Contents

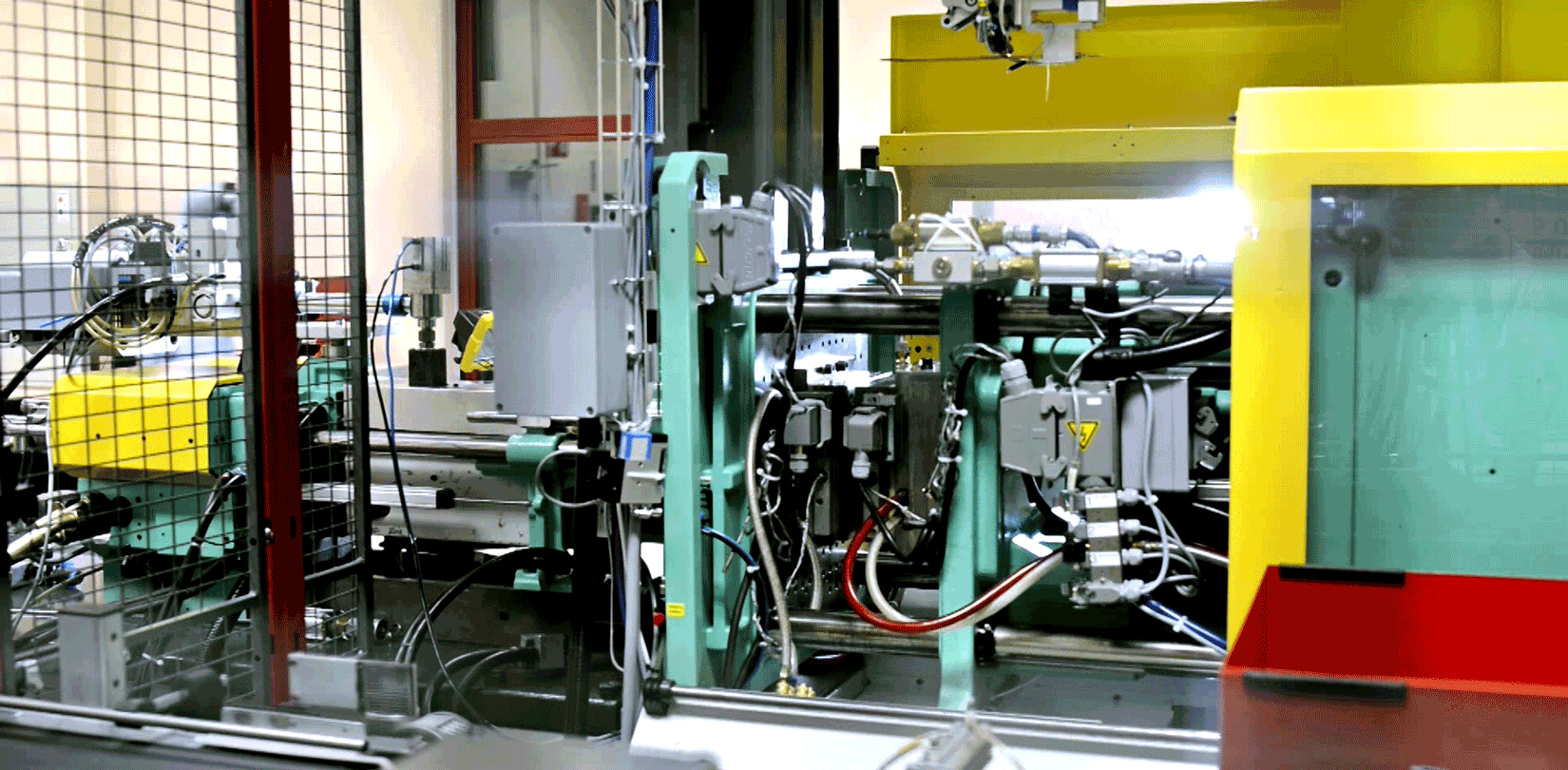

Manufacturing Insight: Silicone Injection Machine

Manufacturing Insight: Liquid Silicone Rubber Injection Molding Technology

Liquid Silicone Rubber (LSR) injection molding represents a critical advanced manufacturing process for producing high-integrity, biocompatible, and thermally stable components. Unlike traditional thermoplastics, LSR is a two-part platinum-cured material requiring precise metering, homogenous mixing, and controlled vulcanization under heat and pressure. This process is indispensable for medical devices, automotive seals, and consumer electronics where material purity, dimensional repeatability, and extreme environmental resistance are non-negotiable. The technology demands specialized machinery capable of maintaining exacting tolerances in temperature, injection speed, and curing cycles to prevent material degradation or incomplete cross-linking.

At Shenzhen Honyo Prototype, we leverage state-of-the-art LSR injection systems engineered for rapid tooling and low-to-medium volume production. Our facility integrates all-cavity pressure monitoring, closed-loop shot control, and automated degating to ensure first-article quality and minimize scrap rates. Crucially, our machines feature cooled feed zones and heated nozzles to manage LSR’s narrow processing window—preventing premature curing in the barrel while ensuring complete vulcanization in the mold. This precision enables us to achieve tolerances as tight as ±0.05 mm on complex geometries, even for parts requiring overmolding onto substrates like PEEK or stainless steel.

Core Technical Capabilities

Honyo’s LSR platform is optimized for accelerating time-to-market without compromising on regulatory compliance. We specialize in rapid aluminum tooling (fabricated in-house within 7–10 days) paired with production-grade stainless steel molds for volumes exceeding 10,000 units. Our process validation adheres to ISO 13485 standards, with full traceability from raw material lot tracking to in-process dimensional checks. This integrated approach reduces prototyping lead times by 40% compared to conventional suppliers while maintaining Class 8 cleanroom compatibility for medical applications.

Key machine specifications underpinning our service delivery include:

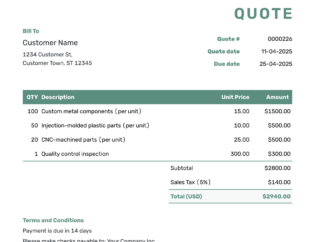

| Parameter | Specification Range |

|——————–|—————————|

| Clamp Force | 50–300 tons |

| Shot Size | 1–200 grams |

| Injection Pressure | Up to 2,500 bar |

| Temperature Control| ±1°C accuracy (barrel/mold)|

| Cycle Time | 15–90 seconds (typical) |

Our engineering team collaborates closely with clients during Design for Manufacturing (DFM) reviews to optimize part geometry, gate placement, and venting—critical factors for eliminating voids or flash in LSR. By combining real-time process analytics with veteran tooling expertise, Honyo consistently delivers zero-defect batches for applications demanding USP Class VI or ISO 10993 biocompatibility.

Partner with Honyo Prototype to transform silicone component concepts into validated production realities. Our end-to-end capability—from rapid tool fabrication to automated molding and post-cure validation—ensures your project meets performance targets while navigating the complexities of rapid scaling. For demanding sectors where material science and precision engineering converge, we deliver the reliability your innovation requires.

Technical Capabilities

Silicone Injection Molding – Technical Capabilities

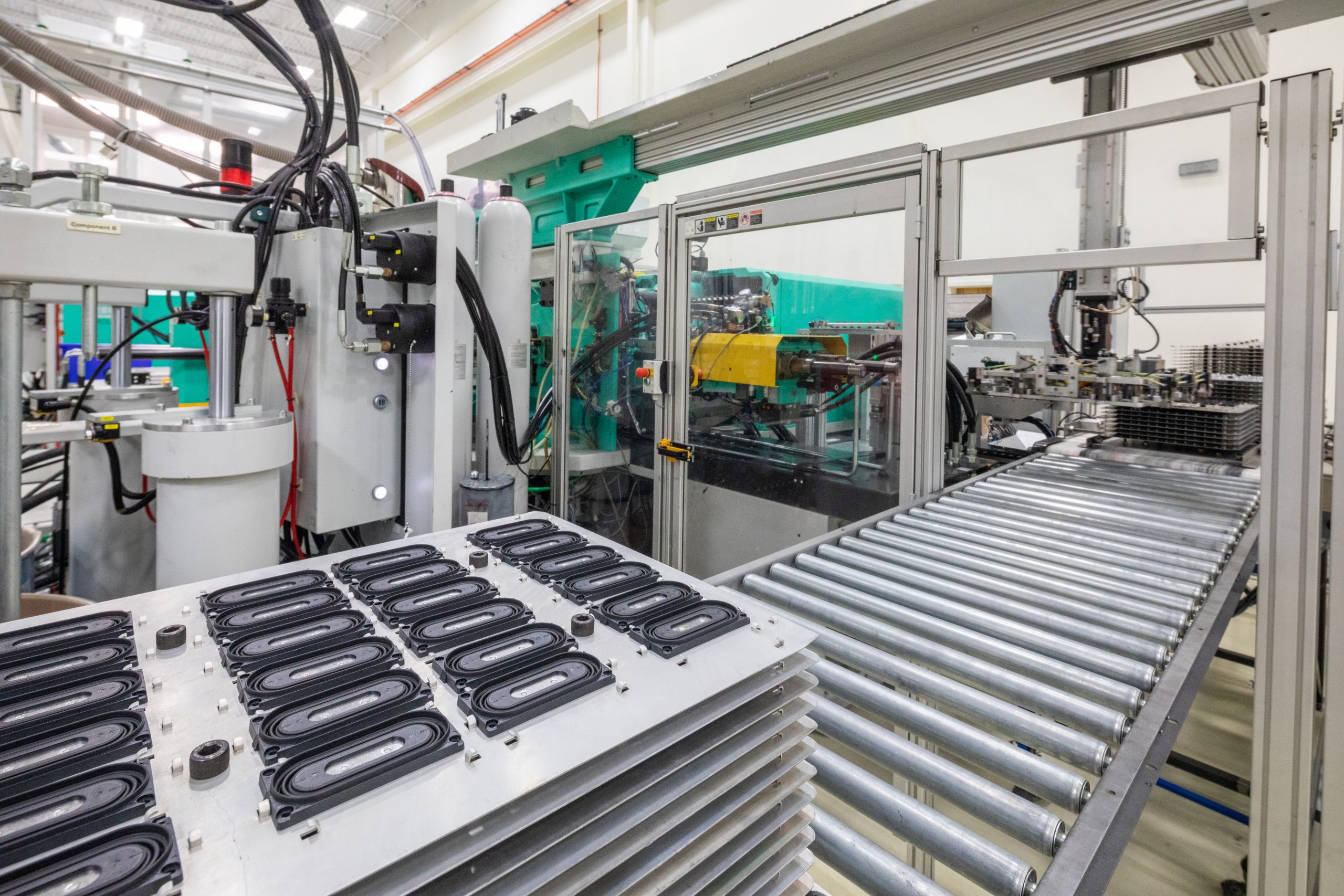

Shenzhen Honyo Prototype leverages advanced silicone injection molding technology to deliver high-precision, repeatable production runs for medical, automotive, and consumer applications. Our in-house silicone injection machines are engineered for rapid tooling cycles and consistent part quality, supporting both aluminum and steel molds to accommodate diverse project timelines and volume requirements. With optimized processing parameters and real-time monitoring systems, we ensure dimensional stability, material integrity, and compliance with industry standards.

Our standard turnaround for T1 samples is 7 days from mold completion, enabling rapid design validation and accelerated product development cycles. This capability is made possible through parallel workflows in mold fabrication, machine setup, and process validation. Aluminum molds are typically used for prototyping and low-volume production (up to 10,000 shots), offering fast machining and thermal conductivity advantages. For higher-volume or long-term production, we utilize P20, H13, or 420 stainless steel molds, capable of withstanding over 500,000 cycles with proper maintenance.

The silicone injection machines operate under controlled conditions, including precise temperature regulation (140°C to 200°C), adjustable clamping forces (ranging from 30 to 150 tons), and closed-loop injection control to minimize flash and ensure uniform fill. We process a full range of liquid silicone rubber (LSR) and high-consistency rubber (HCR) materials, including biocompatible, platinum-cured, and flame-retardant grades certified for ISO 10993, USP Class VI, and UL94 standards.

Material selection is matched to application requirements such as flexibility, thermal resistance, chemical exposure, and regulatory compliance. All molds are designed with optimized gating, venting, and ejection systems to support complex geometries and tight tolerances. In-process quality checks include first-article inspection, hardness testing, and visual defect screening under controlled lighting.

The following table outlines typical tolerances and compatible materials for our silicone injection molding process:

| Feature | Standard Tolerance | Notes |

|——–|——————–|——-|

| Linear Dimensions | ±0.10 mm (±0.004″) | Up to 50 mm; ±0.25% for larger features |

| Wall Thickness | ±0.05 mm (±0.002″) | Minimum recommended: 0.3 mm |

| Hole Diameter | +0.05 / -0.00 mm | Core pin dependent; draft recommended |

| Flatness | ±0.15 mm over 100 mm | Material and part geometry dependent |

| Parting Line Match | ±0.05 mm | Tool finish and clamping pressure dependent |

| Material Type | Hardness Range (Shore A) | Key Properties | Common Applications |

|————-|————————|—————-|———————|

| LSR (Liquid Silicone Rubber) | 10–80 | High purity, thermal stability, biocompatible | Medical devices, seals, infant care |

| HCR (High Consistency Rubber) | 30–90 | Tear-resistant, durable, high-temperature performance | Automotive gaskets, industrial components |

| Fluorosilicone (FVMQ) | 50–80 | Fuel and oil resistance | Aerospace, fuel system seals |

| Conductive Silicone | 30–80 | EMI/RFI shielding, static dissipation | Electronics enclosures, connectors |

All silicone molding projects undergo a process capability review during T1 sampling, with full documentation provided upon request. Shenzhen Honyo Prototype combines technical precision with rapid execution to support clients from prototype to production.

From CAD to Part: The Process

Silicone Injection Molding: From CAD to Finished Part at Honyo Prototype

Shenzhen Honyo Prototype delivers precision silicone components through a rigorously defined rapid tooling workflow, ensuring manufacturability, quality, and speed from initial concept to functional part. Our integrated process leverages advanced engineering analysis and controlled production protocols specifically optimized for liquid silicone rubber (LSR) and high-consistency rubber (HCR) materials. The core sequence begins immediately upon receipt of a validated CAD model.

The workflow initiates with the AI-Powered Quoting System. Upon upload of the customer’s 3D CAD file (STEP, IGES, or native formats), our proprietary AI engine performs an initial geometric analysis. This system rapidly assesses part complexity, volume, material requirements, and estimated tooling needs against historical production data and current machine capacity. The output is a highly accurate preliminary quote detailing expected lead times for tool fabrication and initial production, material costs, and foundational process parameters, providing immediate transparency and enabling faster project initiation.

Following client approval, the critical Design for Manufacturability (DFM) Engineering Phase commences. Honyo’s senior manufacturing engineers conduct an in-depth manual review, focusing exclusively on silicone injection molding constraints. Key analyses include gate location and type optimization to prevent flow marks and ensure complete cavity fill, venting strategy validation to eliminate trapped air and cure voids, wall thickness uniformity checks to prevent sink or incomplete cure, and draft angle verification for reliable demolding of flexible silicone. We rigorously evaluate parting line placement, ejector pin feasibility, and potential undercuts requiring complex side-actions. Material-specific factors like thermal conductivity of the tool steel, coefficient of thermal expansion, and required shrinkage allowances are meticulously calculated. This phase often involves direct collaboration with the client to refine the design, preventing costly tool rework and ensuring the part meets dimensional and functional specifications straight from the first production run.

Upon DFM sign-off and tool fabrication, the Controlled Production Execution phase utilizes Honyo’s precision-engineered silicone injection molding machines. These machines operate under strictly monitored parameters tailored to the specific silicone compound and part geometry. The process involves precise metering and mixing of silicone components, controlled injection into the heated mold cavity, application of adequate holding pressure, and a precisely timed cure cycle at elevated temperatures. Critical parameters are continuously logged and controlled throughout the run. Key production specifications maintained for quality assurance include:

| Parameter | Typical Range for LSR | Typical Range for HCR | Criticality |

| :—————– | :————————– | :————————- | :———————————— |

| Barrel Temperature | 25°C – 40°C | 30°C – 60°C | Prevents premature curing (scorch) |

| Mold Temperature | 160°C – 200°C | 150°C – 180°C | Ensures complete, uniform cure |

| Injection Pressure | 500 – 1500 bar | 800 – 2000 bar | Fills complex geometries completely |

| Clamp Force | 25 – 2000+ tons | 50 – 2500+ tons | Prevents mold flashing |

| Cycle Time | 15 – 120 seconds | 30 – 180 seconds | Balances throughput & part quality |

All production parts undergo rigorous first-article inspection against the original CAD model and final dimensional validation before shipment, guaranteeing adherence to the client’s requirements and Honyo’s stringent quality standards for silicone components. This seamless integration of intelligent quoting, expert DFM, and precision manufacturing defines Honyo Prototype’s rapid tooling excellence.

Start Your Project

Start Your Project with Precision Silicone Injection Molding at Shenzhen Honyo Prototype

When it comes to rapid tooling and precision silicone injection molding, Shenzhen Honyo Prototype delivers unmatched expertise, speed, and reliability. Whether you’re developing medical devices, consumer electronics, automotive seals, or high-performance industrial components, our advanced silicone injection capabilities ensure your prototypes and low-to-mid volume production parts meet the highest standards of quality and consistency.

Silicone injection molding is a critical process for manufacturing durable, heat-resistant, and biocompatible parts. At Honyo Prototype, we specialize in liquid silicone rubber (LSR) injection molding using state-of-the-art machinery and precision-engineered molds. Our in-house rapid tooling solutions enable fast turnaround times without compromising on accuracy or material performance. From concept to final part, we support your project every step of the way with engineering guidance, material selection, mold flow analysis, and rigorous quality control.

Our silicone injection machines are calibrated for optimal performance, ensuring consistent shot control, minimal waste, and excellent repeatability. We work with a wide range of silicone grades, including medical-grade, high-consistency rubber (HCR), and liquid silicone rubber (LSR), tailored to your application’s thermal, mechanical, and regulatory requirements.

To help you evaluate our capabilities, below are key technical specifications of our silicone injection molding systems:

| Parameter | Specification |

|———|—————|

| Clamping Force | 50–200 tons |

| Shot Weight Range | 10–500 grams |

| Material Compatibility | LSR, HCR, Fluorosilicone, Platinum-Cured Silicones |

| Mold Base Standards | HASCO, DME, or Custom |

| Tolerance Capability | ±0.05 mm (standard), down to ±0.02 mm (tight-tolerance) |

| Cycle Time | As low as 20 seconds (depending on part geometry) |

| Cleanroom Molding | Available (Class 10,000 certified) |

| Secondary Operations | Deflashing, assembly, packaging, 100% visual inspection |

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients during the design phase to optimize for manufacturability, reduce costs, and accelerate time to market. Whether you need 50 functional prototypes or 50,000 production units, Honyo Prototype scales with your needs.

Ready to bring your silicone component to life? Contact Susan Leo today to discuss your project requirements, request a quote, or receive technical support. With decades of experience in rapid tooling and injection molding, we are committed to delivering precision, performance, and partnership.

Susan Leo

Project & Business Development Manager

Shenzhen Honyo Prototype Co., Ltd.

Email: info@hy-proto.com

Let’s start shaping the future—together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.