Contents

Manufacturing Insight: Engraving With Cnc Router

Manufacturing Insight: Precision Engraving with CNC Routers

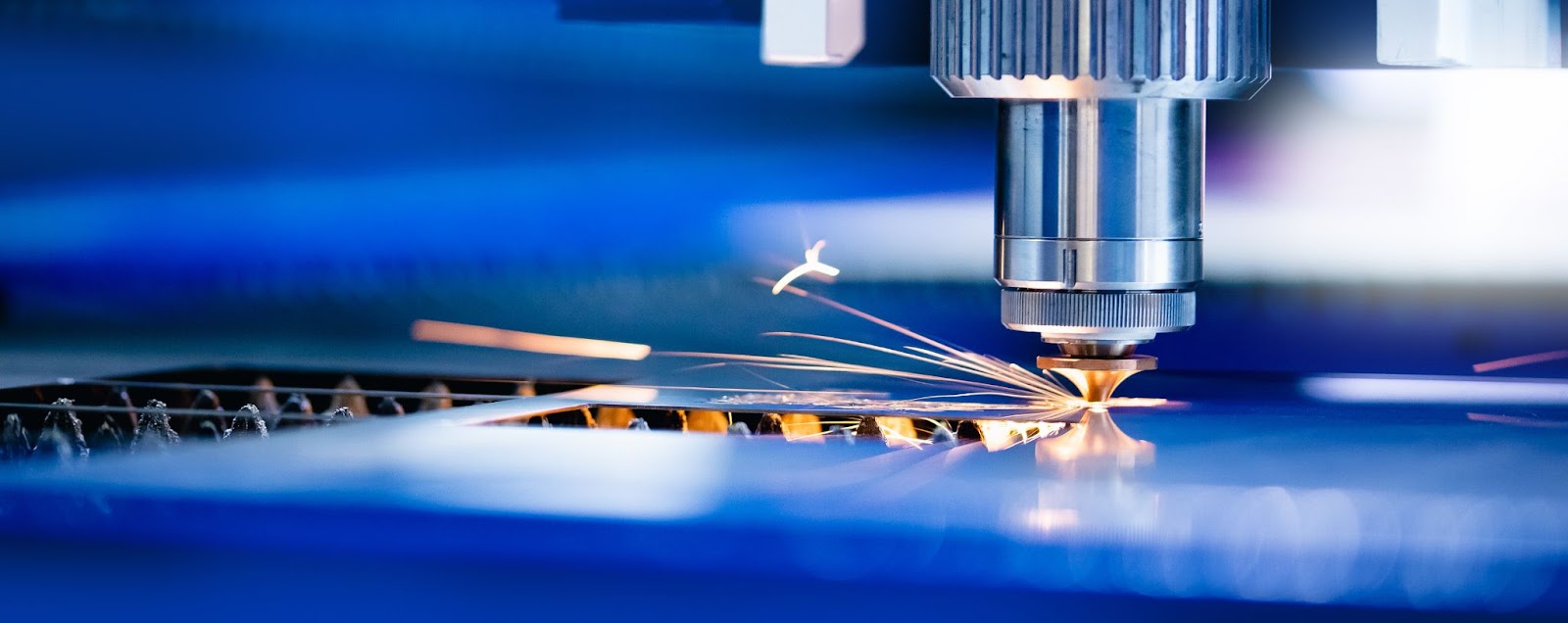

Industrial CNC engraving delivers critical functionality across aerospace, medical, and consumer electronics sectors, transforming substrates with micron-level accuracy for part identification, aesthetic detailing, and functional surface texturing. At Shenzhen Honyo Prototype, our 5-axis CNC routing systems leverage high-frequency spindles and rigid kinematic structures to execute intricate engraving operations on metals, engineering plastics, composites, and wood derivatives. Unlike laser-based methods, mechanical engraving ensures depth consistency in conductive or heat-sensitive materials while eliminating thermal distortion risks—a capability essential for traceability markings on surgical instruments or EMI-shielded enclosures requiring uninterrupted surface conductivity.

Our process excellence stems from proprietary toolpath optimization algorithms that dynamically adjust feed rates and spindle loads during cornering or fine-detail transitions. This prevents chatter on delicate geometries, such as 0.2mm-wide alphanumeric characters in aluminum nameplates or 0.5mm-deep Braille patterns on polymer surfaces. Honyo’s engineering team selects specialized engraving bits—diamond-coated, solid-carbide V-groove, or micro-end mills—based on material hardness and feature complexity, maintaining tool wear compensation protocols to sustain ±0.02mm depth tolerance over production batches. Crucially, we integrate engraving within multi-stage workflows; for instance, engraving alignment fiducials directly onto machined titanium brackets prior to anodizing, eliminating secondary fixturing errors.

The following table summarizes our core engraving capabilities and constraints:

| Parameter | Specification | Supported Materials |

|————————–|———————————–|———————————–|

| Minimum Feature Width | 0.15 mm | Aluminum, Brass, Copper, Steel |

| | 0.25 mm | ABS, Polycarbonate, Delrin |

| | 0.40 mm | Hardwoods, MDF, Carbon Fiber |

| Max Depth Accuracy | ±0.01 mm (shallow engraves <1mm) | All metals & rigid plastics |

| | ±0.03 mm (deep engraves >3mm) | Wood, soft composites |

| Surface Roughness (Ra) | 0.8–1.6 µm | Post-engraving as-machined finish |

| Max Work Envelope | 1200 x 900 x 200 mm | |

| Positioning Accuracy | ISO 2768-mK compliant | |

Honyo differentiates through rapid prototyping integration—clients receive engraved functional prototypes within 72 hours using our in-house material stock library, enabling immediate validation of mark legibility under operational conditions. Our quality assurance protocol employs digital microscopy for depth verification and optical comparators to certify character conformity against ISO/IEC 15459 standards for permanent asset identification. For high-mix production, we implement automated tool-change sequences with pre-calibrated depth setters, ensuring zero setup drift across 50+ part variants in a single job.

This technical rigor positions Honyo as the partner of choice for applications demanding regulatory-compliant permanence, such as FAA-mandated part numbers on aircraft components or UDI-compliant medical device labeling. By embedding engraving within end-to-end CNC workflows, we eliminate supply chain handoffs, reducing lead times by 40% while guaranteeing dimensional harmony between engraved features and critical part geometries.

Technical Capabilities

CNC Router Engraving – Technical Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC router engraving services are engineered to deliver high-precision, repeatable results across a wide range of industrial, commercial, and prototype applications. Leveraging advanced 3-axis, 4-axis, and 5-axis CNC milling platforms, we specialize in intricate surface engraving, serial numbering, logo marking, and custom text or pattern etching on metals, plastics, and composite materials. Our integrated manufacturing approach ensures tight tolerance control, superior surface finish, and rapid turnaround for both low-volume prototyping and high-mix production runs.

Our 3-axis CNC routers provide exceptional accuracy for planar and shallow-depth engraving tasks, ideal for flat or gently contoured surfaces. When complex geometries or multi-faceted components are required, our 4-axis and 5-axis systems enable simultaneous rotational and linear toolpath control. This allows for precise engraving on cylindrical, curved, or compound-angle surfaces without the need for re-fixturing, significantly enhancing dimensional consistency and reducing lead times.

All engraving operations are supported by high-resolution tooling, including micro-carbide end mills and diamond drag tips, selected based on material properties and feature detail. Our CNC systems are calibrated to maintain tolerances as tight as ±0.005 mm for critical marking applications, with typical engraving depths ranging from 0.1 mm to 1.5 mm, depending on design specifications and functional requirements.

We support a broad spectrum of engineering-grade materials, including aluminum alloys (6061, 7075), stainless steel (304, 316), brass, copper, titanium, and high-performance thermoplastics such as PEEK, ABS, PMMA, and polycarbonate. Each material is processed using optimized spindle speeds, feed rates, and tool engagement strategies to prevent chipping, burring, or thermal distortion—especially critical in fine-detail engraving.

Below is a summary of our standard engraving capabilities and achievable tolerances by material type:

| Material Category | Common Materials | Typical Engraving Tolerance (± mm) | Surface Finish (Ra, µm) | Max Engraving Depth |

|——————-|——————|————————————|————————–|———————|

| Aluminum Alloys | 6061, 7075 | 0.010 | 1.6 – 3.2 | 1.5 mm |

| Stainless Steel | 304, 316 | 0.015 | 3.2 | 1.2 mm |

| Brass & Copper | C36000, C11000 | 0.010 | 1.6 – 3.2 | 1.5 mm |

| Titanium | Grade 2, Grade 5 | 0.020 | 3.2 | 1.0 mm |

| Engineering Plastics | ABS, PEEK, PC | 0.005 – 0.010 | 1.6 | 2.0 mm |

| Acrylic (PMMA) | Cast & Extruded | 0.005 | 1.6 | 2.0 mm |

All engraving jobs undergo in-process inspection using coordinate measuring machines (CMM) and optical comparators to verify depth consistency, character legibility, and positional accuracy. We also offer post-processing services such as deburring, polishing, and laser cleaning to ensure a professional, production-ready finish.

Shenzhen Honyo Prototype maintains ISO 9001-certified quality systems and employs experienced manufacturing engineers who work closely with clients to optimize engraving parameters for critical applications in aerospace, medical devices, electronics, and industrial equipment. Whether for traceability, branding, or functional identification, our CNC router engraving delivers precision, durability, and repeatability across diverse material platforms.

From CAD to Part: The Process

CNC Router Engraving: Production Workflow from CAD to Part

At Shenzhen Honyo Prototype, our CNC router engraving process transforms digital designs into precisely marked components through a rigorously defined workflow. This sequence ensures manufacturability, cost efficiency, and adherence to client specifications, leveraging automation and engineering expertise at critical stages. The journey begins with the client’s CAD file and progresses systematically through quotation, design validation, and physical production.

The initial phase utilizes our proprietary AI-powered quoting system. Upon secure CAD file upload, the AI engine rapidly analyzes geometric complexity, feature density, material type, and dimensional tolerances inherent in the engraving design. It cross-references this data against our extensive database of historical production parameters, machine capabilities, and material costs. This generates an accurate, transparent quote within hours, detailing estimated lead time, unit cost, and material requirements. Crucially, the AI flags potential high-risk areas such as excessively fine features or problematic aspect ratios early, prompting immediate engineering review if necessary, rather than during later production stages.

Following quote acceptance, the Design for Manufacturability (DFM) review becomes paramount. Our senior manufacturing engineers conduct a detailed assessment focused specifically on engraving constraints. Key checks include verifying minimum feature size against tool diameter limitations (typically ≥ 0.5mm for depth >0.2mm), assessing substrate suitability (e.g., acrylic vs. aluminum), evaluating depth-to-width ratios to prevent chipping or tool breakage, and confirming file format integrity (DXF, DWG, or vector-based formats preferred). We actively collaborate with the client to suggest minor, non-functional design adjustments that significantly enhance producibility and reduce cost, such as slightly increasing serif widths on text or optimizing path sequencing to minimize tool changes.

Production commences only after DFM sign-off. The validated CAD file is imported into our CAM software, where specialized engraving toolpaths are generated. Selection of the optimal single-flute or V-bit carbide tool (common angles: 30°, 60°, 90°) is critical and based on the required mark depth, width, and material. Precise control of spindle speed, feed rate, and stepover is essential to achieve clean, burr-free results without substrate melting (in plastics) or excessive tool wear (in metals). Rigorous in-process inspection occurs after the first article, measuring engraving depth, edge definition, and positional accuracy against the original CAD model. Final parts undergo 100% visual inspection for consistency and absence of defects before shipment.

Critical CNC Engraving Process Parameters

| Parameter | Typical Range | Critical Notes |

| :—————– | :————————- | :———————————————- |

| Spindle Speed | 12,000 – 24,000 RPM | Higher for plastics/composites; lower for metals |

| Feed Rate | 100 – 800 mm/min | Slower for finer detail, deeper engraves |

| Engraving Depth | 0.05 mm – 0.5 mm | Material & tool angle dependent; ≤ tool radius |

| Tool Diameter | Ø0.2 mm – Ø3.0 mm | Single flute/V-bit standard; defines mark width |

| Stepover | 10% – 30% of tool diameter | Lower % for smoother sidewalls on curves |

This integrated workflow—from AI-driven quoting through targeted DFM and precision-controlled production—ensures Shenzhen Honyo Prototype delivers high-quality, cost-effective engraved prototypes and low-volume production parts with exceptional speed and reliability, meeting the exacting demands of our engineering partners.

Start Your Project

Start Your Engraving Project with Precision CNC Routing at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC engraving services tailored for prototypes, industrial components, and custom-designed parts. Whether you’re developing detailed signage, textured surfaces, or intricate part identification, our advanced CNC routing capabilities ensure clean, repeatable, and dimensionally precise engraving on a wide range of materials—including aluminum, brass, plastics, wood, and engineering composites.

Our CNC engraving process leverages multi-axis machining centers equipped with fine-tip cutting tools, enabling us to achieve depth control down to 0.01 mm and produce sharp, consistent engraving with smooth edge finishes. We support both vector-based and raster engraving methods, allowing flexibility in design complexity and production speed. From simple logos and serial numbers to complex artistic patterns and data matrix codes, our team ensures every engraved detail meets your exact specifications.

We understand that early-stage project decisions impact time-to-market and final part performance. That’s why we offer expert consultation during the design-for-manufacturability (DFM) phase, helping you optimize font selection, line depth, material choice, and toolpath strategy to avoid common pitfalls such as tool breakage, surface chipping, or excessive machining time.

To get started, simply share your design files in DXF, DWG, AI, or STEP format, and our engineering team will conduct a full technical review. We provide rapid feedback on feasibility, lead time estimates, and recommendations for improving engraving quality based on your application requirements.

Below are key technical specifications for our CNC engraving services:

| Parameter | Specification |

|———|—————|

| Minimum Engraving Depth | 0.01 mm |

| Maximum Engraving Depth | 5.0 mm (material-dependent) |

| Line Width (Minimum) | 0.1 mm (steel tools), 0.2 mm (carbide) |

| Positional Accuracy | ±0.02 mm |

| Supported File Formats | DXF, DWG, AI, STEP, IGES, STL |

| Surface Finish (Typical) | Ra 1.6 – 3.2 µm (as-machined) |

| Lead Time (Standard) | 3–7 working days |

| Batch Capacity | 1–500+ units per order |

All projects undergo strict in-process inspection and final quality verification using digital microscopy and coordinate measuring machines (CMM), ensuring every engraved feature conforms to your print.

Ready to bring your engraved components to life? Contact Susan Leo, our dedicated Project Manager, to discuss your requirements, request a quote, or submit your design files for review. We’re committed to supporting your project with technical expertise, fast turnaround, and consistent quality.

Susan Leo

Project Manager, CNC Machining Division

Shenzhen Honyo Prototype

Email: info@hy-proto.com

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.