Contents

Manufacturing Insight: Cnc Machines For Stone

Manufacturing Insight: CNC Machines for Stone

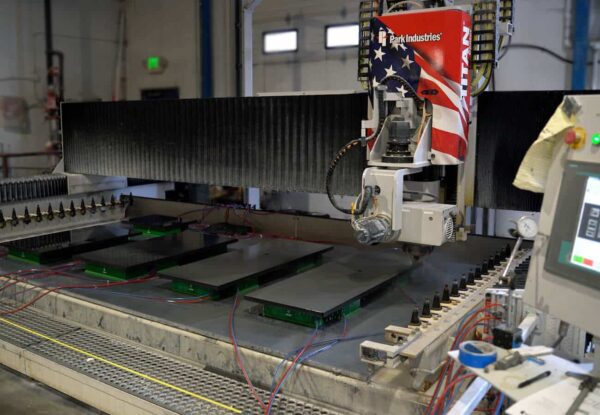

Stone fabrication demands exceptional precision and robust machinery due to the material’s inherent abrasiveness, density, and susceptibility to thermal stress. Conventional methods often struggle with consistency and intricate geometries, making advanced CNC technology essential for high-value applications like architectural elements, countertops, and sculptural art. Honyo Prototype specializes in industrial-grade CNC stone machining, leveraging purpose-built systems engineered to overcome the unique challenges of natural and engineered stone materials. Our process ensures micron-level accuracy while maintaining structural integrity across diverse substrates—from delicate marble to dense basalt—through optimized toolpath strategies and vibration-dampened kinematics.

Unlike standard metal-cutting CNC platforms, stone-specific machines require reinforced gantries, high-torque spindles, and aggressive dust management to handle the substantial particulate load. Abrasive stone dust can rapidly degrade components and compromise surface finish if not immediately evacuated. Honyo’s dedicated stone CNC infrastructure integrates sealed linear guides, corrosion-resistant coatings, and multi-stage extraction systems operating at 2,500+ CFM to protect both machine longevity and operator safety. This foundation enables sustained precision during extended production runs, critical for large-scale projects where dimensional repeatability across dozens of identical pieces is non-negotiable.

Our technical capabilities are anchored in machines calibrated for the material’s exacting demands. The table below outlines key specifications of Honyo’s primary stone CNC platform:

| Parameter | Specification | Industrial Relevance |

|————————-|————————|—————————————————|

| Spindle Power | 15 kW (20 HP) | Cuts granite and quartz composites without stalling |

| Max Work Area | 3,000 x 2,000 x 600 mm | Accommodates slabs up to 10 ft x 6.5 ft |

| Positioning Accuracy | ±5 μm | Ensures seamless tile/panel alignment in facades |

| Dust Extraction | 2,800 CFM | Prevents abrasive recirculation and surface scoring |

| Control System | Siemens 840D SL | Handles complex 5-axis toolpaths for 3D carving |

Honyo’s workflow begins with material-specific CAM programming that adjusts feed rates, spindle speeds, and coolant flow to minimize chipping and thermal cracking. We employ diamond-tipped tooling with optimized flute geometry for clean edge definition, particularly in veined marbles where tear-out is a common failure point. Real-time in-process metrology validates critical dimensions mid-operation, eliminating costly rework. For projects requiring artistic detail—such as reliefs or organic contours—our 5-axis capability executes undercuts and compound curves unachievable with manual techniques, all while maintaining ±0.1 mm tolerance.

Beyond machining, Honyo integrates finishing protocols tailored to stone’s porosity. This includes automated edge profiling, honing, and polishing stages within a single setup to prevent handling-induced defects. Clients benefit from reduced lead times and guaranteed surface consistency, whether producing a single monumental sculpture or a 500-piece cladding order. By marrying German-engineered hardware with material science expertise, Honyo transforms stone’s natural variability into a benchmark for manufacturing excellence. Contact our engineering team to discuss how our stone CNC solutions can elevate your next project’s precision and scalability.

Technical Capabilities

Technical Capabilities: CNC Machining for Stone at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our advanced CNC machining capabilities are specifically engineered to meet the demanding requirements of stone processing. We specialize in high-precision 3-axis, 4-axis, and 5-axis milling technologies, enabling us to produce intricate geometries, complex contours, and tight-tolerance components from a variety of natural and engineered stone materials. Our state-of-the-art CNC systems are integrated with diamond-coated cutting tools and high-torque spindles designed to handle the abrasive nature of stone while maintaining dimensional accuracy and surface finish integrity.

Our 3-axis CNC machines are ideal for flat or two-dimensional relief carving, providing fast and accurate material removal for signage, architectural panels, and decorative elements. When additional angular complexity is required, our 4-axis systems introduce rotational capability along the X-axis, allowing for cylindrical profiling and detailed perimeter engraving on stone columns or curved monuments. For the most demanding applications, our 5-axis CNC milling centers offer simultaneous multi-axis movement, enabling undercuts, freeform sculpting, and compound angle machining without the need for multiple setups. This level of precision is critical for high-end architectural features, custom sculptures, and bespoke interior design elements.

In addition to multi-axis milling, we offer CNC turning for cylindrical stone components such as balusters, vases, and column capitals. Our turning centers are equipped with rigid tooling and adaptive feed controls to ensure smooth surface finishes and consistent roundness, even with dense materials like granite or quartzite.

Tight tolerances are a hallmark of our manufacturing process. We consistently achieve dimensional accuracies down to ±0.02 mm on critical features, supported by in-process probing and post-machining inspection using coordinate measuring machines (CMM). Surface finishes can be controlled to a range of Ra 0.8–3.2 µm, depending on material and design requirements.

The following table outlines the typical tolerance ranges and compatible materials for our CNC stone machining services:

| Material Type | Typical Tolerance (±mm) | Max Feature Accuracy | Surface Finish (Ra, µm) | Suitable for 3/4/5-Axis |

|———————|————————-|————————|————————–|————————–|

| Granite | 0.02 – 0.05 | ±0.02 mm | 1.6 – 3.2 | Yes |

| Marble | 0.02 – 0.05 | ±0.02 mm | 1.6 – 3.2 | Yes |

| Engineered Quartz | 0.03 – 0.06 | ±0.03 mm | 1.6 – 2.5 | Yes |

| Limestone | 0.03 – 0.08 | ±0.05 mm | 2.5 – 3.2 | Yes |

| Slate | 0.05 – 0.10 | ±0.05 mm | 3.2 | 3 & 4-Axis |

| Travertine | 0.05 – 0.10 | ±0.05 mm | 3.2 | 3 & 4-Axis |

All machining operations are supported by proprietary fixturing solutions and water-cooled environments to minimize thermal expansion and dust accumulation. Our technical team collaborates closely with clients during the design-for-manufacturability phase to optimize toolpaths, reduce cycle times, and ensure final parts meet both aesthetic and functional specifications. With comprehensive in-house capabilities, Shenzhen Honyo Prototype delivers precision-engineered stone components for architectural, artistic, and industrial applications worldwide.

From CAD to Part: The Process

From CAD to Stone Part: Honyo Prototype’s CNC Workflow

At Shenzhen Honyo Prototype, transforming a digital stone design into a precise physical component requires a rigorously defined workflow integrating advanced software and specialized stone machining expertise. Our process begins immediately upon receipt of the client’s CAD model, initiating a sequence designed to maximize accuracy, efficiency, and material integrity specific to natural and engineered stone.

The workflow commences with AI-Powered Quoting & Feasibility Analysis. Our proprietary AI engine ingests the CAD file, automatically identifying critical geometric features, material type (e.g., granite, marble, quartz), and dimensional tolerances. It cross-references this data against our extensive database of stone properties, machine capabilities, and historical production parameters. This analysis generates an instant preliminary quote while simultaneously flagging potential high-risk areas such as excessively thin sections, undercuts incompatible with standard tooling, or features approaching the practical limits of stone’s tensile strength. This step provides clients with rapid cost and timeline visibility while setting the stage for actionable engineering feedback.

Critical to stone success is the subsequent Design for Manufacturability (DFM) Review. Our senior manufacturing engineers conduct a hands-on assessment, focusing intensely on stone-specific constraints. We evaluate draft angles for mold release (if applicable), minimum wall thicknesses to prevent fracture during machining or handling, optimal fixture point locations to avoid stress concentrations, and the feasibility of required surface finishes. Crucially, we assess the design’s compatibility with diamond tool paths, ensuring complex contours can be achieved without excessive tool wear or material chipping. Client collaboration at this stage is paramount; we provide specific, actionable recommendations—such as slight radius adjustments or strategic feature relocation—to enhance manufacturability without compromising the core design intent, directly impacting yield and cost.

Upon DFM approval, the project enters Precision Stone CNC Production. Programmers generate optimized G-code using CAM software configured explicitly for stone’s abrasive nature and low thermal conductivity. Toolpaths prioritize gradual material removal, lower spindle speeds, and controlled feed rates compared to metal machining to prevent overheating, tool glazing, and edge chipping. Rigorous fixturing secures the stone blank, often using vacuum tables or custom jigs to distribute clamping forces evenly. Production occurs on dedicated stone CNC routers or milling centers equipped with high-torque spindles, robust dust extraction systems meeting OSHA standards (HEPA filtration is mandatory), and diamond-tipped or diamond-impregnated tooling. Real-time monitoring ensures process stability. Key machining parameters are strictly controlled as shown below:

| Material Type | Spindle Speed (RPM) | Feed Rate (mm/min) | Tool Type | Critical Consideration |

| :———— | :—————— | :—————– | :—————– | :———————————– |

| Granite | 12,000 – 18,000 | 1,500 – 3,000 | Diamond Core Drill | Aggressive cooling; manage vibration |

| Marble | 14,000 – 20,000 | 2,000 – 4,000 | Diamond Router Bit | Minimize heat; prevent burning |

| Engineered Quartz | 10,000 – 16,000 | 1,200 – 2,500 | Polycrystalline Diamond | Consistent feed; avoid dwell spots |

The process concludes with meticulous Inspection & Finishing. Each part undergoes dimensional verification against the original CAD model using CMM or high-resolution optical comparators, checking critical features and surface flatness. Stone-specific post-processing, such as edge polishing or surface honing, is performed as specified. Rigorous visual inspection ensures freedom from micro-fractures, chips, or tool marks. Only after meeting all quality benchmarks is the finished stone component released for shipment, guaranteeing it aligns precisely with the client’s design vision and functional requirements. This integrated workflow ensures predictable, high-quality stone components from digital concept to physical reality.

Start Your Project

Start Your Stone CNC Machining Project with Honyo Prototype

When it comes to precision manufacturing in stone materials, Shenzhen Honyo Prototype stands at the forefront of innovation and reliability. Our advanced CNC machining solutions are engineered to meet the demanding requirements of architectural elements, artistic sculptures, tombstones, countertops, and custom stonework. Whether you’re working with granite, marble, limestone, or engineered stone, our state-of-the-art CNC machines deliver unmatched accuracy, efficiency, and surface finish quality.

At Honyo Prototype, we understand that every project begins with a vision. Our team specializes in turning complex designs into high-precision stone components using computer-controlled routing, carving, drilling, and polishing techniques. With years of experience in the stone fabrication industry, we combine cutting-edge technology with expert craftsmanship to ensure your prototypes and production runs meet exact specifications.

Our stone CNC machines are built for performance, featuring high-torque spindles, rigid gantry structures, and advanced dust extraction systems to maintain optimal operating conditions. These machines support 3-axis, 4-axis, and 5-axis machining, enabling intricate detailing and complex geometries that manual methods simply cannot achieve. Whether you require mass production or a one-off custom piece, our equipment and expertise ensure consistent results across all project scales.

To help you determine the right machine configuration for your needs, we’ve outlined key technical specifications of our standard stone CNC models:

| Model | Working Area (mm) | Spindle Power (kW) | Max Speed (RPM) | Axis Configuration | Dust Extraction |

|——-|——————-|——————–|——————|——————-|—————–|

| HY-CNC3040 | 3000 x 4000 x 600 | 15 | 18,000 | 3-Axis | Integrated Cyclone System |

| HY-CNC4060 | 4000 x 6000 x 800 | 18.5 | 18,000 | 4-Axis | Dual-Stage Filtration |

| HY-CNC5080 | 5000 x 8000 x 1000 | 22 | 24,000 | 5-Axis | Full Enclosure with HEPA Filter |

All models are equipped with user-friendly CNC controls, tool auto-detection, and compatibility with CAD/CAM software for seamless integration into your workflow. We also offer optional features such as laser positioning, automatic tool changers, and water-cooling systems for extended operation.

Starting your project with Honyo Prototype is simple. We provide comprehensive consultation, machine customization, on-site installation, and operator training to ensure a smooth transition into CNC stone machining. Our support doesn’t end after delivery — we offer ongoing technical assistance and maintenance services to keep your operations running at peak performance.

If you’re ready to elevate your stone fabrication capabilities, contact Susan Leo today. As your dedicated project coordinator, Susan will guide you through machine selection, pricing, lead times, and customization options tailored to your production goals.

Contact Susan Leo

Email: info@hy-proto.com

Let us help you bring precision, efficiency, and innovation to your next stone machining project.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.