Contents

Manufacturing Insight: Magnesium Vs Aluminum Weight

Manufacturing Insight: Magnesium vs Aluminum Weight in Precision CNC Prototyping

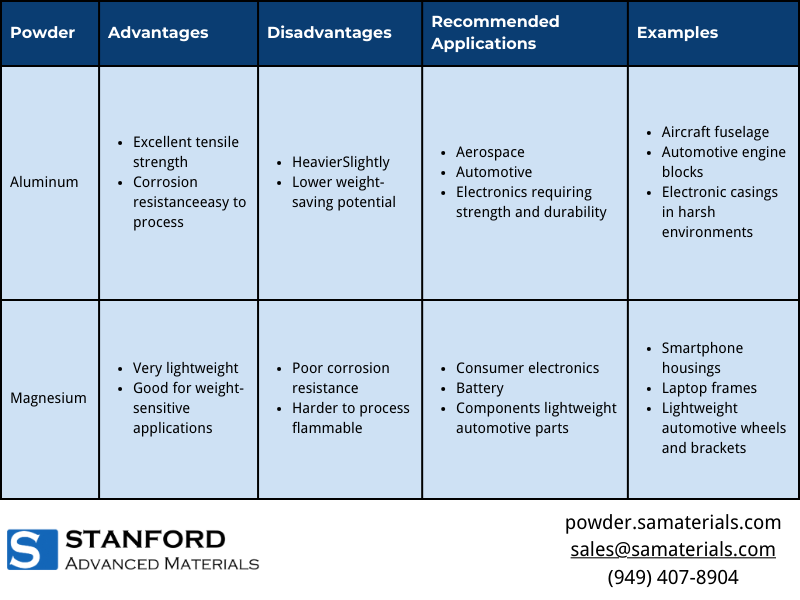

In high-performance industries like aerospace, medical devices, and robotics, minimizing component weight without sacrificing structural integrity is often a critical design driver. Understanding the fundamental material properties of lightweight metals—particularly magnesium versus aluminum—is essential for optimizing prototype performance and manufacturability. While both offer significant weight savings over steel, their distinct characteristics directly impact CNC machining strategies, final part functionality, and suitability for specific applications. Shenzhen Honyo Prototype leverages deep material science expertise to guide clients in selecting the optimal alloy and executing precise, efficient machining processes tailored to these reactive metals.

The core advantage of magnesium lies in its exceptional density. At approximately 1.74 g/cm³, magnesium is nearly 35% lighter than aluminum (2.70 g/cm³ for common 6061-T6), making it the lightest structural metal available. This density difference translates directly to substantial weight reduction in finished components, a decisive factor where every gram impacts system efficiency or payload capacity. However, material selection extends beyond raw density; strength-to-weight ratio, thermal properties, and corrosion resistance are equally vital considerations for functional prototypes. The following table summarizes key comparative specifications relevant to CNC machining and performance:

| Property | Magnesium AZ31B | Aluminum 6061-T6 | Significance for Prototyping |

| :———————- | :————– | :————— | :———————————————– |

| Density (g/cm³) | 1.74 | 2.70 | Mg offers ~35% weight savings for same volume |

| Tensile Strength (MPa) | 220-260 | 310 | Al generally stronger; Mg requires design adjustment |

| Strength-to-Weight Ratio| Higher | Lower | Mg often superior for dynamic load applications |

| Thermal Conductivity (W/m·K) | 50-60 | 150-200 | Al dissipates heat faster; Mg needs thermal mgmt |

| Corrosion Resistance | Low (reactive) | Moderate | Mg requires protective coatings; Al more robust |

| Machinability Notes | High speed, low force, non-ferrous coolants mandatory | Good, standard coolants | Mg demands strict fire safety protocols |

Machining magnesium presents unique challenges distinct from aluminum. Its low ignition temperature necessitates stringent safety measures: specialized non-aqueous coolants, strict chip control to prevent accumulation, and dedicated machine tool zones to mitigate fire risk. Honyo Prototype maintains ISO-certified facilities with engineered ventilation, spark detection systems, and operator training specifically for reactive metals like AZ31B and AZ91D magnesium alloys. Aluminum, while generally easier to machine with standard flood coolant systems, still requires precise parameter control for thin-wall features common in lightweight prototypes. Both materials benefit from optimized toolpaths and rigid setups to maintain dimensional accuracy and surface finish.

At Shenzhen Honyo Prototype, we integrate material science with advanced CNC capabilities (5-axis milling, precision turning) to transform weight-critical designs into functional prototypes. Our engineers collaborate early in the design phase to evaluate whether magnesium’s weight advantage justifies its machining complexity and post-processing needs (like anodizing or chromate conversion), or if high-strength aluminum variants better balance performance, cost, and lead time. We provide comprehensive material certification, in-process metrology, and finish recommendations to ensure prototypes accurately validate the intended application’s weight and performance targets. Partnering with Honyo ensures your lightweight design vision is realized with technical precision and manufacturing rigor.

Technical Capabilities

Magnesium vs Aluminum: Weight and Machinability in Precision CNC Machining

At Shenzhen Honyo Prototype, our advanced 3-, 4-, and 5-axis CNC milling and turning capabilities enable high-precision manufacturing of lightweight structural components, with magnesium and aluminum being two of the most widely specified materials. Both metals offer favorable strength-to-weight ratios, but their differences in density, machinability, and application performance are critical in determining the optimal material for a given design.

Aluminum, particularly grades such as 6061 and 7075, is a staple in aerospace, automotive, and consumer electronics due to its excellent balance of strength, corrosion resistance, and machinability. With a density of approximately 2.7 g/cm³, aluminum provides significant weight savings over steel and remains highly workable under tight tolerance conditions. It is well-suited for complex geometries and is less reactive during high-speed machining, making it ideal for high-volume and long-run production.

Magnesium, by contrast, is the lightest structural metal available for commercial manufacturing, with a density of about 1.74 g/cm³—nearly 35% lighter than aluminum. This makes magnesium an exceptional choice when minimizing mass is a top priority, such as in portable electronics, UAVs, and performance-oriented automotive components. Despite its low density, magnesium alloys like AZ31 and AZ91 exhibit competitive strength and excellent damping capacity. Its high thermal conductivity and favorable chip evacuation characteristics also enhance machining efficiency in 3-, 4-, and 5-axis operations.

However, magnesium requires stringent safety protocols due to its flammability in fine chip or powder form. At Honyo Prototype, we employ specialized dry machining techniques, non-reactive coolants, and enclosed systems with spark suppression to ensure safe and consistent processing. Our CNC turning and milling centers are calibrated for the unique cutting forces and tool wear profiles associated with magnesium, maintaining tight tolerances without compromising operator safety.

Both materials support tight tolerance machining down to ±0.005 mm when required, though achieving such precision depends on part geometry, wall thickness, and fixture strategy. Our 5-axis platforms minimize setups and enhance accuracy, particularly for complex organic shapes common in lightweight structural designs.

Below is a comparative summary of key specifications relevant to CNC machining at Honyo Prototype:

| Material | Density (g/cm³) | Common Grades | Typical Tolerance (Standard) | Tight Tolerance Capability | Machining Speed (Relative) | Key Applications |

|————–|——————|—————-|——————————-|—————————–|—————————-|——————|

| Aluminum | 2.7 | 6061, 7075 | ±0.025 mm | ±0.005 mm | High | Aerospace, Automotive, Electronics |

| Magnesium | 1.74 | AZ31, AZ91 | ±0.025 mm | ±0.005 mm | Very High | UAVs, Portable Devices, Performance Components |

In conclusion, while aluminum remains a versatile and widely adopted material for precision prototypes and end-use parts, magnesium offers a compelling advantage in applications where every gram matters. At Shenzhen Honyo Prototype, we leverage our technical expertise and safety-compliant infrastructure to deliver high-accuracy components in both materials, ensuring optimal performance and manufacturability.

From CAD to Part: The Process

CAD to Part: CNC Production Workflow for Magnesium and Aluminum Components

At Shenzhen Honyo Prototype, our CNC machining process for magnesium and aluminum components follows a rigorously defined sequence from digital model to finished part, ensuring optimal quality and safety, particularly critical when handling combustible magnesium alloys. This workflow integrates material-specific considerations at every stage, starting with the initial AI-powered quotation.

The process commences with an AI-driven quotation system. This tool rapidly analyzes the provided CAD model, automatically identifying key geometric features, material requirements (specifying either aluminum alloy like 6061-T6 or magnesium alloy like AZ31B), and initial complexity metrics. Crucially, for magnesium, the AI flags potential flammability risks associated with fine chips or dry milling early in the costing phase, influencing both pricing and mandatory safety protocol inclusion. The quotation provides clients with transparent lead times and costs, explicitly differentiated based on the selected material’s machining characteristics and safety overhead.

Next, every order undergoes a comprehensive Design for Manufacturability (DFM) review by our engineering team. This is where material-specific expertise is paramount. For aluminum, DFM focuses on optimizing wall thicknesses, hole depths, and tolerances within the metal’s forgiving machining envelope. Magnesium DFM, however, demands heightened scrutiny. Engineers meticulously evaluate chip evacuation paths to prevent accumulation, assess the necessity of through-spindle coolant (oil-based preferred for Mg to avoid hydrogen generation), verify fixture rigidity to minimize vibration (critical due to Mg’s lower stiffness), and confirm all features avoid creating fine, hazardous chips. Any design element posing a combustion risk during machining triggers immediate client consultation for modification.

Upon DFM approval and client sign-off, production initiates under strict material-specific protocols. Aluminum machining utilizes standard high-speed steel or carbide tooling with water-soluble coolants, benefiting from the metal’s excellent thermal conductivity and chip control. Magnesium production occurs in dedicated, isolated cells equipped with certified Class D fire suppression systems and mandatory chip conveyor systems flooded with non-aqueous coolant. Toolpaths are programmed for continuous, heavy cuts to generate coarse chips, avoiding light passes that create fines. Spindle speeds and feed rates are carefully calibrated lower than for aluminum to manage heat generation and ensure robust chip breaking. Rigorous housekeeping protocols, including continuous vacuum collection at the spindle and non-sparking tools for chip handling, are non-negotiable safety measures throughout the magnesium process.

The distinct material behaviors necessitate tailored approaches, directly impacting workflow execution:

| Critical Parameter | Aluminum (e.g., 6061-T6) | Magnesium (e.g., AZ31B) |

| :———————– | :——————————– | :———————————- |

| Primary Safety Focus | General workshop safety | Combustion prevention (chips, fines) |

| Coolant Requirement | Water-soluble emulsions common | Oil-based or non-aqueous mandatory |

| Chip Management | Standard conveyors sufficient | Flooded conveyors + continuous vacuum |

| Toolpath Strategy | Optimized for speed/surface finish | Optimized for coarse chip formation |

This disciplined workflow, from AI-informed quoting through material-conscious DFM to rigorously controlled production, ensures Shenzhen Honyo Prototype delivers precision magnesium and aluminum prototypes and low-volume production parts meeting the highest standards of quality, safety, and performance, especially vital for weight-sensitive applications where material choice is critical.

Start Your Project

Optimize Your CNC Machining Project with the Right Material Choice: Magnesium vs Aluminum Weight Considerations

When initiating a precision CNC machining project, one of the most critical decisions you’ll make is material selection—particularly when weight, strength, and performance are key design drivers. At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC-machined components, helping engineers and product developers choose between lightweight alloys such as magnesium and aluminum based on functional requirements, production timelines, and cost-efficiency.

Magnesium and aluminum are both renowned for their high strength-to-weight ratios, making them ideal candidates for industries including aerospace, automotive, robotics, and portable electronics. However, understanding the nuanced differences between magnesium vs aluminum weight characteristics is essential for optimizing performance and manufacturability.

Magnesium is the lightest structural metal available, with a density of approximately 1.74 g/cm³—about 35% lighter than aluminum, which has a density of 2.70 g/cm³. This significant reduction in mass makes magnesium a compelling choice for applications where every gram matters. Despite its low weight, magnesium offers comparable specific strength (strength relative to density) to many aluminum alloys, particularly in die-cast or machined forms.

However, aluminum remains a more widely used material due to its excellent machinability, corrosion resistance, and thermal conductivity. It is also generally more cost-effective and easier to process using standard CNC techniques. Aluminum alloys like 6061 and 7075 are industry standards for prototypes and end-use parts requiring durability and dimensional stability.

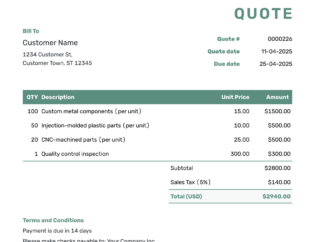

To help you make an informed decision, consider the following comparative specifications:

| Property | Magnesium (AZ31B) | Aluminum (6061-T6) |

|—————————|——————-|———————|

| Density (g/cm³) | 1.74 | 2.70 |

| Tensile Strength (MPa) | 220–260 | 310 |

| Yield Strength (MPa) | 140–180 | 276 |

| Elongation at Break (%) | 10–15 | 12 |

| Thermal Conductivity (W/m·K) | 70 | 167 |

| Machinability Rating | Moderate | Excellent |

| Corrosion Resistance | Low (requires coating) | Good (natural oxide layer) |

While magnesium offers superior weight savings, it requires careful handling during CNC machining due to its higher flammability risk when fine chips accumulate. Specialized cooling and chip removal protocols are necessary, which our team at Honyo Prototype implements rigorously to ensure safety and precision.

Your project’s success begins with the right material and the right manufacturing partner. Whether you’re evaluating magnesium for extreme weight reduction or aluminum for balanced performance and ease of fabrication, Shenzhen Honyo Prototype provides expert guidance and rapid turnaround on CNC-machined prototypes and low-volume production parts.

Start your project today. Contact Susan Leo at info@hy-proto.com to discuss your material selection, design requirements, and machining needs. Let us help you turn your concept into a high-performance reality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.