Contents

Manufacturing Insight: Cnc Lathe Milling

CNC Lathe Milling: Integrated Precision for Complex Components

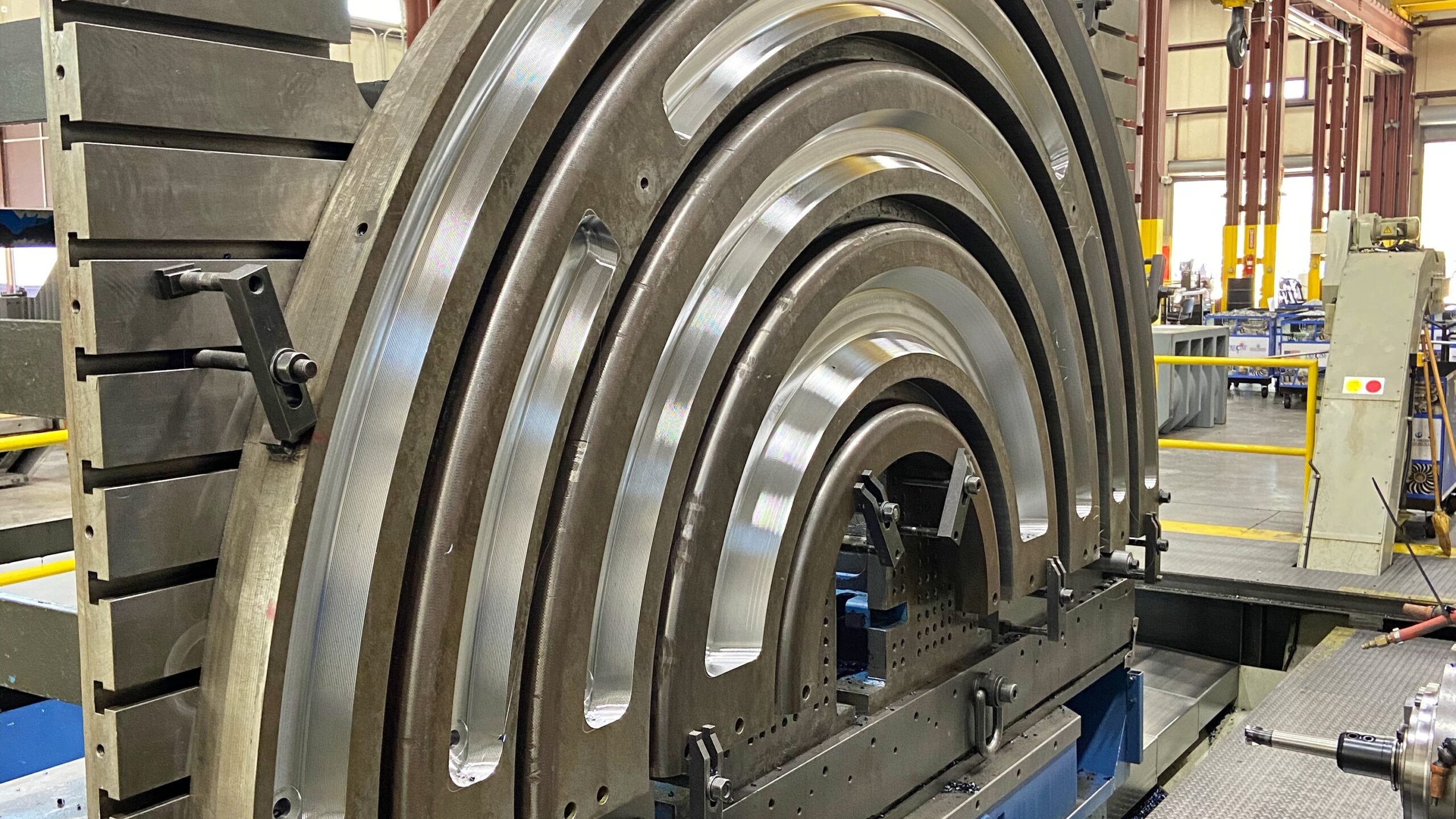

CNC lathe milling represents a transformative advancement in subtractive manufacturing, merging traditional turning operations with multi-axis milling capabilities within a single machine platform. This hybrid process eliminates the need for secondary operations and part re-fixturing, significantly reducing lead times while enhancing geometric accuracy. At Shenzhen Honyo Prototype, we leverage this technology to produce highly complex geometries—including intricate contours, off-axis holes, and sculpted surfaces—that would be impractical or cost-prohibitive using conventional lathes or stand-alone mills. The core advantage lies in maintaining micron-level positional tolerances between turned and milled features, critical for aerospace actuators, medical implants, and fluid control components where assembly integrity is non-negotiable.

Our facility utilizes state-of-the-art multi-turret, multi-spindle CNC lathe-milling centers equipped with live tooling, Y-axis capabilities, and sub-spindles. This enables simultaneous cutting from multiple vectors, supporting bar-fed production for high-volume runs and chucking for larger prototype batches. We routinely machine materials ranging from aluminum alloys (6061, 7075) and stainless steels (303, 316) to titanium, brass, and engineering plastics with tight tolerances down to ±0.005 mm. Honyo’s process excels in consolidating traditionally separate operations: a hydraulic manifold, for instance, can be fully completed in one setup—turning external diameters, drilling internal passages, milling mounting faces, and threading ports—without manual handling between stages. This integration minimizes human error, preserves surface finish consistency, and accelerates time-to-assembly for our clients.

Key performance specifications of our CNC lathe-milling fleet are summarized below:

| Parameter | Turning Range | Milling Range | Units |

|——————–|—————|—————|————-|

| Max. Spindle Speed | 6,000 | 12,000 | RPM |

| X/Z Travel | Ø300 x 500 | Ø200 x 300 | mm |

| Positional Accuracy| ±0.003 | ±0.005 | mm |

| Max. Tool Capacity | 12 | 24 | Stations |

| Typical Tolerance | ±0.01 | ±0.015 | mm |

Quality assurance is embedded at every phase. Each job undergoes rigorous first-article inspection using calibrated CMMs and optical comparators, with full traceability via our digital workflow system. Our engineers collaborate with clients during DFM reviews to optimize part geometry for lathe-milling efficiency—recommending feature consolidation, toolpath strategies, and material-specific cutting parameters that reduce cycle times by 25–40% versus traditional methods. This proactive approach ensures manufacturability without compromising design intent.

For prototypes through low-volume production, Honyo Prototype delivers the precision, flexibility, and technical partnership required to overcome complex machining challenges. By unifying turning and milling in a controlled single-setup environment, we provide not just components, but validated solutions that accelerate your product development lifecycle. Partner with us to transform intricate designs into high-integrity parts with unmatched speed and reliability.

Technical Capabilities

CNC Lathe Milling Technical Capabilities at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in high-precision CNC lathe milling, integrating advanced multi-axis machining technologies to deliver complex, tight-tolerance components for industries including aerospace, medical, automotive, and industrial equipment. Our capabilities span 3-axis, 4-axis, and 5-axis milling alongside precision turning operations, enabling us to produce intricate geometries with consistent accuracy and surface finish. By combining state-of-the-art CNC equipment with expert process engineering, we ensure rapid prototyping and low-to-medium volume production runs meet the most demanding specifications.

Our 3-axis milling systems are ideal for prismatic parts and standard geometries, delivering high repeatability and efficient material removal. For components requiring access to multiple faces or complex contours, our 4-axis and 5-axis CNC machining centers provide enhanced flexibility. The addition of rotary axes allows for single-setup machining of complex organic shapes, reducing lead times and minimizing potential for alignment errors. These systems are particularly effective for turbine blades, impellers, and structural aerospace brackets where angular features and compound surfaces are common.

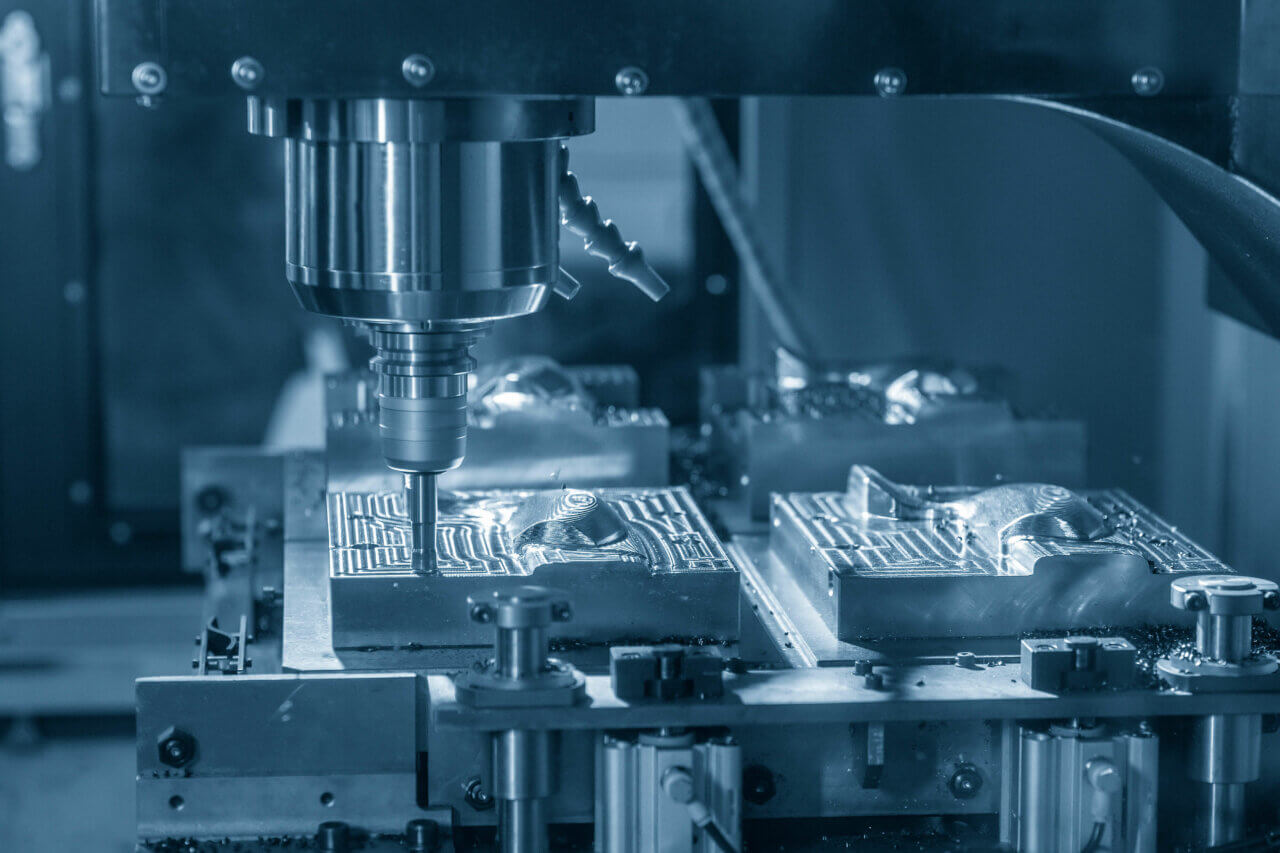

Precision turning operations are performed on advanced CNC lathes equipped with live tooling, enabling simultaneous turning and milling—commonly referred to as mill-turn machining. This hybrid capability allows us to produce fully finished rotational parts with off-axis features such as cross-holes, flats, and slots, eliminating the need for secondary operations. Mill-turn machining significantly improves throughput and dimensional consistency for complex turned components.

Tight tolerance machining is a core strength at Honyo Prototype. Our machines are maintained under strict environmental controls, and our processes follow rigorous calibration protocols. We routinely achieve tolerances down to ±0.005 mm (±0.0002″) on critical dimensions, with surface finishes as fine as Ra 0.4 µm (16 µin) achievable through precision tooling and optimized cutting strategies.

We support a broad range of engineering materials, from aluminum and stainless steel to titanium, brass, and high-performance plastics such as PEEK and PTFE. Each material is processed using customized toolpaths and cutting parameters to ensure dimensional stability and surface integrity.

The following table outlines our standard and precision tolerance capabilities across common material categories:

| Material Category | Standard Tolerance (± mm) | Precision Tolerance (± mm) | Commonly Used Materials |

|——————-|—————————-|—————————–|————————–|

| Aluminum Alloys | 0.010 | 0.005 | 6061, 7075, 2024 |

| Stainless Steel | 0.010 | 0.005 | 303, 304, 316, 17-4PH |

| Titanium | 0.010 | 0.005 | Grade 2, Grade 5 (Ti-6Al-4V) |

| Brass & Copper | 0.010 | 0.005 | C36000, C11000 |

| Engineering Plastics | 0.025 | 0.010 | PEEK, PTFE, Delrin, Nylon |

All CNC lathe milling projects benefit from in-process inspection using coordinate measuring machines (CMM) and optical comparators, ensuring compliance with technical drawings and GD&T requirements. At Shenzhen Honyo Prototype, we combine technical excellence with agile manufacturing to deliver precision-machined parts that meet the highest industry standards.

From CAD to Part: The Process

From CAD to Precision Part: Honyo Prototype’s CNC Lathe Milling Workflow

Shenzhen Honyo Prototype delivers complex, high-precision turned and milled components through a rigorously defined workflow, ensuring efficiency and quality from initial concept to final shipment. Our integrated process leverages automation and engineering expertise to minimize lead times while maximizing manufacturability and part integrity. This guide outlines the critical stages for CNC lathe milling projects: AI-Powered Quoting, Design for Manufacturability (DFM) Analysis, and Production Execution.

AI-Powered Quoting initiates the process upon CAD model submission. Our proprietary AI engine rapidly analyzes the 3D geometry, identifying key features, material requirements, and geometric complexities inherent in multi-axis lathe milling operations. It autonomously generates an initial cost estimate and lead time projection by cross-referencing historical production data, current machine utilization, and material costs. This provides clients with near-instantaneous preliminary feedback, significantly accelerating the project kick-off phase compared to manual quoting methods. The AI output serves as a robust foundation for the subsequent engineering review.

Comprehensive DFM Analysis follows immediately after quote acceptance. Our senior manufacturing engineers conduct a meticulous review of the CAD file, focusing specifically on challenges unique to simultaneous turning and milling. We scrutinize feature accessibility, tool path feasibility, potential for chatter during live tooling operations, optimal stock allowance, and fixture requirements. Critical considerations include minimizing secondary operations through strategic feature placement and verifying that tolerances align with process capabilities. Honyo provides actionable feedback, suggesting modifications to enhance producibility without compromising functional intent, often resolving potential production bottlenecks before machining begins. This proactive step is vital for avoiding costly delays and rework.

Precision Production Execution commences once the final design is approved. Programmers generate optimized G-code using advanced CAM software, simulating the entire process to ensure collision avoidance and efficient material removal. Skilled machinists meticulously set up the CNC lathe mill center, installing custom or standard fixtures, verifying tool geometry offsets, and calibrating the work coordinate system. Production runs utilize high-rigidity machines capable of tight tolerances and fine finishes. Rigorous in-process inspections occur at defined stages, with final verification performed using calibrated CMMs, optical comparators, and surface roughness testers against the original drawing specifications. The table below summarizes our core production capabilities for CNC lathe milling.

| Parameter | Standard Capability | Tight Tolerance Capability |

| :——————— | :———————– | :————————- |

| Dimensional Tolerance | ±0.025 mm (±0.001″) | ±0.005 mm (±0.0002″) |

| Positional Tolerance | ±0.012 mm (±0.0005″) | ±0.003 mm (±0.0001″) |

| Surface Roughness (Ra) | 1.6 µm (63 µin) | 0.4 µm (16 µin) |

| Max Turning Diameter | Ø 300 mm (12″) | Ø 300 mm (12″) |

| Common Materials | Aluminum, Steel, Stainless, Brass, Plastics | Titanium, Exotic Alloys |

Upon successful quality validation, parts undergo final cleaning and deburring as required. Comprehensive inspection reports are compiled before secure packaging and shipment, ensuring clients receive fully documented, precision-engineered components ready for integration. This structured workflow, combining AI efficiency with deep manufacturing expertise, is central to Honyo Prototype’s reputation for reliable, high-quality CNC lathe milling services.

Start Your Project

Start Your CNC Lathe Milling Project with Precision and Confidence

At Shenzhen Honyo Prototype, we specialize in high-precision CNC lathe milling services tailored to meet the exacting demands of engineers, designers, and product developers across industries. Whether you’re prototyping a new component or scaling into low-volume production, our advanced CNC machining capabilities ensure dimensional accuracy, superior surface finishes, and rapid turnaround times. Our facility integrates state-of-the-art 3-axis, 4-axis, and 5-axis milling centers with precision turning lathes, enabling us to handle complex geometries and tight tolerances down to ±0.005 mm.

We understand that every project begins with a vision. That’s why our engineering team works closely with you from the initial concept stage—offering design for manufacturability (DFM) feedback, material selection guidance, and cost-optimized machining strategies. Our expertise spans a wide range of materials, including aluminum alloys (6061, 7075), stainless steel (303, 304, 316), brass, titanium, and engineering plastics such as PEEK and Delrin. With in-house tooling, real-time quality inspection using CMM and optical comparators, and a streamlined workflow, we ensure consistency across prototypes and production runs.

To get started, simply provide your 3D CAD model (in STEP, IGES, or native formats) along with any specific requirements for tolerances, surface finish, or post-processing. Our team will review your design, suggest optimizations if needed, and deliver a detailed quote within 12 hours. We support batch sizes from 1 to 500+ units and offer additional services such as anodizing, powder coating, silk screening, and assembly integration.

Material & Machining Specifications

| Material Category | Common Alloys | Tolerance (Standard) | Max Part Size (mm) | Surface Finish (Ra) |

|——————-|———————|————————|———————|———————-|

| Aluminum | 6061, 7075, 2024 | ±0.005 mm | 600 x 400 x 300 | 1.6 – 3.2 µm |

| Stainless Steel | 303, 304, 316, 17-4 | ±0.008 mm | 500 x 350 x 250 | 1.6 – 3.2 µm |

| Brass | C3604, H59 | ±0.005 mm | 400 x 300 x 200 | 0.8 – 1.6 µm |

| Titanium | Grade 2, Grade 5 | ±0.010 mm | 350 x 250 x 200 | 1.6 – 3.2 µm |

| Engineering Plastics | PEEK, Delrin, Nylon | ±0.020 mm | 500 x 400 x 300 | 3.2 – 6.3 µm |

Our CNC lathe milling processes combine the rotational precision of turning with the versatility of multi-axis milling, allowing us to produce turned-milled complex components in a single setup—reducing lead time and enhancing part accuracy. From medical device housings to aerospace fittings and automotive actuators, we deliver machined parts you can rely on.

Ready to bring your design to life? Contact Susan Leo, your dedicated manufacturing advisor at Shenzhen Honyo Prototype. Email her directly at info@hy-proto.com with your project details, and receive a comprehensive quote and technical assessment within hours. Let us help you move from concept to physical prototype—faster, smarter, and with uncompromised quality.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.