Introduction: Navigating the Global Market for profile of a surface gd&t

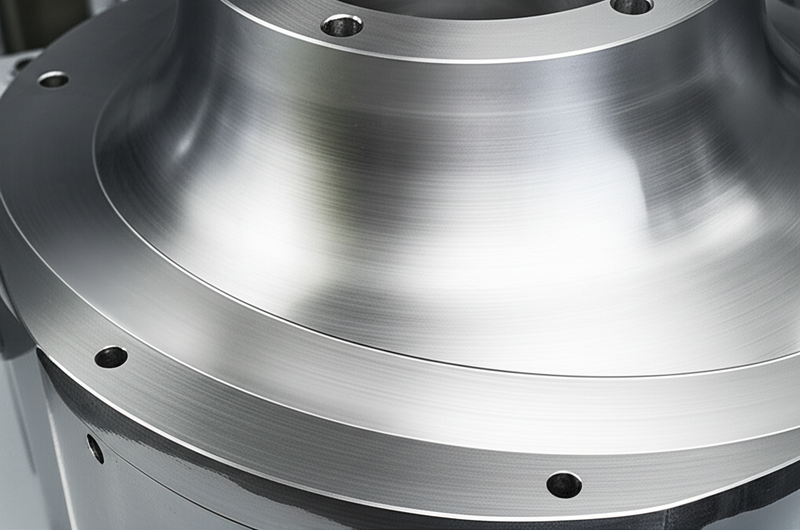

Understanding the intricacies of geometric dimensioning and tolerancing (GD&T), particularly the profile of a surface, is essential for international B2B buyers aiming to optimize manufacturing quality and cost efficiency. This feature control allows precise management of complex outer surfaces, crucial in high-precision industries such as aerospace, automotive, and consumer electronics. Mastery of the profile of a surface ensures parts meet strict functional and aesthetic standards, reducing rework, delays, and costly errors.

This comprehensive guide covers the full spectrum of the profile of a surface—its types, applicable materials, manufacturing and quality control considerations, and key supplier insights. It also provides actionable knowledge on evaluating costs, understanding market dynamics, and addressing frequently asked questions. For buyers from Africa, South America, the Middle East, and Europe (including Vietnam and Colombia), this resource empowers informed sourcing decisions, helping you select suppliers who can deliver complex surfaces with confidence and consistency.

In today’s competitive global market, having a detailed understanding of this critical GD&T feature enhances your ability to negotiate effectively, ensure compliance, and streamline your supply chain. Whether you are sourcing from local manufacturers or international suppliers, this guide equips you with the insights needed to navigate complex surface specifications—ultimately supporting your strategic growth and operational excellence.

Understanding profile of a surface gd&t Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Profile of a Surface (Uncontrolled) | Controls entire surface shape without referencing datums; purely geometric | Complex outer surfaces in aerospace, automotive, consumer products | Pros: High flexibility; suitable for intricate shapes. Cons: Less control over orientation or position, potentially increasing inspection complexity and costs. |

| Profile of a Surface with Datum | Uses datums to control surface orientation and position; combines form and orientation | Precision-engineered components requiring strict alignment | Pros: Precise control over surface location; reduces manufacturing variability. Cons: More complex setup and higher initial costs. |

| Profile of a Line (Cross-Section) | Controls the surface profile along a specific cross-section; localized control | Critical cross-sectional features in turbines, molds | Pros: Tighter control at critical points; cost-effective for targeted areas. Cons: Limited to specific sections, not the entire surface. |

| Profile of a Surface with Material Condition | Considers manufacturing allowances like MMC (Maximum Material Condition) | Assemblies with tight fits, such as sealing surfaces | Pros: Ensures proper assembly fit; accounts for manufacturing variability. Cons: Adds complexity to inspection and verification processes. |

| Composite Profile Control | Combines profile with other GD&T tolerances for complex features | Highly detailed surfaces in aerospace and luxury automotive parts | Pros: Highly detailed control; versatile for complex geometries. Cons: Increased inspection effort and higher costs. |

Characteristics and Suitability

Profile of a Surface (Uncontrolled): This variation offers the greatest flexibility, controlling the entire surface shape based solely on the CAD model or drawing. It is ideal for parts with complex, freeform shapes where other GD&T controls are difficult to apply. Suitable for industries like aerospace and automotive where surface aesthetics and aerodynamics are critical. Buyers should consider manufacturing capabilities, as tight tolerances can increase costs and inspection complexity. It’s best for prototypes or high-value parts requiring detailed surface control.

Profile of a Surface with Datum: Incorporating datums enhances control over the surface’s orientation and position relative to other features. This variation is essential for assemblies where surface alignment affects functionality, such as sealing surfaces or aerodynamic surfaces. It provides higher precision but involves more complex setup and measurement procedures. For B2B buyers, this ensures consistent quality, especially in high-precision industries, but may require investment in advanced measurement tools and skilled inspection.

Profile of a Line (Cross-Section): This variation targets specific critical cross-sections rather than the entire surface, making it cost-effective for tight control in localized areas. It is suitable for turbine blades, molds, or critical sealing edges. Buyers should evaluate whether the criticality of the feature justifies the tighter control and inspection costs. It balances manufacturing flexibility with quality assurance for targeted features.

Profile with Material Condition: This approach accounts for manufacturing allowances like MMC, ensuring parts will fit correctly during assembly. It is especially relevant in tight-tolerance fits, such as sealing surfaces or mating parts. While it enhances assembly reliability, it complicates inspection, as measurement must consider material conditions. B2B buyers should weigh the benefits of guaranteed fit against increased inspection costs and process complexity.

Composite Profile Control: Combining profile with other GD&T tolerances allows for highly detailed and complex surface control. It is used in advanced aerospace and luxury automotive parts where multiple features intersect. This variation offers comprehensive control but demands sophisticated inspection methods and higher costs. Buyers should assess whether the enhanced control justifies the investment, particularly for high-value, precision-critical components.

Key Industrial Applications of profile of a surface gd&t

| Industry/Sector | Specific Application of profile of a surface gd&t | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Manufacturing of turbine blades with complex blade surfaces | Ensures precise surface conformity, enhancing aerodynamic efficiency | High-precision measurement tools, skilled inspection services |

| Automotive | Production of complex exterior body panels (e.g., BiW, A-pillars) | Maintains aesthetic quality and aerodynamic performance | CAD data accuracy, advanced surface measurement equipment |

| Consumer Electronics | Design and manufacturing of smartphone enclosures with intricate curves | Guarantees design fidelity, reducing rework and returns | Tight tolerance control, reliable surface inspection solutions |

| Heavy Machinery | Fabrication of large, curved structural components (e.g., excavator booms) | Ensures functional fit and load distribution, extending lifespan | Robust measurement methods, scalable inspection processes |

| Marine Equipment | Construction of ship hulls with complex outer surfaces | Achieves hydrodynamic efficiency, reducing fuel consumption | Effective surface profiling tools, calibration for large parts |

Aerospace

In aerospace manufacturing, the profile of a surface GD&T is crucial for complex components like turbine blades and wing surfaces. These parts demand extremely precise surface control to meet aerodynamic and structural requirements. International buyers from regions such as Europe or South America often source these components from specialized suppliers capable of delivering tight tolerances. Proper application of surface profile control ensures the manufactured surface conforms closely to CAD models, reducing the risk of aerodynamic inefficiencies and component failures. Buyers must prioritize suppliers with advanced measurement capabilities and strict quality assurance protocols to meet aerospace standards.

Automotive

In the automotive industry, especially for exterior body panels such as BiW structures and A-pillars, the profile of a surface GD&T helps maintain high aesthetic and functional standards. It ensures complex curves and contours are within specified tolerances, which is vital for visual appeal and aerodynamic performance. For international markets like Vietnam or Colombia, sourcing suppliers with precise surface profiling ensures consistent quality, minimizing rework and fitment issues during assembly. This application requires reliable, calibrated measurement systems and detailed CAD data to guarantee surface accuracy throughout the manufacturing process.

Consumer Electronics

Consumer electronics manufacturers, producing smartphones and display cases, rely on the profile of a surface GD&T to achieve intricate, high-quality outer shapes. This control guarantees that complex curves and surfaces match the design intent, reducing defects and rework costs. For buyers in regions like Africa or the Middle East, sourcing from suppliers with advanced surface profiling ensures product quality and brand reputation. It is essential to select partners with precise measurement tools and the capability to verify surface conformity at various stages of production, especially for small, delicate parts.

Heavy Machinery

Large structural components like excavator booms and heavy-duty frames benefit from the profile of a surface GD&T by ensuring complex curved surfaces meet functional and load-bearing specifications. This control helps prevent misalignments that could compromise structural integrity or operational performance. International buyers from Africa or Europe should seek suppliers equipped with scalable measurement systems capable of handling large parts and providing accurate surface profiles. Proper surface control reduces the risk of costly rework, enhances part longevity, and ensures safe, reliable operation in demanding environments.

Marine Equipment

Ship hulls and other marine structures feature complex outer surfaces that require precise control to optimize hydrodynamics. The profile of a surface GD&T ensures these surfaces conform to design specifications, reducing drag and fuel consumption. For international buyers in South America or the Middle East, sourcing from experienced manufacturers with advanced surface profiling capabilities guarantees high-quality, efficient hulls. These suppliers should offer robust inspection processes, capable of handling large, curved surfaces and verifying conformity throughout the fabrication process, ensuring long-term operational efficiency.

Strategic Material Selection Guide for profile of a surface gd&t

Material Selection for Profile of a Surface GD&T Applications

Selecting the appropriate material for components requiring precise surface profiles governed by GD&T is crucial for ensuring manufacturability, functional performance, and compliance with international standards. Different industries and regions demand specific material properties that influence how surface profiles are manufactured, measured, and maintained throughout the product lifecycle. Here, we analyze four common materials—stainless steel, aluminum, carbon steel, and engineering plastics—focusing on their key properties, advantages, limitations, and considerations for international B2B buyers from Africa, South America, the Middle East, and Europe.

Stainless Steel

Key Properties:

Stainless steel offers excellent corrosion resistance, high strength, and good temperature tolerance, making it suitable for harsh environments. It is available in various grades (e.g., 304, 316) that cater to specific media and temperature ranges. Its surface finish can be finely controlled, which is critical for applications requiring tight GD&T profile tolerances.

Pros & Cons:

Advantages include durability, corrosion resistance, and compliance with many international standards such as ASTM and DIN. However, stainless steel can be costly and more challenging to machine due to its hardness, often requiring specialized tooling and processes. Its high strength and corrosion resistance make it ideal for aerospace, medical, and chemical industries.

Impact on Application:

Stainless steel’s media resistance ensures longevity in aggressive environments, such as marine or chemical processing. Its surface profile can be precisely controlled for aerodynamic or fluid dynamic surfaces, especially in aerospace and automotive sectors.

International Buyer Considerations:

Buyers from regions like Africa or South America should prioritize suppliers compliant with local standards (e.g., ASTM, JIS, DIN). Importing stainless steel often involves tariffs and import regulations, so sourcing from certified suppliers with clear documentation is essential. Its high cost may influence project budgets, but its longevity often justifies the investment.

Aluminum

Key Properties:

Aluminum is lightweight, exhibits good corrosion resistance (especially when anodized), and offers excellent machinability. It maintains strength at moderate temperatures and can be easily formed into complex surface profiles, making it popular in aerospace and consumer products.

Pros & Cons:

The primary advantage is its ease of manufacturing, which reduces production costs and lead times. Aluminum’s surface finish can be finely tuned to meet GD&T profile tolerances. However, it is less durable than steel under high-stress or corrosive conditions and can be susceptible to denting or deformation.

Impact on Application:

Ideal for lightweight, high-precision components such as aircraft panels, consumer electronics, and decorative surfaces. Aluminum’s compatibility with various surface treatments enhances its suitability for applications requiring detailed surface profiles.

International Buyer Considerations:

Aluminum is widely available globally, with standards like ASTM B209 and EN standards governing quality. Buyers in regions like Vietnam or Colombia benefit from established supply chains, but should verify supplier certifications to ensure compliance with project-specific standards. Cost-wise, aluminum is generally moderate, making it a cost-effective choice for mass production.

Carbon Steel

Key Properties:

Carbon steel is known for its high strength, toughness, and affordability. It can be heat-treated for enhanced hardness and wear resistance. Its surface can be machined to tight tolerances, suitable for applications where surface profile precision is critical.

Pros & Cons:

Advantages include low cost, wide availability, and ease of fabrication. Its surface profile can be precisely controlled, especially when finished with appropriate surface treatments. The main disadvantage is its susceptibility to corrosion unless protected with coatings or plating, which may add complexity to manufacturing.

Impact on Application:

Commonly used in structural components, machinery, and automotive parts where strength is prioritized over corrosion resistance. Surface profiles in steel components often require protective coatings to maintain integrity in corrosive environments.

International Buyer Considerations:

Buyers from regions with strict environmental standards (e.g., Europe) should ensure steel complies with directives like RoHS or REACH. Importing carbon steel involves considerations around tariffs and quality certifications, such as ASTM A36 or EN 10025. Its affordability makes it attractive for large-volume projects.

Engineering Plastics (e.g., PEEK, Polycarbonate)

Key Properties:

Engineering plastics like PEEK or polycarbonate offer excellent chemical resistance, lightweight, and good dimensional stability. They can be molded into complex surface profiles with high precision and are suitable for applications involving exposure to chemicals or high temperatures.

Pros & Cons:

Advantages include corrosion resistance, electrical insulation, and ease of fabrication. However, plastics generally have lower mechanical strength and temperature tolerance compared to metals, which limits their use in high-stress or high-temperature environments.

Impact on Application:

Ideal for medical devices, electronic enclosures, and chemical processing components where precise surface profiles are essential, and environmental resistance is required. Surface finishing can be optimized for GD&T control, especially in non-metallic applications.

International Buyer Considerations:

Buyers should verify material certifications such as ISO or ASTM standards. In regions like the Middle East or Africa, sourcing from reputable suppliers with traceability is critical due to potential quality variability. Cost varies widely depending on the grade, with high-performance plastics like PEEK being more expensive but offering unique advantages.

Summary Table

| Material | Typical Use Case for profile of a surface gd&t | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel | Aerospace, chemical, marine components | Excellent corrosion resistance, durability | High cost, difficult machining | High |

| Aluminum | Aerospace, consumer electronics, decorative surfaces | Lightweight, easy to machine | Less durable under high stress, susceptible to dents | Med |

| Carbon Steel | Structural parts, machinery, automotive parts | Cost-effective, high strength | Corrosion susceptibility without protective coatings | Low |

| Engineering Plastics | Medical devices, electronic enclosures | Chemical resistance, lightweight | Lower mechanical strength, limited high-temp use | Varies (Med-High) |

Final Remarks

For international B2B buyers, understanding the specific properties and limitations of these materials ensures optimal application of GD&T surface profile controls. Regional standards, supply chain stability, and compliance requirements should guide material selection, balancing performance needs with cost considerations. Engaging with certified suppliers and verifying material certifications aligned with local standards (e.g., ASTM, DIN, JIS) will streamline procurement and ensure high-quality outcomes in surface profile manufacturing.

In-depth Look: Manufacturing Processes and Quality Assurance for profile of a surface gd&t

Manufacturing Processes for Surface Profile GD&T

Achieving precise surface profiles as specified by GD&T requires a structured manufacturing workflow, integrating advanced techniques and rigorous process control. The main stages include:

Material Preparation:

The process begins with selecting suitable raw materials—metals, composites, or plastics—based on functional and aesthetic requirements. Material quality directly impacts the ability to meet surface profile tolerances. International standards such as ISO 9001 emphasize traceability and proper documentation of raw material certifications, which is critical for global supply chains.

Forming and Machining:

Initial shaping often involves subtractive methods like CNC milling, turning, or grinding to approximate the desired surface contours. For complex geometries, additive manufacturing (3D printing) can be employed, especially in prototyping or low-volume production, provided the surface finish and dimensional accuracy meet the GD&T specifications. Precision machining is vital; techniques such as ultra-precision grinding or laser ablation can achieve tight tolerances on surface profiles, especially for aerospace and automotive components.

Assembly and Integration:

Subcomponents are assembled with attention to maintaining the integrity of the surface profile. Fixtures and jigs are employed to hold parts accurately during finishing processes, preventing deformation. In some cases, surface treatments like polishing, electro-polishing, or coating are applied to enhance surface quality and meet functional requirements, especially where surface smoothness influences performance or appearance.

Finishing and Surface Treatment:

Final finishing processes, including lapping, buffing, or coating, refine the surface profile and reduce residual stresses. Surface treatments such as anodizing or plating are common in aerospace and electronics sectors, but they must be compatible with the GD&T tolerances, as they can affect dimensions.

Key Techniques and Equipment:

Advanced manufacturing often relies on Computer Numerical Control (CNC) machines for high precision. Coordinate Measuring Machines (CMMs) and optical profilometers are essential for verifying surface profiles during and after production. For complex surfaces, non-contact methods like laser scanning or white light interferometry enable comprehensive surface mapping, ensuring conformity with GD&T specifications.

Quality Control and Verification Practices

Quality assurance for surface profile GD&T is anchored in adherence to international standards and rigorous inspection protocols. The primary standards include ISO 9001 (quality management systems), ISO 17025 (testing and calibration laboratories), and industry-specific standards such as CE marking for electrical components, API standards for oil and gas equipment, and aerospace standards like AS9100.

Inspection Checkpoints:

– Incoming Quality Control (IQC): Raw materials are inspected for dimensional accuracy, surface finish, and material certifications before entering production. This prevents defects from propagating downstream.

– In-Process Quality Control (IPQC): During manufacturing, surface profiles are monitored using portable CMMs, laser scanners, or contact profilometers. Regular checks ensure that the process remains within tolerance limits, allowing for immediate adjustments if deviations occur.

– Final Quality Control (FQC): After manufacturing, detailed surface profile measurement verifies compliance with GD&T callouts. Techniques include 3D laser scanning, white light interferometry, or coordinate measurement with tactile probes.

Testing Methods:

– Surface Roughness and Finish: Assessed with stylus profilometers or optical methods, as surface finish can influence functional performance.

– Dimensional Verification: CMMs provide high-accuracy 3D measurements to confirm that the entire surface conforms to the virtual surface generated from CAD models.

– Non-Destructive Testing (NDT): Techniques such as ultrasonic testing or dye penetrant inspection ensure surface integrity, especially for critical aerospace or pressure vessel parts.

Verification by B2B Buyers:

International buyers should request detailed inspection reports, including CMM data, surface roughness charts, and NDT results. Engaging third-party inspection agencies or accredited labs ensures unbiased verification. Many suppliers offer digital documentation, including 3D scans and certification packages, which facilitate remote audits—an essential feature for buyers from regions like Africa, South America, the Middle East, and Europe.

Industry and Regional Considerations for Quality Assurance

Standards and Certifications:

Buyers from different regions should verify supplier certifications aligned with their industry standards. For example, European buyers often require CE marking and ISO 9001 certification, while North and South American clients may prioritize ASME or API standards. Suppliers in Vietnam or Colombia should demonstrate adherence to internationally recognized quality management systems and provide traceability documentation.

Supplier Audits and Third-Party Inspection:

Conducting supplier audits remains a cornerstone for B2B buyers to validate manufacturing and QC processes. Remote audits are increasingly common, facilitated by digital tools like video inspections and shared measurement data. Third-party inspectors, such as SGS, TUV, or Bureau Veritas, can provide comprehensive assessments, including surface profile verification, ensuring suppliers meet contractual quality standards.

Cultural and Logistical Nuances:

Buyers from emerging markets should emphasize clear communication of quality expectations, including detailed GD&T specifications and inspection criteria. Establishing long-term relationships with certified suppliers, backed by quality agreements and periodic audits, reduces risks of non-conformance. Additionally, understanding regional manufacturing capabilities and limitations can help in setting realistic tolerance expectations and selecting appropriate fabrication techniques.

Actionable Insights for International B2B Buyers

- Specify Clear GD&T Requirements: Ensure that surface profile tolerances are explicitly defined in technical drawings, with reference to applicable standards.

- Request Comprehensive Certification and Inspection Reports: Demand detailed documentation—CMM reports, surface finish reports, and third-party inspection certificates—to verify supplier compliance.

- Prioritize Suppliers with Proven Quality Management Systems: Look for ISO 9001, AS9100, or equivalent certifications, especially in regions with emerging manufacturing capabilities.

- Engage in Regular Audits and Remote Verification: Use digital tools for virtual audits and remote inspections to maintain oversight without geographical constraints.

- Understand Regional Manufacturing Nuances: Recognize differences in equipment, expertise, and standards; tailor your quality expectations accordingly.

- Collaborate on Continuous Improvement: Foster supplier development through feedback, joint quality initiatives, and training to uphold surface profile tolerances consistently.

By integrating these manufacturing and quality assurance practices, B2B buyers from Africa, South America, the Middle East, and Europe can effectively manage surface profile GD&T requirements, ensuring high-quality outcomes aligned with global standards.

Related Video: Amazing Mountain Working: How Truck Loading & Marbles Manufacturing Process

Comprehensive Cost and Pricing Analysis for profile of a surface gd&t Sourcing

Cost Components Breakdown

When sourcing surface profile GD&T services, the primary cost drivers include materials, labor, manufacturing overhead, tooling, quality control, logistics, and profit margins. Materials are generally minimal since surface profiling often involves measurement rather than raw material costs; however, specialized surface coatings or substrates may influence expenses. Labor costs depend on the complexity of the surface, the precision required, and the skill level of technicians involved in measurement and verification. Manufacturing overhead covers equipment depreciation, calibration, and facility costs, which can vary significantly by region.

Tooling expenses are typically low for measurement services but may be higher if custom fixtures or calibration standards are required for complex geometries. Quality control is a crucial component, especially when certifications (e.g., ISO, AS9100) are mandated; this involves inspection equipment, skilled inspectors, and documentation processes. Logistics costs depend on the location of the supplier and buyer, with international shipping adding to the overall expense. Margins are influenced by the supplier’s market position, demand, and strategic pricing policies.

Price Influencers

Several factors notably impact the final pricing for surface profile GD&T sourcing:

- Volume and Minimum Order Quantities (MOQ): Higher volumes typically reduce unit costs due to economies of scale. For small batch or prototype work, expect premiums reflecting setup and calibration efforts.

- Complexity and Customization: Intricate or highly specialized surfaces requiring advanced measurement techniques or custom fixtures will command higher prices.

- Material and Surface Conditions: Certain materials (e.g., aerospace-grade alloys, composites) or surfaces requiring special preparation or coatings can increase measurement difficulty and costs.

- Quality Certifications and Standards: Suppliers with certifications like ISO 9001 or aerospace-specific standards may charge a premium for compliance assurance.

- Supplier Location and Incoterms: Sourcing from regions with lower labor costs (e.g., Vietnam, Colombia) can reduce prices, but international shipping, tariffs, and import duties must be factored into total costs.

- Turnaround Time: Urgent or expedited services typically attract higher fees, especially when precision measurement is involved.

Buyer Tips for Cost-Effective Sourcing

International B2B buyers from Africa, South America, the Middle East, and Europe should approach sourcing with strategic negotiation and cost-awareness. Establish clear specifications upfront to avoid scope creep, which can inflate costs unexpectedly. Leverage volume commitments where feasible to negotiate better unit prices, especially for recurring projects.

Consider total cost of ownership (TCO) rather than just upfront pricing—this includes shipping, customs, inspection, and potential rework costs. When dealing with international suppliers, verify their calibration standards, certifications, and reputation to avoid costly quality issues. Negotiate flexible Incoterms that balance shipping costs and risks; for example, FOB terms may offer more control over logistics costs.

Finally, build relationships with multiple suppliers to foster competition and leverage better pricing over time. Be aware of regional market conditions—such as currency fluctuations, political stability, and local labor costs—that influence pricing dynamics.

Indicative Price Range

While exact prices vary widely based on project specifics, typical costs for surface profile GD&T measurement services might range from $500 to $2,500 per part for standard complexity. High-precision, certification-required, or highly complex surfaces can push costs upward of $5,000 or more per piece, especially for small batch or prototype work. Always request detailed quotes and consider a comprehensive evaluation of all associated costs for accurate budgeting.

This structured approach enables international buyers to make informed decisions, optimize sourcing strategies, and negotiate effectively in diverse regional markets.

Spotlight on Potential profile of a surface gd&t Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘profile of a surface gd&t’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for profile of a surface gd&t

Critical Technical Properties in Surface Profile GD&T for B2B

Material Grade

Material specifications are fundamental in ensuring that the manufactured surface can meet the required profile tolerances. Different grades of materials (e.g., steel, aluminum, composites) have varied machinability and stability characteristics. Selecting the appropriate grade ensures the surface profile can be reliably produced within tolerances, reducing rework and scrap costs, especially critical when dealing with complex aerospace or automotive parts.

Tolerance Zone

The tolerance zone defines the permissible deviation of the actual surface from its ideal CAD model. Tight tolerances (e.g., ±0.1 mm) are essential for high-precision applications like turbine blades or aerodynamic surfaces, where even minor deviations impact performance. For B2B transactions, understanding and specifying realistic tolerances aligned with manufacturing capabilities helps avoid costly delays or quality issues.

Surface Finish Requirements

While GD&T focuses on geometric accuracy, surface finish (roughness) influences the functional performance of the surface, such as aerodynamics or sealing. Clear specifications on surface finish, in conjunction with profile tolerances, ensure the part functions as intended. For international buyers, specifying finish standards compatible with local manufacturing processes is key to achieving consistent quality.

Manufacturing Capabilities & Process Limits

Understanding the fabrication process limitations (e.g., CNC machining, casting, additive manufacturing) helps set achievable profile tolerances. For example, complex curves may require advanced CNC techniques or surface treatments. B2B buyers should verify that suppliers’ equipment and expertise can meet the specified profile tolerances, minimizing delays and rework.

Inspection & Measurement Methods

Accurate measurement of complex surface profiles necessitates advanced inspection tools like 3D laser scanners or coordinate measuring machines (CMM). Confirming the supplier’s inspection capability ensures the surface profile conforms to specifications before shipment. For international sourcing, establishing clear inspection standards and documentation reduces risks of non-conformance.

Design Intent & Functional Requirements

The profile of a surface often correlates directly with the part’s functional performance, such as aerodynamics or assembly fit. Communicating the design intent clearly to suppliers ensures the surface profile aligns with operational requirements, avoiding costly redesigns or performance issues downstream.

Industry and Trade Terms Relevant to Surface Profile GD&T

OEM (Original Equipment Manufacturer)

An OEM produces parts or assemblies that are integrated into a larger system, such as aircraft or automotive. Understanding OEM standards for surface profiles ensures the supplied components meet strict quality and geometric requirements, vital for compliance and safety in high-stakes industries.

MOQ (Minimum Order Quantity)

This defines the smallest volume a supplier is willing to produce, often influenced by setup costs for complex surface profiles. Clear MOQ agreements help B2B buyers plan production schedules and negotiate prices effectively, especially when dealing with intricate geometries requiring specialized tooling.

RFQ (Request for Quotation)

A formal document sent to suppliers requesting price, lead time, and capability details for specific surface profile requirements. An RFQ ensures transparency and competitive bidding, which is essential for international buyers seeking cost-effective, quality-assured manufacturing partners.

Incoterms (International Commercial Terms)

Standardized trade terms that specify responsibilities for shipping, insurance, and customs. For surface profile parts, understanding Incoterms helps clarify who bears the risk during transit, particularly important for delicate or highly precise components crossing borders.

Tolerance & Geometric Control

These terms refer to the permissible deviations and the control of the part’s shape and position, respectively. Precise understanding ensures that suppliers produce parts within specified limits, maintaining consistency and functional integrity across international supply chains.

CAD/CAM Data & Virtual Prototyping

Refers to digital models used to define the exact surface profile requirements. Sharing accurate CAD data with suppliers streamlines manufacturing and inspection, ensuring the final product matches design intent, which is crucial for complex, high-precision surfaces.

Final Insights for International B2B Buyers

Understanding these technical properties and trade terms empowers buyers to specify accurate surface profile requirements confidently. Clear communication about material, tolerances, and inspection methods, combined with familiarity with key trade terms, reduces risks, accelerates procurement, and ensures the delivery of high-quality components aligned with global standards. This strategic knowledge is vital for maintaining competitiveness in industries demanding complex surface geometries, such as aerospace, automotive, and high-end consumer products.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the profile of a surface gd&t Sector

Market Overview & Key Trends

The global market for precision surface profiling and GD&T (Geometric Dimensioning and Tolerancing) solutions is experiencing significant growth driven by increasing demand for high-precision manufacturing across diverse industries such as aerospace, automotive, and consumer electronics. Advanced manufacturing sectors are emphasizing intricate surface control to ensure functional integrity and aesthetic quality, which elevates the importance of surface profile tolerances.

Emerging trends include the integration of digital technologies like 3D scanning, CAD-based virtual measurement, and automated inspection systems, enabling faster and more accurate quality assurance processes. These innovations are particularly attractive to international buyers from regions such as Africa, South America, the Middle East, and Europe, who seek cost-effective yet high-quality solutions. Countries like Vietnam and Colombia are rapidly expanding their manufacturing capacities, leveraging local expertise and lower production costs to serve global markets.

Market dynamics are also influenced by geopolitical shifts and trade policies, prompting buyers to diversify sourcing strategies. For instance, African and South American companies increasingly seek reliable suppliers with proven technological capabilities to meet stringent standards. Meanwhile, European and Middle Eastern firms focus on sustainable, certified manufacturing practices to enhance brand reputation and comply with evolving environmental regulations.

International B2B buyers should prioritize establishing partnerships with suppliers that demonstrate technological innovation, quality assurance, and adaptability to evolving standards. Emphasizing flexible sourcing options, such as near-shore or on-demand manufacturing, can mitigate supply chain disruptions and optimize lead times. Staying abreast of technological advancements and regional regulatory changes will be crucial for maintaining competitiveness in this rapidly evolving sector.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a central criterion in sourcing surface GD&T solutions, driven by increasing environmental awareness and stricter regulatory frameworks worldwide. For international buyers, integrating environmentally responsible practices into their supply chains not only aligns with global standards but also enhances corporate reputation and market access.

Green certifications such as ISO 14001 (Environmental Management Systems) or LEED (Leadership in Energy and Environmental Design) are gaining recognition among suppliers, signaling a commitment to reducing ecological footprints. Materials used in manufacturing, including corrosion-resistant coatings, environmentally friendly lubricants, and recyclable substrates, are also under scrutiny, with buyers favoring suppliers who prioritize sustainable material sourcing.

Ethical sourcing extends beyond environmental concerns to include labor practices, supply chain transparency, and fair trade principles. Buyers should verify that suppliers adhere to ethical labor standards, avoid conflict minerals, and maintain traceability in their supply chains. Certifications like SA8000 and Fair Trade can serve as indicators of compliance.

For companies in regions like Africa, South America, the Middle East, and Europe, establishing partnerships with suppliers committed to sustainability can open access to premium markets and reduce regulatory risks. Embracing green procurement practices, investing in eco-friendly technologies, and demanding transparency will be vital strategies. These efforts not only meet customer expectations but also contribute to long-term cost savings through resource efficiency and waste reduction.

Brief Evolution/History (Optional)

The development of GD&T, particularly the profile of a surface, has evolved significantly since its formalization in the ASME Y14.5 standard in the mid-20th century. Originally aimed at improving manufacturing precision and interchangeability, the standards have progressively incorporated digital measurement techniques and stricter quality controls.

This evolution reflects the increasing complexity of engineered surfaces, especially in aerospace and automotive industries, where tolerances are critical for safety and performance. Over time, the integration of GD&T into CAD/CAM systems has enhanced design-manufacture collaboration, reducing lead times and rework.

For B2B buyers, understanding this history underscores the importance of partnering with suppliers who utilize modern, standardized methods. It also highlights the continuous need for upgrading inspection capabilities and staff training to keep pace with technological advancements, ensuring consistent quality and compliance across international supply chains.

Frequently Asked Questions (FAQs) for B2B Buyers of profile of a surface gd&t

1. How can I effectively vet suppliers for surface profile GD&T capabilities in international markets?

To ensure supplier competence, verify their experience with GD&T, especially the profile of a surface. Request certifications like ISO 9001 or ASME Y14.5 compliance proofs. Review their past project references and quality records, focusing on complex surface manufacturing. Conduct virtual audits or site visits if feasible, or leverage third-party inspection services. Ask for detailed process documentation and calibration certificates of measurement equipment. Establish clear communication channels to assess technical understanding. This proactive vetting minimizes risks of misinterpretation and ensures suppliers can meet your precise surface profile requirements.

2. What should I consider when requesting customization or specific tolerances for surface profiles?

Clearly define your functional and aesthetic requirements upfront, specifying the allowable tolerance zones for the surface profile. Share detailed CAD models and drawings, emphasizing critical surface areas. Confirm whether the supplier can achieve the tightness of tolerance needed, considering their fabrication and measurement capabilities. Discuss potential trade-offs between tighter tolerances and manufacturing lead times or costs. Request samples or prototypes for validation before full production. Establish a transparent revision process to adjust tolerances if initial outputs do not meet specifications, ensuring your product’s performance and quality are maintained.

3. What are typical minimum order quantities (MOQs), lead times, and payment terms for surface GD&T services from international suppliers?

MOQs for surface profile GD&T services vary depending on the supplier’s capacity, often ranging from small batch runs (50-100 units) to large series production. Lead times generally span from 2 to 8 weeks, influenced by complexity, volume, and manufacturing processes involved. Payment terms commonly include 30% upfront with the balance upon delivery, though some suppliers may offer letters of credit or escrow arrangements for high-value orders. Negotiate flexible terms upfront, especially for prototypes or smaller runs, and clarify costs for expedited production to align with your project schedules.

4. How can I ensure quality assurance and certification compliance for surface profile measurements across borders?

Request detailed quality assurance protocols, including calibration certificates for measuring instruments and traceability to national standards. Suppliers should provide inspection reports, including GD&T compliance certificates aligned with ASME or ISO standards. Consider third-party inspection agencies for independent verification, especially for critical components. Use digital documentation like measurement reports and 3D scan data for transparent validation. Establish clear acceptance criteria in your purchase agreement. Regular audits and ongoing communication on quality metrics help maintain consistent standards and reduce risks of non-compliance during international transactions.

5. What logistical challenges should I anticipate when sourcing surface GD&T services internationally, and how can I mitigate them?

International logistics may involve customs delays, shipping damages, or variable transit times, especially for sensitive measurement equipment or prototypes. Choose suppliers experienced in global freight and ensure proper packaging to protect delicate surfaces. Use reliable carriers with tracking and insurance options. Coordinate with customs brokers to streamline clearance processes and avoid delays. Build buffer times into your project schedules and consider local inspection or warehousing options if feasible. Establish clear communication channels for real-time updates on shipment status, reducing uncertainties and ensuring timely delivery.

6. How should I handle disputes related to surface profile quality or measurement discrepancies with international suppliers?

Draft clear contractual clauses outlining quality standards, inspection procedures, and dispute resolution methods such as arbitration or mediation under internationally recognized frameworks (e.g., ICC). Maintain comprehensive documentation of all communications, inspection reports, and measurement data as evidence. Engage third-party inspectors promptly if discrepancies arise, and compare results against agreed specifications. Foster open dialogue to understand root causes and negotiate corrective actions, such as rework or replacements. Implement a proactive quality management approach to resolve issues swiftly, minimizing project delays and safeguarding your reputation in cross-border trade.

7. What are best practices for integrating supplier measurement data into my quality management system?

Require suppliers to provide detailed measurement reports, including GD&T conformance certificates, preferably in digital formats compatible with your QA system. Use standardized data formats like STEP or IGES files with embedded inspection results for seamless integration. Establish a protocol for data verification, cross-referencing supplier reports with your internal standards. Implement periodic audits to validate measurement accuracy and calibration status. Automate data collection where possible to facilitate trend analysis, ensuring continuous quality improvement. Clear data exchange procedures reduce errors and streamline compliance verification across international supply chains.

8. How can I stay updated on evolving standards and best practices for surface GD&T in international trade?

Subscribe to industry newsletters, attend global trade shows, and participate in technical seminars focused on GD&T and precision manufacturing. Engage with professional organizations like ASME or ISO committees to access updated standards and guidelines. Collaborate with local technical consultants or certification bodies familiar with regional compliance nuances. Leverage online courses and webinars to deepen your understanding of international standards. Building a network of industry peers and experts enables proactive adaptation to technological advances and regulatory changes, ensuring your sourcing strategies remain compliant, competitive, and aligned with best practices globally.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for profile of a surface gd&t

Conclusion and Future Outlook

Effective strategic sourcing of surface GD&T profile expertise is essential for international buyers seeking precision, consistency, and innovation in complex manufacturing. By partnering with experienced suppliers, buyers can access advanced measurement techniques, align manufacturing tolerances with design intent, and ensure high-quality outcomes across diverse industries such as aerospace, automotive, and consumer products. This approach minimizes costly rework and enhances product reliability, ultimately strengthening supply chain resilience.

Looking ahead, the demand for sophisticated surface control techniques will continue to grow, driven by the increasing complexity of product designs and stricter quality standards worldwide. Buyers from Africa, South America, the Middle East, and Europe should prioritize developing long-term relationships with trusted suppliers who leverage advanced GD&T capabilities. Embracing digital tools, such as virtual inspections and real-time quality monitoring, will further optimize sourcing strategies.

To capitalize on these opportunities, international B2B buyers are encouraged to proactively evaluate supplier competencies, invest in ongoing training, and foster collaborative innovation. By doing so, they can secure a competitive edge in delivering precision-engineered products that meet global standards and customer expectations.