Contents

Manufacturing Insight: Acetal Plastic Sheet

Manufacturing Insight: Acetal Plastic Sheet Fabrication

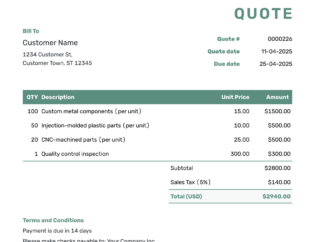

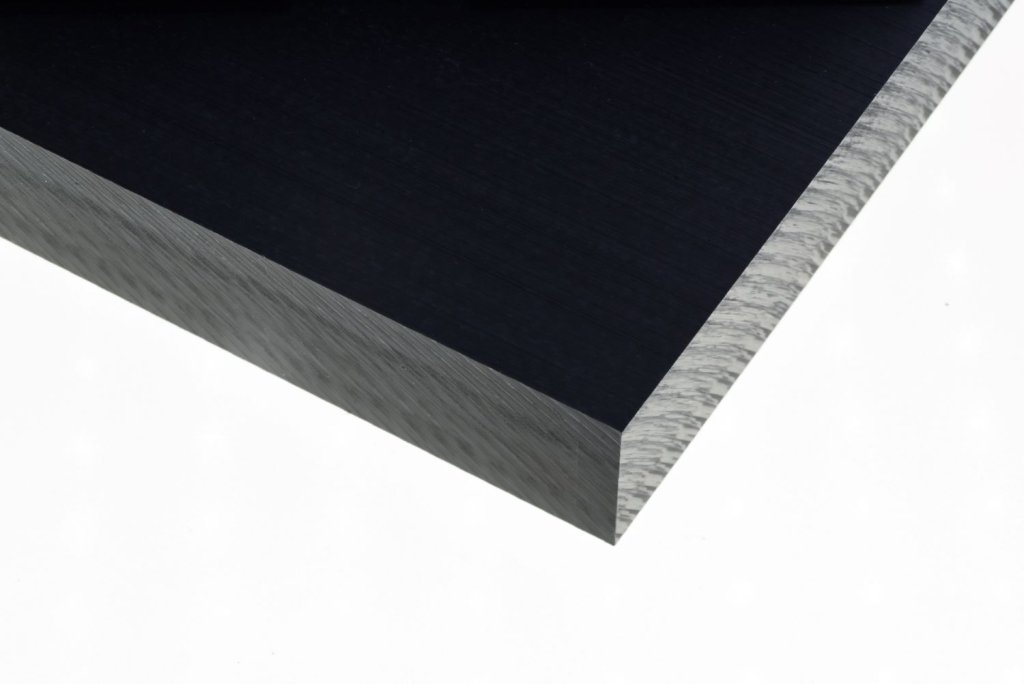

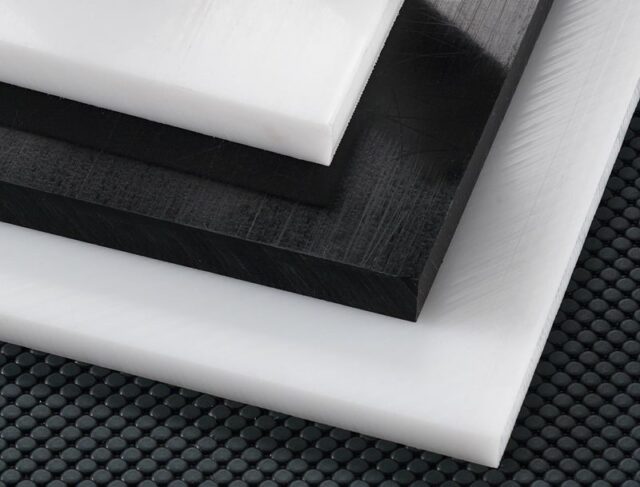

Acetal, commonly known as Polyoxymethylene (POM), is a high-performance engineering thermoplastic renowned for its exceptional balance of mechanical strength, dimensional stability, low friction, and resistance to fatigue, moisture, and many solvents. Its inherent rigidity and creep resistance make it a critical material for precision components in demanding applications across automotive, medical devices, consumer electronics, and industrial machinery. Unlike sheet metal, acetal sheet fabrication requires specialized understanding of polymer behavior to achieve optimal results, particularly concerning thermal management, stress relief, and precise machining parameters. At Shenzhen Honyo Prototype, we leverage deep expertise in polymer processing to transform acetal sheet into high-tolerance functional prototypes and low-volume production parts, ensuring performance meets stringent application requirements.

The unique crystalline structure of acetal presents specific fabrication challenges distinct from metals. It is highly susceptible to internal stresses induced during machining or rapid cooling, which can lead to warpage, cracking, or dimensional drift over time if not properly managed. Effective fabrication demands controlled feed rates, sharp tooling to minimize heat generation, and often mandatory stress-relief annealing cycles post-machining. Laser cutting acetal requires precise power and speed calibration to avoid excessive melting, charring, or the release of formaldehyde fumes, necessitating robust extraction systems. Furthermore, welding acetal successfully requires specialized techniques like hot gas welding or ultrasonic welding with compatible POM rod stock, as adhesives often fail under stress. Honyo’s process protocols are meticulously designed to address these nuances, incorporating pre-machining material conditioning, optimized CNC toolpaths with coolant strategies, and certified annealing ovens operating within strict temperature/time profiles to ensure part integrity and long-term stability.

Honyo Prototype excels in delivering precision acetal components through integrated capabilities tailored to this material’s demands. Our advanced CNC machining centers utilize diamond-coated or polished carbide tooling specifically selected for POM to achieve tight tolerances down to ±0.05mm while minimizing surface defects. We implement mandatory in-process annealing for critical geometries and complex parts, a value-added service critical for dimensional accuracy in end-use environments. Our Class 10,000 cleanroom environment supports medical and optical-grade requirements, and our engineers provide material-specific DFM feedback to optimize part geometry for manufacturability and performance. Understanding the critical link between processing and final part function is paramount; Honyo’s technicians are trained to recognize the subtle indicators of stress in acetal and adjust processes accordingly, ensuring reliability.

Key physical and mechanical properties of standard acetal homopolymer sheet guide our process development:

| Property | Typical Value | Unit |

| :———————— | :—————— | :—— |

| Density | 1.41 – 1.42 | g/cm³ |

| Tensile Strength (Yield) | 65 – 75 | MPa |

| Flexural Modulus | 2,800 – 3,200 | MPa |

| Heat Deflection Temp (1.8 MPa) | 105 – 115 | °C |

| Coefficient of Friction | 0.2 – 0.3 (vs. steel) | – |

Shenzhen Honyo Prototype provides end-to-end acetal sheet fabrication, transforming design intent into reliable, high-performance components. Our commitment to material science expertise, stringent process control, and proactive engineering collaboration ensures clients receive parts that not only meet dimensional specifications but also deliver the functional longevity acetal is engineered for. Partner with Honyo to navigate the complexities of acetal fabrication and accelerate your path from prototype to production.

Technical Capabilities

Acetal Plastic Sheet Manufacturing Capabilities

Shenzhen Honyo Prototype offers precision manufacturing services for acetal plastic sheets, leveraging advanced laser cutting, bending, and welding technologies to deliver high-performance components for industrial, automotive, and consumer applications. Acetal, also known as polyoxymethylene (POM), is a high-strength engineering thermoplastic valued for its excellent dimensional stability, low friction, and resistance to moisture and chemicals. Our processing techniques are optimized to maintain these intrinsic material properties while achieving tight tolerances and clean, repeatable geometries.

Our laser cutting process utilizes CO₂ laser systems calibrated specifically for POM materials. This ensures clean, burr-free edges with minimal thermal distortion. The non-contact nature of laser cutting allows for intricate contours and precise hole geometries, making it ideal for prototyping and low-to-medium volume production. All cuts are performed under controlled environmental conditions to prevent warping and maintain flatness across the sheet.

For forming operations, we employ precision press brakes equipped with custom tooling to achieve accurate bending of acetal sheets. Due to the material’s high crystallinity and elastic memory, bending requires controlled force and optimized bend radii to prevent cracking or stress whitening. We recommend a minimum bend radius of 1.5 times the material thickness to ensure structural integrity. Heat-assisted bending is available for complex angles or tighter radii, ensuring smooth deformation without compromising part strength.

Welding of acetal sheets is performed using hot gas welding and ultrasonic welding methods, selected based on joint design and application requirements. Hot gas welding is ideal for long, continuous seams and provides strong, hermetic joints with proper filler rod (POM-based) integration. Ultrasonic welding is used for localized, high-speed joining of smaller components, offering excellent repeatability and minimal cycle time. Both methods are performed by certified technicians following strict process parameters to ensure weld integrity and cosmetic consistency.

All fabricated parts undergo dimensional inspection and visual quality checks to confirm compliance with customer specifications. Secondary operations such as drilling, tapping, and surface finishing are also available upon request.

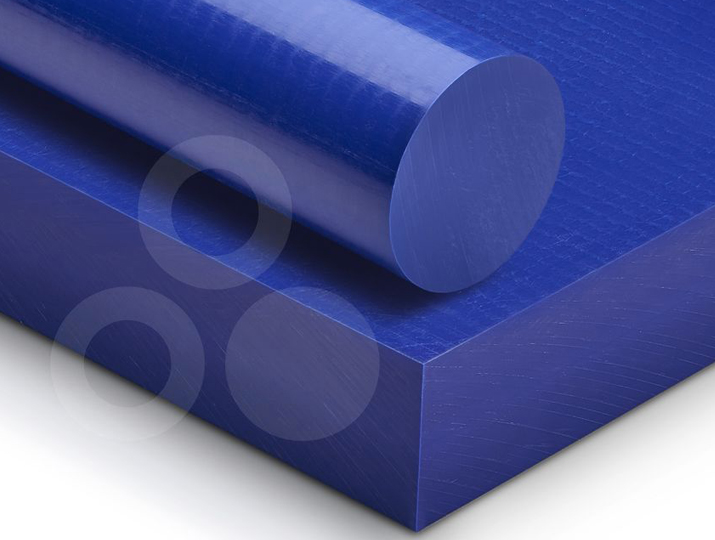

Material and Tolerance Specifications

| Parameter | Specification |

|—————————-|——————————————————————————-|

| Material Type | Homopolymer and Copolymer Acetal (POM) |

| Sheet Thickness Range | 1.0 mm – 25.0 mm |

| Laser Cutting Tolerance | ±0.1 mm (for sheets ≤ 6 mm), ±0.2 mm (for sheets > 6 mm) |

| Edge Quality | Smooth, no charring or excessive melting; kerf width: 0.15 – 0.25 mm |

| Bending Tolerance | ±1° angular tolerance; minimum bend radius: 1.5 × material thickness |

| Welding Method | Hot Gas Welding, Ultrasonic Welding |

| Weld Strength | Up to 85–90% of base material strength (depending on joint preparation) |

| Dimensional Stability | < 0.2% moisture absorption; low creep under sustained load |

| Available Sheet Sizes | Up to 1000 mm × 2000 mm (custom sizes available upon request) |

Shenzhen Honyo Prototype ensures that all acetal sheet fabrication adheres to international quality standards, with full traceability and process documentation provided for critical applications.

From CAD to Part: The Process

Acetal Plastic Sheet Manufacturing Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our acetal (POM) sheet fabrication process integrates digital precision with material-specific expertise to transform CAD models into high-integrity components. Unlike sheet metal, acetal requires tailored thermal and mechanical handling due to its thermoplastic nature, yet our workflow maintains the same rigorous structure: AI Quote initiation, DFM validation, and controlled production. This ensures dimensional stability, minimal stress deformation, and adherence to functional requirements for applications in automotive, medical, and industrial machinery.

The workflow begins with our AI-powered quoting system. Upon receiving a CAD file (STEP, IGES, or native formats), the AI analyzes geometric complexity, sheet thickness, and quantity to generate an instant preliminary quote. It cross-references material grade availability (e.g., POM-C for enhanced machinability or POM-H for higher stiffness), standard sheet sizes, and historical production data. Crucially, the system flags potential issues like non-standard thicknesses or features nearing our machining limits, providing immediate feedback to the client before formal order placement. This reduces iteration cycles and accelerates time-to-prototype by up to 40%.

Following quote acceptance, the Design for Manufacturing (DFM) phase commences. Our engineering team conducts a granular review focused on acetal’s unique behavior. Key considerations include avoiding thin walls (<1.5 mm) that may warp during stress-relief cycles, verifying adequate draft angles for milled pockets, and eliminating sharp internal corners to prevent crack propagation. We assess hole spacing to mitigate thermal expansion effects and validate tolerances against achievable standards. For instance, while acetal allows tight tolerances, we advise ±0.05 mm as standard for features >25 mm, with ±0.02 mm feasible for critical interfaces using slow-cutting strategies. The DFM report details actionable revisions—such as adjusting radii or repositioning features—to optimize yield without compromising function. Client approval of the DFM summary is mandatory before production launch.

| Material Grade | Key Properties | Typical Machining Tolerance | Max Sheet Size (mm) |

|—————-|—————————-|—————————-|———————|

| POM-C (Copolymer) | Low moisture absorption, high chemical resistance | ±0.05 mm (±0.02 mm critical) | 1000 x 2000 x 50 |

| POM-H (Homopolymer) | Higher strength/stiffness, better wear resistance | ±0.05 mm (±0.03 mm critical) | 1000 x 2000 x 30 |

Production leverages CNC milling and routing under strictly controlled conditions. Sheets are stress-relieved pre-machining to counter internal stresses from extrusion. We use sharp carbide tools with high feed rates and minimal depth-of-cut passes to prevent melting or burring. Coolant is avoided; instead, air blow-off manages swarf and heat. Post-machining, parts undergo vibratory deburring and a secondary stress-relief cycle at 80°C for 2 hours, followed by slow cooling. Final inspection verifies dimensions via CMM and surface roughness (Ra 0.8–3.2 µm typical), with critical features rechecked after 24-hour stabilization.

This integrated approach—AI-driven quoting, acetal-specific DFM, and thermally managed production—ensures Honyo delivers prototypes and low-volume runs with metal-like precision while respecting plastic’s inherent properties. We prioritize first-time-right execution, reducing client risk and accelerating path-to-validation for demanding applications.

Start Your Project

Start Your Acetal Plastic Sheet Project with Precision and Expertise

At Shenzhen Honyo Prototype, we specialize in high-precision manufacturing solutions tailored to your engineering and prototyping needs. When it comes to working with acetal plastic sheet—also known as polyoxymethylene (POM)—our expertise ensures that every component meets stringent standards for dimensional accuracy, durability, and functional performance. Whether you’re developing precision gears, structural components, or industrial prototypes, acetal’s excellent mechanical strength, low friction, and resistance to moisture and wear make it an ideal choice for demanding applications.

We understand that successful sheet fabrication begins with the right material selection and processing techniques. Our team is equipped with advanced CNC machining centers, laser cutting systems, and bending tools optimized for thermoplastic sheets like acetal. Unlike traditional sheet metal, acetal requires specialized handling due to its thermal expansion characteristics and machinability profile. That’s why our engineers apply material-specific parameters for cutting speed, tool geometry, and clamping pressure to prevent warping, chipping, or dimensional deviation.

Our process starts with your design. We support a wide range of file formats including STEP, IGES, DXF, and DWG, enabling seamless integration into our production workflow. Once received, our engineering team conducts a comprehensive Design for Manufacturability (DFM) review to optimize part geometry, minimize waste, and reduce lead times—all without compromising on quality.

To ensure clarity and precision in your project, we adhere to strict tolerance standards and surface finish controls. Below are the typical fabrication specifications we maintain for acetal plastic sheet processing:

| Parameter | Specification |

|———|—————|

| Material Types | Homopolymer (POM-C), Copolymer (POM-H) |

| Sheet Thickness Range | 1 mm – 25 mm |

| Standard Sheet Sizes | 500 mm × 500 mm, 1000 mm × 1000 mm |

| Machining Tolerance | ±0.05 mm (standard), down to ±0.02 mm (precision) |

| Surface Finish | As-machined (Ra 3.2 µm), polished finishes available |

| Processing Methods | CNC Milling, Laser Cutting, Routing, Bending |

| Lead Time | 3–7 working days (varies by complexity) |

All materials are sourced from certified suppliers and undergo incoming quality inspection to verify density, tensile strength, and thermal stability. We also offer post-processing services such as drilling, tapping, edge polishing, and custom packaging upon request.

Your project deserves more than just fabrication—it requires partnership, technical insight, and responsive support. At Honyo Prototype, we pride ourselves on fast turnaround, consistent quality, and transparent communication throughout the production cycle.

Ready to move forward? Contact Susan Leo today at info@hy-proto.com to submit your design files, request a quote, or discuss your material and fabrication requirements. Let us help you turn your concept into a high-performance reality—efficiently, accurately, and on schedule.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.