Contents

Manufacturing Insight: Ceramic Resin 3D Printing

Manufacturing Insight: Ceramic Resin 3D Printing at Honyo Prototype

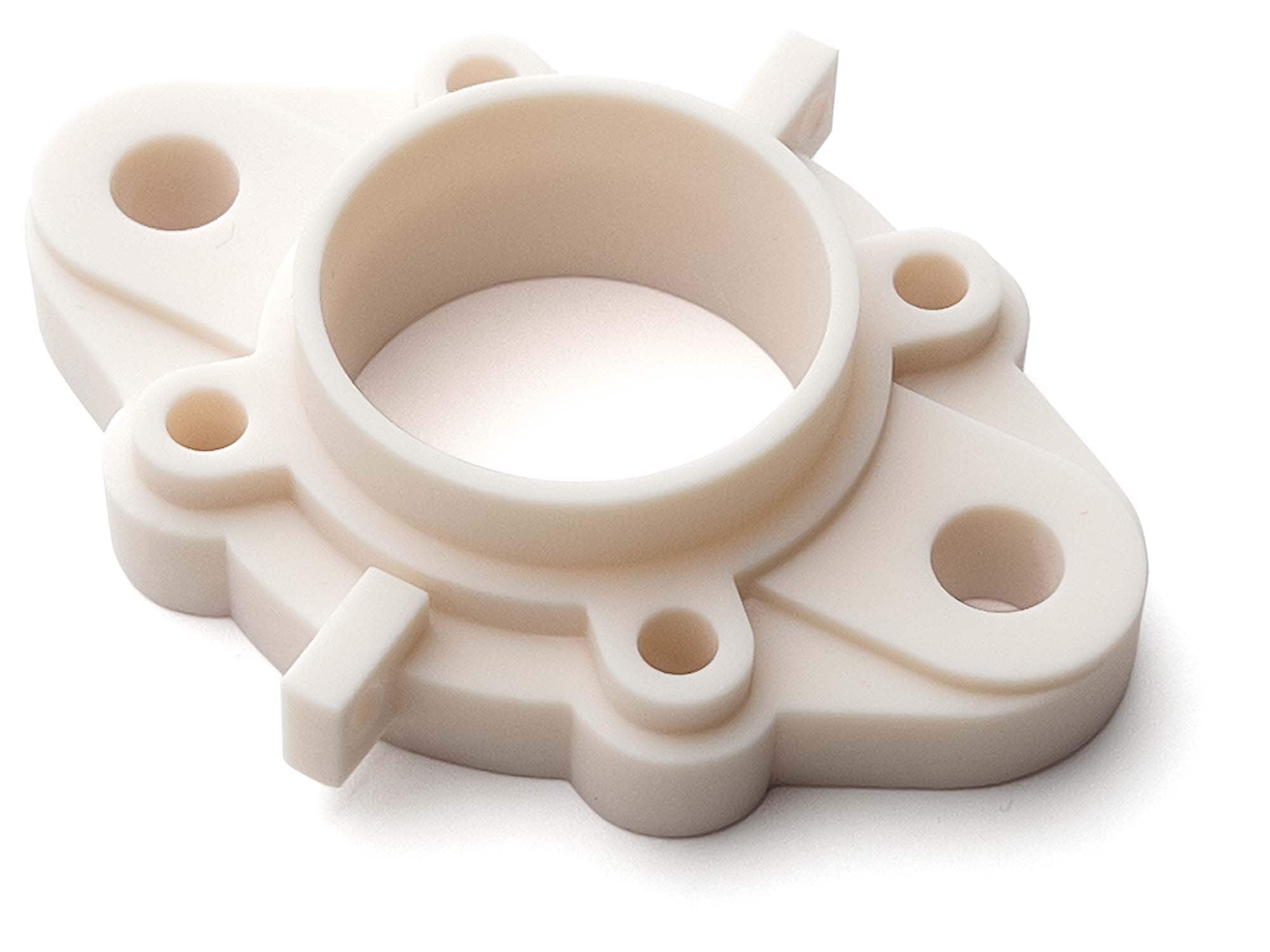

Ceramic resin 3D printing, specifically Lithography-based Ceramic Manufacturing (LCM), represents a transformative approach for producing complex, high-performance ceramic components impossible with traditional methods like injection molding or machining. At Honyo Prototype, we leverage this advanced additive process to deliver precision-engineered ceramic parts for demanding industrial applications in aerospace, medical devices, electronics, and energy. Unlike direct ceramic printing, LCM utilizes UV-curable photopolymers heavily loaded with fine ceramic particles (typically alumina, zirconia, or silicon carbide). The process begins with stereolithography (SLA) or digital light processing (DLP) to build a “green part” – a fragile structure where ceramic powder is bound within a polymer matrix. This initial print stage enables exceptional geometric freedom, capturing intricate details, thin walls, and internal channels with high resolution.

The true manufacturing challenge and Honyo’s core expertise lie in the critical post-processing stages: debinding and sintering. The green part undergoes meticulous thermal debinding to remove the polymer binder without causing cracks or distortion. Subsequently, high-temperature sintering densifies the ceramic particles, achieving near-theoretical density and the final part’s mechanical and thermal properties. Precise control over sintering atmosphere, temperature ramp rates, and dwell times is paramount to manage significant, anisotropic shrinkage (typically 15-25%) and ensure dimensional accuracy and material integrity. Achieving consistent, predictable results demands deep process knowledge and sophisticated equipment.

Honyo Prototype excels in mastering this complex workflow. Our dedicated ceramic printing and sintering facility utilizes industrial-grade LCM systems combined with proprietary process parameters developed through extensive R&D. We possess in-house capabilities for every step, from initial design consultation and support through printing, optimized debinding cycles, and controlled sintering in state-of-the-art furnaces capable of exceeding 1600°C. This vertical integration ensures tight tolerance control and repeatable material properties. Our engineering team focuses on mitigating inherent challenges like shrinkage compensation and residual stress management, translating complex CAD models into reliable, high-fidelity ceramic end-use components or functional prototypes.

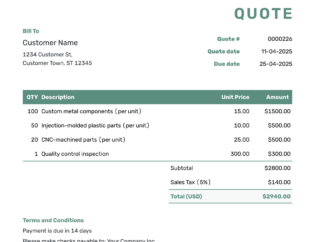

The table below outlines key capabilities achievable through Honyo’s ceramic resin 3D printing process:

| Parameter | Typical Range | Honyo Achievable Target |

| :—————– | :——————– | :———————- |

| Minimum Feature Size | 50 – 100 µm | ≤ 75 µm |

| Layer Thickness | 10 – 50 µm | 25 µm (standard) |

| Sintered Density | > 99% theoretical | > 99.5% |

| Shrinkage Control | ± 0.3% – 0.5% (linear)| ± 0.15% – 0.25% |

| Surface Roughness (Ra) | 1.0 – 3.0 µm (sintered) | < 1.5 µm (as-sintered) |

| Max Build Volume | 150 x 150 x 150 mm | 150 x 150 x 150 mm |

Honyo Prototype delivers more than just printing; we provide a complete manufacturing solution for advanced ceramics. Our commitment to process excellence, rigorous quality control throughout the build and sintering cycles, and deep materials science understanding ensure clients receive components meeting the stringent requirements of high-value industrial sectors. Partner with Honyo to overcome the limitations of conventional ceramic manufacturing and unlock the potential of complex, high-performance ceramic geometries.

Technical Capabilities

Ceramic Resin 3D Printing: Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype offers advanced ceramic resin 3D printing services tailored for industrial applications requiring high precision, thermal stability, and chemical resistance. Our capabilities span multiple additive manufacturing technologies, including Stereolithography (SLA), Selective Laser Sintering (SLS), Multi Jet Fusion (MJF), and Direct Metal Laser Sintering (DMLS) adapted for ceramic-filled resins and hybrid materials. Each process is optimized to deliver functional prototypes, end-use components, and low-volume production parts with exceptional surface finish and dimensional accuracy.

SLA remains the primary method for ceramic resin 3D printing due to its ability to process photopolymer resins loaded with ceramic particles. Our industrial-grade SLA systems support layer resolutions as fine as 25 microns, enabling intricate geometries and smooth surface finishes ideal for investment casting patterns, dental components, and electronic housings. Post-processing includes UV curing, support removal, and optional sintering to enhance mechanical and thermal properties.

While SLS is traditionally used for polymers, we utilize modified SLS platforms capable of processing composite powders with ceramic content. These systems offer robust mechanical performance and are suitable for high-temperature tooling and aerospace components. Similarly, MJF technology is leveraged for faster production of medium-complexity parts with uniform mechanical properties across large build volumes. Although pure ceramic printing is not feasible with MJF, our ceramic-reinforced nylons deliver enhanced thermal conductivity and rigidity.

DMLS is primarily a metal additive process, but we integrate it into our ceramic workflow for hybrid metal-ceramic assemblies. By combining DMLS-fabricated metallic structures with ceramic resin components, we enable multifunctional systems used in thermal management and electrical insulation applications. This hybrid approach expands design freedom for complex industrial systems.

All ceramic resin prints undergo strict quality control, including first-article inspection and coordinate measuring machine (CMM) verification. Support structures are optimized for minimal residual marking, and surface treatments such as sandblasting, polishing, and coating are available upon request.

The following table outlines key technical specifications and tolerances by process:

| Process | Material Type | Layer Thickness | Typical Tolerance | Surface Roughness (Ra) | Max Build Volume (mm) |

|——–|—————|——————|——————-|————————|————————|

| SLA | Ceramic-filled photopolymer | 25–100 µm | ±0.1 mm (first 100 mm), ±0.05 mm thereafter | 0.8–1.6 µm | 140 x 140 x 180 |

| SLS | Ceramic-reinforced polymer powder | 80–120 µm | ±0.3 mm | 3.2–6.3 µm | 250 x 250 x 300 |

| MJF | Ceramic-filled nylon (PA12) | 80 µm | ±0.3 mm | 3.0–5.0 µm | 380 x 280 x 380 |

| DMLS + Ceramic Hybrid | Stainless steel + ceramic resin assembly | N/A (hybrid) | ±0.05 mm (metal), ±0.1 mm (resin) | 5.0 µm (as-built metal) | Varies by component |

Our technical team collaborates closely with clients to select the optimal process, material, and post-processing route based on functional requirements, environmental exposure, and production volume. Shenzhen Honyo Prototype ensures every ceramic resin part meets stringent industrial standards for performance and reliability.

From CAD to Part: The Process

Ceramic Resin 3D Printing Production Workflow: From CAD to Final Part

At Shenzhen Honyo Prototype, our industrial ceramic resin 3D printing process transforms digital designs into high-precision, functional ceramic components through a rigorously controlled workflow. This integrated sequence ensures manufacturability, material integrity, and dimensional accuracy while minimizing lead time and waste. The journey begins with client-supplied CAD geometry and concludes with a sintered, ready-to-use part.

The initial phase is the AI-Powered Quotation and Feasibility Assessment. Upon receiving your CAD file, our proprietary AI engine performs an instant manufacturability scan. This evaluates critical factors such as minimum feature size, wall thickness, overhang angles, and potential stress concentrations against the capabilities of our ceramic resin systems. The AI cross-references material properties—like alumina or zirconia slurry characteristics—and sintering behavior to flag risks like warpage or cracking early. Within minutes, you receive a detailed quotation including estimated lead time, material cost, and a preliminary assessment of whether the design meets our process constraints. This step eliminates guesswork and accelerates project kickoff.

Following quotation acceptance, the Design for Manufacturing (DFM) Collaboration phase commences. Our senior manufacturing engineers conduct an in-depth DFM review, working directly with your design team. We focus on optimizing the geometry for ceramic-specific challenges: incorporating strategic support structures that minimize post-processing, adjusting dimensions to compensate for predictable sintering shrinkage (typically 15-25%), and refining critical surfaces to achieve target roughness. This collaborative stage is non-negotiable for complex or high-tolerance parts; it ensures the design leverages the strengths of ceramic resin printing—such as intricate internal channels or lattice structures—while avoiding pitfalls inherent to the material’s green state fragility and high-temperature densification. Client sign-off on the DFM report is required before production.

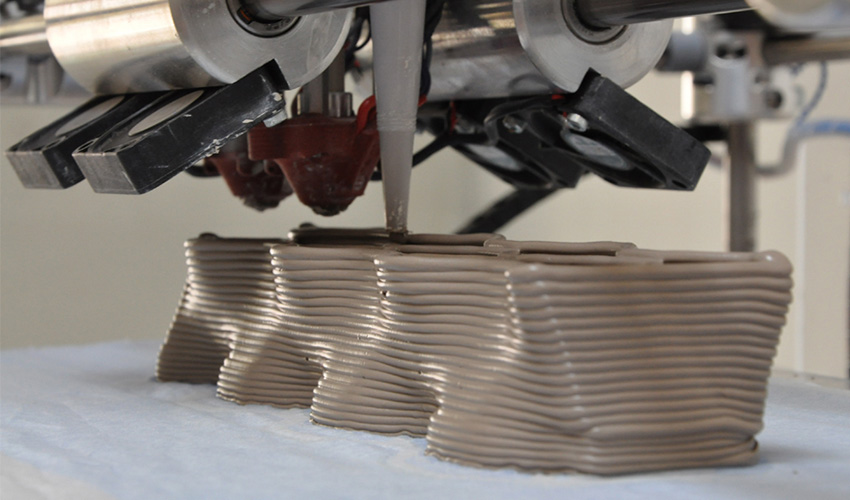

The Production Phase integrates printing, debinding, and sintering under strict environmental controls. First, the optimized build file drives our high-resolution LCD or DLP printers, curing the ceramic-loaded resin layer by layer. Post-print, parts undergo a multi-stage thermal debinding process to remove the polymer matrix without distorting the delicate green part. Finally, sintering occurs in precision-controlled kilns with programmable atmospheres. This step densifies the ceramic to near-theoretical density, achieving the final mechanical and thermal properties. Throughout production, real-time monitoring of temperature, humidity, and furnace atmosphere ensures repeatability. All critical process parameters adhere to the specifications outlined below.

| Parameter | Typical Range | Critical Impact |

|————————|————————|——————————————-|

| Layer Thickness | 25 – 50 µm | Surface finish, feature resolution |

| Sintering Temperature | 1550°C – 1650°C (Al₂O₃)| Density, grain growth, final strength |

| Sintering Dwell Time | 2 – 4 hours | Dimensional stability, porosity control |

| Shrinkage Compensation | 18% – 22% (isotropic) | Net-shape accuracy, tolerance achievement |

| As-Sintered Roughness | Ra 1.5 – 3.0 µm | Post-processing requirements |

The outcome is a fully dense, high-performance ceramic component meeting aerospace, medical, or industrial specifications. By embedding AI-driven feasibility checks and rigorous DFM collaboration upfront, Honyo Prototype achieves first-pass yield rates exceeding 92% for complex ceramic parts, delivering functional prototypes and low-volume production with certified material properties and traceable quality records. Typical lead time from approved DFM to sintered part is 7-10 business days.

Start Your Project

Start Your Project with Precision Ceramic Resin 3D Printing

At Shenzhen Honyo Prototype, we specialize in advanced ceramic resin 3D printing solutions tailored for industrial applications. Whether you’re developing high-performance components for aerospace, medical devices, or electronics, our precision manufacturing capabilities ensure exceptional detail, thermal stability, and mechanical strength. Starting your project with us is the first step toward turning innovative concepts into functional, production-ready ceramic parts.

Ceramic resin 3D printing combines the design freedom of additive manufacturing with the robust material properties of technical ceramics. This process enables complex geometries that are impossible to achieve with traditional machining, all while maintaining dimensional accuracy and surface quality. Our industrial-grade systems support a range of ceramic-filled photopolymers, allowing for parts with outstanding heat resistance, chemical inertness, and electrical insulation.

We understand that each project comes with unique requirements. That’s why our engineering team works closely with clients from the initial design phase through post-processing and final validation. Our end-to-end service includes design for additive manufacturing (DfAM) feedback, material selection, rapid prototyping, and scalable production runs. With in-house sintering, CNC finishing, and metrology labs, we ensure every component meets stringent industry standards.

To help you evaluate the suitability of ceramic resin 3D printing for your application, we’ve outlined key technical specifications available through our platform:

| Parameter | Capability |

|——————————-|———————————————|

| Minimum Feature Size | 100 µm |

| Layer Thickness | 25–100 µm (adjustable) |

| Build Volume | 140 x 80 x 140 mm |

| Supported Materials | Alumina (Al₂O₃), Zirconia (ZrO₂), SiC-filled resins |

| Post-Curing | UV and thermal curing protocols |

| Sintering Support | Full-cycle sintering with shrinkage control |

| Surface Roughness (as-printed)| Ra 1.6–3.2 µm |

| Tolerance (typical) | ±0.1% (with shrinkage compensation) |

| Lead Time (prototype) | 5–7 working days after design approval |

Our team is equipped to assist with material testing, failure mode analysis, and iterative prototyping to optimize performance. Whether you require biocompatible zirconia for dental implants or high-purity alumina for semiconductor fixtures, we provide certified materials and traceable process documentation.

Ready to bring your next ceramic component to life? Contact Susan Leo, our dedicated project manager, to discuss your design requirements, material needs, and production goals. We offer free technical consultations and rapid quoting to keep your development timeline on track.

Susan Leo

Project Manager, Industrial Additive Solutions

Shenzhen Honyo Prototype

Email: info@hy-proto.com

Let us help you harness the full potential of ceramic resin 3D printing—where innovation meets precision manufacturing.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.