Contents

Manufacturing Insight: Cnc Aircraft

Manufacturing Insight: CNC Machining for Aerospace Applications

Precision CNC machining represents a cornerstone technology in modern aircraft component production, where dimensional accuracy, material integrity, and repeatability directly impact flight safety and performance. At Shenzhen Honyo Prototype, we specialize in transforming complex aerospace designs into mission-critical hardware through advanced multi-axis CNC processes. Our capabilities address the stringent demands of the aviation sector, where tolerances often fall below 0.01mm and material properties must withstand extreme operational stresses. Unlike conventional manufacturing, CNC machining ensures zero deviation in high-value components such as turbine blades, structural brackets, and hydraulic manifolds—eliminating the risk of in-flight failure through deterministic, traceable production.

Honyo leverages a dedicated aerospace-grade CNC facility featuring 5-axis milling, turning-milling hybrid centers, and high-speed machining cells. Our equipment portfolio includes DMG MORI and Makino platforms calibrated to NIST standards, enabling us to machine exotic alloys like Inconel 718, Titanium Grade 5, and 7075-T6 aluminum with thermal stability and minimal residual stress. Every process adheres to AS9100D quality management protocols, with full material traceability from certified mills through final inspection. We integrate non-destructive testing (NDT) methodologies—including coordinate measuring machine (CMM) validation and surface roughness profiling—to certify conformance to FAA and EASA regulatory frameworks. This systematic approach ensures components meet not only geometric specifications but also fatigue life and corrosion resistance requirements essential for airworthiness.

Our technical performance metrics reflect aerospace-specific optimization, as summarized below:

| Parameter | Specification | Relevance to Aircraft Manufacturing |

|——————–|———————|———————————————|

| Positional Tolerance | ±0.005 mm | Critical for aerodynamic surface alignment and engine balance |

| Surface Finish | Ra 0.4 μm (typical) | Reduces drag and prevents stress concentration points |

| Material Range | Aluminum, Titanium, Inconel, Magnesium alloys | Supports lightweighting while maintaining strength-to-weight ratios |

| Max Work Envelope | 1200 x 800 x 600 mm | Accommodates large structural assemblies and subframes |

| Certification | AS9100D, ISO 9001 | Mandatory for Tier-1 supplier qualification in global aerospace supply chains |

Beyond technical execution, Honyo accelerates time-to-flight through integrated design-for-manufacturability (DFM) collaboration. Our engineering team collaborates with clients during prototyping to resolve geometric conflicts, optimize toolpaths for thin-wall features, and recommend material substitutions that reduce weight without compromising safety margins. This proactive engagement minimizes costly redesign cycles—a critical advantage in an industry where prototype validation delays can incur six-figure daily penalties.

For aircraft manufacturers and MRO operators, partnering with Honyo Prototype means accessing CNC expertise calibrated to aviation’s unforgiving standards. We deliver not just machined parts, but documented evidence of process control that satisfies auditors and engineers alike. In an era where aircraft efficiency hinges on micron-level precision, our facility stands ready to support your next-generation aerospace innovations with zero-compromise manufacturing integrity.

Technical Capabilities

Technical Capabilities: Precision CNC Machining for Aerospace Applications

Shenzhen Honyo Prototype delivers advanced CNC machining solutions tailored to the stringent demands of the aerospace industry. Our capabilities in 3-axis, 4-axis, and 5-axis milling, combined with precision turning and tight-tolerance machining, ensure that every aircraft component meets the highest standards for performance, reliability, and compliance. With state-of-the-art equipment and a team of experienced engineers, we support the production of complex geometries, lightweight structural parts, and high-integrity assemblies used in commercial, private, and unmanned aerial vehicles.

Our 3-axis milling services provide efficient material removal and accurate feature machining for simpler geometries, ideal for flat or prismatic components such as brackets, housings, and mounting plates. For parts requiring rotational indexing or additional undercuts, our 4-axis CNC milling platforms offer enhanced flexibility with one rotational axis, enabling efficient machining of curved surfaces and peripheral features.

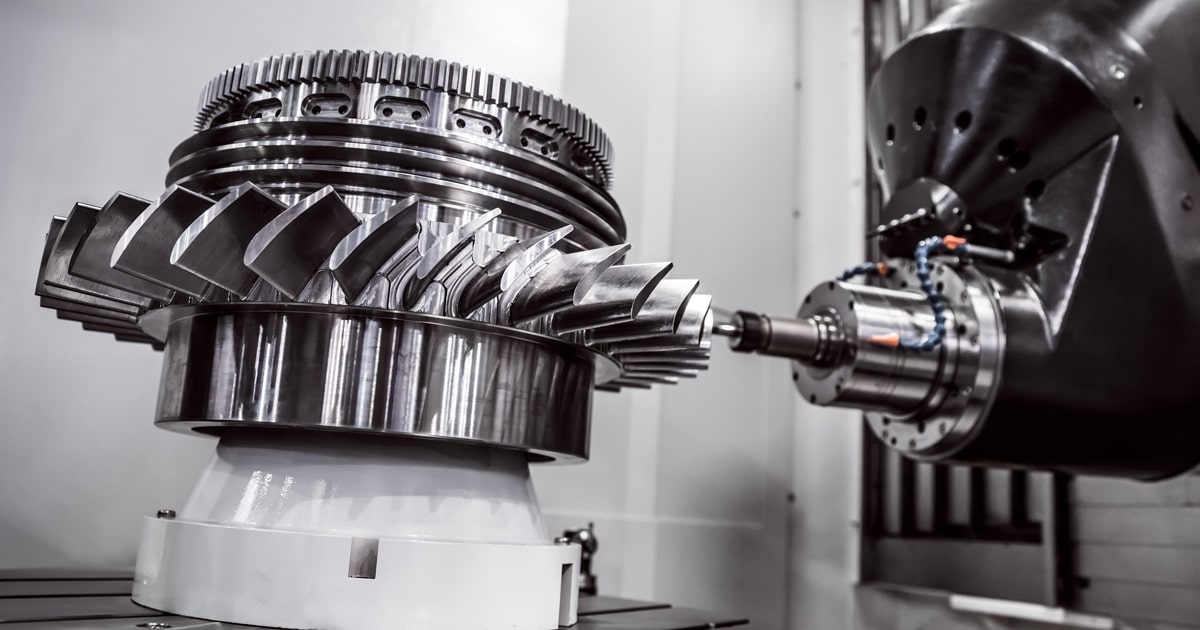

The cornerstone of our aerospace machining capability lies in 5-axis simultaneous milling. This technology allows for the precise fabrication of highly complex components—such as turbine blades, engine mounts, and aerodynamic housings—with minimal setup changes. By maintaining tool perpendicularity across contoured surfaces, 5-axis machining improves surface finish, dimensional accuracy, and throughput, while reducing the risk of part rework.

Complementing our milling capacity, our CNC turning centers handle shafts, bushings, nozzles, and other rotationally symmetric components with diameters up to 300 mm. Multi-axis turning with live tooling enables the completion of intricate features in a single setup, ensuring concentricity and reducing lead times.

Tight-tolerance machining is a core competency at Honyo Prototype. We consistently achieve tolerances down to ±0.005 mm for critical dimensions, with geometric tolerances controlled to meet ASME Y14.5 and ISO GPS standards. Surface finishes as fine as Ra 0.4 µm are routinely achieved, supporting both functional performance and regulatory compliance in flight-critical applications.

The table below outlines our standard machining tolerances and compatible aerospace-grade materials.

| Feature | Standard Tolerance | Tight Tolerance Capability |

|——–|———————|—————————-|

| Linear Dimensions | ±0.05 mm | ±0.005 mm |

| Hole Diameter | ±0.025 mm | ±0.01 mm (reamed/ground) |

| Positional Tolerance | ±0.05 mm | ±0.01 mm |

| Flatness | 0.05 mm | 0.005 mm |

| Surface Finish (Ra) | 1.6 µm | 0.4 µm |

| Material Category | Common Materials |

|——————|——————|

| Aluminum Alloys | 2024, 5052, 6061, 7075 |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) |

| Stainless Steel | 303, 304, 316, 17-4 PH |

| Nickel Alloys | Inconel 625, Inconel 718 |

| Plastics | PEEK, PTFE, Ultem, PPS |

All materials are sourced from certified suppliers and can be provided with material test reports (MTRs) upon request. Our quality management system includes CMM inspection, optical comparators, and first-article inspection reports (FAIRs) to ensure every component meets aerospace specifications. At Shenzhen Honyo Prototype, we combine technical precision with rigorous quality control to deliver CNC-machined aircraft components that perform under extreme conditions.

From CAD to Part: The Process

CNC Aircraft Component Production Workflow: From CAD to Certified Part

At Shenzhen Honyo Prototype, our aerospace CNC machining process adheres to AS9100 and NADCAP standards, ensuring precision and compliance for critical aircraft components. The workflow begins with AI-powered quoting, where our system analyzes submitted CAD files (STEP, IGES, or native formats) to instantly generate cost and lead time estimates. This phase validates geometric complexity, material certifications (e.g., AMS 4127 aluminum or AMS 4928 titanium), and initial tolerance feasibility against FAA/EASA regulatory constraints. Automated checks flag potential issues like non-machinable radii or unsupported thin walls, reducing quoting errors by 35% compared to manual methods.

Design for Manufacturability (DFM) is the pivotal second stage, conducted by our aerospace-specialized engineering team. We collaborate with clients to resolve conflicts between design intent and machining realities. Common optimizations include adjusting wall thicknesses to prevent chatter (minimum 0.8mm for aluminum), modifying internal corner radii to match standard tooling (≥0.5mm), and reorienting features to minimize setups. This phase reduces post-production rework by up to 50% and typically completes within 24–48 hours. Clients receive a detailed DFM report with annotated CAD markups, material utilization analysis, and actionable recommendations for weight reduction or cost savings without compromising structural integrity.

Production commences only after client sign-off on the DFM report. Raw materials undergo dual verification against mill certificates and our internal chemical composition database. Machining occurs on 5-axis Haas and DMG MORI platforms with real-time tool wear monitoring and temperature-controlled environments (±1°C). Critical processes include:

High-speed roughing with indexable carbide cutters

Precision finishing using polycrystalline diamond (PCD) tools for mirror surfaces

In-process CMM inspections at 30% and 70% completion stages

Final verification via Zeiss CONTURA CMMs and surface profilometry

All components undergo full first-article inspection (FAI) per AS9102 standards, with comprehensive reports including GD&T validation and material traceability logs. This end-to-end workflow ensures zero-defect delivery for landing gear brackets, fuel system manifolds, and avionics housings.

Key Production Specifications for Aerospace Components

| Parameter | Specification | Compliance Standard |

|——————–|———————————–|———————|

| Tolerance Range | ±0.005 mm (standard) to ±0.001 mm (critical) | ASME Y14.5-2018 |

| Surface Finish | Ra 0.4 µm (standard) to Ra 0.1 µm (sealing surfaces) | AMS 2750F |

| Materials | 7075-T6, 2024-T3, Ti-6Al-4V, Inconel 718 | AMS 4027, AMS 4928 |

| Inspection Coverage| 100% critical features, 30% non-critical | AS9102 Rev D |

| Lead Time | 7–15 days (prototype), 10–20 days (low-volume) | Customer agreement |

Our integrated AI-to-inspection pipeline transforms digital designs into flight-ready hardware through rigorous technical collaboration. By embedding manufacturability analysis early and leveraging closed-loop quality control, Honyo Prototype delivers airworthy components with 99.2% first-pass yield rates—accelerating your time-to-certification while mitigating supply chain risks. Partner with us for CNC solutions where precision engineering meets aerospace accountability.

Start Your Project

Start Your CNC Aircraft Project with Precision Engineering from Shenzhen Honyo Prototype

When developing high-performance aircraft components, precision, reliability, and rapid turnaround are non-negotiable. At Shenzhen Honyo Prototype, we specialize in CNC machining for aerospace applications, delivering mission-critical parts that meet the rigorous demands of modern aviation. Whether you’re prototyping a new UAV system, refining an engine component, or scaling production for certified aircraft systems, our advanced manufacturing capabilities ensure unmatched dimensional accuracy, material integrity, and compliance with industry standards.

Our CNC machining services leverage state-of-the-art 3-, 4-, and 5-axis milling and turning centers, enabling us to produce complex geometries with tight tolerances down to ±0.005 mm. We work with a broad range of aerospace-grade materials, including aluminum alloys (such as 6061-T6 and 7075-T6), titanium (Grade 5, Ti-6Al-4V), stainless steel (17-4 PH, 316L), and high-performance engineering plastics like PEEK and PTFE. Every component undergoes stringent in-process and final inspections using coordinate measuring machines (CMM), optical comparators, and surface roughness testers to guarantee adherence to AS9100 and ISO 9001 quality standards.

We understand that aircraft development cycles demand speed without compromise. Our streamlined workflow—from CAD/CAM programming to first-article inspection—ensures rapid prototyping in as little as 3–5 working days, with scalable production support for low- to mid-volume runs. Our engineering team collaborates closely with clients to optimize part design for manufacturability, reducing lead times and minimizing costly iterations.

To support your project from concept to certification, we offer comprehensive documentation, including inspection reports, material certifications, and traceability records. Our facility in Shenzhen is equipped for full digital process control, ensuring consistency across batches and full transparency throughout production.

Below is an overview of our core CNC machining capabilities tailored for aircraft component manufacturing:

| Specification | Detail |

|————-|——–|

| Machining Types | 3-axis, 4-axis, 5-axis milling; CNC turning; mill-turn machining |

| Tolerance | Standard: ±0.01 mm; Precision: up to ±0.005 mm |

| Materials | Aluminum (6061, 7075), Titanium (Ti-6Al-4V), Stainless Steel (17-4 PH, 304, 316), PEEK, PTFE, and more |

| Max Work Envelope | 1200 × 600 × 500 mm (5-axis); 2000 × 1000 × 800 mm (3-axis) |

| Surface Finish | As-machined, anodizing (Type II & III), passivation, bead blasting, powder coating |

| Quality Standards | ISO 9001:2015, AS9100D compliant, full inspection reporting |

| Lead Time | Prototype: 3–7 days; Production: 7–15 days (varies by complexity) |

Initiating your CNC aircraft project with Honyo Prototype is simple. Contact Susan Leo, our dedicated project coordinator, to discuss your design requirements, material specifications, and delivery timelines. We support STEP, IGES, SolidWorks, and DXF file formats and provide free DFM feedback within 24 hours.

Reach out today at info@hy-proto.com to accelerate your aerospace innovation with manufacturing precision you can trust.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.