Introduction: Navigating the Global Market for laser cutting of acrylic sheets

Acrylic sheet is increasingly recognized as a material of choice in global manufacturing, thanks to its clarity, durability, and adaptability across applications from signage and displays to protective panels and industrial parts. Laser cutting has become instrumental in unlocking the full potential of acrylic sheets: enabling high-precision cuts, clean edges, and design complexities previously unattainable through traditional methods. For international B2B buyers—whether sourcing from the industrial hubs of Turkey, the creative markets of Colombia, or the advanced fabrication centers of the UK—understanding the nuances of laser cutting acrylic is vital for meeting evolving customer demands and maintaining competitive advantage.

As supply chains become more interconnected and customer expectations for quality and customization continue to rise, selecting the right laser cutting capabilities and acrylic types can directly impact project outcomes, operational efficiency, and profitability. Choices between cast and extruded acrylic, assessment of suitable laser technologies, and the discernment of local versus global supplier competencies all bring strategic implications, especially in rapidly developing regions across Africa and South America and in mature, quality-focused markets such as Europe and the Middle East.

This comprehensive guide delivers in-depth, actionable insights tailored to international B2B procurement leaders. It covers the full spectrum: comparison of acrylic types and laser technologies, material selection strategies, manufacturing and quality control best practices, critical supplier evaluation criteria, real-world cost and market intelligence, and expert answers to common sourcing questions. Armed with this knowledge, buyers are empowered to make well-informed sourcing decisions—minimizing risk, optimizing costs, and securing sustainable partnerships that support both immediate project needs and long-term business growth in the dynamic world of acrylic laser cutting.

Understanding laser cutting of acrylic sheets Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CO₂ Laser Cutting of Cast Acrylic | High precision, smooth polished edges, superior clarity | Premium signage, displays, optical components | Exceptional quality; higher material and equipment cost |

| CO₂ Laser Cutting of Extruded Acrylic | Uniform thickness, cost-effective, rapid processing | Industrial panels, protective screens, mass signage | Lower material cost; minor clarity and edge quality trade-offs |

| CNC Laser Cutting with Automation | Integrated CNC controls, automated handling, repeatable accuracy | High-volume manufacturing, export-focused fabrication | Boosts productivity; requires higher upfront investment and expertise |

| Mixed Laser Cutting & Engraving | Enables both intricate engraving and full cuts in one workflow | Custom branding, architectural decor, point-of-sale materials | Versatile and efficient; may require more advanced equipment |

| Diode Laser Cutting of Acrylic | Adapted for colored/opaque sheets, lower power | Promotional goods, basic labeling, low-volume custom products | Lower cost and flexibility; limitations with clarity and sheet thickness |

CO₂ Laser Cutting of Cast Acrylic

CO₂ laser cutting machines, when applied to cast acrylic, deliver premium precision, ultra-smooth edges, and exceptional optical clarity. This makes them the top choice for businesses producing high-end signage, luxury retail displays, and specialized optical components where surface finish and appearance are critical. International B2B buyers should assess supplier capabilities around quality assurance, verify consistency of the cast acrylic supply, and factor in the higher price point. Partnering with experienced providers often yields more predictable, client-ready results.

CO₂ Laser Cutting of Extruded Acrylic

Extruded acrylic offers a cost-effective alternative, especially suitable for large-scale production and applications where uniform thickness is vital. Its process efficiency and lower price make it ideal for manufacturing protective barriers, industrial panels, and mass-produced displays. Buyers targeting markets in regions like Africa or South America where budget and throughput are priorities will find this variation attractive. Considerations should include consistency in sheet quality and potential requirements for post-processing due to softer, less polished cut edges.

CNC Laser Cutting with Automation

Integrating automation and CNC controls with laser cutting elevates both efficiency and output consistency, which is particularly valuable for export-oriented and high-volume manufacturing environments. This solution streamlines repetitive or complex production, reducing labor costs and ensuring highly repeatable quality. Buyers in regions with strong manufacturing growth—such as the Middle East or Eastern Europe—benefit from faster turnaround and scalability. However, a higher initial investment, ongoing maintenance, and the need for skilled operators are key considerations.

Mixed Laser Cutting & Engraving

Combining laser cutting with engraving capabilities allows manufacturers to create entirely finished acrylic products—shaped and branded—in a single workflow. This dual-purpose approach is highly valued in applications such as custom displays, architectural elements, and branded point-of-sale materials. Buyers should look for equipment that maintains both engraving finesse and clean cut quality. Supplier expertise in workflow integration and support for design file types is critical to unlocking productivity and minimizing operational downtime.

Diode Laser Cutting of Acrylic

Diode lasers are best suited for cutting colored or opaque acrylic sheets, where their specific wavelengths can be effectively absorbed. They are commonly used for producing promotional products, simple labels, or basic custom fabrication, particularly where cost control is paramount. However, diode lasers struggle with clear acrylics and thicker sheets, offering limited edge quality and depth. B2B buyers should carefully match this variation to the application’s material constraints and production volume needs, ensuring technical compatibility before procurement.

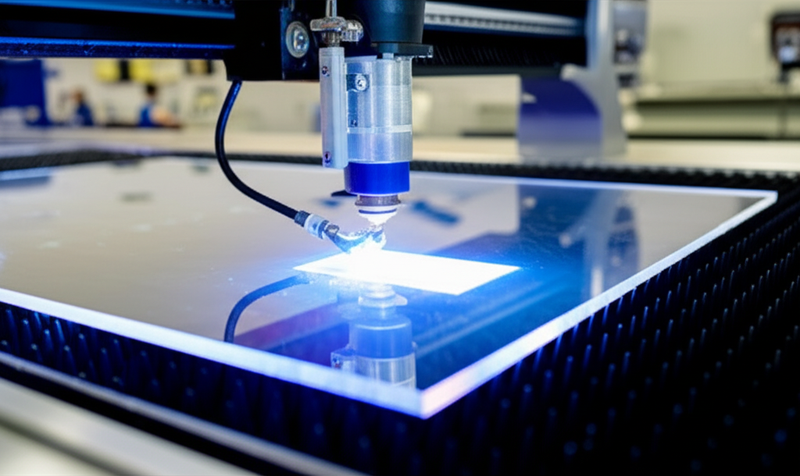

Related Video: Laser engraving and cutting acrylic

Key Industrial Applications of laser cutting of acrylic sheets

| Industry/Sector | Specific Application of laser cutting of acrylic sheets | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Retail & Visual Merchandising | Custom signage, POP displays, display cases | High visual impact, branding, rapid design changes | Optical clarity, thickness consistency, precision edge finishing, batch repeatability |

| Architecture & Interior Design | Decorative panels, partitions, lighting features | Modern aesthetics, design flexibility, cost efficiency | Material grade (cast vs. extruded), flame-polished edges, sheet size availability |

| Electronics & Electrical | Instrument panels, display covers, protective shielding | Precision fitting, lightweight, insulation | Tight tolerances, consistent thickness, compatibility with electronics standards |

| Automotive & Transportation | Light covers, dashboard components, trim elements | Customization, weight reduction, rapid prototyping | UV stability, impact resistance, OEM certification requirements |

| Medical & Laboratory | Equipment housings, barrier shields, sample trays | Hygiene, precision, ease of cleaning | Chemical resistance, biocompatibility, regulatory-compliant materials |

Retail & Visual Merchandising

Laser cutting of acrylic sheets is pivotal in producing bespoke signage, point-of-purchase (POP) displays, and elegant display cases. Businesses benefit from the ability to incorporate intricate branding details and adapt quickly to design revisions or seasonal campaigns. This precise cutting technology solves challenges related to uniform appearance and edge quality across high-volume orders. For international buyers, ensuring uniform optical clarity, consistent thickness, and well-polished edges is essential for maintaining premium brand standards and facilitating seamless global rollouts.

Architecture & Interior Design

Architects and interior designers utilize laser-cut acrylic sheets for decorative wall panels, space dividers, and innovative lighting installations. The precision of laser cutting supports complex geometric patterns and crisp edges, enhancing aesthetics and functionality. This application addresses the demand for customization and rapid modifications in project scopes. Buyers operating in global markets should prioritize sourcing high-grade cast acrylic for clarity and durability, alongside suppliers capable of delivering large-format, defect-free sheets with polished, flame-treated edges.

Electronics & Electrical

In electronics manufacturing, laser-cut acrylic is used for control panel overlays, display windows, and protective shielding around sensitive components. Its dielectric properties and lightweight nature make it ideal in situations requiring clarity and insulation. Businesses achieve better fitment and reduce material waste through highly accurate CNC-driven laser cutting. Key requirements for B2B buyers include tight production tolerances, high repeatability across batches, and compliance with relevant electronics safety or quality standards for international shipments.

Automotive & Transportation

Automotive manufacturers leverage laser cutting of acrylic for customizable light covers, dashboard panels, and interior/exterior trim elements. This allows for vehicle personalization, weight savings, and rapid iteration in the prototyping or short-run manufacturing process. The process resolves issues around part precision and complex design execution. Buyers must insist on certified, UV-stable acrylic material and verify impact resistance to meet industry safety requirements, especially for clients in regions with intense sunlight or variable temperatures.

Medical & Laboratory

Laser-cut acrylic is extensively used for laboratory sample trays, instrument housings, and protective shields for both staff and instrumentation. Its non-porous surface ensures easy cleaning and strict hygiene standards, addressing the stringent needs of healthcare and research environments. The accuracy of laser cutting guarantees consistent slotting and fitting for equipment assemblies. Buyers should seek suppliers offering chemical-resistant, medical- or laboratory-grade acrylic, and assurance of regulatory compliance with international health and safety standards.

Strategic Material Selection Guide for laser cutting of acrylic sheets

Overview of Common Acrylic Sheet Materials

When evaluating acrylic sheets for laser cutting applications, international B2B buyers face critical decisions that impact manufacturing efficiency, product quality, and regulatory compliance. The main materials encountered are cast acrylic, extruded acrylic, impact-modified acrylic, and, in some specialized cases, colored or specialty acrylic. Each presents distinct advantages and constraints across performance, cost, processing, and market compatibility—factors that can influence procurement strategies across Africa, South America, the Middle East, and Europe.

Cast Acrylic

Key Properties:

Cast acrylic is formed via a batch polymerization process, resulting in a homogenous structure with exceptional optical clarity (≤1% haze), high chemical resistance, and stable thermal properties—typically handling temperatures up to 80°C. It is often compatible with international standards such as ASTM D4802 (US), DIN EN ISO 7823-1 (Europe), and JIS K 6735 (Japan).

Pros & Cons:

* Pros include superior transparency, brilliant surface finish after laser cutting, and precise engraving capability. Cons* involve moderate cost (higher than extruded types) and slight non-uniformity in thickness, which can introduce variability in exacting technical applications.

Application Impact:

Due to its clarity and edge polish, cast acrylic excels in signage, display fabrication, and high-end glazing, serving industries requiring precise visual appeal. Its broad standardization eases product certification and cross-border compliance—a significant advantage for B2B buyers managing exports or global supply chains.

Buyer Considerations:

African and South American buyers appreciate the reliability and global acceptance of cast acrylic, while European and Middle Eastern buyers often demand documented compliance with relevant standards for architectural and technical uses. Sourcing from ISO-certified producers is prudent to guarantee consistent sheet quality and traceability.

Extruded Acrylic

Key Properties:

Extruded acrylic, manufactured via continuous extrusion, offers greater thickness uniformity and is typically lower in cost. However, it’s more sensitive to heat and prone to thermal distortion during laser cutting, with a slightly higher haze (1–2%).

Pros & Cons:

* Pros include economical pricing, ease of thermoforming, and reliable thickness—making it suitable for projects that prioritize budget or mass production. Cons* revolve around lower optical purity, increased risk of edge melting or charring when laser cut, and less defined engraving quality.

Application Impact:

Common for routine point-of-sale displays, indoor partitions, and mid-tier products where cost controls outweigh ultra-clear finishes. However, buyers targeting premium markets or intricate laser engraving work should weigh the limitations in finished aesthetics.

Buyer Considerations:

For buyers in cost-conscious regions like parts of Africa and South America, extruded acrylic supports large-scale production with reasonable performance. However, variability in regional manufacturing standards necessitates supplier vetting to ensure sheets meet at least ASTM D4802 or EU equivalents for downstream compliance.

Impact-Modified Acrylic

Key Properties:

This acrylic type integrates additives or co-monomers to increase durability against shock and mechanical impact (Izod impact resistance), which is beneficial for applications subject to handling stresses. It typically demonstrates slightly lower optical clarity compared to cast and extruded grades and may handle temperatures up to 70–75°C.

Pros & Cons:

* Pros are its enhanced toughness and reduced risk of cracking during installation or transit—valuable for B2B logistics. Cons* include marginally diminished transparency, slightly higher cost than standard extruded acrylic, and less favorable performance for ultra-fine engravings or aesthetics-focused projects.

Application Impact:

Optimal for laser-cut protective panels, machine guards, safety signage, and industrial glazing where impact resistance is essential. In markets with challenging logistic chains or heavy usage environments—common in parts of Africa and the Middle East—these grades can minimize in-transit losses and post-installation failures.

Buyer Considerations:

Buyers must confirm compatibility with technical specifications and seek supplier documentation on impact performance and compliance (ASTM, DIN, or EN certifications) to align with local industry requirements.

Colored & Specialty Acrylic

Key Properties:

Colored, frosted, and specialty acrylic sheets (such as UV-resistant or mirrored varieties) expand design flexibility. Properties such as UV stabilization, pigmentation consistency, and opacity are specific to the chosen variant and critical for branding or specialty installations.

Pros & Cons:

* Pros include broad decorative options and functional enhancements (e.g., light diffusion, UV resistance). Cons* involve variable laser cutting performance (as pigmentation can affect cut quality), premium pricing, and occasional limitations in stock thicknesses and color uniformity.

Application Impact:

Widely used in retail branding, architectural features, and signage where color accuracy and visual differentiation are key. Market demand is especially strong in Europe and the Middle East for hospitality and retail sectors.

Buyer Considerations:

International buyers must scrutinize color matching capabilities, pigmentation durability, and regional compliance—especially concerning safety standards for flame retardancy or outdoor use. Consistent sourcing is vital for large branding deployments.

Summary Table: Comparison of Acrylic Sheet Materials for Laser Cutting

| Material | Typical Use Case for laser cutting of acrylic sheets | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Cast Acrylic | Premium signage, displays, architectural glazing | Superior optical clarity and polished edges | Higher cost and potential thickness variability | High |

| Extruded Acrylic | Mass-produced displays, partitions, budget signage | Lower cost and uniform thickness | Inferior clarity, prone to melting/charring | Low |

| Impact-Modified Acrylic | Protective panels, safety guards, industrial glazing | Higher impact resistance | Slightly reduced clarity, higher cost than extruded | Medium |

| Colored & Specialty Acrylic | Branded signage, architectural features, retail displays | Broad color options and functional add-ons | Variable cutting quality, premium price, limited stock options | High |

In-depth Look: Manufacturing Processes and Quality Assurance for laser cutting of acrylic sheets

Overview of Laser Cutting Acrylic Sheet Manufacturing

The laser cutting of acrylic sheets is a high-precision manufacturing process vital for industries such as signage, retail displays, electronics, and construction. For B2B buyers, comprehending the manufacturing stages and integrated quality assurance (QA) measures is essential for sourcing consistent, defect-free components that adhere to international standards and withstand the rigors of global supply chains.

Key Stages in Laser Cutting Acrylic Sheet Production

1. Material Selection and Preparation

- Material Sourcing: Success begins with choosing between cast and extruded acrylic. Cast acrylic offers superior clarity and is favored for applications demanding premium aesthetics and optical performance, whereas extruded acrylic is more cost-effective and suited for projects with lower tolerances.

- Sheet Inspection: Incoming raw acrylic sheets undergo Incoming Quality Control (IQC), where they are checked for uniform thickness, color consistency, and the absence of surface defects such as cracks or inclusions. Thickness variation in cast acrylic or contamination in extruded sheets can undermine final quality.

- Cleaning: Prior to laser processing, sheets must be free from dust, oils, and protective films in cutting zones, as contaminants affect laser focus and edge quality.

2. Laser Cutting Process

- Design File Preparation: CAD files are precision-checked for accurate dimensions, tolerances, and nesting optimization to maximize material yield and minimize waste.

- Equipment Set-up: CO₂ lasers, with their high compatibility with acrylic’s absorption spectrum, are calibrated for appropriate power, speed, and focus parameters, tailored to sheet thickness and type. Machine calibration is vital for edge clarity and dimensional accuracy.

- Automated & Controlled Cutting: CNC systems guide the laser head with precision. Key parameters such as focal distance, cut velocity, and assist gases (often nitrogen) are closely monitored to prevent issues like edge charring and melting, especially with extruded acrylic which is more heat-sensitive.

3. Post-cut Finishing

- Edge Quality Management: Although CO₂ laser cutting typically results in polished, flame-finished edges (especially with cast acrylic), some products require secondary processes like flame polishing or manual deburring for added clarity or smoothness.

- Protective Film Reapplication: To avoid surface scratches during later assembly or shipping, protective films may be reapplied post-processing.

- Part Cleaning: Ionized air or bristle brushing removes micro-particles from cut channels, especially critical for optical or display applications.

4. Assembly and Packaging

- Assembly (if needed): For assemblies such as display stands, parts proceed to laser-based welding or adhesive-based assembly, with careful quality control around bond strength and optical clarity at joints.

- Packaging: Finished components are inspected for cosmetic and dimensional quality, then packaged with anti-abrasion materials to prevent shipping damage.

Integrated Quality Assurance and International Standards

Multistage Quality Control (QC) Checkpoints

-

Incoming Quality Control (IQC):

– Checks raw acrylic for thickness, clarity, and uniformity.

– Verifies certificates from suppliers, especially for high-spec projects (e.g., UV-resistant or flame-retardant grades). -

In-Process Quality Control (IPQC):

– Involves process monitoring during cutting for real-time detection of deviations (e.g., incomplete cuts, thermal damage, aberrant edge finishes).

– Employs sample inspection using measurement gauges, visual checks, and sometimes digital imaging systems. -

Final Quality Control (FQC):

– Completes full or statistical inspection of final parts for dimension, edge polish, surface integrity, and packaging quality.

– Key tests include dimensional tolerance (using vernier calipers, CMM, or laser scanners), edge finish assessments, and haze/clarity checks for optical applications.

Testing Methods and Documentation

- Dimensional and Tolerance Testing: Handheld calipers or automated CMMs check for adherence to drawing specifications.

- Edge Quality Assessment: Visual inspection under defined lighting, supplemented by feeler gauges for burr-detection.

- Optical Properties: Haze measurement instruments evaluate light transmission and clarity; vital for display or lighting applications.

- Physical Stress Tests: As required, tensile and impact tests assure structural integrity, especially for safety shields or paneling.

- Batch Tracking: Each production batch is documented, with traceability extending from raw material lot to finished product shipment, crucial for after-sales quality trace.

Compliance with International Standards

- ISO 9001: The most widely recognized quality management certification, ensuring systematic process control, documentation, and continual improvement.

- CE Marking: Mandated in Europe for fabricated products in certain categories (e.g., architectural or safety glazing) to meet EU safety, health, and environmental requirements.

- Additional Certifications: Depending on application or region, flame retardancy (UL-94), food contact compliance (FDA/EU), or project-specific supplier approvals may be necessary—for example, API standards for industrial containment panels.

Ensuring Supplier Quality: Verification Strategies for International B2B Buyers

1. Audits and Supplier Assessments

- On-site Audits: Conduct pre-contract or periodic factory audits (in-person or via third-party agencies) to assess process control, equipment maintenance, operator training, and adherence to process documentation.

- Remote Video Audits: Increasingly common for international buyers to minimize travel; focus on live demonstrations of key stages and interviews with QC staff.

2. Inspection and Reporting

- Third-party Inspection: Engage independent inspection firms to perform pre-shipment or in-process QC according to your specifications. This is especially critical for first-time or high-volume orders leaving Asia for Africa, South America, or the Middle East, where in-country oversight is challenging.

- Quality Reports: Require comprehensive QC documentation with each batch, including measurement reports, process logs, non-conformance records, and photographic evidence of critical dimensions.

3. Certifications and Traceability

- Certification Review: Request up-to-date ISO 9001, CE, UL, or relevant certificates. Confirm authenticity with the certifying body where possible.

- Material Traceability: Insist on batch or lot-level traceability, particularly for regulatory-sensitive applications. This enables root-cause analysis and minimizes risks in the event of recalls or field failures.

- Samples and Golden Units: Establish clear “golden samples”—physical or digital reference parts that define acceptable visual and dimensional standards—to reduce the risk of interpretation errors across language and geographic boundaries.

Regional Considerations for International Buyers

Africa

- Local Standards: Cross-check supplier capabilities against any local standards for architectural, infrastructural, or industrial use.

- Infrastructure Gaps: Mitigate risks from variable logistics quality by emphasizing robust packaging and in-transit protection.

South America

- Customs and Certifications: Ensure documentation is robust for customs clearance and that suppliers are familiar with any country-specific import requirements.

- Bespoke Designs: For projects demanding unique geometries, clarify IPQC checkpoints that protect design intent.

Middle East

- Climate Considerations: Specify additional UV or impact resistance if acrylic products will face high ambient temperatures or solar exposure.

- Project Timelines: Due diligence in supplier lead times and scalability is vital given fast-paced regional construction cycles.

Europe

- CE and RoHS Compliance: For many end-products, strict adherence to European Directives (CE, RoHS) is non-negotiable, necessitating robust documentation.

- Supplier Reputation: Preference often given to suppliers with documented EU market delivery experience and proven post-sales support.

Actionable Takeaways for B2B Buyers

- Define detailed technical and QC requirements up front: Share reference samples, drawings, and certification needs in the RFQ stage.

- Vet suppliers through audits and traceable documentation: Negotiating contracts with clear QC, traceability, and corrective action provisions mitigates cross-border quality risks.

- Utilize third-party or remote inspection: Especially valuable for buyers in emerging markets or sourcing from unfamiliar territories.

- Monitor compliance with regional regulations: Ensure legal conformity and minimize customs or market-entry delays.

Employing a rigorous, multi-step quality and manufacturing control process ensures not just superior laser-cut acrylic sheets but also more resilient supply chains and fewer surprises upon delivery—regardless of your company’s location or sector.

Related Video: China’s Top 5 Manufacturing and Mass Production Videos | by @miracleprocess

Comprehensive Cost and Pricing Analysis for laser cutting of acrylic sheets Sourcing

Understanding Cost Drivers in Acrylic Laser Cutting

Accurately assessing costs is essential when sourcing laser-cut acrylic sheets, especially for international B2B buyers aiming to optimize both price and quality. The total landed cost extends well beyond initial unit pricing, reflecting a multifaceted structure shaped by material choice, production parameters, supply chain considerations, and buyer-supplier dynamics.

Breakdown of Key Cost Components

1. Raw Materials:

– Acrylic Type: Cast acrylic typically commands higher prices due to superior optical quality and consistency, ideal for applications demanding premium clarity. Extruded acrylic is generally more cost-effective but may require additional post-processing to address edge quality.

– Sheet Thickness and Size: Thicker or oversized sheets proportionally increase both material and cutting time costs.

2. Labor:

– Technical Workforce: Labor costs vary by region. European or Middle Eastern suppliers may offer higher automation but also have higher wage bases, while emerging markets like Africa or South America may present cost advantages.

3. Manufacturing Overhead:

– Facility and Machine Investment: Depreciation of advanced CO₂ laser systems, utilities, and shop-floor overheads are typically factored into pricing.

– Tooling and Setup: For highly customized runs, initial programming and setup may contribute a one-time fee, particularly with complex geometries.

4. Quality Control:

– Inspection and Testing: Cost may rise if buyers require certifications (ISO, CE) or rigorous QC protocols, especially for export to regulated markets.

5. Logistics and Packaging:

– Shipping Methods: Air freight—preferred for urgent, high-value shipments—incurs a premium, while ocean/ground freight offers better cost efficiency for bulk orders.

– Protective Packaging: Essential for preventing surface scratches or damage during transit, especially on clear or high-gloss acrylic panels.

6. Supplier Margins:

– Market Position & Value-added Services: Suppliers with strong reputations, advanced customization, or integrated logistics capabilities may price higher but often provide enhanced value and reliability.

Principal Pricing Influencers

– Order Volume and MOQ:

Larger orders generally achieve reduced per-unit costs due to economies of scale. Minimum order quantities (MOQs) may vary by supplier and production method—negotiating flexible MOQs can benefit buyers in new markets.

– Customization and Specifications:

Intricate cutting patterns, variable sheet sizes, or detailed engraving require more programming and slower cutting speeds, increasing cost. Clear communication of technical drawings (DXF, CAD files) is crucial for accurate pricing.

– Material Quality and Certification Needs:

Demand for certified or branded acrylic (e.g., Plexiglas®) and documentation can increase material and compliance costs.

– Production Location and Supplier Expertise:

Proximity to raw material sources, access to skilled labor, and technological capabilities all influence quotations. Established suppliers may offer better quality assurance, while newer entrants might be more price-competitive.

– Incoterms and Payment Terms:

Pricing can be quoted EXW, FOB, CIF, etc. International buyers must clarify responsibilities for insurance, transport, and customs when comparing quotes, as these significantly affect landed costs.

Actionable Insights & Cost-Saving Strategies for International Buyers

- Benchmark and Diversify Suppliers: Solicit detailed quotations from multiple regions—buyers in Africa or South America could realize savings by comparing offers from Asia, Europe, or the Middle East.

- Negotiate Beyond Price: Explore options for value-added packaging, phased shipments, or supplier-borne QC to offset higher unit prices.

- Optimize Order Batches: Consolidate orders to surpass volume discount thresholds or combine multiple product SKUs where feasible.

- Leverage Technology for Specifications: Provide clear, standardized files to minimize back-and-forth, prevent costly errors, and lock in fixed pricing.

- Scrutinize Total Cost of Ownership (TCO): Weigh upfront price against long-term cost factors—reject rates, rework, transit time, and aftersales support—particularly critical for buyers in regions distant from major production hubs.

- Understand the Market Context: Tariffs, currency risks, and local taxes can greatly impact final costs in regions like Colombia or the UK; factor these into budget planning and negotiations.

Disclaimer: Price indications in this sector are subject to material market fluctuations, regional labor rates, energy costs, and currency volatility. The insights above serve as an analytical guide—always obtain tailored and up-to-date quotations for precise cost assessment.

By adopting a comprehensive, informed approach to cost analysis, B2B purchasers can strategically balance price, quality, and risk to maximize their sourcing value in the dynamic market for laser-cut acrylic sheets.

Spotlight on Potential laser cutting of acrylic sheets Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘laser cutting of acrylic sheets’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

15 Laser Cutting Machine Manufacturers 2024 (www.mytcnc.com)

Jinan Bond Laser Co., Ltd., featured among the “15 Laser Cutting Machine Manufacturers 2024,” is a prominent player in China’s laser processing equipment sector. The company originally built its reputation on CO₂ laser systems, highly effective for cutting and engraving acrylic sheets with clarity and edge precision. Recently, Bond Laser has pivoted to offer advanced fiber laser cutting machines, expanding its material capabilities for high-volume and complex industrial applications. They emphasize R&D-driven product innovation and have extensive manufacturing capabilities, likely backed by internationally recognized quality standards (such as ISO certification). With an established export presence, Bond Laser is positioned to serve international B2B buyers, including those from Africa, South America, the Middle East, and Europe. Dedicated after-sales support and custom engineering options make them a strong candidate for procurement partnerships.

10 Laser Cutting Machine Manufacturers in 2024 (www.machinemfg.com)

10 Laser Cutting Machine Manufacturers in 2024, featured by MachineMFG, represent a collective of leading global suppliers specializing in advanced laser cutting technology. Their product offerings encompass CO₂, fiber, and YAG laser machines tailored for precise and efficient acrylic sheet cutting. These manufacturers focus on robust construction, high automation, and integration of essential assist systems—such as cooling, smoke extraction, and gas supply—to support continuous industrial operation. While detailed certifications and individual company accreditations are not publicly specified, their presence in key international markets highlights a commitment to export standards and diverse client requirements, including buyers in Africa, South America, the Middle East, and Europe. Notably, their emphasis on both innovation and comprehensive after-sales support positions them as a reliable choice for B2B buyers needing scalable acrylic processing solutions.

The Top Laser Cutter Manufacturers in 2024 (www.cncsourced.com)

xTool, a sub-brand of Makeblock established in 2019 (China), has quickly earned global recognition for affordable and innovative laser cutting solutions. Notably awarded the Red Dot Design Award in 2022, xTool’s product offerings focus on accessible, precise desktop and entry-level industrial laser cutters well-suited for processing acrylic sheets. Their systems are designed for ease of integration and reliability in small-batch production, prototyping, signage, and creative acrylic fabrication. While detailed certifications (such as ISO) are not publicly listed, the brand emphasizes user-friendly automation, robust safety features, and adaptability for diverse workflows. xTool’s growing global distribution network indicates active engagement with B2B customers across Europe, Africa, South America, and the Middle East, making them a practical choice for buyers seeking cost-effective and scalable acrylic cutting technology.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| 15 Laser Cutting Machine Manufacturers 2024 | China-based; CO₂/fiber lasers; export-ready supplier | www.mytcnc.com |

| 10 Laser Cutting Machine Manufacturers in 2024 | Versatile acrylic-focused laser cutting solutions | www.machinemfg.com |

| The Top Laser Cutter Manufacturers in 2024 | Affordable, award-winning desktop acrylic laser cutters | www.cncsourced.com |

Essential Technical Properties and Trade Terminology for laser cutting of acrylic sheets

Core Technical Specifications for B2B Laser-Cut Acrylic Purchases

When sourcing laser-cut acrylic sheets, understanding the essential technical properties ensures you receive materials that meet both functional and regulatory requirements. Below are the most critical specifications B2B buyers should confirm and communicate with suppliers:

1. Material Type and Grade (Cast vs. Extruded)

Acrylic sheets come primarily in two forms: cast and extruded. Cast acrylic provides superior optical clarity, higher heat resistance, and cleaner laser-engraved details—ideal for high-value applications or where edge quality is paramount. Extruded acrylic, though more cost-effective and uniform in thickness, is prone to thermal distortion and may require secondary finishing after cutting. Clearly specifying grade helps suppliers match your quality and cost expectations.

2. Thickness and Thickness Tolerance

Sheet thickness—most commonly ranging from 2mm up to 25mm—and its tolerance (acceptable deviation) directly impact cut quality, structural performance, and compatibility with downstream processes or assemblies. For laser cutting, sheets with tight thickness tolerances (±0.2mm or better) enable precise, consistent results across large production runs, minimizing waste and rework. Always specify both nominal thickness and allowed tolerance.

3. Optical Clarity (Haze and Light Transmission)

Optical clarity is critical for signage, displays, and architectural applications. This is typically measured through haze percentage (amount of light diffused) and total light transmission. Cast acrylic often offers <1% haze and over 90% light transmission, enabling crisp, transparent results. Buyers should request clarity certifications or datasheets if aesthetics or optical performance is a priority.

4. Laser Compatibility (Wavelength Absorption & Cut Quality)

Acrylic’s effectiveness with laser cutting relies on its absorption of certain laser wavelengths, particularly 10.6 µm emitted by CO₂ lasers. Not all acrylic formulations perform equally—some additives or colors affect cut edge quality and engraving definition. Confirm with suppliers that the supplied sheets are optimized and tested for laser cutting, especially if using automated CNC-laser systems for high throughput.

5. Dimensional Accuracy & Edge Finish

For components used in assembly or visible applications, dimensional accuracy (the precision of cut shapes relative to CAD drawings) and edge quality (smoothness, level of burrs or melting) are vital. Ask suppliers about their cutting tolerances (e.g., ±0.1mm) and post-cutting processes offered—for example, edge polishing or deburring—to achieve required standards.

6. Heat Resistance (Softening and Melting Points)

The ability of acrylic to withstand laser energy without excessive melting or edge discoloration depends on its heat resistance. This is particularly important for thick sheets or complex geometries. Suppliers should provide data on Vicat softening temperature and recommendations for laser settings that avoid warping, especially in high-temperature environments or under sustained production.

Key Industry & Trade Terms for International B2B Buyers

Navigating global trade for laser-cut acrylic requires fluency in critical terminology. Mastering these common acronyms and terms streamlines communication, quotes, and contract negotiations:

-

OEM (Original Equipment Manufacturer): Refers to a manufacturer producing items to be branded and sold by another company. In acrylic sourcing, OEM supply arrangements can allow for customized sheet sizes, colors, or proprietary formulations.

-

MOQ (Minimum Order Quantity): The minimum volume of product a supplier is willing to sell per order. Understanding MOQ helps buyers balance cost savings from scale with inventory risk, which is especially relevant when importing heavy or bulky acrylic sheets.

-

RFQ (Request For Quotation): A formal document issued to suppliers detailing specifications, quantities, and delivery requirements, soliciting detailed pricing and terms. Precise RFQs—covering material grade, dimensions, tolerances, and quality requirements—help buyers compare offers on an apples-to-apples basis.

-

Incoterms (International Commercial Terms): Globally recognized rules defining responsibilities for shipping, insurance, and customs clearance. Common Incoterms for bulk acrylic shipments include FOB (Free On Board), CIF (Cost, Insurance & Freight), and DDP (Delivered Duty Paid). Choosing the right term allocates risks and costs transparently.

-

QA/QC (Quality Assurance/Quality Control): QA refers to systematic processes ensuring product quality from raw material selection to final inspection, while QC addresses the specific checks and inspections performed during and after production. Always verify a supplier’s QA/QC certifications (e.g., ISO 9001) to minimize the risk of defective or non-conforming shipments.

-

Lead Time: The total time from order confirmation to delivery at the buyer’s facility. Factors such as production schedule, supply chain logistics, and customs clearance can affect lead time for international B2B acrylic orders. Clear agreement on expected lead times helps maintain project schedules and inventory planning.

A clear understanding of these technical specifications and trade terms empowers international buyers to make informed, precise, and commercially advantageous decisions when sourcing laser-cut acrylic sheets across different markets. This minimizes risks, ensures high-quality outcomes, and supports seamless cross-border collaboration.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the laser cutting of acrylic sheets Sector

Global Market Overview and Key Trends

The laser cutting of acrylic sheets industry is experiencing robust growth, driven by increasing demand for precision manufacturing, customization, and rapid prototyping across sectors such as signage, retail fixtures, electronics, and construction. With acrylic’s versatility and clarity, manufacturers from the UK to Colombia are prioritizing advanced laser technologies to deliver intricate designs, enhanced product aesthetics, and complex assemblies at scale.

Key trends include a rapid shift towards digital automation and integration of CNC (Computer Numerical Control) laser systems. CNC-enabled laser cutters are empowering B2B buyers to achieve repeatable, high-precision results with reduced labor costs and minimal material wastage. The adoption of modular, scalable laser systems is facilitating just-in-time manufacturing and quick turnaround for custom orders—a significant advantage for buyers in dynamic markets like the Middle East and Africa, where supply chain agility is crucial.

Another trend is the growing preference for cast acrylic over extruded types in high-end applications, driven by its superior clarity, durability, and consistent laser-cutting performance. Cast acrylic’s higher initial cost is often balanced by reduced post-processing and waste, appealing to quality-focused buyers in Europe and export-driven South American firms.

For international procurement teams, it is essential to evaluate suppliers based on their technical capabilities, machine maintenance protocols, and value-added services like design support and logistics. Engaging with producers that offer transparent quality certifications and global after-sales support is increasingly standard practice, ensuring risk mitigation for cross-border transactions. Additionally, ongoing advancements in laser power, speed, and automation—such as integrated robotic handling—are making it feasible to handle larger production runs with consistent quality, meeting the scaling needs of both established and emerging markets.

Actionable Insight: B2B buyers should prioritize suppliers who demonstrate technical leadership with updated laser systems, comprehensive material traceability, and a clear commitment to international delivery performance to support business growth and resilience.

Sustainability and Ethical Sourcing in Laser-Cut Acrylic

Sustainability and ethical considerations are rapidly moving to the forefront of sourcing strategies in the laser cutting of acrylic sheets. Environmental concerns stem primarily from the production and disposal of acrylic (PMMA), a non-biodegradable plastic, as well as from the energy consumption associated with laser machinery. However, the shift toward closed-loop manufacturing processes and the sourcing of greener raw materials is reshaping industry norms.

Leading suppliers increasingly offer recycled or bio-based acrylic sheet options, helping buyers reduce their carbon footprint. Certification to standards such as ISO 14001 (Environmental Management), as well as third-party eco-labels, is becoming a key differentiator in supplier selection, especially within European and North American markets. Buyers from regions with evolving regulatory frameworks—like parts of Africa and South America—can leverage these standards for supply chain alignment and to enhance their reputational positioning in export markets.

Moreover, ethical procurement extends beyond environmental criteria. Responsible buyers are evaluating factors such as labor practices, safe working conditions, and transparent material sourcing throughout the supply chain. Traceability tools and digital documentation are increasingly required to verify compliance and support due diligence during audits or certification processes.

Procurement managers are also encouraged to seek suppliers who offer energy-efficient laser machinery, such as modern CO₂ systems, and who invest in renewable energy for operations. These preferences not only align with global climate goals but often lead to cost reductions over time through improved operational efficiency.

Actionable Insight: Incorporate sustainability and ethical sourcing criteria—such as recycled material content, globally recognized environmental certifications, and supply chain transparency—into your supplier evaluation process. This helps future-proof your procurement against regulatory shifts and growing customer demand for responsible sourcing.

Brief Evolution and Industry Context

The laser cutting of acrylic sheets originated alongside rapid advances in laser technologies in the late 20th century. Initially reserved for high-value, precision-demanding sectors such as aerospace and electronics, the widespread adoption of CO₂ laser systems in the 1980s and 1990s democratized acrylic processing. With the rise of digital design tools and CNC integration, laser cutting expanded into signage, architectural applications, and creative industries globally.

Today, advancements in laser efficiency, automation, and software integration continue to drive the sector. B2B buyers now benefit from scalable, modular manufacturing solutions that offer both mass production and bespoke prototyping, enabling new business models and product offerings in international markets.

Actionable Insight: Investing in suppliers with a proven history of equipment modernization and process innovation can provide B2B buyers with ongoing competitive advantage as the acrylic laser cutting landscape continues to evolve.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of laser cutting of acrylic sheets

-

How should we evaluate and select a reliable international supplier for laser-cut acrylic sheets?

To select a reliable supplier, prioritize those with a proven track record in exporting to your region. Request documentation on quality management systems (such as ISO 9001), and ask for digital or physical samples to evaluate cut quality and material type (cast vs. extruded acrylic). Look for suppliers who maintain clear, responsive communication and offer transparency about their manufacturing process, production capacity, and adherence to international standards. Conduct reference checks, and consider visiting their facilities virtually or in person, if feasible, to verify capabilities. -

What options are available for customizing laser-cut acrylic sheets to our specifications?

Customization options typically include selecting acrylic type (cast vs. extruded), thickness, dimensions, edge finishes, engraving details, and protective masking. Many suppliers can accommodate specific shape designs via CAD drawings and adjust production to match branding or end-use requirements (e.g., signage, displays). Communicate your technical specifications clearly, and confirm using technical drawings or prototypes. Ensure your supplier has CAD/CAM integration and experience with bulk custom orders, as this streamlines production and minimizes errors. -

What are common minimum order quantities (MOQs), payment terms, and lead times for international B2B orders?

MOQs can vary widely—ranging from as low as 10 sheets for standard products up to several hundred for specialized or custom runs. Lead times often range from 2-6 weeks, depending on complexity and order size, with additional shipping time based on destination (e.g., Africa/Middle East 2–5 weeks, Europe 1–3 weeks). Payment terms generally include TT (Telegraphic Transfer), LC (Letter of Credit), or, for smaller orders, PayPal or credit card. For large or repeat orders, negotiate staged payments or deposits to mitigate risk. -

How do leading suppliers ensure consistent product quality and compliance with relevant certifications?

Reputable suppliers employ robust quality assurance protocols, including in-process inspection, final QC checks, and batch traceability. Request certificates of conformity, testing reports (e.g., RoHS compliance for environmental safety where applicable), and details of quality management systems (such as ISO 9001). For European buyers, ensure REACH compliance; for the Middle East and Africa, ask about certifications recognized by local regulators. Regularly review inspection reports and, where possible, inspect shipments upon arrival for adherence to agreed specifications. -

What are the key considerations for international shipping, logistics, and safe delivery of acrylic sheets?

Acrylic sheets are sensitive to scratching and warping, so insist on proper protective packaging (e.g., double shrink wrap, corner guards, wooden crating for sea freight). Clarify incoterms (e.g., FOB, CIF, DAP) to define risk transfer points. Ask about the supplier’s experience with your country’s customs clearance and request documentation such as commercial invoices, packing lists, and certificates of origin. Track shipments using reliable logistics partners, and secure marine insurance for high-value consignments to mitigate transit risks. -

How should we handle defects, damages, or disputes with an overseas supplier?

Establish clear written agreements regarding defect rates, quality expectations, and returns prior to placing orders. Require a clause specifying remedies (e.g., replacement, refund, or credit note) for non-conforming products. Document any issues on receipt with time-stamped photos and reports, and notify the supplier promptly. Most international suppliers will have standard protocols for dispute resolution; for large contracts, consider using third-party inspection services and specifying arbitration clauses under a recognized international legal framework (such as ICC rules). -

What factors influence the price of laser-cut acrylic sheets in global trade, and how can we optimize cost-efficiency?

Pricing depends on raw material costs, acrylic type (cast is costlier than extruded), customization level, order volume, technological sophistication of the supplier, and shipping method. To optimize cost, consolidate orders, standardize specifications where possible, and request bulk discounts. Factor in local import duties and VAT for accurate landed cost calculations. Develop long-term partnerships to leverage better pricing and more favorable payment terms, and regularly benchmark suppliers to stay competitive. -

What technical and regulatory documentation should we require for international procurement of laser-cut acrylic sheets?

Request a comprehensive technical data sheet detailing material grade, properties, and laser processing specifications. For regulated industries, require health, safety, and environmental compliance declarations (e.g., RoHS/REACH certificates for Europe, GCC standards for the Middle East). Ensure all export documents—commercial invoice, packing list, bill of lading/airway bill, and certificate of origin—are supplied before shipment. Proper documentation not only ensures customs clearance efficiency but also serves as protection in case of disputes or audits.

Strategic Sourcing Conclusion and Outlook for laser cutting of acrylic sheets

International B2B buyers exploring laser cutting solutions for acrylic sheets must prioritize material selection, supplier reliability, and technological compatibility to ensure successful long-term partnerships and superior project outcomes. Understanding the distinctions between cast and extruded acrylic—such as differences in clarity, thermal properties, and cutting quality—enables precise alignment of material characteristics with specific application demands, from signage to high-tech electronics.

Strategic sourcing involves more than price negotiations; it requires assessing supplier capabilities, adherence to international quality standards, and after-sales support. When evaluating suppliers, consider the integration of advanced CNC laser systems—especially CO₂ laser solutions—for consistent performance, reduced material waste, and scalability across diverse industry sectors. Leveraging the right equipment and expertise supports seamless transitions from design prototyping to high-volume production, which is especially critical for dynamic markets in Africa, South America, the Middle East, and Europe.

Looking forward, the intersection of digital automation and laser technology is set to further revolutionize acrylic fabrication. B2B buyers who invest in robust sourcing relationships and stay attuned to global advancements position themselves to meet evolving customer requirements rapidly and competitively. Act now to foster supplier collaborations and harness innovation, ensuring your business remains resilient and ahead in the global marketplace for laser-processed acrylic solutions.