Contents

Manufacturing Insight: Cnc Quotes

Manufacturing Insight: CNC Machining Quoting Fundamentals

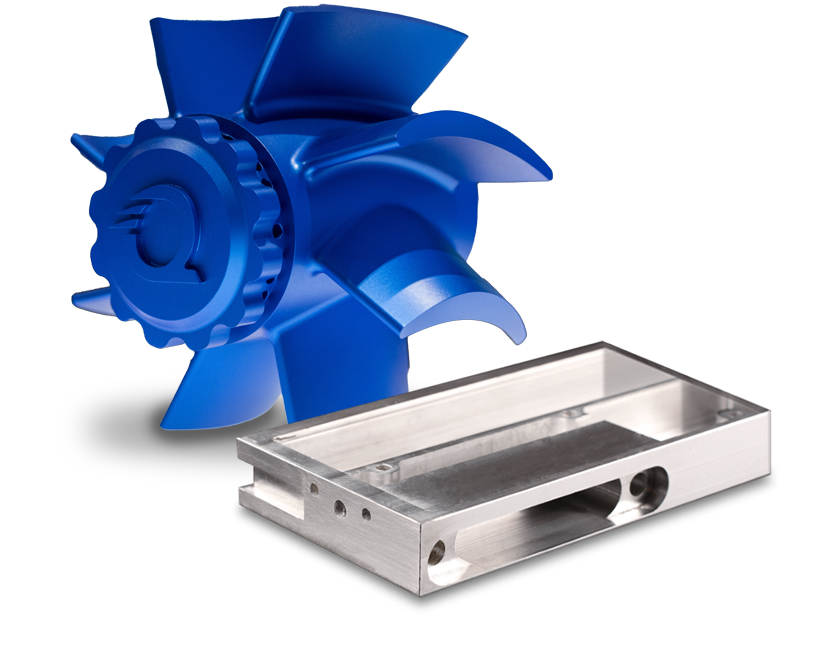

CNC machining remains the cornerstone of precision prototype and low-volume production manufacturing, delivering unmatched repeatability and material versatility for demanding engineering applications. At Shenzhen Honyo Prototype, our quoting process transcends basic cost calculation; it integrates deep manufacturing insight to ensure technical feasibility, optimal lead times, and cost efficiency from the earliest design stages. Understanding the interplay between part geometry, material selection, tolerances, and machine capabilities is critical for generating accurate, actionable quotes that align with project objectives.

Honyo Prototype leverages advanced 3-, 4-, and 5-axis CNC milling and turning centers to handle complex geometries with micron-level precision. Our engineering team evaluates every RFQ against stringent manufacturability criteria, identifying potential design optimizations that reduce machining time without compromising functionality. This proactive approach prevents costly revisions and accelerates time-to-market. Key technical capabilities underpinning our quoting accuracy include tight tolerancing down to ±0.005 mm, high-speed machining for hardened steels and exotic alloys, and integrated multi-operation setups that minimize secondary handling. Material expertise spans aerospace-grade aluminum (7075-T6, 2024), stainless steels (303, 304, 17-4PH), titanium (Grade 5), engineering plastics (PEEK, Delrin), and copper alloys.

The following table summarizes core CNC machining specifications driving our quoting parameters:

| Parameter | Capability Range | Impact on Quote |

|——————–|——————————|———————————-|

| Tolerance | ±0.005 mm to ±0.05 mm | Tighter tolerances increase cycle time and cost |

| Max Work Envelope | 1000 x 600 x 500 mm (5-axis) | Larger volumes require specialized equipment |

| Surface Finish | Ra 0.8 μm to Ra 3.2 μm | Finer finishes necessitate additional passes |

| Lead Time | 3–15 working days | Complexity and material availability are key variables |

| Material Types | Metals, Plastics, Composites | Exotic materials affect tooling and machining strategy |

Quality assurance is embedded within our quoting methodology. Every quote reflects the cost of mandatory in-process inspections using calibrated CMMs, optical comparators, and surface roughness testers, ensuring compliance with ISO 9001 and AS9100 standards. We factor in first-article inspection (FAI) requirements and material certification costs upfront, eliminating hidden expenses. For high-mix, low-volume production, our digital workflow—integrating CAD/CAM validation and real-time machine monitoring—enables rapid iteration while maintaining traceability.

Honyo Prototype’s quoting advantage lies in our engineers’ hands-on production experience. Rather than relying solely on automated systems, we conduct technical deep dives to anticipate challenges like thin-wall deflection, internal cavity access, or heat-sensitive material machining. This human expertise, combined with our Shenzhen-based facility’s strategic supply chain access, allows us to deliver quotes that balance speed, precision, and value. By partnering with us early in the design phase, clients gain actionable data to refine DFM, avoid non-recurring engineering (NRE) surprises, and secure a reliable path from prototype to pilot production. Trust Honyo to transform your CNC machining requirements into a transparent, technically robust manufacturing plan.

Technical Capabilities

Technical Capabilities for CNC Machining at Shenzhen Honyo Prototype

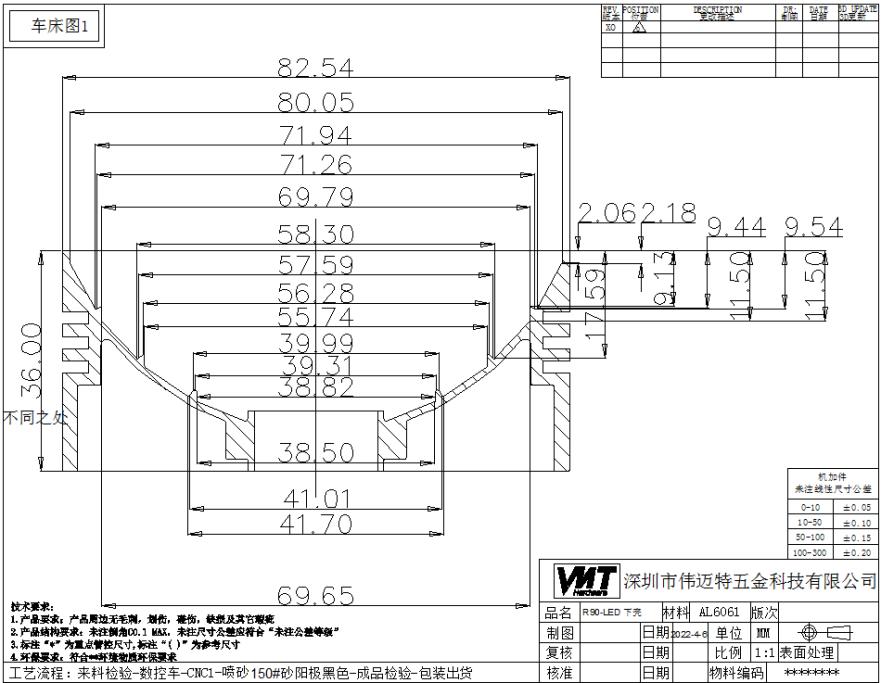

At Shenzhen Honyo Prototype, our CNC machining services are engineered to deliver precision, repeatability, and rapid turnaround for prototypes and low-volume production runs. We specialize in 3-axis, 4-axis, and 5-axis milling, as well as CNC turning, enabling us to handle complex geometries and tight-tolerance components across a wide range of engineering materials. Our advanced machining centers are operated by experienced technicians who follow strict quality control protocols to ensure every part meets or exceeds customer specifications.

Our 3-axis milling capabilities support standard prismatic parts with high accuracy and surface finish consistency. For more complex features such as undercuts, angled surfaces, and organic shapes, we utilize 4-axis and 5-axis simultaneous machining to reduce setup次数 and improve geometric precision. This multi-axis approach allows for single-setup machining of intricate components, minimizing human error and ensuring tighter feature-to-feature tolerances.

CNC turning is employed for cylindrical or rotational parts, including shafts, bushings, and threaded components. We support both standard turning and mill-turn operations, where live tooling enables off-center drilling, tapping, and milling on a turning center—ideal for fully finished parts in one operation.

A core strength of our service is our ability to maintain tight tolerances. While standard machining tolerances are held to ±0.05 mm, we routinely achieve ±0.005 mm for critical dimensions upon request. Our quality assurance process includes first-article inspection (FAI), in-process checks, and final CMM verification for high-precision jobs.

We support a broad range of materials, including aluminum alloys, stainless and carbon steels, brass, copper, titanium, and engineering plastics such as PEEK, Delrin, and nylon. Material selection is optimized based on application requirements for strength, weight, corrosion resistance, and machinability.

Below is a detailed summary of our standard and tight tolerance capabilities across common material groups:

| Material Category | Common Materials | Standard Tolerance (mm) | Tight Tolerance (mm) | Max Part Size (mm) | Surface Finish (Ra, µm) |

|——————-|——————|————————–|————————|——————–|————————–|

| Aluminum Alloys | 6061, 7075, 2024 | ±0.05 | ±0.005 | 600 x 400 x 300 | 1.6 – 3.2 |

| Stainless Steel | 303, 304, 316, 17-4PH | ±0.05 | ±0.005 | 500 x 350 x 250 | 1.6 – 3.2 |

| Carbon Steel | 1018, 1045, 4140 | ±0.05 | ±0.008 | 500 x 350 x 250 | 1.6 – 3.2 |

| Brass & Copper | C36000, C11000 | ±0.05 | ±0.005 | 400 x 300 x 200 | 1.6 – 3.2 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | ±0.05 | ±0.008 | 400 x 300 x 200 | 1.6 – 3.2 |

| Engineering Plastics | PEEK, Delrin, Nylon, PC | ±0.05 | ±0.01 | 600 x 500 x 300 | 3.2 – 6.3 |

All CNC quote requests are evaluated for geometry, tolerance requirements, material availability, and surface finish needs. Our engineering team provides Design for Manufacturability (DFM) feedback to optimize part design, reduce lead time, and lower costs. With ISO-compliant processes and full traceability, Shenzhen Honyo Prototype ensures consistent quality for every machined component.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s CNC Machining Workflow

Shenzhen Honyo Prototype delivers precision CNC machined parts through a rigorously defined workflow, ensuring efficiency, quality, and cost-effectiveness from initial inquiry to final shipment. Our integrated process eliminates ambiguity and accelerates time-to-part, leveraging automation and expert engineering oversight at critical junctures. The journey begins with the AI Quote phase, progresses through essential Design for Manufacturability (DFM) analysis, and culminates in controlled production execution.

The AI Quote phase initiates when a customer uploads their CAD model to our online portal. Our proprietary AI engine instantly analyzes geometric complexity, material selection, required tolerances, and surface finish specifications against current machine capabilities and material stock availability. This system generates a highly accurate preliminary quote within minutes, including estimated lead time and cost breakdown, providing immediate transparency. Crucially, this initial assessment identifies potential high-risk geometries or unrealistic specifications that require further engineering review, setting clear expectations before formal order placement.

Following quote acceptance and order confirmation, the DFM phase commences. Our senior manufacturing engineers conduct a comprehensive manual review, moving beyond the AI’s initial scan to optimize manufacturability and prevent costly errors. This critical step examines feature feasibility, tool access, workholding strategies, and secondary operation requirements. Key parameters scrutinized during DFM are detailed below:

| Parameter | Standard Tolerance | Critical Check | Typical Action |

|——————–|——————–|————————————|————————————|

| Minimum Feature Size | ±0.05 mm | Tool diameter vs. cavity width | Recommend design modification |

| Wall Thickness | ≥ 0.8 mm (Al) | Stability during machining | Suggest thickness increase |

| Tight Tolerances | < ±0.025 mm | Required metrology capability | Confirm CMM availability |

| Surface Finish | Ra 1.6 µm standard | Achievable via standard machining | Advise on post-process options |

Engineers collaborate directly with the client to resolve any DFM flags, proposing practical solutions that maintain functional intent while enhancing producibility. Formal approval of the DFM report is mandatory before production release.

Production execution leverages Honyo’s advanced infrastructure. Approved CAD data drives CAM programming, where optimized toolpaths are generated and rigorously simulated to prevent collisions and ensure efficient material removal. Machinists then perform meticulous machine setup, verifying datum points, tooling, and program integrity against the approved DFM and engineering drawings. Machining occurs on our maintained CNC mills and lathes under controlled environmental conditions. Throughout production, in-process inspections validate critical dimensions, with final First Article Inspection (FAI) reports provided per customer requirements. Rigorous material traceability and post-processing (deburring, cleaning, optional finishing) precede final QA release and shipment. This seamless, checkpoint-driven workflow guarantees that every part shipped from Shenzhen Honyo Prototype meets the highest standards of precision and reliability, directly translating your CAD design into a flawless physical component.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When it comes to precision CNC machining for prototypes and low-volume production, Shenzhen Honyo Prototype delivers unmatched quality, speed, and technical expertise. Whether you’re an engineer, product designer, or procurement manager, starting your project with us is seamless, transparent, and engineered for success. Our advanced CNC capabilities support a wide range of materials, tolerances, and complex geometries, ensuring your parts meet exact specifications—on time and within budget.

At Honyo, we specialize in turning design concepts into high-precision components using state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling and turning centers. Our machining services are ideal for industries such as aerospace, medical devices, robotics, automotive, and consumer electronics, where reliability and repeatability are non-negotiable. With in-house quality control, including CMM inspection and surface finish verification, every component is manufactured to ISO 9001 standards.

To begin your project, simply reach out to Susan Leo, our dedicated Customer Engineering Manager. Susan serves as your single point of contact throughout the entire manufacturing process, providing technical guidance, real-time updates, and expert feedback on design for manufacturability (DFM). Her role is to ensure your project moves smoothly from CAD file to finished part with minimal delays and maximum efficiency.

We understand that every project has unique requirements. That’s why we offer tailored solutions based on your timeline, material selection, surface finish needs, and volume expectations. By submitting your request early, you gain access to our engineering review process, which can identify potential cost savings and performance improvements before machining begins.

Below is an overview of our standard CNC machining specifications to help you assess feasibility and plan accordingly.

| Specification | Capability |

|—————|————|

| Machining Types | 3-axis, 4-axis, 5-axis milling; CNC turning; mill-turn |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Steel (4140, 1018), Titanium, Brass, Plastics (Delrin, Nylon, PEEK) |

| Tolerances | Standard: ±0.05 mm; Tight: ±0.005 mm (achievable with inspection) |

| Maximum Work Envelope | 1000 mm × 600 mm × 500 mm (XYZ) |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Bead Blasting |

| Lead Times | As fast as 3–5 days for prototypes; production runs within 10–15 days |

| Quality Standards | ISO 9001:2015 certified; First Article Inspection (FAI) and PPAP available |

Starting your project is easy. Send your 3D CAD files (STEP, IGS, or native formats preferred) and any special instructions directly to Susan Leo at info@hy-proto.com. Our team will respond within 4 business hours with a detailed quote, DFM report, and production timeline. We accept RFQs for single prototypes up to 500-piece batches, with volume pricing available upon request.

Partner with Shenzhen Honyo Prototype and experience CNC machining that combines precision, professionalism, and proactive support. Let us help you bring your next innovation to life—accurately, efficiently, and reliably.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.