification and Compliance Standards

Refers to the industry or regional standards (e.g., ISO, CE, ASTM) that ensure a tool’s safety, quality, and environmental compliance. Choosing certified tools reduces legal and safety risks, and facilitates smooth import and export processes across different regions.

By understanding these technical properties and trade terms, B2B buyers can make informed decisions that optimize procurement efficiency, ensure product quality, and mitigate risks in international sourcing of metal cutting tools.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the best metal cutter tool Sector

Market Overview & Key Trends

The global market for metal cutting tools is experiencing dynamic shifts driven by technological innovation, increasing industrialization, and evolving supply chain complexities. Key drivers include rising infrastructure projects, automotive manufacturing, and energy sector expansion across Africa, South America, the Middle East, and Europe. These regions are witnessing heightened demand for high-precision, durable tools capable of handling diverse materials, from structural steel to advanced alloys.

Emerging trends significantly influence sourcing strategies. Digitalization and Industry 4.0 integration enable manufacturers to offer smarter, automated cutting solutions—such as CNC laser and plasma systems—that improve efficiency and reduce waste. Buyers are increasingly prioritizing equipment with advanced control systems, remote diagnostics, and automation capabilities, which enhance productivity and minimize downtime.

Supply chain resilience is a critical focus for international B2B buyers, especially amid geopolitical uncertainties and logistical disruptions. Regional sourcing is gaining traction, with buyers in Africa and South America seeking local or nearby suppliers to reduce lead times and costs. Conversely, Europe and the Middle East often leverage established global networks for premium, high-tech tools, emphasizing quality assurance and compliance.

Cost competitiveness remains vital, prompting buyers to explore a mix of OEMs, authorized distributors, and emerging suppliers from Asia, Eastern Europe, and Turkey. Strategic sourcing now involves a holistic evaluation of supplier reliability, aftersales support, and adherence to international standards. As environmental standards tighten, buyers are also tracking suppliers’ ability to meet evolving regulations and sustainability benchmarks.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a decisive factor in sourcing metal cutting tools. Manufacturers and procurement teams worldwide are increasingly emphasizing environmentally responsible practices, driven by both regulatory pressures and corporate social responsibility commitments. For B2B buyers, selecting suppliers committed to reducing environmental impact is essential for ensuring long-term operational sustainability and brand integrity.

Eco-friendly manufacturing practices include the use of recycled materials, energy-efficient production processes, and reduced emissions. For example, suppliers utilizing green manufacturing certifications such as ISO 14001 demonstrate a commitment to environmental management. Additionally, the adoption of biodegradable or low-impact consumables—like grinding wheels and abrasive discs—aligns with sustainability goals.

Ethical sourcing extends beyond environmental concerns to include social responsibility. Buyers should verify suppliers’ adherence to fair labor practices, safe working conditions, and transparent supply chains. Certifications such as SA8000 or Fair Trade can serve as indicators of ethical compliance.

Another critical aspect is the traceability of raw materials, particularly steel and other metals. Sourcing from suppliers who provide documentation on sustainable extraction practices—such as responsible mining certifications—helps mitigate reputational risks. Incorporating ‘green’ certifications and eco-labels into procurement criteria not only enhances sustainability but also ensures compliance with international standards, making the supply chain more resilient and future-proof.

Brief Evolution/History

The evolution of metal cutting tools reflects technological progress and market demands. Historically, tools relied on basic carbon steels and manual methods, suitable for small-scale fabrication. The advent of alloy steels, carbide inserts, and advanced coatings revolutionized the industry, enabling faster, more precise cuts and longer tool life.

The introduction of CNC automation and laser technology in the late 20th century marked a significant turning point, allowing for intricate, high-precision manufacturing at scale. These innovations reduced waste, improved safety, and expanded application possibilities across industries. Today, digital tools with integrated IoT features enable real-time monitoring and predictive maintenance, further optimizing operational efficiency.

For international B2B buyers, understanding this evolution underscores the importance of investing in advanced, reliable tools aligned with industry standards. The shift towards sustainable, smart, and automated solutions reflects a broader industry trend that emphasizes quality, efficiency, and environmental responsibility—core considerations for strategic procurement in today’s competitive landscape.

Related Video: Made in the world: Better understanding global trade flows

Frequently Asked Questions (FAQs) for B2B Buyers of best metal cutter tool

1. How can I effectively vet international suppliers to ensure they provide high-quality metal cutting tools?

Effective vetting begins with comprehensive supplier due diligence. Request detailed company profiles, including manufacturing certifications (ISO, CE, ANSI), quality management systems, and product certifications. Conduct virtual audits or request third-party audit reports where feasible. Review customer references and seek feedback on reliability, product quality, and after-sales support. Evaluate supplier responsiveness, communication clarity, and their ability to meet technical specifications. Additionally, verify their compliance with regional standards and export regulations. Building strong communication channels and establishing clear expectations upfront minimizes risks and ensures a reliable supply chain.

2. What should I consider when requesting customization or specific specifications for metal cutter tools?

Clarify your technical requirements early, including dimensions, material compatibility, cutting precision, and safety features. Ensure the supplier has the capability to customize tools according to your specifications—ask for examples or prototypes if possible. Discuss lead times for customization and confirm whether they have in-house R&D or rely on external OEMs. It’s vital to specify compliance standards and quality benchmarks for customized tools. Establish clear communication channels and document all specifications in a detailed purchase agreement to avoid misunderstandings. Regular follow-ups during production help ensure the final product aligns with your needs.

3. What are typical minimum order quantities (MOQs) and lead times for importing metal cutting tools, and how can I manage them effectively?

MOQs vary widely depending on the supplier and tool type, ranging from small batch orders to container loads. Discuss MOQs upfront and negotiate for flexibility, especially if you’re testing new suppliers. Lead times depend on manufacturing location, complexity, and logistics—expect anywhere from 2-8 weeks for production, plus additional shipping time. To manage effectively, plan procurement cycles well in advance, maintain safety stock, and establish strong relationships with suppliers for priority processing. Consider consolidating orders to optimize shipping costs and ensure timely delivery aligned with your project schedules.

4. What documentation and certifications should I request from suppliers to ensure compliance and quality?

Request comprehensive documentation, including product specifications, material test reports, and certificates of conformity. For international trade, essential certifications include ISO standards, CE marking (Europe), ANSI/ASME (North America), and regional safety standards. For metals, material traceability reports and compliance certificates (e.g., RoHS, REACH) are vital. Verify that all documentation is current and matches the shipped products. These certifications not only ensure quality but also facilitate customs clearance and compliance with regional import regulations, reducing delays and potential legal issues.

5. How can I optimize logistics and shipping when importing metal cutter tools from overseas suppliers?

Start by selecting suppliers with proven logistics capabilities and reliable freight partners. Choose shipping modes based on urgency and cost—air freight for urgent deliveries, sea freight for bulk orders, and land transportation for regional shipments. Negotiate Incoterms (e.g., FOB, CIF) that clearly define responsibilities and costs. Work with freight forwarders experienced in handling industrial tools and ensure proper packaging to prevent damage. Track shipments diligently, and plan for customs clearance, tariffs, and import duties specific to your region. Building strong logistics partnerships reduces delays, minimizes costs, and ensures timely project execution.

6. What are common disputes in international B2B metal cutter tool transactions, and how can I prevent or resolve them?

Common disputes include quality discrepancies, late deliveries, payment issues, or non-compliance with specifications. Prevention starts with clear, detailed contracts covering scope, specifications, quality standards, payment terms, and dispute resolution mechanisms. Use escrow accounts or letters of credit to secure payments. Maintain open communication and document all transactions. If disputes occur, engage in amicable negotiation first; if unresolved, escalate through arbitration or legal channels as per contractual terms. Working with reputable, certified suppliers and establishing mutual trust minimizes risks and facilitates swift resolution when issues arise.

7. How important are quality assurance processes and certifications when sourcing metal cutters internationally?

Quality assurance (QA) is critical to ensure tools meet performance, safety, and durability standards. Prioritize suppliers with ISO 9001 certification and those adhering to industry-specific standards like ASTM, EN, or JIS. Request inspection reports, in-process quality checks, and test certificates before shipment. Consider third-party inspections or pre-shipment audits for high-value or critical tools. Reliable QA processes reduce the risk of defective products, improve operational safety, and ensure compliance with your regional standards. Investing in quality assurance upfront saves costs related to rework, downtime, or safety incidents later.

8. What strategies can I implement to mitigate risks associated with currency fluctuations and payment terms in international sourcing?

Negotiate flexible payment terms such as letters of credit, advance payments, or open accounts based on supplier trustworthiness. Use forward contracts or currency hedging tools to lock in exchange rates, reducing exposure to currency volatility. Diversify your supplier base across regions to avoid over-reliance on a single country or currency. Establish clear, mutually agreed-upon payment schedules aligned with delivery milestones. Regularly monitor currency markets and adjust contracts as needed. These strategies help stabilize costs, improve cash flow management, and protect your profit margins in international transactions.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for best metal cutter tool

Strategic Sourcing Conclusion and Outlook for Best Metal Cutter Tool

Effective procurement of metal cutting tools is a strategic imperative that directly influences operational efficiency, safety, and cost management across diverse industries worldwide. By thoroughly understanding the various tool types—such as band saws, plasma cutters, and laser systems—and aligning them with specific project needs, international B2B buyers can make informed sourcing decisions that mitigate risks and enhance productivity.

Prioritizing supplier evaluation, quality assurance, and supply chain resilience is essential in navigating the complexities of global markets, especially in regions like Africa, South America, the Middle East, and Europe. Building strong relationships with reputable manufacturers and leveraging technological advancements will be key to securing reliable, high-performance tools.

Looking ahead, proactive and strategic sourcing will remain vital amid evolving materials, regulatory standards, and logistical challenges. International buyers are encouraged to continuously assess supplier capabilities, embrace innovation, and foster long-term partnerships. Doing so will ensure they stay competitive, adapt to market shifts, and capitalize on emerging growth opportunities in the dynamic landscape of metal fabrication and manufacturing.