Contents

Manufacturing Insight: Cnc Tube Bending Service

Manufacturing Insight: Precision CNC Tube Bending Service

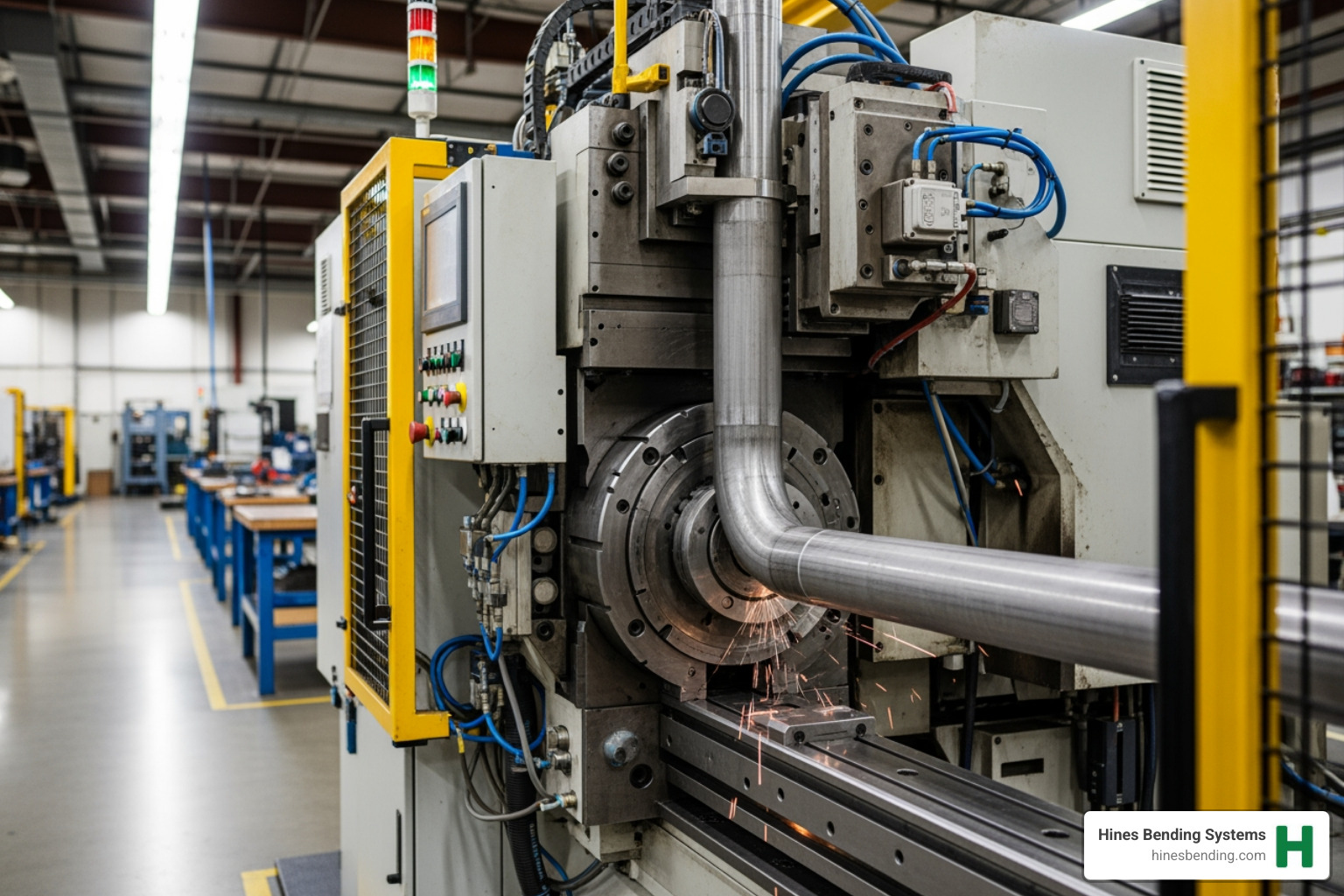

CNC tube bending represents a critical capability in modern precision fabrication, enabling complex geometries for hydraulic systems, aerospace conduits, medical devices, and structural frameworks. Unlike manual or semi-automated methods, CNC-controlled bending delivers repeatability, tight tolerances, and seamless integration with digital workflows. At Shenzhen Honyo Prototype, we leverage advanced CNC tube bending technology to transform 3D CAD models into high-integrity components, minimizing material waste and eliminating human-induced variability. Our process utilizes real-time feedback systems to compensate for material springback and wall thinning, ensuring dimensional accuracy across diverse alloys and production volumes.

Honyo’s CNC tube bending service supports rapid prototyping and low-to-mid volume production with engineering-grade materials. Our facility operates state-of-the-art CNC benders equipped with rotary draw and mandrel-assisted forming capabilities, accommodating both structural and precision fluid-handling applications. Key technical specifications are summarized below:

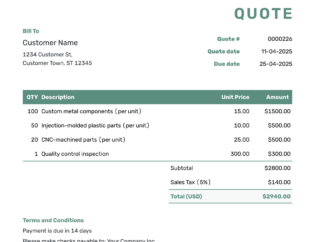

| Parameter | Capability | Tolerance/Range |

|————————|————————————-|———————–|

| Max. Tube Diameter | 60 mm (2.36″) | – |

| Min. Centerline Radius | 1.5x Tube Diameter | – |

| Material Compatibility | Stainless Steel (304, 316), Aluminum (6061, 7075), Copper, Carbon Steel | – |

| Angular Tolerance | ±0.1° per bend | – |

| Linear Tolerance | ±0.2 mm | – |

| Max. Single-Pass Length| 3000 mm (118″) | – |

This precision is achieved through rigorous material characterization databases and adaptive tooling setups. Each job undergoes pre-bend simulation to predict deformation, while in-process laser metrology validates bend angles and spatial relationships against the native CAD file. For thin-walled or high-precision tubing, our mandrel systems prevent ovality and collapse, maintaining critical internal diameters for fluid dynamics applications. We prioritize material integrity through optimized speed/feed parameters and proprietary lubrication protocols, reducing surface marring on sensitive finishes like electropolished stainless steel.

Beyond bending, Honyo integrates secondary operations—such as CNC milling, laser cutting, welding, and anodizing—within a single facility. This vertical integration eliminates supply chain handoffs, accelerating time-to-assembly for clients in automotive, robotics, and life sciences. All components undergo first-article inspection per ASME Y14.5 standards, with full traceability from raw material to finished part. Our engineering team collaborates directly with clients during DFM analysis to optimize bend sequences, reduce fixture complexity, and identify cost-saving opportunities without compromising performance.

For manufacturers requiring complex tubular assemblies with zero defect tolerance, Honyo delivers a seamless transition from prototype validation to serialized production. Our CNC tube bending service combines German-engineered machinery with ISO 9001-certified processes, ensuring every component meets the functional and regulatory demands of high-stakes industries. Partner with us to convert intricate tubing designs into reality with uncompromised precision and agility.

Technical Capabilities

CNC Tube Bending Service – Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC tube bending services tailored for industries requiring high repeatability, tight tolerances, and complex geometries. Our advanced 3-axis, 4-axis, and 5-axis CNC tube bending machines integrate seamlessly with multi-axis milling and turning centers, enabling comprehensive in-house manufacturing of bent tube components with secondary machining operations. This integration ensures dimensional accuracy and reduces lead times by eliminating external handling and setup transfers.

Our CNC tube bending technology supports a wide range of diameters, wall thicknesses, and bend radii, accommodating both simple and highly complex 3D tube forms. Utilizing state-of-the-art CNC controls and servo-driven bending heads, we achieve consistent angular precision and minimal ovality. Each machine is equipped with real-time feedback systems that monitor bend angle, rotation, and feed positioning, ensuring adherence to strict geometric specifications.

Tight tolerance bending is a core capability, with standard angular accuracy maintained within ±0.2° and dimensional tolerances held to ±0.005″ (±0.13 mm) on critical features. For high-precision applications such as aerospace fluid systems, medical devices, and performance automotive components, we offer enhanced process validation with SPC (Statistical Process Control) monitoring and first-article inspection reports (FAIR).

Material compatibility is a key strength of our tube bending service. We process a broad spectrum of metals commonly used in demanding engineering environments. Our machines are calibrated to handle both soft and hard alloys, with optimized tooling and speed parameters to prevent cracking, wrinkling, or excessive thinning.

Below is a summary of our standard technical specifications:

| Parameter | Specification |

|—————————-|————-|

| Tube Diameter Range | 0.125″ – 2.0″ (3.18 mm – 50.8 mm) |

| Wall Thickness Range | 0.015″ – 0.188″ (0.38 mm – 4.78 mm) |

| Minimum Centerline Radius | 1.5x Tube Diameter |

| Maximum Bend Angle | ±180° per bend |

| Angular Accuracy | ±0.2° |

| Linear Tolerance | ±0.005″ (±0.13 mm) |

| Axis Configuration | 3-axis, 4-axis, 5-axis CNC |

| Secondary Machining | In-line milling, drilling, tapping, turning |

| Max Tube Length | 120″ (3050 mm) |

We support a variety of materials, including those listed below:

| Material Type | Common Grades |

|—————————-|—————|

| Stainless Steel | 304, 304L, 316, 316L, 17-4 PH |

| Aluminum | 6061-T6, 5052, 3003 |

| Carbon Steel | 1010, 1020, 1045 |

| Copper Alloys | C11000, C12200, C26000 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) |

| Nickel Alloys | Inconel 625, Inconel 718 |

All tube bending jobs are supported by our in-house CAD/CAM programming team, using industry-standard software to simulate bending sequences and avoid collisions. We accept 3D models in STEP, IGES, and native SolidWorks formats to ensure accurate data translation and reduce programming errors.

At Shenzhen Honyo Prototype, our CNC tube bending service combines precision engineering with agile manufacturing to deliver high-integrity components for prototyping and low-to-mid volume production.

From CAD to Part: The Process

CNC Tube Bending Production Process: From CAD to Finished Component

At Shenzhen Honyo Prototype, our CNC tube bending service transforms digital designs into precision-engineered components through a rigorously defined workflow. This process ensures manufacturability, quality, and efficiency from initial inquiry to final shipment. The core sequence integrates advanced digital tools with expert engineering oversight, structured into three critical phases: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Precision Production Execution.

The workflow initiates upon receipt of a validated CAD model (STEP, IGES, or native formats preferred). Our proprietary AI quoting engine immediately analyzes the geometry, extracting key parameters including tube diameter, wall thickness, material specification, total length, and the sequence of bend angles and radii. This automated analysis generates an initial, data-driven cost and lead time estimate within minutes, providing rapid feedback while flagging potential high-risk features like extremely tight bend radii or complex spatial orientations requiring secondary operations. This AI stage accelerates the quotation process significantly compared to manual methods.

Following client confirmation of the quote, the project enters the mandatory DFM phase. Our senior manufacturing engineers conduct a detailed technical review, focusing on bend feasibility, tooling requirements, and process optimization. Critical checks include verifying minimum bend radius against material properties and machine capabilities, assessing clamp and rotation zone clearances to prevent collisions, evaluating the necessity of mandrels for thin-walled or high-precision bends, and optimizing the bend sequence to minimize handling and secondary operations. Material compatibility with bending stresses and surface finish requirements are also scrutinized. Client collaboration is essential here; we provide specific, actionable feedback and recommendations to resolve any manufacturability issues before production commences, preventing costly delays or rework.

Only after DFM sign-off does the project move to production. The approved CAD model is directly imported into our offline programming (OLP) system. Programmers generate optimized machine code (G-code), defining precise axis movements, clamp positions, bend angles, and rotation sequences. Critical process parameters like助推力 (push force), bend speed, and mandrel settings are meticulously configured based on material grade and geometry. A first-article sample is produced under controlled conditions. This sample undergoes rigorous dimensional inspection against the original CAD data using coordinate measuring machines (CMM) and visual surface checks. Full production proceeds only after the first article meets all specifications. Throughout batch production, statistical process control (SPC) monitors key dimensions, and final inspection ensures every component adheres to the agreed quality standards before packaging and shipment.

Honyo Prototype’s integrated workflow, combining AI efficiency with deep engineering expertise, guarantees that your tube bending project transitions smoothly from concept to high-integrity physical part. The following table summarizes our core production capabilities:

| Parameter | Specification Range | Critical Consideration |

| :——————— | :————————————– | :—————————————– |

| Material Types | Stainless Steel, Aluminum, Copper, Carbon Steel | Material grade dictates bend radius limits |

| Tube Diameter | 4 mm to 80 mm (0.16″ to 3.15″) | Larger diameters require higher tonnage |

| Wall Thickness | 0.5 mm to 5.0 mm (0.02″ to 0.2″) | Thin walls necessitate mandrel support |

| Minimum Bend Radius | 1.5x Tube Diameter (Material Dependent) | Tighter radii increase springback & risk |

| Angular Tolerance | ±0.5° | Affected by material, tooling, machine rigidity |

| Linear Dimension Tolerance | ±0.2 mm per 100 mm length | Cumulative error managed via bend sequence |

Start Your Project

Start Your CNC Tube Bending Project with Precision and Confidence

When it comes to high-precision fabrication in modern manufacturing, CNC tube bending stands out as a critical process for industries ranging from automotive and aerospace to medical devices and industrial equipment. At Shenzhen Honyo Prototype, we specialize in delivering reliable, repeatable, and accurate CNC tube bending services tailored to your exact specifications. Whether you’re developing a prototype or scaling up for low- to mid-volume production, our advanced capabilities ensure your components meet the highest standards of quality and performance.

Our CNC tube bending technology combines state-of-the-art machinery with expert engineering oversight, enabling us to handle complex geometries, tight bend radii, and a wide range of tube materials and diameters. We support both metric and imperial units, and our team works closely with your design inputs to optimize manufacturability, reduce material waste, and ensure dimensional accuracy across every batch.

To get started, simply share your technical drawings, 3D models, or project requirements with our engineering team. We accept common file formats including STEP, IGES, DWG, DXF, and PDF, and provide fast turnaround on quotations and design for manufacturability (DFM) feedback. Our goal is to streamline your development process and minimize time-to-market without compromising on precision or structural integrity.

Below are the key technical specifications we support for CNC tube bending:

| Parameter | Range / Capability |

|—————————-|———————————————————|

| Tube Diameter | 3 mm – 60 mm (0.12” – 2.36”) |

| Wall Thickness | 0.5 mm – 5 mm (0.02” – 0.2”) |

| Bend Radius (CLR) | As low as 1x tube diameter (based on material & diameter)|

| Material Compatibility | Stainless Steel, Aluminum, Carbon Steel, Copper, Brass |

| Maximum Tube Length | Up to 6,000 mm (236”) |

| Tolerance (Bend Angle) | ±0.5° |

| Tolerance (Bend Position) | ±0.2 mm (±0.008”) |

| Finishing Options | Deburring, Cleaning, Passivation, Bead Blasting |

We understand that every project has unique demands. Our engineers are equipped to advise on material selection, bend sequence optimization, and assembly integration to ensure your final product performs as intended under real-world conditions.

Ready to move forward? The next step is simple. Contact Susan Leo, your dedicated project coordinator at Shenzhen Honyo Prototype, to discuss your CNC tube bending requirements. We offer rapid response times, competitive pricing, and full project transparency from quote to delivery.

Email Susan Leo at info@hy-proto.com with your design files and specifications. Our team will provide a detailed quotation, DFM analysis, and production timeline within 24 business hours. Let us help you transform your concept into a high-precision reality—efficiently, accurately, and reliably.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.