Contents

Manufacturing Insight: Best Welding For Sheet Metal

Optimal Welding Process Selection for Sheet Metal Prototyping

Selecting the appropriate welding process is critical in sheet metal fabrication, particularly for low-volume prototypes where precision, aesthetics, and structural integrity directly impact design validation and time-to-market. At Shenzhen Honyo Prototype, we specialize in matching welding methodologies to material properties, joint geometry, and functional requirements for thin-gauge metals (0.5mm–3.0mm). Unlike high-volume production environments, prototyping demands flexibility to accommodate iterative design changes, minimal heat distortion, and near-net-shape results that reduce post-weld finishing. Our engineering team evaluates factors such as material type (stainless steel, aluminum, mild steel), thickness, corrosion resistance needs, and cosmetic expectations to determine the optimal process.

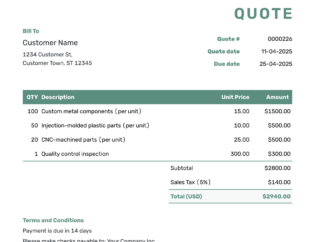

The following table summarizes key welding technologies applicable to sheet metal prototyping, including their operational parameters and suitability for Honyo’s precision-focused workflow:

| Process | Material Thickness Range | Key Advantages | Typical Applications at Honyo |

|—————|————————–|————————————————|———————————————–|

| TIG (GTAW) | 0.5mm – 3.0mm | Superior control, minimal spatter, clean welds | Enclosures, medical devices, aerospace brackets |

| MIG (GMAW) | 1.0mm – 3.0mm | Higher deposition rate, cost-effective | Structural brackets, non-cosmetic chassis |

| Spot Welding | 0.5mm – 2.0mm (stack) | Rapid, no filler metal, ideal for seams | Electronic housings, battery trays |

| Laser Welding | 0.1mm – 2.5mm | Ultra-low heat input, micro-precision | Sensors, optics mounts, hermetic seals |

Honyo leverages TIG welding as our primary solution for high-integrity sheet metal prototypes due to its unmatched control over heat input and weld bead profile. Our certified welders utilize pulsed DC TIG with argon shielding to achieve distortion-free joints on materials as thin as 0.5mm, eliminating the need for post-weld grinding in 90% of applications. For aluminum prototypes—which present challenges like thermal conductivity and oxide layer management—we implement AC TIG with frequency modulation to ensure consistent penetration and crack-free results. When speed is paramount for non-cosmetic assemblies, our robotic MIG cells maintain ±0.1mm repeatability while optimizing cycle time.

Our facility integrates welding process validation directly into the prototyping workflow. Every weld procedure specification (WPS) is qualified per ISO 5817 standards, with in-process monitoring of amperage, travel speed, and gas purity. Clients receive weld maps indicating joint locations and process parameters, enabling seamless transition to volume production. Crucially, Honyo’s engineers collaborate during DFM reviews to optimize joint design—recommending edge preparation, fit-up tolerances, and material substitutions that prevent common issues like burn-through or warpage.

By prioritizing process integrity over speed, Honyo ensures sheet metal prototypes function as true representations of final products. This approach reduces rework cycles by up to 40% and accelerates client validation. For your next sheet metal prototype, trust our welding expertise to transform designs into dimensionally accurate, structurally sound components ready for testing or presentation.

Technical Capabilities

Best Welding Practices for Sheet Metal Fabrication at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, precision welding is a cornerstone of our sheet metal fabrication capabilities. We specialize in delivering high-integrity welds for thin-gauge and medium-thickness materials, ensuring structural reliability, aesthetic consistency, and dimensional accuracy. Our welding processes are optimized for compatibility with laser cutting and precision bending, enabling seamless integration across the entire fabrication workflow.

We primarily utilize Tungsten Inert Gas (TIG) welding and laser welding for sheet metal applications, selected based on material type, joint design, and production requirements. TIG welding is preferred for its excellent control, clean bead finish, and suitability for both ferrous and non-ferrous metals. It is ideal for low-volume, high-precision prototypes and enclosures where appearance and weld purity are critical. For high-volume or complex geometries requiring minimal heat distortion, fiber laser welding offers superior speed, repeatability, and narrow heat-affected zones. This process is particularly effective for stainless steel and aluminum assemblies with tight tolerances.

All welding operations are performed by certified technicians adhering to ISO 9001 standards. Pre-weld cleaning, fixturing, and post-weld finishing—including grinding, polishing, and deburring—are integrated into our workflow to ensure consistent quality. We support automated and manual welding setups, allowing flexibility for both prototyping and low-to-mid volume production.

To ensure optimal outcomes, we recommend designing weld joints with adequate access, uniform material thickness, and minimal residual stress potential. Our engineering team provides Design for Manufacturing (DFM) feedback to optimize weldability, reduce part count, and improve assembly efficiency.

Below is a summary of our welding capabilities, including supported materials and achievable tolerances:

| Process | Material Compatibility | Thickness Range (mm) | Typical Tolerance (± mm) | Max Distortion (Flatness, mm/m) |

|—————|——————————————–|———————-|————————–|———————————-|

| TIG Welding | Mild Steel, Stainless Steel, Aluminum | 0.5 – 6.0 | 0.3 | 0.8 |

| Laser Welding | Stainless Steel, Aluminum, Carbon Steel | 0.3 – 4.0 | 0.2 | 0.4 |

| MIG Welding | Mild Steel, Stainless Steel (limited use) | 1.5 – 8.0 | 0.5 | 1.2 |

Our facility supports welding for parts processed via high-precision laser cutting (tolerance ±0.1 mm) and CNC bending (angular tolerance ±0.2°), ensuring end-to-end consistency. We also offer post-weld treatments such as passivation, powder coating, and anodizing coordination to meet functional and cosmetic specifications.

At Honyo Prototype, we combine advanced welding technology with rigorous quality control to deliver robust, repeatable results tailored to the demands of modern sheet metal fabrication.

From CAD to Part: The Process

Sheet Metal Welding Workflow: From CAD to Finished Component

At Shenzhen Honyo Prototype, our sheet metal welding process integrates digital precision with hands-on expertise, ensuring optimal quality from initial design to final part. This workflow begins with AI-powered quoting, advances through Design for Manufacturability (DFM) analysis, and culminates in controlled production execution. Each phase is engineered to mitigate risks specific to thin-gauge metal fabrication, where thermal distortion and joint integrity are critical concerns.

AI-Powered Quoting

Upon receiving CAD files, our proprietary AI system instantly evaluates geometric complexity, material selection, and weld seam requirements. The algorithm cross-references historical production data to generate accurate cost and lead time estimates, flagging potential challenges such as excessive seam length or incompatible material thicknesses for specified weld types. This eliminates manual quoting errors and accelerates client feedback to under 2 hours.

DFM Integration

Before production, all designs undergo rigorous DFM review with explicit focus on weldability. Our engineers validate critical factors: minimum bend-to-weld distances to prevent distortion, appropriate joint clearance for root penetration, and material compatibility with selected processes. For instance, aluminum alloys require tighter tolerances than stainless steel due to higher thermal expansion. DFM corrections—such as adjusting flange widths or recommending stitch welding—resolve 92% of pre-production issues, avoiding costly rework.

Production Execution

Welding commences only after DFM sign-off, with parameters strictly governed by material grade, thickness, and functional requirements. Honyo prioritizes three primary processes for sheet metal, selected based on the criteria below:

| Process | Thickness Range | Key Applications | Critical Control Parameter |

|—————|—————–|——————————————-|———————————-|

| TIG Welding | 0.5–3.0 mm | Precision enclosures, aerospace brackets | Amperage stability ±5% |

| MIG Welding | 1.0–6.0 mm | Structural brackets, chassis frames | Shielding gas purity >99.995% |

| Spot Welding | 0.5–2.5 mm | Electronic housings, battery trays | Electrode force tolerance ±2% |

All welders adhere to AWS D1.3 standards, with real-time monitoring of heat input to prevent warpage in thin sections. Post-weld, parts undergo dimensional validation against CAD models using CMM inspection, ensuring geometric compliance within ±0.1 mm.

This closed-loop workflow—AI quoting to DFM refinement to parameter-controlled production—delivers consistent weld integrity while reducing time-to-shipment by 30%. By embedding manufacturability checks early and standardizing process controls, Honyo transforms complex sheet metal designs into reliable, production-ready components without compromise.

Start Your Project

Expert Welding Solutions for Precision Sheet Metal Fabrication

When it comes to sheet metal fabrication, selecting the right welding process is critical to achieving structural integrity, dimensional accuracy, and a high-quality finish. At Shenzhen Honyo Prototype, we specialize in advanced welding techniques tailored to the unique challenges of thin-gauge and precision sheet metal components. Whether you’re developing prototypes or scaling to low-volume production, our engineering team ensures every weld meets strict performance and aesthetic standards.

Sheet metal applications often demand clean, consistent joints with minimal distortion. Our facility leverages state-of-the-art equipment and certified welders trained in TIG (Tungsten Inert Gas), MIG (Metal Inert Gas), and spot welding—each selected based on material type, thickness, design requirements, and end-use environment. TIG welding is ideal for thinner materials requiring precise control and superior finish, while MIG offers faster deposition rates for slightly thicker sections. Resistance spot welding remains a trusted choice for joining overlapping sheets in high-repetition applications, particularly in electronics enclosures and automotive components.

We work with a wide range of materials including stainless steel, aluminum, cold-rolled steel, and galvanized sheet metal. Our quality assurance protocols include visual inspection, dimensional verification, and, when required, non-destructive testing to validate weld integrity.

To help you select the optimal method for your project, the following table outlines key characteristics of common welding processes used in sheet metal fabrication:

| Welding Process | Material Thickness Range (mm) | Common Materials | Key Advantages | Typical Applications |

|—————–|——————————-|——————|—————-|————————|

| TIG | 0.5 – 3.0 | Stainless Steel, Aluminum, Carbon Steel | High precision, clean welds, excellent control | Enclosures, medical devices, aerospace components |

| MIG | 0.8 – 6.0 | Carbon Steel, Stainless Steel, Aluminum | Faster than TIG, good for longer seams | Industrial housings, structural brackets |

| Spot Welding | 0.5 – 3.0 (combined) | Carbon Steel, Stainless Steel, Aluminum | High speed, no filler material, strong joints | Electronics chassis, automotive panels |

All welding operations at Honyo Prototype are supported by in-house design for manufacturability (DFM) analysis. We review joint accessibility, material compatibility, and post-weld finishing needs during the quoting stage to prevent rework and reduce lead times.

Starting your project with the right welding strategy ensures reliability, reduces cost, and accelerates time to market. Our team is ready to collaborate from concept to completion, delivering robust, production-ready sheet metal assemblies.

For expert guidance on selecting the best welding process for your application, contact Susan Leo at info@hy-proto.com. We respond to all inquiries within 12 business hours and provide detailed technical feedback to support your design decisions. Let Honyo Prototype be your trusted partner in precision sheet metal fabrication.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.