Introduction: Navigating the Global Market for cnc mechanic

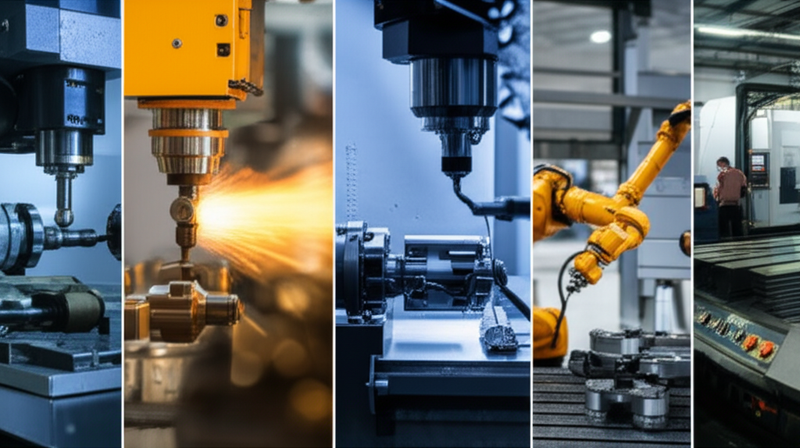

In today’s interconnected manufacturing landscape, the role of a skilled CNC mechanic is more vital than ever. These specialists are the backbone of precision machining, ensuring that complex components meet exacting specifications across industries such as aerospace, automotive, electronics, and industrial machinery. For international B2B buyers—from Africa, South America, the Middle East, and Europe—accessing top-tier CNC machining services can significantly influence product quality, time-to-market, and overall competitiveness.

This comprehensive guide is designed to equip procurement professionals with the essential insights needed to navigate the global CNC machining market confidently. It covers a broad spectrum of topics, including the different types of CNC machined parts—such as milled, turned, drilled, and multi-axis components—and their key applications. Additionally, it explores critical material options, manufacturing workflows, and quality standards to help buyers select suppliers who consistently deliver high-quality results.

Furthermore, the guide offers strategic advice on evaluating and sourcing suppliers across regions, understanding market dynamics, and managing costs effectively. With actionable checklists, FAQs, and best practices, this resource empowers international buyers to make informed decisions, mitigate risks, and establish reliable partnerships. Whether sourcing from emerging markets or established hubs like Spain or Turkey, this guide ensures you are equipped to optimize your CNC machining procurement process and secure competitive advantage in the global marketplace.

Understanding cnc mechanic Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| CNC Milling Mechanic | Utilizes multi-axis milling tools for complex geometries; supports high precision and surface finish | Aerospace components, automotive housings, custom enclosures | Offers design flexibility and high accuracy; however, it can be costly for intricate parts and may have longer lead times |

| CNC Turning Mechanic | Operates on lathes with rotational symmetry; excels at producing cylindrical parts | Shafts, pins, bushings, connectors | Cost-effective for round parts, fast production; limited in producing complex shapes outside cylindrical geometries |

| CNC Drilling & Tapping Mechanic | Specializes in creating precise holes and threads; often integrated with other machining processes | Mounting brackets, flanges, connectors | Ensures high positional accuracy; suitable for parts requiring threaded features but less effective for complex 3D shapes |

| Multi-Axis CNC Mechanic | Uses 4 or 5 axes for simultaneous multi-directional machining; enables intricate features in one setup | Medical devices, impellers, aerospace parts | Reduces assembly needs and lead times; requires specialized programming and higher investment, suitable for complex geometries |

| CNC Plastic Mechanic | Machined from engineered plastics; lightweight and corrosion-resistant | Electronics housings, prototypes, medical devices | Cost-effective and easy to machine; lower strength and thermal resistance compared to metals, suitable for non-structural applications |

CNC Milling Mechanic

CNC milling mechanics are distinguished by their ability to produce complex, high-precision parts through multi-axis cutting. They are especially suitable for manufacturing intricate enclosures, brackets, and engine covers. These mechanics support detailed surface finishes and tight tolerances, making them ideal for industries like aerospace and automotive where precision is critical. B2B buyers should evaluate supplier capabilities in handling complex geometries, request samples, and consider lead times and costs associated with high-precision milling. They are suitable for custom, small-batch, or high-value components, but may require higher investment for complex designs.

CNC Turning Mechanic

CNC turning mechanics are optimized for producing symmetrical, cylindrical parts such as shafts, pins, and bushings. They excel in high-volume production due to their speed and material efficiency. These mechanics are generally more cost-effective for simple geometries and are widely used in automotive, machinery, and industrial sectors. B2B buyers should focus on supplier expertise in handling specific materials and tolerances, and inquire about post-machining finishing processes like grinding or polishing. They are less suitable for complex or non-cylindrical parts but are excellent for standardized, round components.

CNC Drilling & Tapping Mechanic

This type specializes in creating precise holes, slots, and threaded features, often integrated with other machining operations. It is ideal for producing mounting plates, flanges, and connector bases that require accurate hole positioning and threading. These mechanics are valued for their high accuracy and repeatability, making them suitable for assembly-critical parts. B2B buyers should verify the supplier’s capability to meet specific tolerances and thread standards, and assess whether additional finishing or heat treatment is needed. They are less suited for producing complex 3D geometries but excel in producing precise, feature-rich components.

Multi-Axis CNC Mechanic

Multi-axis CNC mechanics leverage 4 or 5 axes for simultaneous machining, enabling the creation of complex geometries and features in a single setup. They are highly suitable for producing impellers, medical implants, and aerospace components that require intricate contours and angles. These mechanics significantly reduce assembly time and improve accuracy, making them attractive for high-value, complex parts. B2B buyers should consider the supplier’s programming expertise and equipment investment, ensuring they can handle their specific design requirements. They are ideal for parts that demand high precision and complex features but involve higher costs.

CNC Plastic Mechanic

CNC machining of plastics offers a lightweight, corrosion-resistant alternative to metals, suitable for prototypes, electronic housings, and medical devices. These mechanics can produce detailed features with good surface quality and tight tolerances. They are cost-effective for low to medium-volume production and are often used in industries where chemical resistance or weight savings are priorities. B2B buyers should evaluate the mechanical properties of the selected plastics and their suitability for the intended application, considering factors like thermal stability and load-bearing capacity. They are less appropriate for structural or high-temperature applications but excel in rapid prototyping and lightweight components.

Related Video: What are Transformer Models and how do they work?

Key Industrial Applications of cnc mechanic

| Industry/Sector | Specific Application of CNC Mechanic | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Aerospace | Precision manufacturing of turbine blades and structural components | Ensures high tolerance, lightweight parts, and complex geometries | Material quality, certification standards (e.g., AS9100), supplier expertise in aerospace-grade materials |

| Automotive | Production of engine blocks, transmission components, and custom fixtures | High-volume, consistent parts with tight tolerances, reducing assembly time | Capabilities for high-volume runs, surface finish quality, scalability, and compliance with automotive standards |

| Medical Devices | Fabrication of surgical instruments, prosthetics, and implants | High precision, biocompatible materials, and complex geometries | Cleanroom certifications, material safety standards, and ability to produce small, intricate parts |

| Electronics & Tech | Manufacturing of enclosures, heat sinks, and connectors | Precise fit for electronic components, lightweight, and thermal management | Material selection (e.g., plastics, aluminum), surface finishing, and supplier flexibility for prototyping and small batches |

| Industrial Machinery | Custom machine parts, gear components, and tooling fixtures | Durability, high accuracy, and ability to produce complex, custom designs | Ability to handle diverse materials, lead times, and capacity for large or complex parts |

Aerospace

CNC mechanics play a critical role in aerospace manufacturing, where they produce turbine blades, structural brackets, and aerodynamic components with extreme precision. These parts demand high-quality alloys and must meet rigorous standards such as AS9100 for safety and reliability. For international B2B buyers, sourcing from regions with advanced CNC capabilities ensures compliance and consistency, reducing costly rework or failures. Suppliers must demonstrate certification, material traceability, and experience in aerospace-grade production to mitigate risk.

Automotive

In the automotive sector, CNC mechanics are essential for fabricating engine blocks, transmission parts, and custom fixtures. They enable high-volume, repeatable production with tight tolerances, crucial for assembly line efficiency. Buyers from Africa, South America, or Europe should prioritize suppliers with proven capacity for mass manufacturing, quality control, and adherence to automotive standards like IATF 16949. Consistent quality and reliable delivery are vital to maintain production schedules and reduce downtime.

Medical Devices

CNC machining is indispensable in medical device manufacturing, especially for surgical instruments, prosthetics, and implants requiring complex geometries and biocompatible materials. The precision and surface finish achieved through CNC mechanics directly impact device performance and safety. International buyers must ensure suppliers comply with stringent standards such as ISO 13485 and possess cleanroom facilities if necessary. Material sourcing should emphasize biocompatibility and sterilization compatibility, with a focus on traceability and regulatory adherence.

Electronics & Tech

CNC mechanics facilitate the production of electronic enclosures, heat sinks, connectors, and other components that demand tight tolerances and high-quality finishes. These parts support the miniaturization and thermal management needs of modern electronics. Buyers from regions like Turkey, Spain, or South America should seek suppliers capable of rapid prototyping and small batch runs, with expertise in working with plastics, aluminum, or composite materials. Surface treatment and finishing options are also critical to ensure durability and aesthetic quality.

Industrial Machinery

Manufacturing of custom machine parts, gear components, and tooling fixtures relies heavily on CNC mechanics for durability and precision. These parts often operate under harsh conditions, requiring high-strength materials and exact tolerances. Sourcing from regions with established industrial manufacturing hubs enables access to a wide range of materials and complex geometries. Buyers should evaluate supplier capacity for large or intricate parts, lead times, and their ability to adapt to design modifications during ongoing production cycles.

Related Video: What is CNC Machining and How Does it Work?

Strategic Material Selection Guide for cnc mechanic

Analysis of Common Materials for CNC Mechanics

Selecting the appropriate material for CNC mechanical components is critical for ensuring performance, durability, and cost-efficiency. For international B2B buyers from regions such as Africa, South America, the Middle East, and Europe, understanding the key properties and regional considerations of these materials is essential for making informed sourcing decisions.

Aluminum Alloys are among the most popular materials in CNC machining due to their excellent machinability and lightweight nature. The 6061 and 7075 aluminum alloys are widely used for mechanical parts requiring strength and corrosion resistance. Aluminum offers good thermal conductivity and is suitable for applications exposed to moderate environmental conditions. Its relatively low cost and ease of machining make it attractive for high-volume production. However, aluminum can be susceptible to wear under heavy loads and may deform at high temperatures, which limits its use in high-heat environments. For international buyers, compliance with standards such as ASTM B209 or EN 573 is common, and sourcing from regions with established aluminum industries (e.g., Europe, Turkey) can ensure quality.

Carbon Steel, such as AISI 1045 or 4140, is valued for its strength, toughness, and affordability. It performs well under mechanical stress and is often used in structural components, shafts, and fasteners. Its high durability makes it suitable for heavy-duty applications, but it is prone to corrosion if not properly protected through coating or treatment. For buyers in regions with limited access to high-quality surface finishing (e.g., some African or South American markets), additional surface treatment costs should be considered. Carbon steel generally complies with standards like ASTM A36 or DIN 17100, and sourcing from Europe or Turkey can provide access to certified suppliers adhering to these standards.

Stainless Steel, particularly grades like 304 and 316, offers excellent corrosion resistance, high strength, and good thermal stability. These properties make stainless steel ideal for components exposed to harsh environments, such as marine or chemical industries. Its high machinability and ability to withstand extreme temperatures are advantageous for precision parts. However, stainless steel is more expensive and harder to machine compared to aluminum or carbon steel, which can impact overall project costs. Buyers should verify compliance with standards like ASTM A240 or EN 10088, and sourcing from regions with mature stainless steel industries (e.g., Europe, Turkey) can facilitate quality assurance.

Engineering Plastics, such as PEEK, PTFE, and Nylon, are increasingly used in CNC machining for lightweight, corrosion-resistant, and electrically insulating parts. PEEK, in particular, offers high-temperature resistance and mechanical strength suitable for demanding applications like medical devices or aerospace components. Plastics are generally easier and faster to machine, reducing production costs, but they typically have lower load-bearing capacity and thermal stability compared to metals. For international buyers, ensuring material certifications (e.g., RoHS, REACH compliance) is vital, especially when sourcing from regions with strict regulatory environments like Europe or the Middle East.

Summary Table

| Material | Typical Use Case for CNC Mechanic | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Aluminum Alloys (e.g., 6061, 7075) | Lightweight structural parts, enclosures, brackets | Excellent machinability, corrosion resistance, lightweight | Lower strength compared to steel, susceptible to deformation at high temps | Low to Medium |

| Carbon Steel (e.g., AISI 1045, 4140) | Shafts, fasteners, structural components | High strength, cost-effective, durable | Prone to corrosion if untreated, heavier | Low |

| Stainless Steel (e.g., 304, 316) | Marine, chemical, medical parts | Corrosion resistance, high strength, temperature stability | Higher cost, more difficult to machine | High |

| Engineering Plastics (e.g., PEEK, PTFE, Nylon) | Insulating components, medical devices, lightweight parts | Corrosion resistance, electrical insulation, lightweight | Lower mechanical strength, thermal limits | Medium to High |

This comprehensive understanding of material properties and regional considerations enables international buyers to select the most suitable materials for their CNC mechanical components, balancing performance, cost, and compliance requirements across diverse markets.

In-depth Look: Manufacturing Processes and Quality Assurance for cnc mechanic

Manufacturing Processes for CNC Mechanics

Manufacturing CNC mechanical components involves a series of precise, methodical stages designed to ensure high-quality output tailored to client specifications. The process begins with material preparation, where raw materials—typically metals such as aluminum, steel, or alloys—are selected based on performance requirements. Suppliers often source materials certified to international standards (e.g., ASTM, EN) to ensure consistency and traceability.

Following material procurement, the forming stage involves machining operations, which can include milling, turning, drilling, tapping, or multi-axis machining. Advanced CNC machines equipped with multi-axis capabilities enable complex geometries in a single setup, reducing errors and production time. Key techniques during this stage include high-speed cutting, precision tool paths, and adaptive machining to optimize material removal rates while maintaining tight tolerances.

Once the parts are machined to near-net shape, they undergo assembly, if applicable. Assembly might involve joining multiple machined components via fasteners, welding, or adhesive bonding. For CNC mechanics, especially those used in critical applications like aerospace or automotive, assembly processes are often tightly controlled to prevent dimensional deviations and ensure functional integrity.

The finishing stage encompasses processes such as deburring, polishing, surface treatments, and coating applications (e.g., anodizing, plating). These steps enhance surface quality, corrosion resistance, and aesthetic appeal. For high-precision applications, additional treatments like laser marking or protective coatings are often applied to meet specific industry standards.

Throughout manufacturing, automation and digital controls are employed to improve repeatability and accuracy. Modern CNC facilities leverage CAD/CAM integration, real-time monitoring, and predictive maintenance to minimize downtime and defects. This results in highly consistent components that meet the stringent demands of international markets.

Quality Control (QC) in CNC Manufacturing

Effective quality assurance is fundamental to delivering reliable CNC components, especially in the context of international B2B transactions. The cornerstone of quality management systems in CNC manufacturing is compliance with recognized standards such as ISO 9001, which emphasizes process consistency, documentation, and continuous improvement. For aerospace and defense sectors, AS9100 certification is often required, reflecting stringent control over design, manufacturing, and testing processes.

QC checkpoints are embedded at various stages of production:

-

Incoming Quality Control (IQC): Raw materials and initial components are inspected upon receipt. Suppliers must provide material test reports (MTRs), certificates of compliance, and sometimes third-party verification to confirm material integrity and traceability.

-

In-Process Quality Control (IPQC): During machining, real-time monitoring ensures dimensional accuracy, surface finish, and process stability. Techniques include coordinate measuring machines (CMM), laser scanners, and optical comparators to verify critical features against CAD specifications.

-

Final Quality Control (FQC): The finished component undergoes comprehensive inspection before shipment. This includes dimensional verification, surface integrity checks, and functional testing where applicable. For critical parts, non-destructive testing (NDT) methods such as ultrasonic, dye penetrant, or X-ray inspection are employed to detect internal flaws.

Common testing methods used in CNC component QC include:

- Dimensional inspection: Using CMMs or 3D scanners to verify tolerances.

- Surface finish testing: Employing profilometers to assess roughness levels.

- Material testing: Conducting hardness tests, tensile testing, or chemical analysis to confirm material properties.

- Functional testing: For assembled parts, testing for fit, movement, or operational performance.

Certifications and documentation are critical for international buyers. Suppliers should provide detailed inspection reports, calibration certificates for measurement equipment, and compliance certificates aligned with industry standards (e.g., CE marking for European markets, API certifications for oil & gas).

Verifying Supplier Quality for International B2B Buyers

Global buyers, especially from Africa, South America, the Middle East, and Europe, must adopt robust verification strategies to ensure supplier reliability. Pre-qualification audits are essential, where buyers or third-party inspectors evaluate the supplier’s manufacturing environment, equipment, personnel expertise, and quality management systems. These audits help identify potential risks and confirm adherence to required standards.

Requesting comprehensive quality documentation is vital. This includes ISO 9001 certificates, process control records, inspection reports, and test certificates. Buyers should review these documents meticulously to verify compliance with contractual and regulatory requirements.

Third-party inspection agencies such as SGS, Bureau Veritas, or TÜV can conduct independent audits and product inspections. These inspections can be scheduled at different production stages or before shipment to confirm that parts meet specified standards and tolerances.

Factory audits also provide insight into the supplier’s capacity, workflow efficiency, and quality culture. For buyers in regions with developing manufacturing infrastructure, working with certified suppliers with proven quality management systems mitigates risks of non-conformance and delays.

Sample testing and pilot runs are recommended before large-volume orders. These samples should undergo the same QC procedures as full production parts, allowing buyers to verify dimensions, surface quality, and functionality.

Special Considerations for Regional Buyers

Buyers from regions like Africa, South America, the Middle East, and Europe face unique challenges and opportunities in quality assurance. In emerging markets, suppliers may lack certain certifications or advanced testing facilities. Therefore, establishing clear quality expectations upfront, and possibly investing in third-party inspections, becomes crucial.

European buyers are often accustomed to stringent standards such as CE, RoHS, and REACH compliance, necessitating suppliers with relevant certifications and documented QC processes. Conversely, buyers from regions like Turkey or Spain may have access to well-established manufacturing hubs with advanced certifications, easing compliance burdens.

Buyers from Africa or South America should prioritize suppliers with proven export experience, robust QC documentation, and the ability to provide detailed inspection reports. Developing strong communication channels and conducting periodic audits can foster transparency and continuous quality improvement.

In conclusion, meticulous manufacturing and rigorous quality assurance are non-negotiable for international B2B buyers sourcing CNC mechanics. Understanding each stage of production, verifying supplier certifications, and employing third-party inspections are vital steps to ensure that components meet global standards, perform reliably, and uphold your company’s reputation across borders.

Related Video: The World’s Largest Bevel Gear CNC Machine- Modern Gear Production Line. Steel Wheel Manufacturing

Comprehensive Cost and Pricing Analysis for cnc mechanic Sourcing

Cost Components in Sourcing CNC Mechanics

Understanding the comprehensive cost structure is vital for effective budgeting and negotiations. The primary components include:

-

Materials: The choice of raw materials—such as steel, aluminum, plastics, or composites—significantly influences costs. High-performance or specialty materials like titanium or carbon-fiber composites command premium prices. Material costs are also affected by global supply dynamics and regional availability.

-

Labor: Skilled CNC mechanics and operators are essential for precision machining, especially for complex or customized parts. Labor costs vary widely based on regional wage levels, with European and Middle Eastern countries generally having higher rates compared to some African or South American regions.

-

Manufacturing Overheads: These encompass machine depreciation, maintenance, energy consumption, and facility costs. Advanced CNC equipment, multi-axis machines, or automation systems increase overhead but also improve efficiency and quality.

-

Tooling and Fixtures: Custom tooling, jigs, and fixtures are often necessary for complex parts. While initial tooling costs can be significant, they reduce cycle times and improve repeatability, offering long-term cost savings.

-

Quality Control (QC): Rigorous inspection processes—including 3D measurement, surface finish testing, and certification compliance—add to the overall cost. Suppliers with ISO or industry-specific certifications may have higher QC expenses but offer greater assurance of quality.

-

Logistics and Shipping: International sourcing entails freight costs, customs duties, tariffs, and insurance. Shipping methods (air vs. sea) influence costs and lead times, with air freight being faster but more expensive.

-

Profit Margin: Suppliers embed their profit margins into the final price, which can vary based on market competition, supplier reputation, and order volume.

Price Influencers and Market Dynamics

Several factors can sway the final price:

-

Order Volume and MOQ: Larger quantities typically enable suppliers to offer discounts due to economies of scale. Buyers from regions like Africa or South America should aim to consolidate orders to maximize cost savings.

-

Specifications and Customization: Highly complex, tight-tolerance, or customized parts require more setup time, specialized tooling, and expertise, elevating costs. Clear specifications and detailed drawings reduce misunderstandings and cost overruns.

-

Material Selection: Premium materials increase costs but may be necessary for critical applications. Regional material costs and availability can also impact pricing, especially in areas with limited supply chains.

-

Quality Certifications: Suppliers with ISO 9001, AS9100, or industry-specific certifications often incur higher QC costs but provide higher assurance, reducing risks of defects and delays.

-

Supplier Factors: Experienced, reputable suppliers with advanced machinery tend to charge higher prices but offer better quality, consistency, and shorter lead times. Conversely, emerging or smaller suppliers may be more price-competitive but require thorough vetting.

-

Incoterms and Logistics: Shipping terms (e.g., FOB, CIF, DDP) influence who bears transportation and customs costs. Buyers should negotiate to include or exclude certain costs based on their logistical capabilities and regional import duties.

Buyer Tips for Cost Optimization

-

Negotiate Effectively: Leverage volume discounts, long-term partnerships, and flexible payment terms. Discuss bundled services such as design assistance or post-machining finishing to reduce overall costs.

-

Focus on Total Cost of Ownership (TCO): Consider not just unit price but also lead times, defect rates, rework costs, and logistical expenses. Sometimes paying a premium for higher quality can lower total costs over the product lifecycle.

-

Optimize Specifications: Provide precise, comprehensive drawings and specifications to prevent costly revisions and rework. Avoid over-engineering; balance quality with cost-efficiency.

-

Understand Pricing Nuances: International buyers should be aware of regional pricing trends, currency fluctuations, and geopolitical influences. For example, Turkish or Spanish suppliers may have different pricing structures compared to suppliers in South America or African regions.

-

Plan for Lead Times and Customs: Longer lead times or customs clearance can incur additional costs. Building buffer periods into schedules and understanding regional import regulations can mitigate unexpected expenses.

Disclaimer

Indicative prices for CNC mechanic services vary depending on complexity, volume, and region. As a rough guide, simple CNC machined parts can range from $20 to $100 per unit for small batches, while high-precision or complex components may exceed $200 per piece at low volumes. Bulk orders or long-term partnerships often attract better rates. Always request detailed quotes and conduct due diligence to validate pricing assumptions.

By comprehensively analyzing these cost components and influencing factors, international B2B buyers can make informed decisions, negotiate effectively, and achieve optimal value in sourcing CNC mechanics across diverse regions.

Spotlight on Potential cnc mechanic Manufacturers and Suppliers

This section looks at several manufacturers active in the ‘cnc mechanic’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct extensive due diligence before any transaction. Information is synthesized from public sources and general industry knowledge.

Essential Technical Properties and Trade Terminology for cnc mechanic

Critical Technical Properties for CNC Mechanics

1. Material Grade and Composition

Material selection is fundamental in CNC machining, impacting durability, weight, corrosion resistance, and cost. For example, high-grade stainless steels (such as 304 or 316) are preferred for corrosion resistance in medical or marine environments, while aluminum alloys (like 6061 or 7075) are favored for lightweight aerospace components. Buyers should specify the exact grade to ensure suppliers meet performance expectations. Understanding material standards helps prevent issues like deformation, wear, or failure during operation.

2. Tolerance Levels

Tolerance defines the permissible deviation from specified dimensions, directly influencing fit, function, and quality. Common tolerances in CNC machining range from ±0.01mm for high-precision parts to ±0.1mm for less critical components. Precise tolerances are essential for applications like aerospace or medical devices, where even tiny discrepancies can cause assembly or safety issues. Clear tolerance specifications ensure that suppliers deliver parts that meet your functional and quality standards.

3. Surface Finish

Surface finish affects both the aesthetics and performance of machined parts, especially in applications requiring minimal friction or corrosion resistance. Finishes are measured in Ra (roughness average), with common levels from 0.8μm (highly smooth) to 3.2μm (standard). For instance, medical implants require very smooth surfaces to prevent bacterial adhesion, while structural parts may tolerate rougher finishes. Specifying finish requirements upfront helps avoid rework, delays, and additional costs.

4. Production Volume and Lead Time

Understanding expected production quantities and delivery timelines is critical for planning and cost control. Small batch or prototype runs may require different setups compared to mass production, affecting costs and lead times. Clear communication ensures suppliers allocate resources effectively, avoiding bottlenecks. Accurate lead time estimates support just-in-time inventory strategies and project scheduling.

5. Material Compatibility and Post-Processing Needs

Some components require specific materials compatible with subsequent processes like welding, coating, or assembly. Additionally, parts may need secondary finishing such as anodizing, plating, or polishing. Confirming these requirements early ensures suppliers can accommodate them without compromising quality or schedule. This proactive approach reduces risk of delays and additional costs.

Common Trade and Industry Terms for CNC Mechanics

1. OEM (Original Equipment Manufacturer)

Refers to the company that designs and produces the original parts for a product. In CNC machining, OEM specifications often dictate strict quality and dimensional standards. Understanding whether a supplier is an OEM or a subcontractor helps assess their capacity to meet original design intent and compliance.

2. MOQ (Minimum Order Quantity)

The smallest quantity of parts a supplier is willing to produce in a single batch. MOQs can significantly influence procurement costs, especially for low-volume or prototype orders. Negotiating MOQ is essential for cost-effective sourcing, particularly in regions where suppliers prefer larger runs.

3. RFQ (Request for Quotation)

A formal process where buyers solicit price and lead time estimates from multiple suppliers. An RFQ includes detailed drawings, material specs, tolerances, and quantities. Effectively managing RFQs ensures competitive pricing and clarity on supplier capabilities before committing.

4. Incoterms (International Commercial Terms)

Standardized trade terms published by the ICC that define responsibilities for shipping, insurance, and customs. Common Incoterms like FOB (Free on Board) or CIF (Cost, Insurance, and Freight) clarify who bears costs and risks at each stage of transportation. Knowledge of Incoterms helps international buyers negotiate better logistics terms and avoid surprises.

5. CPK (Capability Index)

A statistical measure of a manufacturing process’s ability to produce within specified tolerances. A higher CPK (above 1.33) indicates consistent quality and process stability. Monitoring CPK values ensures suppliers maintain quality levels, reducing defects and rework.

6. First Article Inspection (FAI)

A detailed examination of the initial production run to verify that parts conform to design specifications before full-scale manufacturing. FAI is a critical step for high-precision or safety-critical components, providing assurance of quality compliance.

By understanding these key properties and terms, international B2B buyers from Africa, South America, the Middle East, and Europe can make more informed sourcing decisions. Clear specifications, effective communication, and familiarity with trade terminology help mitigate risks, optimize costs, and ensure the delivery of high-quality CNC machined parts aligned with their project needs.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the cnc mechanic Sector

Market Overview & Key Trends

The global CNC mechanic sector is experiencing robust growth driven by technological advancements, increasing demand across industries, and evolving sourcing strategies. Key drivers include the rapid expansion of aerospace, automotive, medical devices, and electronics sectors, which require high-precision, complex components. Emerging trends such as automation, Industry 4.0 integration, and digital manufacturing platforms are transforming sourcing approaches, enabling buyers from Africa, South America, the Middle East, and Europe to access a broader range of suppliers with enhanced capabilities.

For international B2B buyers, understanding regional market dynamics is crucial. Countries like Turkey and Spain are notable for their advanced manufacturing infrastructure and quality standards, making them attractive sourcing hubs within Europe. In contrast, emerging markets in Africa and South America are increasingly investing in CNC technology, often offering competitive costs and niche expertise. The rise of online platforms and digital marketplaces simplifies supplier discovery, quotation, and communication, reducing lead times and fostering transparency.

Supply chain resilience remains a top concern, especially amidst geopolitical uncertainties, fluctuating tariffs, and logistics disruptions. Buyers are now prioritizing suppliers with proven quality certifications, flexible production capacities, and sustainable practices. Additionally, the adoption of automation and AI-driven quality control enhances consistency, enabling buyers to meet stringent industry standards more reliably. As the sector continues to evolve, those who leverage technological integration and regional sourcing intelligence will gain competitive advantages in cost, quality, and delivery.

Sustainability & Ethical Sourcing in B2B

Sustainability has become a pivotal criterion in B2B sourcing within the CNC mechanic sector. Environmental impacts from manufacturing processes—such as energy consumption, waste generation, and material sourcing—are under increasing scrutiny. Buyers from Africa, South America, the Middle East, and Europe are actively seeking suppliers that demonstrate a commitment to reducing their carbon footprint through greener practices.

Implementing ethical sourcing standards is vital for building resilient supply chains. This includes verifying suppliers’ adherence to fair labor practices, safe working conditions, and responsible resource extraction. Certifications like ISO 14001 (Environmental Management) and ISO 26000 (Social Responsibility) serve as benchmarks for suppliers committed to sustainability. Additionally, the adoption of eco-friendly materials—such as recycled metals, biodegradable plastics, and low-impact coatings—can significantly reduce environmental footprints.

The push for ‘green’ certifications and materials not only aligns with global environmental goals but also offers competitive advantages. Certified sustainable CNC machining suppliers can command higher trust and often access preferential trade terms. Moreover, consumers and regulatory bodies in Europe and increasingly in other regions are demanding transparency around sourcing practices. By integrating sustainability into procurement strategies, international buyers from emerging markets and established regions alike can foster more responsible, future-proof supply chains that meet both regulatory standards and consumer expectations.

Brief Evolution/History

The CNC mechanic sector has evolved significantly over the past few decades, transitioning from manual machining to highly automated, digitally integrated processes. In the 1960s and 1970s, CNC technology revolutionized manufacturing by enabling precise, repeatable operations that drastically reduced production times and errors. As technology advanced, the integration of CAD/CAM software, multi-axis machining, and IoT connectivity transformed CNC shops into smart factories.

This evolution has expanded opportunities for international B2B buyers by increasing access to highly specialized, high-quality components across regions. Countries like Turkey and Spain became early adopters of CNC automation, establishing themselves as key hubs within Europe. Meanwhile, emerging markets in South America and Africa are rapidly catching up by investing in modern CNC equipment, driven by local industry growth and government incentives.

Today, the sector continues to evolve with innovations like additive manufacturing integration, AI-powered quality control, and sustainable material development. These advancements enable buyers to procure components that meet complex specifications with greater efficiency, reliability, and environmental responsibility. Understanding this historical progression helps B2B buyers appreciate the technological potential and strategic importance of partnering with forward-looking CNC suppliers worldwide.

Related Video: Global Trade & Logistics – What is Global Trade?

Frequently Asked Questions (FAQs) for B2B Buyers of cnc mechanic

-

How can I effectively vet CNC machining suppliers in international markets like Turkey, Spain, or Brazil?

To ensure supplier reliability, start by reviewing certifications such as ISO 9001 or industry-specific standards like AS9100. Request detailed company profiles, including manufacturing capabilities, quality control processes, and client references. Conduct virtual audits or visit facilities if feasible. Leverage online B2B platforms with verified reviews, and consider engaging third-party inspection services for pre-shipment assessments. Establish clear communication channels to evaluate responsiveness and transparency. Building strong relationships based on due diligence minimizes risks of quality issues, delays, or non-compliance, ensuring a more secure procurement process. -

What are the best practices for customizing CNC machined parts for regional industry standards?

Begin by thoroughly understanding the technical specifications, material preferences, and tolerance requirements prevalent in your target region’s industries. Collaborate with your supplier early in the design phase to incorporate regional standards and regulations, such as CE marking in Europe or local certifications in Africa or South America. Use detailed CAD files and clearly specify surface finishes, material grades, and testing protocols. Regularly communicate with your supplier during prototyping to validate designs and ensure they meet your functional and regulatory needs, reducing costly rework or delays. -

What should I consider regarding minimum order quantities (MOQs), lead times, and payment terms when sourcing internationally?

Negotiate MOQs based on your project size and supplier capacity; many suppliers are flexible for prototype or small batch orders but may have higher MOQs for larger runs. Clarify lead times upfront, accounting for manufacturing, customs clearance, and shipping logistics, and plan accordingly. Payment terms like deposits, letters of credit, or open accounts should reflect your trust level and order size—seek terms that balance supplier security with cash flow needs. Establish clear contractual agreements to avoid misunderstandings, and consider incremental ordering to test supplier performance before committing to large volumes. -

How can I ensure quality assurance and compliance with certifications when sourcing CNC parts globally?

Require suppliers to provide relevant quality certifications, such as ISO 9001, ISO/TS 16949, or industry-specific standards. Insist on detailed inspection reports, material certificates, and process documentation for each batch. Incorporate quality checkpoints at key production stages, and consider third-party inspection or lab testing before shipment. Implement a robust supplier audit process and set clear quality KPIs. Regularly review supplier performance and maintain open communication channels to address issues proactively, ensuring your parts consistently meet regulatory and performance standards. -

What logistics considerations should I prioritize when importing CNC machined parts from regions like the Middle East or South America?

Evaluate the reliability and capacity of freight carriers, considering options like sea, air, or land transport based on urgency and cost. Factor in customs procedures, tariffs, and import duties specific to your country—working with experienced freight forwarders can streamline clearance. Pack parts securely to prevent damage during transit, especially for delicate or precision components. Track shipments closely and establish contingency plans for delays. Collaborate with logistics providers familiar with regional regulations to optimize delivery times and reduce unforeseen costs, ensuring a smooth supply chain. -

How should I handle disputes or quality issues with international CNC machining suppliers?

Establish clear contractual terms covering quality standards, inspection rights, and dispute resolution mechanisms before order placement. In case of issues, document discrepancies with detailed photos, inspection reports, and communication records. Engage in direct dialogue with the supplier to seek resolution—many issues can be resolved through corrective actions or partial refunds. If disputes persist, consider mediation or arbitration in a neutral jurisdiction. Maintaining good supplier relationships and transparent communication often leads to quicker resolutions and ongoing trust. -

What are the key factors influencing pricing and total cost when sourcing CNC machined parts internationally?

Pricing is affected by material costs, complexity of design, order volume, and lead times. Additional costs include tooling, setup fees, freight, customs duties, and inspection expenses. Suppliers offering lower unit prices might have higher setup costs or longer lead times, so perform a total cost analysis rather than focusing solely on unit price. Building long-term relationships can lead to better pricing, flexible payment terms, and priority production. Always request detailed quotes and compare not just prices but also service levels, quality assurance, and delivery reliability. -

What actionable steps can I take to mitigate risks when sourcing CNC machining parts internationally?

Diversify your supplier base to avoid dependency on a single source. Conduct comprehensive due diligence, including certifications, references, and site visits if possible. Use clear, detailed specifications and quality agreements to prevent misunderstandings. Incorporate flexible contract terms that include penalties for delays or defects. Regularly monitor supplier performance through audits and feedback. Employ reliable logistics partners and have contingency plans for disruptions. Staying informed about geopolitical developments and currency fluctuations also helps in proactive risk management, ensuring stable and predictable sourcing operations.

Important Disclaimer & Terms of Use

⚠️ Important Disclaimer

The information provided in this guide, including content regarding manufacturers, technical specifications, and market analysis, is for informational and educational purposes only. It does not constitute professional procurement advice, financial advice, or legal advice.

While we have made every effort to ensure the accuracy and timeliness of the information, we are not responsible for any errors, omissions, or outdated information. Market conditions, company details, and technical standards are subject to change.

B2B buyers must conduct their own independent and thorough due diligence before making any purchasing decisions. This includes contacting suppliers directly, verifying certifications, requesting samples, and seeking professional consultation. The risk of relying on any information in this guide is borne solely by the reader.

Strategic Sourcing Conclusion and Outlook for cnc mechanic

Strategic Sourcing Conclusion and Outlook for CNC Mechanics

Effective strategic sourcing of CNC machined parts is vital for international buyers aiming to optimize quality, cost, and lead times in a competitive global marketplace. Prioritizing supplier capabilities, rigorous quality standards, and understanding regional market dynamics can significantly mitigate risks and enhance supply chain resilience. Leveraging digital platforms for supplier evaluation and fostering strong, transparent partnerships will further ensure consistent delivery of high-precision components.

Looking ahead, technological advancements such as automation, AI-driven quality control, and innovative materials will continue to reshape the CNC machining landscape. Buyers from Africa, South America, the Middle East, and Europe—particularly regions like Spain and Turkey—should stay informed about these trends to capitalize on emerging opportunities. Developing a strategic, data-driven approach to sourcing not only safeguards against disruptions but also positions your business for sustainable growth in an increasingly interconnected manufacturing ecosystem.

Now is the time for international buyers to deepen supplier relationships, embrace innovation, and proactively adapt their sourcing strategies—ensuring they remain competitive and responsive in the evolving CNC machining market.