Introduction: Navigating the Global Market for restricter plate

In today’s unpredictable global landscape, the humble restricter plate has become a linchpin in critical industries ranging from automotive and heavy machinery to energy, mining, and process manufacturing. As international supply chains face mounting pressure from geopolitical shifts, shifting tariffs, and rapidly evolving regulatory requirements, B2B buyers in Africa, South America, the Middle East, and Europe must adapt with agility and foresight. Sourcing restricter plates—integral in flow control, system safety, and operational performance—now demands a nuanced understanding of market dynamics, quality standards, and risk mitigation strategies.

Against this backdrop, sourcing decisions for restricter plates are increasingly complex. Factors such as fluctuating raw material costs, new trade barriers, and the fast pace of technological innovation can profoundly impact both price and supply reliability. The stakes are especially high for international buyers managing cross-border logistics, regulatory compliance, and cost-containment in regions impacted by volatile tariff policies and changing manufacturing footprints.

This comprehensive guide is designed to demystify the global market for restricter plates, equipping buyers with the latest insights and expert best practices. Inside, you will find:

- Analysis of restricter plate types and materials—ensuring selection that matches precise application demands

- Overview of manufacturing processes and quality control protocols—helping buyers validate supplier capabilities

- Supplier evaluation criteria and sourcing strategies—with actionable tips for risk reduction and cost optimization

- Current price drivers and regional market trends

- Practical FAQs tailored for international buyers navigating complex import/export scenarios

By distilling technical complexities and market intelligence into actionable guidance, this resource enables procurement leaders from Poland to Mexico, Nigeria to the UAE, to make confident, data-driven sourcing decisions. Stay ahead of tariff disruptions, ensure uncompromising quality, and secure lasting supply chain resilience—starting with the right approach to restricter plate procurement.

Understanding restricter plate Types and Variations

| Type Name | Key Distinguishing Features | Primary B2B Applications | Brief Pros & Cons for Buyers |

|---|---|---|---|

| Fixed Orifice Restricter Plate | Non-adjustable, precision-machined opening | Flow control in chemical, water, oil & gas pipelines | Reliable and cost-effective, but inflexible for changing conditions |

| Adjustable Orifice Restricter Plate | Modifiable plate or insert for variable restriction | Process systems needing adaptable flow (e.g., batch production) | Customizable for diverse flows, may require more maintenance |

| Multi-Hole Restricter Plate | Several smaller holes instead of one large orifice | Noise-sensitive processes, reduction of cavitation and vibration | Lowers pressure surges; complex design increases lead time and price |

| Conical Restricter Plate | Tapered or cone-shaped bore for smoother flow | High-pressure gas or aggressive liquid handling | Reduces pressure loss and turbulence, but higher initial cost |

| Slotted Restricter Plate | Long, machined slots rather than circular holes | Slurry, pulp, or contaminant-laden fluids | Resists clogging in dirty flows, but may have less precise control |

Fixed Orifice Restricter Plate

A fixed orifice restricter plate features a single, specific-size opening for precise, predictable flow control. Its robust, simple design is particularly suitable for environments with stable process conditions—common in oil & gas, municipal water supply, and industrial chemical transfer. For B2B buyers, these plates offer reliable performance and cost efficiency, with minimal calibration or adjustment required. However, their lack of adjustability means any future changes in flow rate demand replacement or modification, so careful planning regarding process scalability is critical in procurement.

Adjustable Orifice Restricter Plate

This type enables field adjustment to fine-tune flow rates without needing complete plate replacement. Adjustable plates are optimal where process requirements may fluctuate, such as in contract manufacturing, pilot plants, or systems handling variable product loads. They provide procurement flexibility and long-term operational adaptability, which can offset the greater initial investment. Buyers should assess ease of adjustment, durability of moving parts, and compatibility with existing infrastructure to ensure ongoing value.

Multi-Hole Restricter Plate

By distributing flow through multiple smaller holes, multi-hole types significantly decrease flow turbulence and reduce vibration or cavitation risk. Their advanced design suits industries where equipment longevity and low noise are priorities, such as food processing or pharmaceuticals. The complexity of design and manufacturing leads to higher costs and longer lead times, factors B2B buyers must consider in projects with tight deadlines or strict budgetary constraints. Partnering with suppliers capable of highly consistent fabrication is essential for making these plates a sound investment.

Conical Restricter Plate

Conical restricter plates utilize a tapered bore to facilitate smoother pressure reduction across the plate, minimizing energy loss and preventing sharp flow disruptions. Their suitability for high-pressure gases or erosive liquids makes them favored in petrochemical and power generation applications. While the superior flow characteristics support improved process efficiency, procurement teams should anticipate higher upfront costs and prioritize vendors with experience in precision machining to ensure performance consistency.

Slotted Restricter Plate

Designed with elongated slots, these plates excel in handling fibrous, abrasive, or solid-laden media—applications prevalent in mining, pulp and paper, or wastewater sectors. Slotted plates are less prone to blockage and are easier to maintain in processes with contaminants or particulates. For B2B buyers facing challenging flow conditions, the increased reliability and lower maintenance downtime can justify their potential for reduced flow accuracy. Evaluating the degree of slot customization and after-sales technical support is advisable before final selection.

Related Video: Extended Entity Relationship Models (EER diagrams)

Key Industrial Applications of restricter plate

| Industry/Sector | Specific Application of restricter plate | Value/Benefit for the Business | Key Sourcing Considerations for this Application |

|---|---|---|---|

| Oil & Gas | Flow regulation in pipelines | Enhances precise control of flow rates and pressure | Compliance with API/ISO standards, material strength, corrosion resistance |

| Chemical Processing | Process line throttling and mixing control | Improves process stability and safety | Chemical compatibility, sanitation requirements, traceability |

| Water & Wastewater | Flow restriction for metering and treatment | Accurate dosing and process optimization | Durability, flange compatibility, local water standards |

| Power Generation | Steam and feedwater flow balancing | Optimal equipment longevity and operational safety | High-temperature resistance, pressure ratings, local code adherence |

| Food & Beverage | Sanitary flow control in production lines | Ensures product consistency and hygiene | HACCP certification, food-grade materials, clean-in-place (CIP) compatibility |

Oil & Gas: Flow Regulation in Pipelines

Restricter plates are integral in oil and gas pipeline systems, providing essential throttling to manage flow rates and maintain optimal pressure levels. This is especially vital in regions with long transmission distances or variable well outputs, such as in the Middle East and West Africa. For buyers, ensuring materials are highly resistant to corrosion and conform to recognized standards (such as API or ISO) is critical to guarantee both performance and compliance in harsh environments.

Chemical Processing: Process Line Throttling and Mixing Control

In chemical processing facilities, restricter plates enable the fine tuning of material flows during mixing, dilution, or sequential reactions. They help prevent over-pressurization and maintain consistent production quality. Facilities in locations such as the Middle East and Poland may handle aggressive chemicals; therefore, buyers must prioritize options offering high chemical compatibility, validated traceability, and adherence to sanitation protocols alongside reliable supply chain documentation for local regulatory needs.

Water & Wastewater: Flow Restriction for Metering and Treatment

Water and wastewater treatment plants use restricter plates to control flow rates entering treatment stages, which is essential for accurate chemical dosing and process stability. African and Latin American markets, where infrastructure investments are accelerating, particularly benefit from durable, locally certified plates that are easy to install with existing flanges. Buyers should confirm compliance with regional water standards and seek low-maintenance designs for efficient long-term operation.

Power Generation: Steam and Feedwater Flow Balancing

In thermal and combined-cycle power plants, restricter plates help regulate steam and feedwater distribution, balancing flows to different turbines or boilers. This contributes directly to system safety and extends equipment lifespan. European buyers, especially in power-intensive regions, must pay attention to high-temperature material specifications, pressure ratings, and conformity with local codes—key to avoiding costly operational disruptions or regulatory penalties.

Food & Beverage: Sanitary Flow Control in Production Lines

Restricter plates are also used in food and beverage processing, ensuring controlled, hygienic flow of liquids in dairy, brewing, and bottling operations. Maintaining cleanable, corrosion-resistant systems is essential to meeting HACCP and food-safety standards, particularly in export-focused markets like Mexico and Europe. Buyers should look for plates constructed from food-grade stainless steel with proven compatibility for clean-in-place (CIP) procedures, minimizing contamination risk and enabling seamless integration into automated production lines.

Related Video: What are all the Laboratory Apparatus and their uses?

Strategic Material Selection Guide for restricter plate

Selecting the Optimal Material for Restricter Plates: A Comparative B2B Analysis

Restricter plates play a critical role in controlling fluid flow in pipelines, process systems, and industrial equipment across various industries and regions. Material selection is the foundation for balancing performance, lifecycle cost, regulatory compliance, and supply chain resilience—each particularly vital for international B2B buyers operating in Africa, South America, the Middle East, and Europe. Below is a comparative, actionable overview of four prevalent material options for restricter plates.

1. Stainless Steel (e.g., 304, 316, 316L)

Key Properties:

Stainless steels offer excellent corrosion resistance, moderate to high strength, and can withstand both elevated and cryogenic temperatures. Common grades like 316/316L are particularly valued for their resistance to chlorides and many acidic media.

Pros:

– High durability and long service life in corrosive environments.

– Suitable for food, pharmaceutical, chemical, and petrochemical applications.

– Readily available in standardized forms (typically ASTM A240, DIN 1.4404, or JIS SUS316).

Cons:

– Higher cost compared to carbon or alloy steels, especially during price surges.

– Potentially longer procurement times if sourcing specialty grades.

Application Impact:

Best suited for corrosive fluids (acids, seawater, aggressive chemicals) and environments demanding maximum hygiene or minimal contamination.

Buyer Considerations:

International buyers should confirm grade authenticity due to global quality variations. Certification to recognized standards (ASTM, DIN, or JIS) is crucial. Stainless steel is often preferred in areas where water quality poses corrosion risks—such as coastal Africa or oil-producing Middle Eastern nations.

2. Carbon Steel (e.g., ASTM A516, A105)

Key Properties:

Known for high mechanical strength and ease of fabrication, carbon steels are widely used for non-corrosive or mildly corrosive applications. They perform reliably at moderate temperatures but are not recommended for aggressive corrosive media.

Pros:

– Cost-effective and easily sourced globally.

– Good machinability and weldability.

– Compliant with international norms (e.g., ASTM A516/A105, DIN EN 10025).

Cons:

– Susceptible to corrosion if not coated or lined.

– Limited to non-corrosive or mildly corrosive environments.

Application Impact:

Ideal for water, steam, air, and general industrial service lines. Not suitable for seawater, acids, or aggressive chemicals without additional protection.

Buyer Considerations:

Local preferences may favor carbon steel due to cost sensitivity, especially in heavy industry and infrastructure projects in Mexico and Poland. For African and Middle Eastern buyers, attention to local environmental conditions (humidity, salinity) is essential to prevent premature degradation.

3. Duplex Stainless Steel (e.g., 2205, ASTM A182 F51)

Key Properties:

Duplex grades blend the properties of austenitic and ferritic stainless steels, providing exceptional strength and resistance to chloride-induced stress corrosion cracking.

Pros:

– Superior mechanical strength (higher than standard stainless steels).

– Excellent corrosion and pitting resistance—well-suited for seawater and harsh chemical environments.

– Typically meets stringent international standards (ASTM A182 F51, DIN 1.4462).

Cons:

– Higher material and fabrication cost.

– More challenging to weld and process; requires specialist capabilities.

Application Impact:

Best for offshore, petrochemical, and desalination projects where both high strength and corrosion resistance are essential.

Buyer Considerations:

Duplex steels are increasingly specified for their lifecycle value. They’re particularly relevant for buyers in the Middle East (oil & gas, desalination) and coastal regions of Africa and South America. Sourcing may be subject to tariffs or require careful supplier vetting for compliance and quality assurance.

4. Nickel Alloys (e.g., Inconel 625, ASTM B446)

Key Properties:

Nickel-based alloys are engineered for extreme environments—high temperature, pressure, and the most aggressive chemicals. Inconel 625 is a representative choice, offering outstanding corrosion and oxidation resistance.

Pros:

– Handles aggressive acids (HCl, HNO₃), seawater, high and low temperatures.

– Maintains mechanical properties under stress and thermal cycling.

– Often specified for critical, high-value applications requiring exceptional reliability.

Cons:

– High raw material cost and limited availability.

– Specialized manufacturing; longer lead times and complex quality control.

Application Impact:

Applied in refineries, power generation (including nuclear), and chemical processing plants handling highly corrosive fluids.

Buyer Considerations:

Nickel alloys may be impacted by export controls and high import tariffs—buyers in South America and the Middle East should evaluate local alternatives or regional supply chains. Verifying international compliance (ASTM B446, DIN, JIS) and quality documentation is critical to avoid costly downtime and ensure application safety.

Comparative Summary Table

| Material | Typical Use Case for restricter plate | Key Advantage | Key Disadvantage/Limitation | Relative Cost (Low/Med/High) |

|---|---|---|---|---|

| Stainless Steel (304/316) | Corrosive fluids; food/pharma; chemical processes | High corrosion resistance; durability | Higher cost; possible longer lead times | Medium to High |

| Carbon Steel (A516/A105) | General industrial, water, low-risk environments | Cost-effective; easy to source | Corrodes easily without protection; limited to non-corrosive media | Low |

| Duplex Stainless (2205/F51) | Seawater, offshore, oil & gas, harsh chemicals | Superior strength; resists pitting & SCC | Costlier than carbon/stainless; complex fabrication | High |

| Nickel Alloys (Inconel 625) | Extreme chemicals, high T/P, critical reliability | Withstands extreme environments | Very high cost; long lead times; supply challenges | High |

In-depth Look: Manufacturing Processes and Quality Assurance for restricter plate

Manufacturing Processes and Quality Control Considerations for Restricter Plate Sourcing

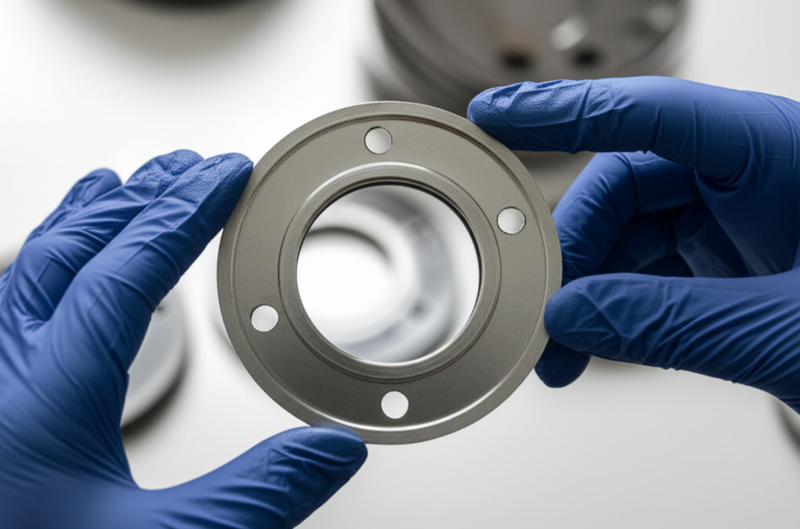

When sourcing restricter plates—critical components often found in automotive, industrial, and fluid control systems—understanding both the manufacturing process and rigorous quality assurance requirements is essential. This awareness empowers B2B buyers from diverse global regions to make informed procurement decisions, mitigate supply chain risk, and ensure product compliance across international markets.

Key Stages in Restricter Plate Manufacturing

The process of manufacturing a restricter plate integrates precision engineering and controlled workflows to achieve the required functionality, tight tolerances, and durability.

1. Material Selection and Preparation

– Material Choice: Common materials include stainless steel, carbon steel, and specific engineered alloys, selected based on corrosion resistance, mechanical strength, and regulatory requirements.

– Procurement and Inspection: Sourced raw materials undergo initial quality checks (Incoming Quality Control, IQC), verifying certifications (e.g., mill test reports) and assessing for defects or inconsistencies.

2. Forming and Machining

– Cutting/Stamping: Plates are cut to shape using CNC machines, laser or waterjet cutting, or stamping dies, ensuring dimensional precision and repeatability.

– Drilling and Piercing: Precision drilling or laser cutting forms the restrictor orifices. Tolerances are closely monitored, as minor deviations can impact flow characteristics or safety.

– Surface Treatment: Depending on application, plates may receive deburring, polishing, passivation, or coating (e.g., anti-corrosion treatments) to enhance surface finish and longevity.

3. Assembly (If Applicable)

– In more complex assemblies, restricter plates may be integrated with gaskets, seals, or mounting components. Automated or semi-automated assembly lines ensure consistent fitment.

4. Finishing and Packaging

– Final Processing: Surface cleaning, marking (e.g., laser-engraved part numbers, traceability codes), and protective packaging prepare the product for shipment and end use.

– Pre-shipment Inspection: Finished batches undergo a last round of quality checks to verify conformity to specifications.

Quality Assurance Frameworks and Certifications

Leading manufacturers implement institutionalized quality assurance (QA) processes to satisfy increasingly stringent global requirements.

International and Industry-Specific Standards

– ISO 9001: The foundational quality management certification, ensuring systematic, documented processes from procurement to final delivery.

– ISO 14001/45001: Environmental and occupational health certifications sometimes demanded in major projects or by large buyers.

– CE Marking (Europe): Mandatory for certain applications, confirming compliance with EU directives on safety, health, and environmental protection.

– API/ASME (Oil & Gas): For plates used in process and energy sectors, American Petroleum Institute or ASME standards may be specified.

– Custom OEM Specifications: Many buyers, particularly in automotive or defense sectors, require adherence to proprietary QA protocols in addition to certifications.

Critical QC Checkpoints

1. IQC (Incoming Quality Control):

– Raw materials inspected for composition, mechanical properties, and certifications.

– Supplier CoC (Certificate of Compliance) and product traceability typically verified.

2. IPQC (In-process Quality Control):

– On-line inspections during key stages—dimensional checks post-cutting/drilling, surface finish measurement, and process log reviews.

– Statistical Process Control (SPC) applied for high-volume, precision components.

3. FQC (Final Quality Control):

– Comprehensive multi-point inspections before shipment:

– Dimensional analysis (using coordinate measuring machines—CMM, gauges)

– Visual inspection for surface defects, burrs, contamination

– Pressure or flow testing (for fluid system applications)

– Hardness and material verification (random sampling or 100% for critical lots)

Testing Methods

– Non-Destructive Testing (NDT): Dye penetrant, ultrasonic, or other NDT methods can be used to detect internal flaws.

– Functional Testing: For plates with flow-control capability, actual flow-rate or pressure-drop tests may be conducted, sometimes witnessed by third-party inspectors.

– Chemical Analysis: Spectrometry or XRF checks confirm alloy composition.

Verifying Supplier Quality: Strategies for International B2B Buyers

Supplier Audits and Due Diligence

– On-site Audits: Ideally, visit the manufacturing site to assess QA/QC infrastructure, certifications, and process discipline. For buyers unable to travel, commissioning a local third-party audit (such as SGS, Bureau Veritas, TÜV) can serve as a robust alternative.

– Review of Documentation: Ensure full access to supplier certifications (ISO, CE, etc.), calibration logs for measuring equipment, and detailed process flowcharts. Request samples of previous QC reports and product traceability documentation.

Inspection Protocols

– Pre-shipment & In-process Inspections: Contractualize third-party inspections at key milestones—before shipment, after critical process stages, or for random sampling.

– Acceptance Criteria: Clearly specify measurable quality benchmarks (e.g., tolerance limits, surface roughness, marking requirements) in purchase agreements and monitor compliance with detailed inspection reports.

Ongoing Quality Monitoring

– Batch Sampling: For recurring orders, require batch-by-batch reporting, including statistical analysis of key parameters.

– Returns and Nonconformities: Define protocols for managing quality failures—rewriting contracts to clarify supplier liability, return procedures, and corrective/preventive actions (CAPA).

Regional and Compliance Nuances

Africa

- Infrastructure Constraints: Logistics and inspection processes can be impacted by local infrastructure; prioritize suppliers experienced with African customs and capable of providing extra documentation or robust crating for transport.

- Regulatory Awareness: Highlight compliance with any unique local standards or public procurement rules.

South America (e.g., Mexico, Brazil)

- Customs and Tariffs: Ensure supplier familiarity with Mercosur, NAFTA/USMCA, or other regional trade agreements to mitigate tariff exposure and streamline cross-border documentation.

- Certification Recognition: Confirm that international certifications (like ISO 9001, CE) are recognized by local authorities or end users.

Middle East

- Project-Based Requirements: Focus on supplier experience with large-scale infrastructural or energy projects. Emphasize compliance with regionally prevalent standards (e.g., SABER for Saudi Arabia, ESMA for UAE).

- Traceability and Localization: Some projects require traceability from raw material to finished component and preference for in-region supply chain involvement.

Europe (e.g., Poland)

- Strict Compliance Culture: European buyers typically demand rigorous documentation, traceability, and adherence to CE and RoHS directives.

- Supplier Transparency: Expect regular provision of nonconformity and CAPA reports; insist on GDPR-compliant data management for supplier records.

Actionable Recommendations for B2B Buyers

- Thoroughly define technical and testing specifications in RFQs/RFPs—attach technical drawings, inspection protocols, and required certifications.

- Prioritize suppliers with internationally recognized certifications and demonstrated experience exporting to your region.

- Demand full transparency: request complete production and inspection records for each lot.

- Contractually embed quality assurance requirements, including right to audit, obligations for corrective action, and supplier accountability for nonconforming goods.

- Utilize reputable third-party inspection agencies whenever possible to reduce risk, particularly for first-time or high-value orders.

- Establish ongoing quality review routines for long-term supply relationships—including statistical sampling, performance tracking, and periodic supplier requalification.

Adopting these best practices ensures buyers receive restricter plates that meet project requirements, regulatory frameworks, and global quality expectations—while insulating their supply chains from disruptions, compliance pitfalls, and costly quality failures.

Related Video: Lean Manufacturing – Lean Factory Tour – FastCap

Comprehensive Cost and Pricing Analysis for restricter plate Sourcing

Key Cost Components in Restricter Plate Sourcing

For international buyers, especially those in Africa, South America, the Middle East, and Europe, understanding the layered cost structure of restricter plate procurement is essential for robust budgeting and negotiation. The following elements make up the primary cost drivers:

- Raw Materials: The choice of materials (e.g., stainless steel, aluminum alloys) is the greatest initial determinant of cost. Material grades suitable for precision and wear resistance generally carry premium prices.

- Labor: Labor costs are closely tied to the manufacturing region. Countries with higher wage levels will generally reflect this in the delivered price, but automation and advanced production can offset these differentials.

- Manufacturing Overhead: Factory overhead includes plant maintenance, utilities, equipment depreciation, and indirect labor. Overhead allocation varies by supplier efficiency and production volume.

- Tooling and Setup: For custom or high-tolerance restricter plates, initial tooling and dies represent a significant upfront investment, often amortized across order volume.

- Quality Control (QC): Strict QC protocols and required certifications (like ISO, TS, or specific industry standards) can add notable cost but are vital for compliant and reliable use.

- Logistics and Shipping: Freight charges, insurance, customs duties, and port charges can be substantial, particularly for buyers outside North America, Europe, or East Asia. The choice of Incoterms (e.g., FOB, CIF, DDP) directly impacts the portion of these costs borne by the buyer.

- Supplier Margin: Margins reflect the supplier’s pricing strategy, market demand, and competitive landscape, and can be more flexible for large or repeat orders.

Main Price Influencers for Global Buyers

Several factors will more directly influence the final quoted price for restricter plates:

- Order Volume & Minimum Order Quantities (MOQ): Larger orders typically yield lower per-unit prices due to economies of scale, sharing fixed costs over higher quantities, and incentivizing supplier commitment.

- Specifications and Customization: Non-standard dimensions, unique designs, or additional surface treatments (e.g., anodizing, powder coating) increase production complexity and price.

- Material Selection: Sourcing corrosion-resistant or specialty alloys adds to base costs, especially during periods of commodity price volatility.

- Quality Requirements and Certifications: Demanding higher QC, traceability, or third-party inspection reports increases costs, often justified for regulated industries (aerospace, automotive, oil & gas).

- Supplier Profile and Geographic Location: Working with suppliers known for advanced capabilities, established credentials, or strategic geographic proximity (to reduce tariffs/logistics risk) can influence pricing positively or negatively.

- Incoterms and Delivery Terms: The point at which risk and cost transfer (EXW vs. DDP, etc.) substantially affects the landed cost for importers, especially when factoring in local taxes, tariffs, and logistics.

Actionable Strategies for International B2B Buyers

For organizations sourcing restricter plates amidst volatile tariffs and shifting supply chain landscapes, consider the following best practices:

- Diversify Supplier Base: Don’t rely on a single country or supplier—evaluate alternative regions with favorable trade terms or lower logistics barriers (e.g., consider Eastern Europe for EU buyers, or Mexico for Americas). This helps mitigate tariff shocks and ensures supply continuity.

- Negotiate on Total Cost of Ownership (TCO): Move beyond unit pricing. Evaluate lifetime cost, quality, failure rates, shipping, and after-sales support. In some markets, a slightly higher upfront cost yields long-term savings on maintenance or replacement.

- Leverage Volume Commitments: Where feasible, consolidate purchases to maximize scale advantages or negotiate longer-term agreements for price stability amid commodity volatility.

- Integrate Tariff Adjustment Clauses: In volatile markets, ensure contracts cover potential changes in duties or trade restrictions, sharing cost impacts clearly between parties.

- Optimize Shipping and Inventory: Work with suppliers to recalibrate delivery schedules or batch shipments to manage freight costs and minimize customs exposures, especially when import/export regulations change suddenly.

- Monitor Regulatory Shifts: Stay informed about evolving tariffs, local content requirements, and import/export controls in target sourcing geographies to anticipate and mitigate pricing disruptions.

Regional Pricing Nuances and Considerations

- Africa & Middle East: Logistics, port infrastructure, and customs clearance can present hidden costs. Engage local freight forwarders and clarify delivery responsibilities for cost transparency.

- South America: Tariff structures and import restrictions vary widely. Bulk shipments and working with local distribution partners often lower total landed costs.

- Europe (e.g., Poland): EU market access can reduce some barriers, but labor and quality expectations may increase base product costs. Consider regional (Eastern/Central Europe) suppliers for cost and lead time optimization.

- Mexico: Nearshoring potential for North and South American buyers can reduce tariffs, logistics, and lead times compared to Asia.

Disclaimer: The above pricing insights are indicative. Actual cost structures and final pricing may vary significantly depending on global supply-demand dynamics, regional policies, and supplier-specific conditions. Always request detailed, up-to-date quotations and confirm all terms in writing.

By systematically evaluating these cost factors and incorporating robust negotiation strategies, international buyers can secure more competitive and resilient supply chains for restricter plates.

Spotlight on Potential restricter plate Manufacturers and Suppliers

This section offers a look at a few manufacturers active in the ‘restricter plate’ market. This is a representative sample for illustrative purposes; B2B buyers must conduct their own extensive due diligence before any engagement. Information is synthesized from public sources and general industry knowledge.

Orifice Plates, Restriction Orifice Unions & RTJ Plate Holders (usaindustries.com)

USA Industries specializes in precision-engineered flow measurement solutions, including a comprehensive portfolio of orifice plates, restriction orifice unions, and RTJ plate holders widely used in global process industries. The company offers Series 500 Universal Orifice Plates, Series 520 Paddle Type Plates, and advanced RTJ holder plates, delivering compatibility with leading international standards such as AGA, ISA, ANSI, ASME, API, and AWWA. They stock durable 304 and 316 stainless steel options in multiple thicknesses, with custom manufacturing available to meet unique project requirements—making them a reliable partner for buyers with challenging specifications.

Key strengths:

– Extensive product range: Supports diverse measurement and flow control needs.

– Custom solutions: Responsive to demanding applications and non-standard requests.

– Rigorous standards compliance: Ensures product acceptance for regulated and high-integrity projects.

– International supply experience: Well-equipped to meet the needs of B2B buyers from Africa, South America, the Middle East, and Europe, including fast turnaround and technical support.

Restriction Orifice Plates (www.solartronisa.com)

Solartron ISA, a brand under Restriction Orifice Plates, delivers engineered flow-control solutions, focusing on restriction orifice plates for precise flow regulation across industrial applications. Their portfolio includes standard single- and multi-hole designs to mitigate noise and reduce cavitation, as well as multi-stage units for high-pressure gas and liquid processes. The company is recognized for leveraging proven design methodologies, drawing on established flow engineering best practices, and integrating robust manufacturing capabilities—evident through their adherence to R.W. Miller flow engineering principles and commitment to safety and reliability.

Key strengths include customization to unique process conditions and a track record in critical environments where flow accuracy and durability are paramount. While explicit certifications (such as ISO or CE) are not prominently marketed, the technical rigor and breadth of reference applications suggest alignment with international standards. Their international presence and history imply capability to support projects in Africa, South America, the Middle East, and Europe, offering B2B buyers access to application engineering support and responsive global distribution.

Unique selling points:

– Engineering for complex service conditions (noise/cavitation)

– Proven technical expertise and customization

– Support for global project requirements and distribution

Pikotek® Flow Restriction Orifice Plates (www.gptindustries.com)

Pikotek®, a brand under GPT Industries, specializes in advanced flow restriction orifice plates engineered for precise control and isolation within pipelines. The company’s products feature a unique construction, combining 316 stainless steel with G-10 fiberglass-reinforced laminate, and integrate a PTFE spring-energized seal within a precision-tapered groove—designed for enhanced leakage protection and durability. Pikotek’s capabilities include custom plate thickness options (.260″ or .308″) to suit various pressure classes and application needs, showcasing a commitment to tailored industrial solutions.

Key strengths include robust sealing performance, resistance to corrosive environments, and a focus on safety-critical applications—crucial for oil, gas, and process industries in regions like Africa, South America, the Middle East, and Europe. Although detailed certification information is limited, Pikotek’s engineering focus and international distribution channels suggest suitability for high-specification, export-driven projects demanding proven reliability and adaptability.

Quick Comparison of Profiled Manufacturers

| Manufacturer | Brief Focus Summary | Website Domain |

|---|---|---|

| Orifice Plates, Restriction Orifice Unions & RTJ Plate Holders | Precision-engineered, standards-compliant, custom orifice solutions | usaindustries.com |

| Restriction Orifice Plates | Multi-hole, custom-engineered restricter plate solutions | www.solartronisa.com |

| Pikotek® Flow Restriction Orifice Plates | Hybrid stainless/G-10, engineered seals, global reach | www.gptindustries.com |

Essential Technical Properties and Trade Terminology for restricter plate

Critical Technical Specifications of Restricter Plates

Understanding the essential technical properties of restricter plates is vital for B2B buyers to ensure safety, reliability, and compliance within their industrial operations. Below are the core specifications international buyers should evaluate when sourcing restricter plates:

-

Material Grade

The restricter plate’s material, commonly stainless steel (e.g., SS304, SS316) or engineered alloys, determines corrosion resistance, mechanical strength, and suitability for specific media or pressures. For industries such as petrochemicals, food processing, or water treatment, selecting the appropriate material grade ensures compliance with local regulations and longevity in harsh environments. -

Dimensional Tolerance

Tolerance levels specify allowable variations in plate thickness, diameter, and aperture size. Precision here is crucial, as even minor deviations can impact flow characteristics or system pressure. Clear documentation (often in micrometers or millimeters) supports consistent product performance and ease of installation across global supply chains. -

Flow Aperture Size (Orifice Diameter)

This refers to the central opening in the plate, which directly regulates flow rate. Buyers must align aperture sizing with system requirements (expressed in mm or inches). Confirming manufacturer adherence to client-specified measurements reduces risk of costly mismatches or process inefficiencies. -

Operating Pressure & Temperature Range

Restricter plates must be rated for maximum operating pressures and temperature ranges. International standards (e.g., ASME, DIN) govern these ratings. Confirming this compatibility is vital for safety and regulatory acceptance, especially in high-risk installations or those subject to periodic inspection. -

Surface Finish

The surface quality (measured in Ra microinch or micrometer) impacts cleanability, frictional losses, and, for sanitary environments, the likelihood of bacterial contamination. Specifying finish quality is essential when sourcing for food, beverage, or pharmaceutical uses to meet hygiene standards. -

Coating or Treatment

Some applications require additional coatings (e.g., Teflon, epoxy) or heat treatments to enhance chemical resistance or durability. Clarifying these treatments during procurement helps ensure plates withstand aggressive media or extended service intervals.

Key Industry and Trade Terms for Global Restricter Plate Procurement

Navigating technical documentation and supplier communications is easier with familiarity in standard trade jargon. Here are critical terms for international B2B buyers:

-

OEM (Original Equipment Manufacturer)

Refers to companies that design and manufacture parts, often for integration into another manufacturer’s systems. Specifying whether restricter plates must be OEM-grade can affect quality, warranty, and compatibility with existing process lines. -

MOQ (Minimum Order Quantity)

The smallest batch size a supplier is willing to produce or sell. MOQs are particularly relevant when consolidating shipments or entering new markets, as they impact both cost-efficiency and inventory management. -

RFQ (Request for Quotation)

A formal inquiry sent to suppliers soliciting prices and terms for a specified restricter plate. RFQs should always detail technical specs, quantities, and delivery timelines, streamlining the comparison process across multiple vendors. -

Incoterms (International Commercial Terms)

Standardized rules published by the International Chamber of Commerce to define the responsibilities of buyers and sellers regarding shipping, insurance, customs clearance, and delivery. Common examples include FOB (Free on Board), CIF (Cost, Insurance and Freight), and DDP (Delivered Duty Paid). Selecting the right Incoterm minimizes risk and clarifies logistics arrangements. -

Lead Time

The total duration from order placement to delivery, including manufacturing and shipping. Lead times are especially relevant when sourcing across continents, allowing for contingency planning against supply chain disruptions. -

Compliance Certificates (e.g., EN, ASME, ISO)

Official documents verifying restricter plates meet certain quality or safety standards. Ensuring certification is crucial for market access in Europe, the Middle East, and other regulated regions, reducing risk during audits and inspections.

By mastering these technical properties and trade terms, international buyers can evaluate suppliers more effectively, enhance supply chain resilience, and drive better value from cross-border sourcing of restricter plates.

Navigating Market Dynamics, Sourcing Trends, and Sustainability in the restricter plate Sector

Global Market Dynamics and Sourcing Trends

The restricter plate sector, integral to automotive, industrial machinery, and energy applications, is undergoing dynamic shifts spurred by global economic factors and technological disruption. Market volatility is being driven by fluctuating raw material costs—particularly metals—and the growing impact of tariffs and trade barriers between major economies. These pressures are acutely felt in regions reliant on imports or exposed to currency fluctuations, such as Africa and South America, while European countries like Poland and Middle Eastern buyers are leveraging regional trade agreements to optimize sourcing strategies.

Key international trends include the diversification of supplier bases, as buyers seek to reduce exposure to tariffs and political instability. Sourcing is expanding beyond traditional hubs in Asia, with increased interest in nearshoring to Eastern Europe, Mexico, or North Africa. This is particularly relevant given recent disruptions in logistics networks, which have prompted firms to prioritize suppliers offering shorter lead times and more predictable delivery schedules.

Technological advancements are also reshaping procurement strategies. Digital platforms for supplier discovery, contract management, and compliance tracking are being adopted widely. Real-time analytics enable buyers to better forecast demand, monitor price trends, and evaluate supplier risk, which is especially important in highly regulated or volatile markets. Furthermore, contract renegotiation—embedding cost adjustment and tariff clauses—has become a standard practice to mitigate unforeseen supply chain shocks.

For buyers in emerging markets, building resilience involves balancing cost control with reliability. Investing in local or regional partnerships and leveraging multi-modal logistics can help circumvent bottlenecks and take advantage of favorable trade policies. Regulatory uncertainty means that proactive engagement with suppliers and continual market monitoring are necessary for sustained competitiveness.

Sustainability and Ethical Sourcing Considerations

Sustainability is quickly ascending the agenda for B2B restricter plate buyers globally. With increasing environmental regulations and corporate social responsibility expectations, companies are pressed to demonstrate the sustainability of their supply chains. This shift is especially pronounced in the EU, where directives on sustainable sourcing and carbon reporting are directly influencing procurement requirements for components like restricter plates.

Environmental impacts of restricter plate manufacturing—energy use, carbon footprint, and waste generation—are under scrutiny. International buyers must seek suppliers who adopt advanced manufacturing processes that minimize resource consumption and utilize recycled or certified ‘green’ metals. Steel and aluminum with Environmental Product Declarations (EPDs), or sourced from mills with ISO 14001/EMAS certification, are increasingly favored.

Ethical sourcing now extends beyond environmental considerations to social compliance, including workplace safety, fair labor practices, and anti-corruption efforts. Auditable, transparent supply chains are becoming a non-negotiable standard. Buyers should prioritize suppliers participating in recognized sustainability initiatives, such as the Responsible Steel Standard or EcoVadis ratings.

Certification and transparency not only mitigate regulatory and reputational risks but can also enhance market access—especially for public sector or multinational contracts. For buyers in Africa, South America, or the Middle East, aligning with internationally recognized standards can confer a competitive advantage and open export opportunities to regions with stringent sustainability requirements.

The Evolution of the Restricter Plate Market

Originally developed to modulate airflow or fluid flow in engines and industrial systems, restricter plates have transitioned from simple stamped metal components to precision-engineered products with demanding tolerance and quality requirements. Over the past two decades, shifts in automotive emissions regulations and the push for higher-efficiency power systems have driven both innovation in design and tighter material standards.

Supply chains once characterized by localized production are now truly global, driven by the quest for cost efficiency and new materials. Today, the need for traceability, sustainability, and dynamic risk management is pushing the sector towards integrated digital supply chains and responsible sourcing models. For international B2B buyers, understanding this evolution is crucial for making informed decisions and building resilient, future-ready procurement strategies.

Related Video: How Trump’s tariffs are changing the rules of global trade | The Take

Frequently Asked Questions (FAQs) for B2B Buyers of restricter plate

-

How should I evaluate and select a reliable restricter plate supplier in the current global trade environment?

Start by conducting comprehensive due diligence on potential suppliers, focusing on their compliance with international standards, responsiveness, and reputation for quality. Request business licenses, audit reports, and check previous client references—especially for exporters active in Africa, South America, the Middle East, and Europe. Assess their ability to adapt to shifting trade regulations and tariffs. Having a backup supplier or a diversified supplier base can also help mitigate risks stemming from sudden trade policy changes or supply disruptions. -

What customization options are typically available for restricter plates, and how can I ensure my specifications are met?

Most manufacturers offer customization in terms of material grade, size, thickness, hole pattern, and surface finishes to align with specific industrial requirements. Clearly communicate your requirements with technical drawings or detailed datasheets, and request pre-production samples when possible. Establish clear agreements on tolerance limits and functionality. Regular factory communication and possible on-site inspections or third-party verification can further guarantee that your restricter plates are made to precise specifications. -

What is a standard minimum order quantity (MOQ) and lead time when sourcing restricter plates internationally?

MOQs vary by manufacturer and order complexity, typically ranging from 50 to 200 pieces per batch for standard designs, but may be higher for custom products. Lead times can span 4–8 weeks, factoring in manufacturing schedules, customization, and international shipping. Early engagement and order placement—especially before peak manufacturing seasons—will help secure preferred production slots. Always confirm lead times in writing and include buffer periods to account for potential customs delays or logistics disruptions. -

Which quality assurance processes and certifications should I require from restricter plate suppliers?

Insist on internationally recognized quality certifications, such as ISO 9001, as well as material traceability documents and relevant test reports (e.g., for metallurgy or corrosion resistance). Request details on the supplier’s in-house quality control processes, including dimensional inspection, hardness testing, and final product audits. For critical applications or regulated industries, third-party inspections—even video inspections for distant partnerships—add an additional layer of assurance. -

What are the most reliable payment terms and methods for cross-border restricter plate transactions?

Secure payment methods like letters of credit (L/C) or escrow services are recommended, especially for first-time transactions across regions such as Africa or South America. Many suppliers may accept a mix of advance deposits and balance upon shipment with established buyers. Choose payment options that balance risk and cost—open account terms or longer credit can be negotiated as relationships mature. Consult your bank or a trade finance specialist to ensure alignment with local regulations and currency controls. -

How can I optimize logistics and manage shipping risks for restricter plates across multiple continents?

Strategically select shipping routes and logistics partners based on reliability, transit time, and cost. Consider Incoterms such as FOB, CIF, or DAP based on your risk appetite and local import infrastructure. Factor in duties, tariffs, and possible regulatory changes that may impact ports in Africa, the Middle East, or Latin America. Using experienced freight forwarders and maintaining transparent communication with your supplier helps prevent shipment delays and ensures proper documentation for hassle-free customs clearance. -

What are effective strategies for handling disputes or quality issues with overseas restricter plate suppliers?

Clearly define quality expectations, resolution steps, and penalties in the purchase contract—from replacement and refunds to arbitration clauses. Document all communications and keep photographic or video records of any issues for evidence. If disputes arise, approach resolution through negotiation first, escalating to third-party mediation or arbitration if necessary, and ensure you select a recognized arbitration center. Maintaining a professional relationship and proactive communication can often prevent minor issues from escalating. -

How can I stay compliant and proactive amid changing global tariffs and trade regulations affecting restricter plate imports?

Monitor regulatory updates in both your country and supplier jurisdictions, using government sources or trusted trade advisors. Consider sourcing from alternative supplier regions to mitigate exposure to high-tariff areas. Renegotiate supply contracts regularly to include tariff adjustment clauses and clarify cost-sharing mechanisms. Engaging regional customs brokers or consultants helps anticipate and respond to regulatory shifts, enabling you to remain agile and competitive in your procurement strategy.

Strategic Sourcing Conclusion and Outlook for restricter plate

Strategic sourcing for restricter plates is now defined by resilience, adaptability, and informed decision-making. International B2B buyers—particularly those operating in complex markets across Africa, South America, the Middle East, and Europe—face a landscape shaped by shifting tariffs, evolving trade policies, and rapid advancements in manufacturing technology.

Key takeaways for sourcing success include the prioritization of supplier diversification to mitigate regional or regulatory risks, regular renegotiation of contracts to address tariff fluctuations, and the embrace of sourcing optimization through localized or near-shore suppliers when feasible. Ongoing regulatory monitoring remains essential, ensuring buyers can anticipate changes and maintain continuity. Leveraging the latest digital tools and automation can further streamline sourcing processes, improve visibility, and support agile responses to sudden supply chain disruptions.

Ultimately, the value of strategic sourcing for restricter plate procurement lies in the ability to secure competitive pricing, reliable quality, and robust risk management. By proactively adjusting sourcing strategies—through diversification, technology adoption, and continuous market analysis—B2B buyers can not only weather current challenges but position themselves for future advantage.

Now is the time to re-examine existing supply networks, invest in supplier relationships, and adopt forward-thinking sourcing practices. Stay agile, remain informed, and leverage expert insights to maintain supply security and cost competitiveness as global trade dynamics continue to evolve.