Contents

Manufacturing Insight: High Precision Cnc Machine

High Precision CNC Machining: Technology Overview and Honyo Prototype Capabilities

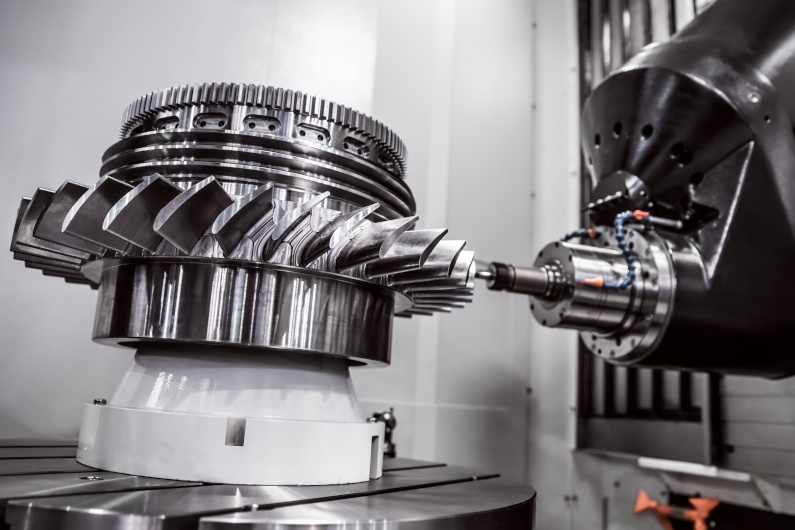

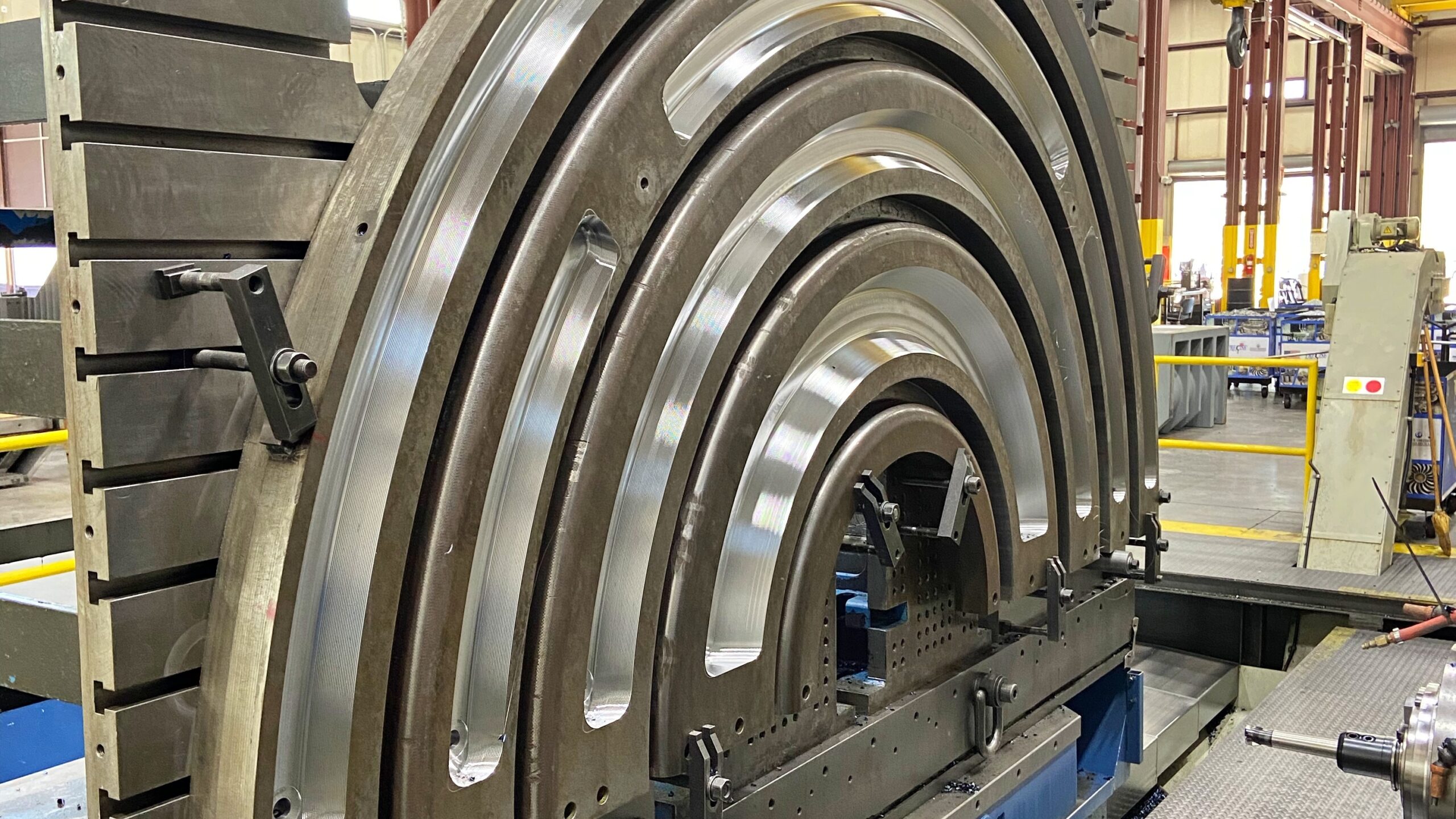

High precision CNC machining represents the pinnacle of subtractive manufacturing, enabling the production of components with micron-level tolerances and exceptional surface finishes critical for advanced industries. This technology utilizes computer-controlled machine tools—mills, lathes, and multi-axis centers—to remove material from a workpiece with extreme accuracy, governed by meticulously programmed toolpaths. Achieving true high precision demands far more than advanced software; it requires a holistic integration of rigid machine structures, thermally stable components, high-resolution feedback systems, and sophisticated environmental controls to mitigate factors like thermal drift, vibration, and mechanical deflection. Applications span aerospace turbine components requiring tight geometric conformity, medical implants demanding biocompatibility and flawless surface integrity, semiconductor manufacturing equipment needing nanometer-level repeatability, and精密光学 systems where light-path accuracy is non-negotiable. The ability to consistently hold tolerances below ±0.0002 inches (±0.005 mm) separates standard machining from this specialized tier, directly impacting product performance, longevity, and regulatory compliance in mission-critical assemblies.

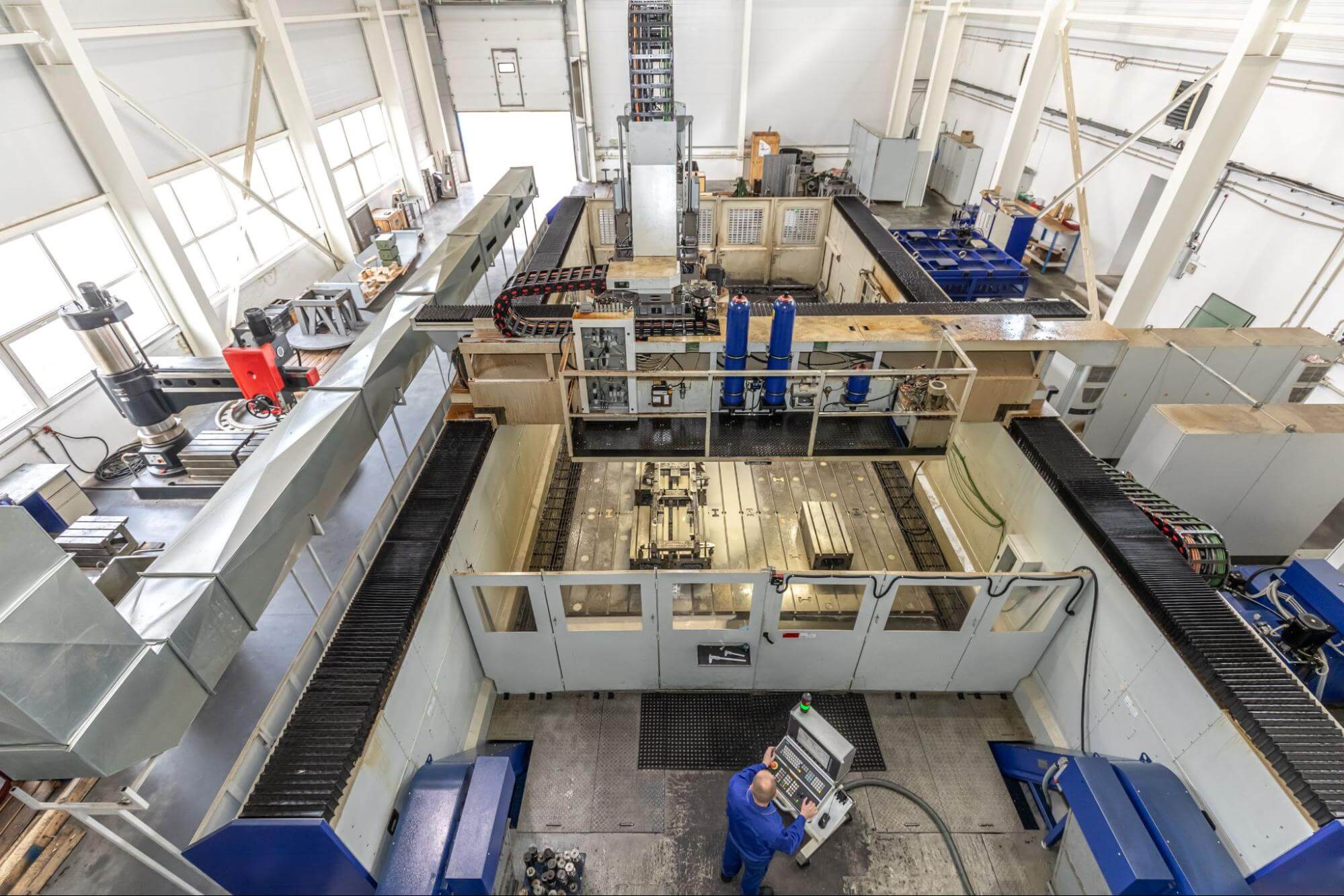

At Shenzhen Honyo Prototype, we have engineered our high precision CNC capability around a foundation of purpose-built equipment and rigorous process control. Our facility houses state-of-the-art multi-axis machining centers from leading manufacturers, specifically selected and calibrated for sub-micron performance. We implement stringent thermal management protocols, including 24/7 climate-controlled production environments and pre-machining thermal stabilization cycles for both machines and critical workpieces. Our engineering team employs advanced metrology, including laser interferometers and coordinate measuring machines (CMMs) with sub-micron resolution, for continuous machine validation and first-article inspection. This commitment to process discipline ensures that every component delivered meets the most demanding specifications, minimizing scrap and rework while guaranteeing dimensional stability across production runs. Our expertise extends beyond operation to proactive collaboration during the design phase, where we provide manufacturability insights to optimize part geometry for precision machining efficiency without compromising functional requirements.

Honyo Prototype’s core high precision machining specifications are engineered to exceed industry benchmarks for critical applications:

| Parameter | Typical Capability (Honyo Prototype) | Standard Industry Benchmark |

| :———————- | :———————————– | :————————– |

| Positioning Accuracy | ±0.00008 inches (±0.002 mm) | ±0.0002 inches (±0.005 mm) |

| Repeatability | ±0.00004 inches (±0.001 mm) | ±0.0001 inches (±0.0025 mm) |

| Surface Roughness (Ra) | 0.4 µin (0.01 µm) achievable | 3.2 – 8.0 µin (0.08 – 0.2 µm) |

| Maximum Machine Axes | 5-Axis Simultaneous | 3-Axis Common |

| Thermal Drift Control | < 1.0 µm over 8-hour shift | 2.0 – 5.0 µm common |

This technical infrastructure, combined with our AS9100-certified quality management system, positions Honyo Prototype as a trusted partner for clients requiring uncompromising precision. We understand that in sectors where component failure is not an option, the machining process must be as reliable as the final part. Our focus on continuous machine calibration, operator expertise development, and real-time process monitoring ensures that the theoretical capabilities of our equipment translate into consistent, verifiable results for your most challenging projects. Partnering with Honyo means gaining access to a manufacturing ecosystem designed from the ground up to deliver precision you can measure and depend upon.

Technical Capabilities

Technical Capabilities: High Precision CNC Machining at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in high precision CNC machining, delivering complex, mission-critical components with exceptional accuracy and repeatability. Our advanced CNC infrastructure supports 3-axis, 4-axis, and 5-axis milling, as well as precision turning operations, enabling us to manufacture intricate geometries across a broad spectrum of engineering materials. These capabilities are ideal for industries requiring high-performance parts, including aerospace, medical devices, automation, and advanced electronics.

Our 5-axis simultaneous CNC machining centers are equipped with high-rigidity spindles, thermal compensation systems, and vacuum clamping solutions, allowing for single-setup machining of complex 3D contours. This reduces cumulative error, improves surface finish, and shortens lead times. The integration of 4-axis rotary indexing further enhances our ability to produce angular features and undercuts without manual repositioning. For high-volume or symmetrical components, our precision turning centers support both bar-fed and chucking operations, with live tooling for mill-turn capabilities.

A cornerstone of our service is the ability to achieve tight tolerances consistently. Our machines operate in temperature-controlled environments and are routinely calibrated using laser interferometers and touch-probe systems. We maintain geometric tolerances down to ±0.002 mm and positional tolerances within ±0.005 mm, depending on part complexity and material. Surface finishes as fine as Ra 0.4 µm are routinely achieved, with optional polishing or micro-machining for optical-grade requirements.

The table below outlines our standard tolerance capabilities and compatible materials:

| Process | Typical Tolerance | Positional Accuracy | Surface Finish (Ra) | Max Work Envelope (mm) |

|———————–|——————-|———————-|———————-|————————|

| 3-Axis Milling | ±0.010 mm | ±0.005 mm | 1.6 – 3.2 µm | 1000 × 600 × 500 |

| 4-Axis Milling | ±0.008 mm | ±0.005 mm | 1.6 – 3.2 µm | 800 × 500 × 400 |

| 5-Axis Milling | ±0.005 mm | ±0.003 mm | 0.8 – 1.6 µm | 600 × 600 × 500 |

| CNC Turning | ±0.010 mm | ±0.005 mm | 1.6 – 3.2 µm | Ø300 × 750 |

| Mill-Turn (Live Tool) | ±0.008 mm | ±0.005 mm | 0.8 – 1.6 µm | Ø65 × 200 |

We support a wide range of materials, including aerospace-grade aluminum alloys (e.g., 7075-T6, 6061), titanium (Grade 2, Grade 5), stainless steels (303, 304, 316, 17-4 PH), brass, copper, and engineering plastics such as PEEK, PTFE, and Delrin. Each material is processed using optimized toolpaths, cutting parameters, and fixturing strategies to minimize deformation and ensure dimensional stability.

All high precision machining projects are supported by in-house CMM inspection, 3D scanning, and first-article inspection reports (FAIR), ensuring full traceability and compliance with ISO 9001 standards. At Shenzhen Honyo Prototype, our technical capabilities are engineered to deliver precision, consistency, and rapid turnaround for prototyping and low-to-mid volume production.

From CAD to Part: The Process

High-Precision CNC Machining: From CAD to Finished Part at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype employs a rigorously defined workflow for high-precision CNC machining, ensuring optimal quality, efficiency, and client satisfaction from initial design submission through to final part delivery. This structured process eliminates ambiguity and proactively addresses potential manufacturing challenges.

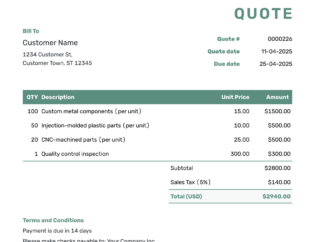

The workflow initiates with the AI-Powered Quoting Engine. Upon receipt of a client’s CAD file (STEP, IGES, or native formats preferred), our proprietary AI system performs an immediate, multi-faceted analysis. It automatically extracts critical geometric features, identifies specified tolerances and surface finishes, assesses part complexity, estimates material requirements, and evaluates machine time based on defined parameters. This rapid analysis generates a highly accurate initial quote within hours, including detailed cost breakdowns and preliminary lead time estimates. Crucially, the AI flags potential high-risk geometries or conflicting specifications for immediate engineering review, ensuring the quote reflects realistic manufacturability before human engagement. This stage significantly accelerates the commercial process while setting clear technical expectations.

Following quote acceptance, the project enters the Engineering-Driven DFM (Design for Manufacturability) Review. This is not a passive step but an active collaboration. Our senior manufacturing engineers conduct a meticulous manual review of the CAD model, focusing on precision requirements. We scrutinize feature geometries for machinability, assess the feasibility of tight tolerances (±0.005mm achievable routinely), evaluate tool access for deep cavities or undercuts, analyze wall thickness stability, and verify optimal material selection. We identify potential sources of vibration, deflection, or thermal distortion that could compromise precision. The outcome is a comprehensive DFM report presented to the client, detailing specific, actionable recommendations for design optimization to enhance precision, reduce cost, and shorten lead times. Client feedback and approval on any proposed modifications are mandatory before proceeding, ensuring alignment on the final manufacturable design.

With DFM sign-off, the project transitions to Precision Production Execution. CAM programming commences using industry-leading software (Mastercam, Fusion 360), generating optimized toolpaths that prioritize dimensional accuracy and surface integrity. Programs undergo rigorous simulation to verify collision avoidance and path correctness. Production leverages our advanced multi-axis CNC machining centers (3-axis, 4-axis, 5-axis), equipped with high-resolution probing systems for precise workholding and in-process verification. Machining occurs under strict environmental controls, utilizing premium cutting tools and optimized coolant strategies. Critical dimensions are monitored in real-time using on-machine probes. Post-machining, every component undergoes stringent metrology: Coordinate Measuring Machines (CMM) verify complex geometries against the CAD model, surface roughness testers confirm finish specifications, and optical comparators check critical profiles. Final inspection documentation, including full CMM reports, is provided with the shipment.

Material selection directly impacts achievable precision and surface quality. The following table outlines typical capabilities for common materials:

| Material Group | Example Alloys | Standard Tolerance (mm) | Typical Surface Finish (Ra µm) | Key Considerations |

|—————-|—————-|————————-|——————————–|——————-|

| Aluminum Alloys | 6061-T6, 7075-T6 | ±0.010 | 0.8 – 1.6 | Excellent machinability; high thermal conductivity requires stable fixturing |

| Stainless Steel | 303, 304, 17-4PH | ±0.008 | 0.4 – 0.8 | Work-hardening necessitates optimized speeds/feeds; corrosion resistance critical |

| Engineering Plastics | POM (Delrin), PEEK | ±0.025 | 1.6 – 3.2 | Low thermal stability demands minimal cutting forces; chip evacuation vital |

| Titanium Alloys | Ti-6Al-4V | ±0.010 | 0.8 – 1.6 | Low thermal conductivity requires aggressive cooling; high tool wear management |

This integrated workflow—AI Quoting for speed and initial risk assessment, Engineering DFM for precision optimization, and Controlled Production Execution with rigorous metrology—ensures Shenzhen Honyo Prototype consistently delivers high-precision CNC machined parts that meet the most demanding specifications.

Start Your Project

Start Your High-Precision CNC Machining Project with Shenzhen Honyo Prototype

When it comes to delivering complex, high-precision components on time and to exact specifications, Shenzhen Honyo Prototype stands at the forefront of CNC machining excellence. Our advanced manufacturing capabilities, combined with rigorous quality control and engineering expertise, make us the preferred partner for industries ranging from aerospace and medical devices to automation and R&D. Whether you’re developing a prototype or scaling to low-volume production, our high-precision CNC machines ensure repeatability, tight tolerances, and superior surface finishes—every time.

Our state-of-the-art CNC machining center is equipped with multi-axis milling and turning systems capable of handling a wide range of engineering-grade materials, including aluminum alloys, stainless steel, titanium, brass, PEEK, and engineered plastics. With in-house 3-, 4-, and 5-axis machining, we support complex geometries and intricate details that standard CNC services cannot achieve. Our machines operate under tight environmental controls to maintain micron-level accuracy, ensuring dimensional stability across all production runs.

At Honyo Prototype, we understand that every project begins with a vision. That’s why our engineering team works closely with clients from the initial design review through final inspection. We provide Design for Manufacturability (DFM) feedback to optimize part geometry, reduce lead times, and minimize costs—without compromising performance or precision.

We maintain full traceability and adhere to international quality standards, including ISO 9001:2015. Every component undergoes comprehensive inspection using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify conformance to your technical drawings and specifications.

Below are key capabilities of our high-precision CNC machining services:

| Specification | Detail |

|————–|——–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 1200 × 600 × 500 mm (XYZ) |

| Typical Tolerances | ±0.01 mm (standard), down to ±0.005 mm (tight tolerance) |

| Surface Finish | As low as Ra 0.4 μm (polished), standard Ra 3.2 μm |

| Materials Supported | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr5), Brass, PEEK, PC, POM, and more |

| Lead Time | As fast as 3–5 days for prototypes; 7–12 days for production batches |

Starting your project with Honyo Prototype is simple. Just send your 3D CAD files and technical requirements, and our team will provide a detailed quotation within 12 hours. We support common file formats including STEP, IGES, SolidWorks, and PDF drawings.

Ready to bring your precision components to life? Contact Susan Leo today at info@hy-proto.com to discuss your project requirements, request a quote, or schedule a technical consultation. At Shenzhen Honyo Prototype, we don’t just manufacture parts—we engineer precision. Let’s build your next innovation together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.