Contents

Manufacturing Insight: Which Stainless Steel Is Magnetic

Manufacturing Insight: Understanding Stainless Steel Magnetism in CNC Machining

A persistent misconception in precision manufacturing is that all stainless steel is non-magnetic. This oversimplification can lead to significant challenges during CNC machining and final part performance. At Honyo Prototype, we recognize that magnetic properties are intrinsically linked to stainless steel’s microstructure, directly impacting material selection, machining strategy, and end-use suitability. Understanding this relationship is critical for achieving dimensional accuracy, surface finish, and functional reliability in prototype and low-volume production components.

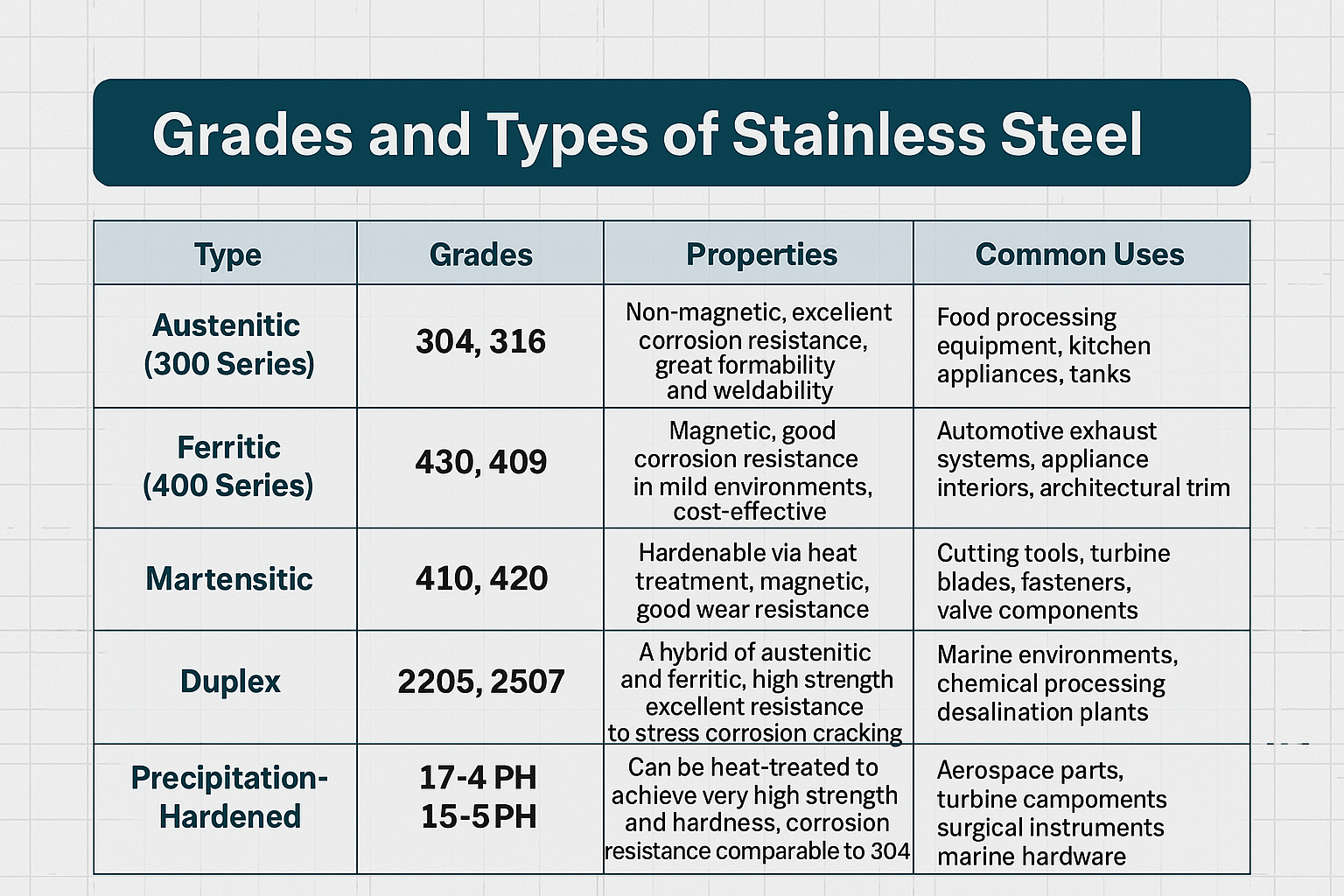

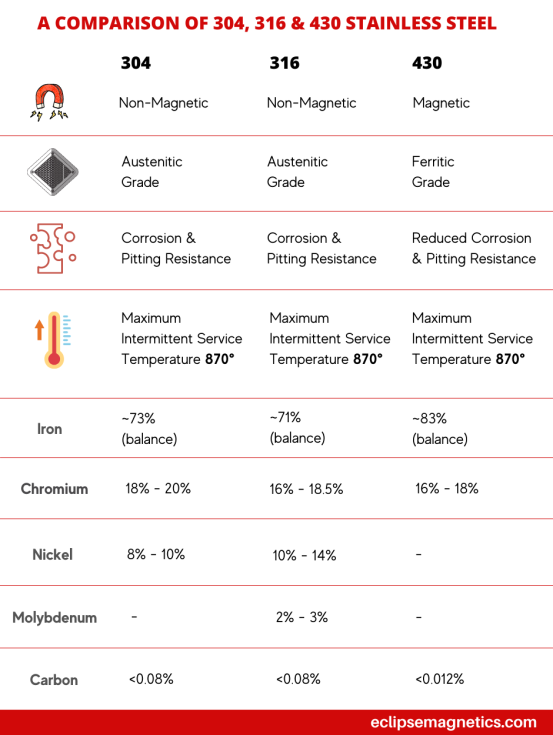

The magnetism of stainless steel is determined by its crystalline structure, primarily influenced by alloy composition and processing history. Austenitic grades (e.g., 304, 316) possess a face-centered cubic (FCC) structure stabilized by nickel and manganese. This structure is inherently non-magnetic in the annealed state. However, cold working during machining or forming can induce a partial transformation to martensite, a body-centered tetragonal (BCT) structure, resulting in detectable magnetism—particularly near cut edges or formed areas. Conversely, ferritic (e.g., 430) and martensitic (e.g., 410, 440C) grades feature a body-centered cubic (BCC) structure rich in chromium, making them inherently magnetic. Duplex grades (e.g., 2205) combine austenitic and ferritic phases, exhibiting moderate magnetism due to their ferritic content.

Material selection must align with both functional requirements and manufacturability. Magnetic properties affect fixturing stability during CNC operations, as magnetic chucks are ineffective on non-magnetic grades. More critically, the work-hardening tendency of austenitic steels during machining can exacerbate induced magnetism and increase tool wear, demanding optimized cutting parameters and toolpath strategies. Below is a comparison of common stainless grades relevant to precision machining:

| Grade | Primary Structure | Magnetic in Annealed State | Key Machining Consideration for CNC |

|————|——————-|—————————-|————————————-|

| 304 / 304L | Austenitic | No | High work hardening; requires sharp tools, high feed rates, rigid setup to minimize induced magnetism and burring |

| 316 / 316L | Austenitic | No | Similar to 304 but with molybdenum; slightly better corrosion resistance but comparable machinability challenges |

| 430 | Ferritic | Yes | Moderate machinability; lower work hardening than austenitics but prone to edge chipping; magnetic fixturing viable |

| 17-4 PH | Precipitation Hardening | Conditionally* | Machinable in annealed state; magnetic after final heat treatment; requires tight thermal control |

| 410 | Martensitic | Yes | Hardenable; abrasive; requires lower speeds; magnetic throughout processing |

*17-4 PH is non-magnetic in solution-treated condition but becomes magnetic after aging.

At Honyo Prototype, our CNC machining expertise extends beyond operational execution to proactive material science integration. Our engineering team evaluates magnetic implications during Design for Manufacturability (DFM) reviews, ensuring optimal grade selection for both application demands and machining efficiency. We deploy specialized tooling, adaptive CNC strategies, and in-process metrology to mitigate challenges like work-hardening-induced magnetism in austenitic steels, guaranteeing consistent part quality. For magnetic-sensitive applications—such as medical devices, sensors, or RF enclosures—we provide precise material certification and post-machining validation. Leveraging our deep understanding of stainless steel metallurgy, Honyo transforms material complexities into manufacturing advantages, delivering prototypes and production parts that meet exacting functional and dimensional requirements on schedule. This technical rigor underscores our commitment to being a strategic manufacturing partner, not just a job shop.

Technical Capabilities

Understanding Magnetic Properties in Stainless Steel for Precision CNC Machining

At Shenzhen Honyo Prototype, our expertise in 3-, 4-, and 5-axis CNC milling and turning enables us to deliver high-precision components from a wide range of stainless steel alloys. A critical consideration in material selection—particularly for applications involving electromagnetic environments, sensors, or assembly processes—is the magnetic response of stainless steel. Contrary to common perception, not all stainless steels are non-magnetic. The magnetic properties depend largely on the alloy’s microstructure, which is determined by its chemical composition and processing history.

Stainless steels are categorized into several families: austenitic, ferritic, martensitic, duplex, and precipitation-hardening. Among these, ferritic and martensitic grades are typically magnetic due to their body-centered cubic (BCC) crystal structure, which allows magnetic domains to align under an external field. Common magnetic grades include 430 (ferritic), 410, and 440C (martensitic). These are often selected for applications requiring moderate corrosion resistance and magnetic permeability, such as in automotive sensors, fasteners, and pump shafts.

In contrast, the widely used 300-series austenitic stainless steels—such as 303, 304, and 316—are generally non-magnetic in the annealed state due to their face-centered cubic (FCC) structure. However, cold working during machining or forming can induce partial transformation to martensite, resulting in slight magnetism, particularly in heavily machined areas. This phenomenon is important to consider in high-precision components where even minimal magnetic response could affect performance.

Our CNC machining capabilities support tight tolerance manufacturing across all magnetic and non-magnetic stainless steel grades. With advanced 5-axis milling and precision turning centers, we maintain tolerances as tight as ±0.005 mm, ensuring dimensional accuracy and repeatability. Multi-axis coordination allows for complex geometries to be machined in a single setup, minimizing variability and enhancing part consistency—especially critical when working with magnetically sensitive components.

Below is a summary of commonly machined stainless steel grades, their magnetic characteristics, and achievable tolerances under our precision CNC processes.

| Material Grade | Type | Magnetic? | Typical Applications | Machining Tolerance (± mm) |

|—————-|————–|———|———————————-|—————————-|

| 303 | Austenitic | No* | Shafts, gears, fasteners | 0.010 |

| 304 / 304L | Austenitic | No* | Food processing, enclosures | 0.010 |

| 316 / 316L | Austenitic | No* | Marine, medical, chemical | 0.010 |

| 410 | Martensitic | Yes | Valves, pump parts, cutlery | 0.008 |

| 430 | Ferritic | Yes | Automotive trim, fasteners | 0.010 |

| 440C | Martensitic | Yes | Bearings, surgical instruments | 0.005 |

| 17-4 PH | Precipitation Hardening | No* | Aerospace, high-strength parts | 0.008 |

* May exhibit slight magnetism after cold work.

Shenzhen Honyo Prototype applies strict process controls to ensure material integrity and dimensional accuracy across all stainless steel machining projects. Whether the application demands non-magnetic performance or leverages magnetic properties, our technical team supports optimal material and process selection to meet functional and regulatory requirements.

From CAD to Part: The Process

Understanding Stainless Steel Magnetism in CNC Production Workflow

At Honyo Prototype, clarifying stainless steel magnetism is critical for precision CNC machining projects. Contrary to popular belief, magnetism depends on metallurgical phase structure—not merely the “stainless” label. Austenitic grades (e.g., 304, 316) are generally non-magnetic due to their face-centered cubic crystal structure, while ferritic and martensitic grades (e.g., 430, 410) exhibit magnetism from body-centered cubic structures. This distinction directly impacts applications involving electromagnetic interference, such as medical devices or sensor housings, making accurate material specification essential from project inception.

Our production workflow begins with the AI-Powered Quotation Phase. Clients submit CAD models with material requirements, including magnetic properties. Honyo’s AI engine cross-references grade specifications against magnetic behavior databases, flagging discrepancies (e.g., a requested “non-magnetic 430” is metallurgically impossible). Real-time cost and lead-time estimates adjust dynamically based on grade availability and machinability factors. This phase ensures alignment between design intent and material physics before engineering resources are committed.

Next, the Design for Manufacturability (DFM) Review scrutinizes magnetic requirements against geometric complexity. Honyo’s engineers verify if the specified grade (e.g., 304L for non-magnetic needs) aligns with part function, tolerances, and secondary operations. Cold working during CNC machining can induce slight magnetism in austenitic steels—a risk assessed via strain simulation. If magnetism sensitivity is mission-critical (e.g., aerospace sensors), we recommend stress-relief annealing post-machining and validate with Gauss meter testing. DFM adjustments might include modifying wall thicknesses to minimize work-hardening or suggesting alternative grades like 316L for enhanced corrosion resistance without magnetic compromise.

During CNC Production, magnetism awareness informs process parameters. Ferritic grades (magnetic) machine with higher thermal conductivity but lower ductility than austenitic grades, requiring adjusted feeds, speeds, and tool geometries to prevent edge chipping. Below is a comparison of common stainless grades relevant to magnetic performance and machining:

| Grade | Crystal Structure | Magnetic Response | Key Machining Consideration |

|———–|——————-|——————-|————————————–|

| 304/304L | Austenitic | Non-magnetic* | Prone to work-hardening; use sharp tools, low RPM |

| 316/316L | Austenitic | Non-magnetic* | Higher chloride resistance; similar to 304 but gummier |

| 430 | Ferritic | Magnetic | Easier chip control; avoid high heat to prevent warping |

| 410 | Martensitic | Magnetic | Requires pre-heat for complex geometries; high tool wear |

Note: Cold working may induce slight magnetism in austenitic grades.

All parts undergo final validation per ISO 2626 for magnetic particle inspection where specified. Honyo’s closed-loop workflow—from AI-driven quoting to DFM-optimized production—ensures magnetic properties align with functional requirements, eliminating costly rework. By integrating material science into every production phase, we deliver parts that perform reliably in even the most demanding electromagnetic environments.

Start Your Project

Understanding Stainless Steel Magnetism in CNC Machining Applications

When selecting materials for precision CNC machining projects, one of the most frequently misunderstood properties is magnetic response in stainless steel. At Shenzhen Honyo Prototype, we recognize that material behavior directly impacts manufacturability, performance, and final application suitability. A common technical inquiry we receive is: which stainless steel is magnetic? The answer is not as straightforward as it may seem, as magnetism in stainless steel depends on its microstructure, which is determined by alloy composition and processing history.

Stainless steels are primarily categorized into five groups: austenitic, ferritic, martensitic, duplex, and precipitation-hardening. Among these, austenitic stainless steels—such as the widely used 304 and 316 grades—are generally non-magnetic in the annealed state due to their face-centered cubic crystal structure. However, cold working during machining or forming can induce partial transformation to martensite, leading to slight magnetic responsiveness. This phenomenon is often observed in machined edges or bent sections and should be considered in applications involving electromagnetic fields or sensor systems.

In contrast, ferritic and martensitic stainless steels—such as 430 and 410—are inherently magnetic due to their body-centered cubic and tetragonal structures, respectively. These grades are often selected for applications requiring moderate corrosion resistance combined with magnetic properties, such as in automotive sensors, enclosures, or fasteners. Duplex stainless steels, like 2205, exhibit a mixed microstructure and moderate magnetism, offering a balance between strength, corrosion resistance, and magnetic response.

Understanding these differences is critical during the design and prototyping phase. Misjudging magnetic characteristics can lead to functional failures in sensitive electronic or medical applications. At Honyo Prototype, our CNC machining services are backed by material science expertise, ensuring that your selected grade aligns not only with mechanical and environmental requirements but also with electromagnetic considerations.

Below is a comparative overview of common stainless steel grades and their magnetic properties:

| Grade | Type | Magnetic? | Typical Applications |

|——-|——|———|———————-|

| 304 / 304L | Austenitic | Generally No (may become slightly magnetic after cold work) | Food processing, medical devices, general hardware |

| 316 / 316L | Austenitic | Generally No (may develop slight magnetism) | Marine environments, chemical processing |

| 430 | Ferritic | Yes | Automotive trim, appliance components |

| 410 | Martensitic | Yes | Cutlery, valves, pumps |

| 2205 | Duplex | Yes (moderate) | Oil & gas, high-strength structural components |

When initiating your next CNC machining project, ensure material selection is guided by both functional requirements and technical behavior. At Shenzhen Honyo Prototype, we support engineers and product developers with material consultation, rapid prototyping, and high-precision machining to meet exacting standards.

For expert guidance on stainless steel selection, including magnetic properties and machinability, contact Susan Leo at info@hy-proto.com. Let us help you start your project on the right foundation—technically sound, efficiently produced, and ready for real-world performance.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.