Contents

Manufacturing Insight: Cnc Calculator

Manufacturing Insight: CNC Calculator

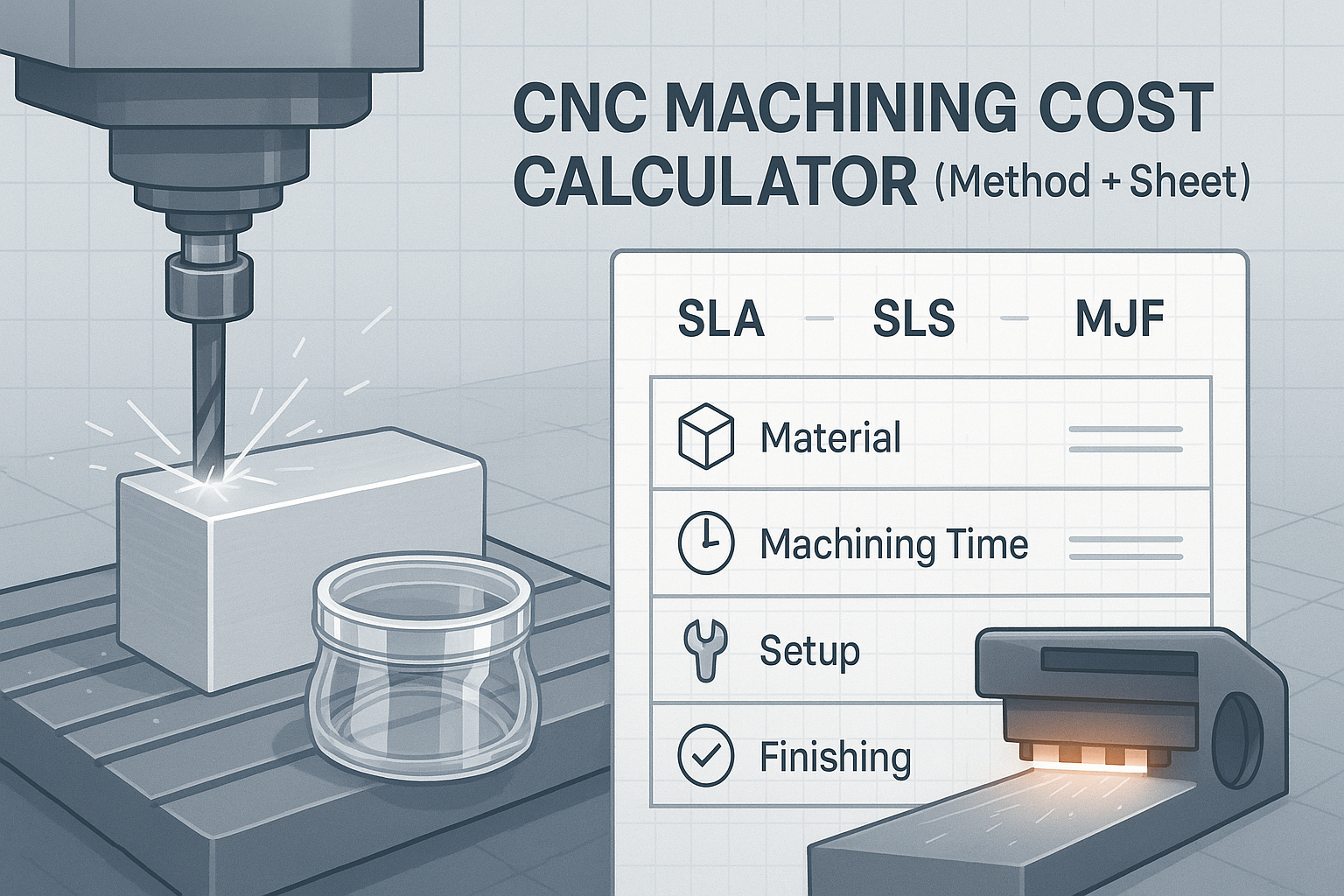

Precision CNC machining demands rigorous pre-production analysis to balance speed, cost, and quality. A CNC calculator is an essential engineering tool that quantifies machining time, material utilization, and operational feasibility by processing geometric complexity, material properties, and machine capabilities. At Shenzhen Honyo Prototype, we integrate advanced CNC calculation methodologies into our prototyping workflow to eliminate estimation guesswork, ensuring clients receive accurate lead times and cost projections before a single chip is cut. This transparency accelerates decision-making for R&D teams and supply chain partners, directly supporting agile product development cycles where time-to-market is critical.

Honyo’s Precision Calculation Framework

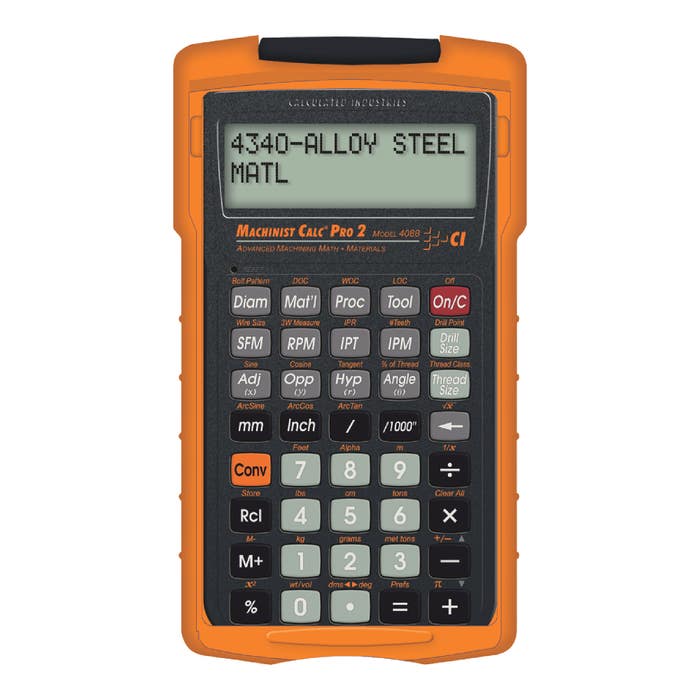

Our proprietary CNC calculation system transcends basic time estimators by incorporating real-world variables such as toolpath optimization, spindle load dynamics, and secondary operation sequencing. Unlike generic online calculators, Honyo’s model accounts for our specific machine park—including 3-axis mills, 5-axis DMG MORI centers, and Swiss-type lathes—and material-specific cutting parameters validated through decades of prototyping experience. Complex geometries with tight tolerances (±0.005mm) or challenging alloys (e.g., Inconel 718, titanium Ti-6Al-4V) undergo multi-stage simulation to predict micro-vibrations, thermal drift, and tool wear. This prevents costly rework by identifying manufacturability risks during quotation, not during machining. Crucially, all calculator outputs undergo validation by our senior process engineers who apply tolerance stack analysis and DFMA principles to refine feasibility.

The following table outlines key parameters integrated into Honyo’s calculation logic, reflecting our commitment to granular accuracy:

| Parameter | Honyo’s Calculation Scope |

|———————–|————————————————————|

| Material Type | 50+ metals/polymers with dynamic feed/speed databases |

| Machine Configuration | Axis count, spindle power, coolant type, probing capability|

| Feature Complexity | Pocket depth ratios, thin-wall stability, undercuts |

| Tolerance Class | ISO 2768-mK to精密 aerospace grades (e.g., ISO 286-2 IT5) |

This approach delivers actionable insights beyond time/cost figures. For instance, when machining a medical implant bracket in 316L stainless steel with 12 threaded inserts, our calculator identified a 22% cycle time reduction by recommending a hybrid 3+2 axis strategy over full 5-axis, while maintaining positional accuracy. Clients receive a detailed breakdown showing how material waste, machine depreciation, and labor converge into the final quote—no hidden variables.

Honyo Prototype leverages CNC calculation not as a standalone tool but as the foundation of our engineering partnership. By quantifying the interplay between design intent and manufacturing physics, we transform ambiguous “can it be made?” inquiries into data-driven “how it will be optimized” solutions. This rigor ensures your prototype progresses from CAD model to functional part with minimal iteration, preserving your R&D budget for innovation, not correction. Engage our engineering team to apply this precision to your next project.

Technical Capabilities

CNC Machining Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype offers advanced CNC machining services engineered for precision, speed, and repeatability across a broad range of industries, including aerospace, medical, automotive, and industrial equipment. Our state-of-the-art facility is equipped with high-performance 3-axis, 4-axis, and 5-axis milling centers, as well as multi-axis turning centers, enabling us to produce highly complex geometries with consistent accuracy. These capabilities are integrated with robust quality control systems to ensure every component meets stringent technical requirements.

Our 3-axis milling machines are ideal for prismatic parts with straightforward geometries, offering fast cycle times and excellent surface finishes. For components requiring access to multiple faces or angled features, our 4-axis CNC mills add rotational capability (A-axis), allowing for continuous machining without manual repositioning. The 5-axis machining centers provide simultaneous movement across X, Y, Z, and two rotary axes (typically A and B), making them suited for highly intricate parts such as impellers, turbine blades, and complex housings. These machines reduce setup time, improve accuracy, and minimize human error by completing most features in a single setup.

In addition to milling, our CNC turning centers support both standard and Swiss-type turning operations, accommodating parts up to 300 mm in diameter and 600 mm in length. These machines are capable of high-precision external and internal turning, threading, grooving, and drilling, often combined with live tooling for mill-turn operations. This hybrid capability allows us to produce fully finished turned parts with milled features such as flats, slots, or cross-holes.

A key differentiator of our service is our ability to hold tight tolerances consistently. We routinely maintain tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, with geometric tolerances such as flatness, concentricity, and perpendicularity controlled to ISO 2768-mK or tighter upon request. Our metrology lab is equipped with coordinate measuring machines (CMM), optical comparators, and surface roughness testers to verify dimensional compliance and surface integrity.

The following table outlines our standard tolerance capabilities and compatible materials:

| Operation | Standard Tolerance | Tight Tolerance Capability | Commonly Used Materials |

|———————|——————–|—————————-|———————————————|

| 3-Axis Milling | ±0.025 mm | ±0.005 mm | Aluminum 6061, 7075; Steel 1018, 4140; Stainless Steel 303, 316; Brass C360; Plastics (PEEK, Delrin, Nylon) |

| 4-Axis Milling | ±0.025 mm | ±0.008 mm | Same as above, with added support for cast aluminum and titanium alloys |

| 5-Axis Milling | ±0.015 mm | ±0.005 mm | Titanium Grade 5, Inconel 718, Aluminum 2024, Stainless Steel 17-4PH |

| CNC Turning | ±0.010 mm | ±0.005 mm | Steel, Stainless Steel, Brass, Aluminum, PEEK, Acetal |

| Turn-Mill Hybrid | ±0.010 mm | ±0.005 mm | Multi-material compatibility with bar feed automation |

All materials are sourced from certified suppliers and subjected to incoming inspection. Material certifications and traceability are provided upon request. With full in-house programming, tooling, and inspection, Shenzhen Honyo Prototype ensures every CNC-machined part meets the highest standards of precision and reliability.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s CNC Machining Workflow

At Shenzhen Honyo Prototype, we transform digital designs into precision-engineered components through a streamlined, quality-focused CNC machining workflow. Our integrated process—AI Quote, DFM Analysis, and Production Execution—minimizes lead times while ensuring manufacturability and part integrity. This structured approach is fundamental to delivering reliable prototypes and low-volume production parts efficiently.

The workflow initiates with our AI-Powered Quoting System. Upon receiving a customer’s CAD file (STEP, IGES, Parasolid, or native formats), our proprietary algorithm rapidly analyzes geometric complexity, material requirements, tolerances, and surface finish specifications. This system cross-references real-time machine availability, tooling constraints, and material costs to generate an accurate, instant quote within minutes. Key inputs driving the quote include part volume, feature density, and critical dimension callouts. This immediate feedback loop allows customers to make informed design or budgetary decisions early, significantly accelerating project kickoff compared to manual quoting methods.

Following quote acceptance, the design enters our rigorous Design for Manufacturability (DFM) Analysis phase. Our senior manufacturing engineers conduct a methodical validation against CNC machining capabilities and limitations. This critical step identifies potential production risks before material is cut, preventing costly revisions or delays. We assess factors such as minimum wall thicknesses, internal corner radii, hole depth-to-diameter ratios, and tolerance feasibility relative to standard machining practices. Common issues and our standard resolutions are summarized below:

| Potential Design Issue | Honyo Standard Resolution | Manufacturing Impact Mitigated |

|————————|—————————|——————————-|

| Wall thickness < 0.8mm | Recommend minimum 0.8mm | Prevents vibration, breakage during machining |

| Sharp internal corners | Suggest 0.5mm minimum radius | Ensures tool access, reduces stress concentration |

| Deep blind holes (D:d > 4:1) | Propose stepped drills or alternative solutions | Maintains hole straightness, prevents tool breakage |

| Non-standard tolerances (e.g., ±0.005mm over 50mm) | Confirm necessity or suggest GD&T | Balances precision requirements with cost efficiency |

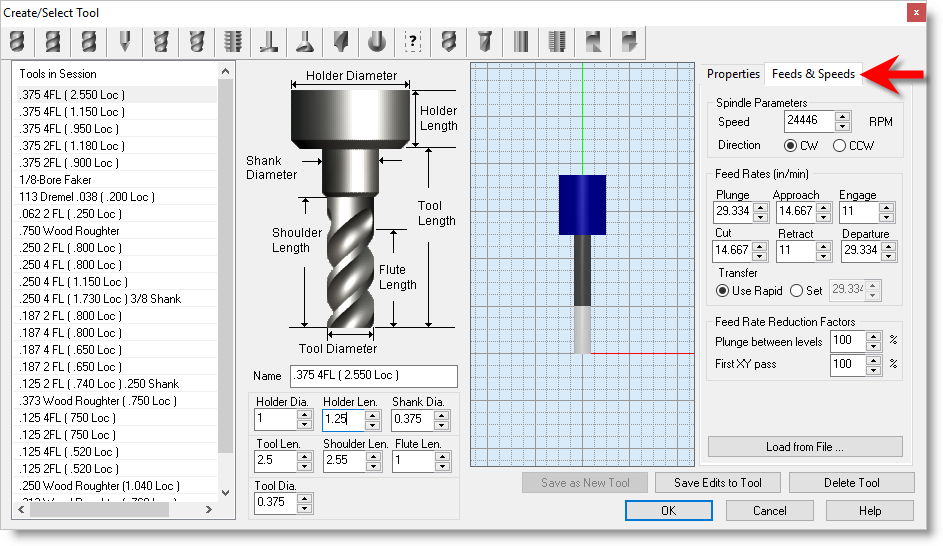

Only after DFM sign-off—where all parties agree on the optimized manufacturing strategy—does the project advance to Production Execution. Our CAM programmers develop efficient, collision-avoidant toolpaths using Mastercam and Fusion 360, selecting optimal tooling, speeds, and feeds for the specified material (aluminum, steel, plastics, etc.). Rigorous machine setup follows, including precise workholding, tool calibration, and origin point verification. Machining proceeds through defined roughing, semi-finishing, and finishing stages on our modern Haas and DMG MORI equipment, including 3-axis, 4-axis, and 5-axis vertical machining centers plus Swiss-type lathes. Throughout production, in-process inspections verify critical dimensions, with final First Article Inspection reports provided against customer drawings. This disciplined transition from validated design to controlled machining ensures every Honyo part meets stringent quality standards upon delivery. Our integrated workflow guarantees precision from CAD model to functional component, delivering speed without compromise.

Start Your Project

Start Your CNC Machining Project with Confidence at Shenzhen Honyo Prototype

When it comes to precision CNC machining, the foundation of a successful project lies in accurate planning, expert consultation, and access to advanced manufacturing capabilities. At Shenzhen Honyo Prototype, we specialize in delivering high-quality CNC-machined parts with tight tolerances, fast turnaround times, and exceptional material versatility. Whether you’re developing a single prototype or scaling to low-volume production, our team is equipped to support your engineering goals from concept to completion.

Our CNC calculator is designed to streamline your quoting process, offering fast, transparent cost estimates based on your part specifications. However, for optimal results, we strongly recommend direct collaboration with our manufacturing engineers. Every project presents unique challenges—material selection, feature complexity, surface finish requirements, and design for manufacturability—all of which can significantly impact cost, lead time, and part performance. By engaging with our team early, you ensure your design is optimized for precision, efficiency, and cost-effectiveness.

At Honyo Prototype, we support a wide range of materials including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics such as PEEK, Delrin, and nylon. Our 3-axis and 5-axis CNC milling centers, combined with advanced turning capabilities, allow us to produce complex geometries with tolerances as tight as ±0.005 mm. With in-house quality inspection using CMM and optical measurement systems, we guarantee every component meets your exact specifications.

To get started, simply prepare your 3D CAD model in STEP, IGES, or X_T format, along with any specific requirements for finish, tolerances, or certifications. While our online tools provide a preliminary estimate, a personalized quote from our team ensures all technical nuances are addressed. This step is critical for avoiding delays, reducing iteration cycles, and achieving first-time-right production.

Below is an overview of our standard CNC machining capabilities:

| Parameter | Specification |

|—————————-|———————————————–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Maximum Work Envelope | 1000 × 600 × 500 mm (milling) |

| Tolerances | ±0.005 mm standard |

| Materials | Aluminum, steel, stainless steel, brass, titanium, plastics |

| Surface Finishes | As-machined, anodizing (Type II & III), powder coating, passivation, polishing |

| Lead Times | As fast as 3–5 days for prototypes |

| Quality Standards | ISO 9001:2015 compliant; full inspection reports available |

Partnering with Honyo Prototype means you’re not just placing an order—you’re gaining a manufacturing ally committed to your project’s success. Let us help you turn your design into a precision-engineered reality.

For expert guidance and a tailored quote, contact Susan Leo directly at info@hy-proto.com. Our team is ready to assist with technical feedback, material recommendations, and rapid prototyping solutions that keep your development on track.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.