Contents

Manufacturing Insight: 3D Stl Cnc

Manufacturing Insight: Integrated 3D Printing and CNC Machining for Precision Prototyping and Low-Volume Production

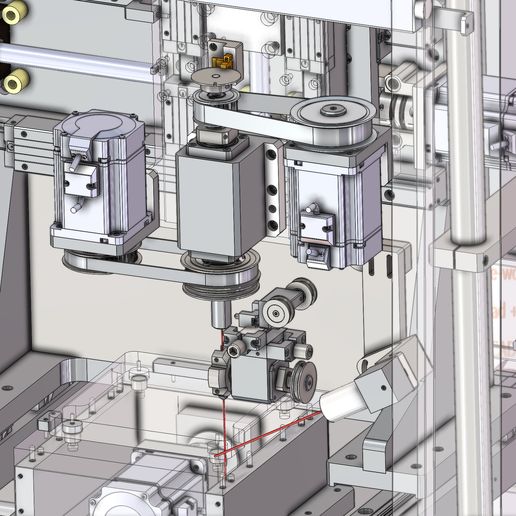

Shenzhen Honyo Prototype leverages the synergistic integration of additive manufacturing (3D printing from STL files) and subtractive CNC machining to deliver superior prototype and low-volume production components. This hybrid approach, often referenced as “3D STL CNC,” strategically combines the geometric freedom and rapid iteration capabilities of industrial 3D printing with the micron-level precision, superior surface finish, and material integrity achievable through CNC machining. It addresses a critical gap in the product development lifecycle where complex initial forms require final features, tight tolerances, or critical mating surfaces that pure additive processes cannot consistently achieve alone. At Honyo, we utilize this methodology not as a sequential afterthought, but as a co-engineered manufacturing strategy planned from the initial design phase, optimizing for both speed and end-use performance.

Our facility houses a dedicated cell for this integrated workflow, featuring high-precision industrial polymer and metal 3D printers capable of processing a wide range of engineering-grade materials directly from client STL files. Crucially, these systems feed into our advanced 3-, 4-, and 5-axis CNC machining centers, operated by technicians trained in the specific requirements of post-processing additively manufactured parts. This seamless transition within a single facility eliminates logistics delays and quality handoff risks inherent in outsourcing secondary operations. We prioritize maintaining the as-printed core geometry’s complexity while applying CNC to critical interfaces, sealing surfaces, bearing journals, or threads where ISO 2768-mK or tighter tolerances are mandated. Material compatibility is rigorously managed; for instance, metal parts undergo stress relief prior to machining, and polymer selections consider thermal stability during cutting.

Honyo’s integrated process delivers significant client advantages. Lead times for functional prototypes requiring both complex internal structures and precise external features are reduced by 30-50% compared to traditional multi-vendor paths. Component reliability is enhanced through the elimination of secondary operation errors and the inherent strength of machined features in the final material. This is particularly vital for aerospace, medical device, and automotive applications where performance validation is non-negotiable. Our quality management system, certified to ISO 9001:2015, ensures traceability from digital model through additive build to final CNC inspection, with comprehensive metrology reports including CMM and optical scanning data provided for critical dimensions.

Key technical capabilities for our integrated 3D STL CNC service are summarized below:

| Parameter | Capability Range | Notes |

| :————————- | :——————————————– | :——————————————————————– |

| Build Envelope (3D) | 500 x 500 x 500 mm (Polymer) | Up to 250 x 250 x 250 mm for Direct Metal Laser Sintering (DMLS) |

| | 250 x 250 x 250 mm (Metal – DMLS) | |

| Materials | Engineering Polymers (PA12, ABS, PC, PEKK) | Includes ULTEM™ 9085 for FST applications |

| | Metals (AlSi10Mg, Ti6Al4V, 316L, Inconel 718) | |

| Typical Tolerance (CNC)| ±0.025 mm (Standard) | Achievable on machined features post-printing |

| | ±0.010 mm (Precision) | Requires specific design for manufacturability |

| Surface Finish (CNC) | Ra 0.8 µm (Typical) | Down to Ra 0.4 µm achievable on critical surfaces |

| Lead Time (Prototype) | 5-8 Working Days | From approved STL/CAD to shipped, functional part (varies by complexity) |

This integrated manufacturing insight underscores Honyo Prototype’s commitment to providing not just fabrication, but engineered manufacturing solutions. By mastering the convergence of 3D printing and CNC, we empower clients to accelerate validation, reduce risk, and confidently transition complex designs from concept to functional reality.

Technical Capabilities

Shenzhen Honyo Prototype delivers advanced industrial 3D printing solutions tailored for precision prototyping and low-volume production. Our technical capabilities span multiple additive manufacturing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS). Each process is optimized for specific performance requirements, material properties, and end-use applications, enabling us to support diverse industries such as aerospace, medical devices, automotive, and consumer electronics.

SLA is our go-to technology for high-resolution prototypes requiring smooth surface finishes and fine details. Utilizing photosensitive resin cured by a UV laser, SLA produces parts with exceptional dimensional accuracy and visual clarity, ideal for form and fit testing, master patterns, and transparent components. SLS leverages a high-powered laser to sinter nylon-based powders, creating durable, functional parts with excellent mechanical properties. This process does not require support structures, allowing for greater design freedom and nested builds to maximize throughput.

MJF, developed by HP, uses inkjet array technology to selectively apply fusing and detailing agents across a nylon powder bed, followed by infrared heating. The result is isotropic parts with consistent mechanical properties, faster build speeds, and superior surface texture compared to traditional SLS. For metal components, DMLS offers full-density metallic parts using a fiber laser to melt and fuse metal powder layer by layer. This process supports complex geometries unachievable through conventional machining and is widely used in high-stress, high-temperature applications.

Our equipment fleet is maintained to strict calibration standards, ensuring repeatable accuracy and material consistency across all platforms. Post-processing services—including stress relieving, bead blasting, dyeing, coating, and CNC finishing—are integrated into our workflow to meet exacting customer specifications.

The following table outlines the key technical specifications, tolerances, and material options available across our core 3D printing technologies:

| Technology | Typical Tolerance | Layer Thickness | Common Materials | Max Build Size (mm) |

|———–|——————-|—————–|——————|———————|

| SLA | ±0.1 mm (±0.004 in) | 25–100 µm | Standard Resin, Tough Resin, Transparent Resin, Dental Resin | 145 x 145 x 185 |

| SLS | ±0.2 mm (±0.008 in) | 80–120 µm | PA12 (Nylon 12), PA11, Glass-Filled Nylon | 250 x 250 x 300 |

| MJF | ±0.2 mm (±0.008 in) | 80 µm | HP PA12, HP PA12 Glass Bead, HP PA11 | 360 x 280 x 380 |

| DMLS | ±0.05 mm (±0.002 in) | 20–50 µm | Stainless Steel (316L, 17-4PH), Titanium (Ti6Al4V), Aluminum (AlSi10Mg), Inconel 718 | 250 x 250 x 325 |

All processes are supported by rigorous in-house quality control, including first-article inspection, CMM verification, and material traceability. At Shenzhen Honyo Prototype, we combine technical depth with manufacturing agility to deliver reliable, high-performance 3D-printed components aligned with industrial standards.

From CAD to Part: The Process

From CAD to Production-Ready Part: Industrial 3D Printing Workflow at Honyo Prototype

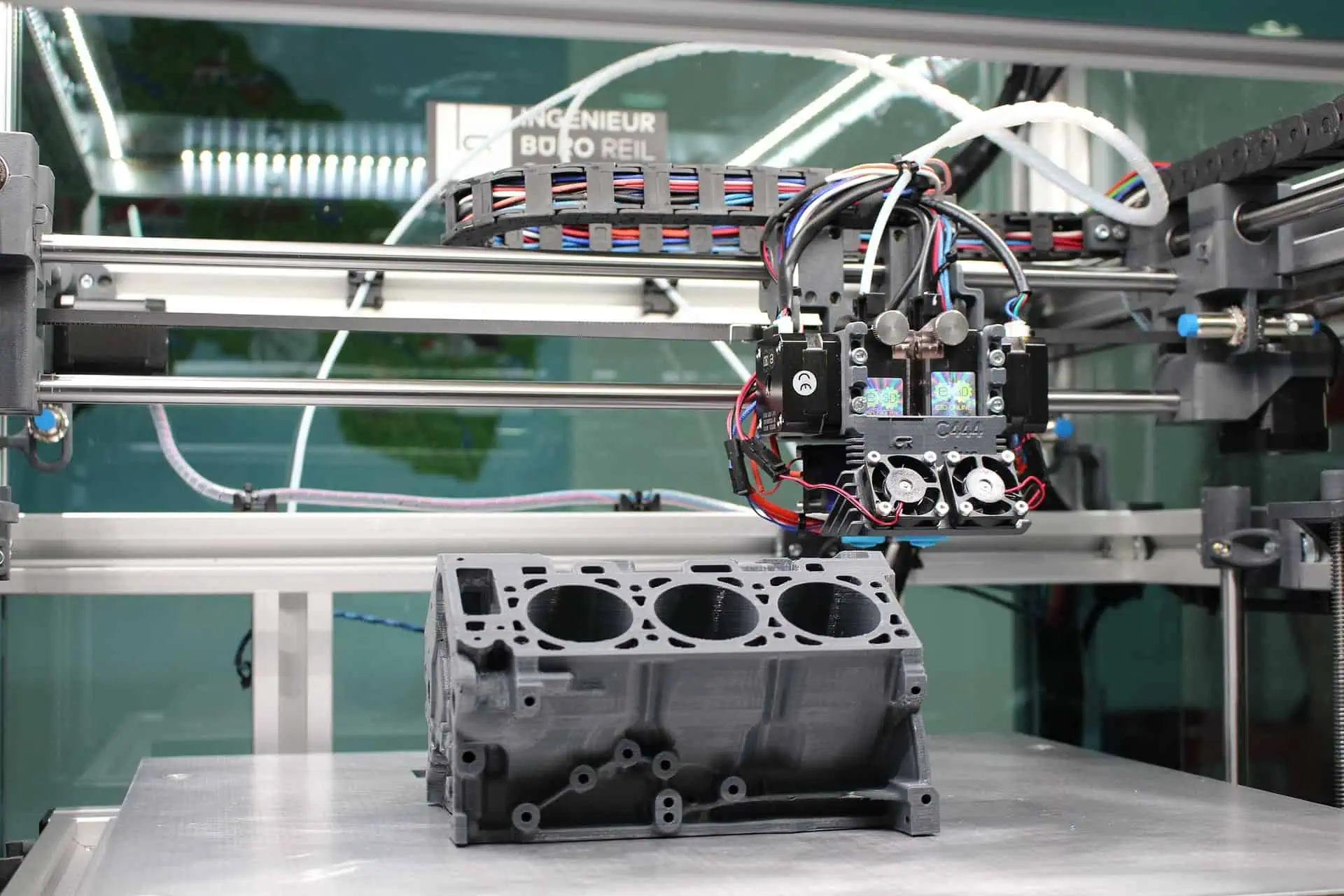

Shenzhen Honyo Prototype delivers precision industrial 3D printed components through a rigorously defined workflow, transforming digital CAD models into functional, production-ready parts. Our process prioritizes efficiency, quality, and manufacturability from the initial inquiry through final delivery, specifically optimized for STL file inputs destined for CNC post-processing or direct application.

The journey begins with the AI-Powered Quoting phase. Upon receiving a client’s STL file and requirements via our online portal, our proprietary AI engine performs an instant analysis. This system evaluates geometric complexity, part volume, required material properties, and surface finish specifications against our extensive manufacturing database. Crucially, it assesses factors critical for downstream CNC integration, such as wall thickness consistency and datum feature identification potential. The AI generates a highly accurate, transparent quote within minutes, including estimated lead time and material cost breakdown, eliminating traditional quoting delays and providing immediate project feasibility insight.

This is immediately followed by mandatory Engineering Review & DFM Analysis. Our senior manufacturing engineers conduct a deep-dive Design for Manufacturing assessment. We scrutinize the STL geometry for printability, identifying potential issues like overhangs exceeding 45 degrees, thin features prone to warpage, or internal cavities requiring complex support structures that could impede subsequent CNC machining. We proactively collaborate with the client to suggest optimizations – such as strategic feature reorientation, minor wall thickness adjustments, or support structure modification – ensuring the design fully leverages the capabilities of industrial-grade FDM, SLS, or SLA systems while maintaining tolerance integrity for any planned CNC operations. This stage is non-negotiable for achieving first-time-right production and cost efficiency.

Only after DFM sign-off does Precision Production commence. Parts are manufactured on our calibrated fleet of industrial 3D printers (Stratasys F900, EOS M 290, Formlabs Form 3L) within controlled environmental chambers. Material selection adheres strictly to application demands, as defined during quoting and DFM. Post-printing, parts undergo rigorous, documented post-processing: support removal, precision bead blasting for uniform surface texture, and thermal annealing where necessary to relieve internal stresses and enhance dimensional stability – critical for parts requiring tight CNC tolerances. Final quality verification employs CMM, optical scanning, and manual inspection against the original CAD nominal, with full inspection reports provided. The result is a geometrically accurate, structurally sound component ready for immediate use or seamless integration into CNC secondary operations.

Material selection directly impacts final part performance and CNC compatibility. Key options include:

| Material | Key Properties | Typical Applications |

| :—————- | :——————————————— | :——————————————– |

| Nylon 12 (SLS) | High strength, chemical resistance, flexibility | Functional prototypes, ducting, living hinges |

| ABS-M30 (FDM) | Excellent toughness, thermal stability | Jigs, fixtures, end-use automotive components |

| Engineering Resin (SLA) | High resolution, thermal/vapor polishable | Investment casting patterns, fluidics |

This integrated AI Quote → DFM → Production workflow ensures Shenzhen Honyo Prototype consistently delivers industrial 3D printed parts that meet stringent functional and dimensional requirements, providing clients with a reliable, high-fidelity manufacturing solution from digital concept to physical reality.

Start Your Project

Start Your Industrial 3D Printing Project with Shenzhen Honyo Prototype

When it comes to rapid prototyping and low-volume production in the industrial sector, precision, speed, and material reliability are non-negotiable. At Shenzhen Honyo Prototype, we specialize in high-accuracy industrial 3D printing services that transform your STL, CNC, and CAD designs into fully functional prototypes and end-use parts—fast. Whether you’re in aerospace, automotive, medical devices, or consumer electronics, our advanced additive manufacturing capabilities ensure your project moves from concept to physical reality with unmatched efficiency.

Our expertise spans multiple 3D printing technologies, including SLA, SLS, MJF, and metal DMLS, allowing us to support a broad range of engineering requirements. We understand that every project has unique demands, which is why we offer tailored solutions—from material selection and design optimization to post-processing and finishing. With in-house CNC machining and hybrid manufacturing options, we deliver parts that meet strict dimensional tolerances and surface quality standards.

At Honyo Prototype, we pride ourselves on fast turnaround times without compromising on quality. Our facility in Shenzhen is equipped with state-of-the-art machines and operated by a team of experienced engineers who ensure every part is produced to specification. We work closely with clients globally, providing real-time updates, detailed inspection reports, and DFM feedback to streamline your development cycle.

Below is an overview of our core industrial 3D printing capabilities:

| Parameter | Specification |

|—————————-|————————————————|

| Layer Resolution | 25 – 100 μm (SLA/SLS), 20 – 50 μm (DMLS) |

| Build Envelope (Max) | 700 x 380 x 580 mm (SLS), 250 x 250 x 300 mm (DMLS) |

| Dimensional Accuracy | ±0.1 mm (typical), ±0.05 mm (tight tolerance) |

| Lead Time | As fast as 2–3 days for standard prototypes |

| Supported File Formats | STL, STEP, IGES, DWG, X_T |

| Finishing Options | Sanding, Painting, Anodizing, Plating, Texturing |

From initial design review to final delivery, we ensure seamless collaboration at every stage. Our engineering team provides free Design for Manufacturability (DFM) analysis to optimize your 3D model for printability, strength, and cost-efficiency—helping you avoid costly revisions down the line.

Ready to bring your next project to life? Contact Susan Leo, our dedicated project coordinator, to discuss your requirements, request a quote, or submit your 3D files for immediate review. At Shenzhen Honyo Prototype, we’re committed to accelerating your innovation with precision manufacturing solutions you can trust.

Contact Susan Leo

Email: info@hy-proto.com

Let’s start building together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.