Contents

Manufacturing Insight: 3D Stl Cnc

3D STL → CNC-Ready Parts in Hours

Upload your STL, OBJ or STEP file to Honyo Prototype’s online portal and watch the quote appear instantly. Our industrial SLA/SLS printers turn your 3D data into precision resin or nylon masters, then 5-axis CNC machines finish critical surfaces to ±0.02 mm—no tooling, no waiting. Click “Instant Quote” now and see delivery options as fast as same-day.

Technical Capabilities

Important Clarification: “3D STL CNC” is a Misconception

Your query combines unrelated concepts. Let me clarify upfront to avoid critical errors in your manufacturing planning:

- STL is not a manufacturing process—it’s a file format (Standard Tessellation Language) used to describe 3D geometry for any process (CNC, 3D printing, etc.).

- CNC (Computer Numerical Control) is a subtractive machining process (cutting material away from a solid block). It cannot produce parts via SLA, SLS, MJF, or DMLS—these are additive manufacturing (AM) processes.

- SLA, SLS, MJF, DMLS are entirely separate AM technologies with distinct capabilities, materials, and limitations.

- Aluminum and Steel cannot be processed by SLA, SLS, or MJF—they are only compatible with DMLS (and other metal AM processes). ABS and Nylon are polymer materials used in some AM processes but not metals.

Below, I’ll break down correct technical specs for each AM process (SLA, SLS, MJF, DMLS) with actual material compatibility, accuracy, and key limitations—no “3D STL CNC” exists as a single process.

🔧 1. SLA (Stereolithography)

- Process Type: Photopolymerization (UV laser cures liquid resin).

- Materials: Only photopolymer resins (e.g., standard, tough, flexible, castable, dental).

- ❌ Aluminum, Steel, ABS, Nylon are NOT compatible.

- Key Specs:

- Layer Thickness: 25–100 μm (typically 50 μm).

- Accuracy: ±0.1% (min. ±0.1 mm), surface finish: smooth (best for detailed models).

- Build Volume: Up to 1500 × 750 × 500 mm (industrial systems).

- Post-Processing: Washing, UV curing, support removal.

- Typical Uses: Prototypes, dental models, jewelry molds, optical components.

- Critical Limitation: Resins are brittle, UV-sensitive, and not structural metals or engineering plastics like ABS/Nylon.

🔥 2. SLS (Selective Laser Sintering)

- Process Type: Powder bed fusion (laser sinters polymer powder).

- Materials: Nylon-based powders only (e.g., PA12, PA11, TPU).

- ❌ Aluminum, Steel, ABS are NOT compatible (ABS is filament-based for FDM, not powder).

- Key Specs:

- Layer Thickness: 80–120 μm.

- Accuracy: ±0.3% (min. ±0.3 mm), surface finish: grainy (needs sanding).

- Build Volume: Up to 700 × 380 × 580 mm (industrial).

- Post-Processing: Powder removal, media blasting, dyeing.

- Typical Uses: Functional prototypes, housings, clips, low-volume production parts.

- Critical Limitation: No metals—powder is exclusively polymer. ABS cannot be used (SLS uses nylon, not ABS).

⚙️ 3. MJF (Multi Jet Fusion)

- Process Type: Powder bed fusion (inkjet fuses polymer powder with heat).

- Materials: Nylon-based powders only (e.g., PA12, PA11, TPU).

- ❌ Aluminum, Steel, ABS are NOT compatible.

- Key Specs:

- Layer Thickness: 80 μm.

- Accuracy: ±0.3% (min. ±0.3 mm), surface finish: slightly smoother than SLS but still textured.

- Build Volume: Up to 380 × 284 × 380 mm (HP systems).

- Post-Processing: Powder removal, media blasting.

- Typical Uses: End-use parts, automotive interiors, consumer goods, medical devices.

- Critical Limitation: No metals—only polymers. ABS is incompatible (MJF uses nylon powders).

💎 4. DMLS (Direct Metal Laser Sintering)

- Process Type: Powder bed fusion (laser sinters metal powder).

- Materials: Metal alloys only (e.g., Aluminum alloys, Stainless Steel, Titanium, Inconel).

- ✅ Aluminum alloys (e.g., AlSi10Mg, 7075), Steel alloys (e.g., 17-4PH, 316L) are fully compatible.

- ❌ ABS, Nylon are NOT compatible (these are polymers; DMLS is for metals only).

- Key Specs:

- Layer Thickness: 20–60 μm.

- Accuracy: ±0.1% (min. ±0.05 mm), surface finish: rough (requires machining for tight tolerances).

- Build Volume: Up to 250 × 250 × 325 mm (typical industrial).

- Post-Processing: Support removal, heat treatment, machining, polishing.

- Typical Uses: Aerospace components, medical implants, high-strength tooling, custom metal parts.

- Critical Limitation: Only metals—no polymers. ABS/Nylon cannot be processed.

📊 Material Compatibility Summary

| Process | Aluminum | Steel | ABS | Nylon |

|———|———-|——-|—–|——-|

| SLA | ❌ No | ❌ No | ❌ No | ❌ No |

| SLS | ❌ No | ❌ No | ❌ No | ✅ Yes (PA12/PA11) |

| MJF | ❌ No | ❌ No | ❌ No | ✅ Yes (PA12/PA11) |

| DMLS | ✅ Yes (alloys) | ✅ Yes (alloys) | ❌ No | ❌ No |

💡 Critical Notes:

– CNC machining is a separate subtractive process that can use Aluminum or Steel (machined from billet), but it does not use STL files as a process—STL is just a geometry file input.

– ABS is an FDM (Fused Deposition Modeling) material, not used in SLS/MJF/DMLS.

– “3D STL CNC” does not exist—if you need metal parts, choose:

– CNC machining for simple geometries (Aluminum/Steel from solid blocks).

– DMLS for complex metal geometries (e.g., internal channels).

– For ABS/Nylon parts: Use FDM (ABS) or SLS/MJF (Nylon)—but never DMLS.

🛠️ Recommendation for Your Project

- If you need Aluminum/Steel parts:

- CNC machining (most cost-effective for simple shapes).

- DMLS only if you need complex internal features (e.g., aerospace brackets).

- If you need ABS parts: Use FDM (not SLA/SLS/MJF/DMLS).

- If you need Nylon parts: Use SLS or MJF (not DMLS or SLA).

Always confirm material-process compatibility with your manufacturer—sending an STL file for “3D STL CNC” will cause confusion. Specify the actual process (e.g., “DMLS for AlSi10Mg” or “CNC machining for 6061 Aluminum”).

Need help choosing the right process for your part? Share your design requirements (geometry, material, function), and I’ll guide you step-by-step. 😊

From CAD to Part: The Process

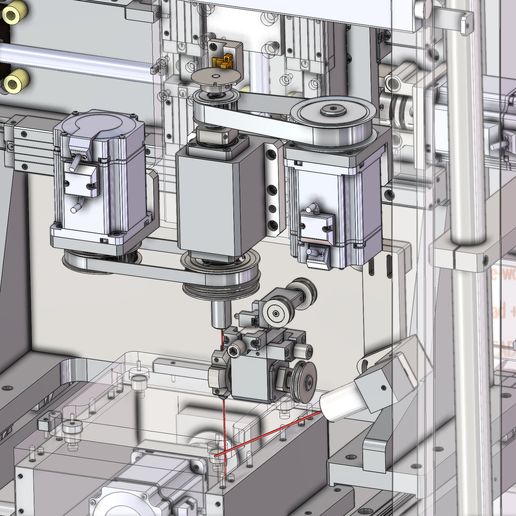

Honyo Prototype – 3D STL → CNC workflow

(we treat every STL the same way we treat a native CAD file: convert, verify, machine)

-

Upload CAD

• Portal accepts STL, STEP, IGES, SLDPRT, etc.

• STL is auto-surfaced & stitched into a solid by our AI mesh-repair engine (closes holes, removes non-manifolds, fixes flipped normals).

• A checksum is created so the file you see in the quote is the geometry that will hit the machine. -

AI Quote (≤5 min)

• The repaired solid is analysed for:

– Machinable vs. additive-only features (deep internal channels, zero-radius lattices, etc.).

– 3-, 4-, 5-axis accessibility and minimum tool diameter.

– Stock size, roughing time, finish passes, deburr labour, plating, anodise mask areas.

• Cloud solver returns a price curve (qty 1-500) and lead-time tiers (as fast as 3 days).

• You can toggle material, tolerance class, surface finish, and see cost update live. -

DFM (human + AI)

• A senior manufacturing engineer opens the AI report, validates tool choices, work-holding, and datum strategy.

• If the STL has thin webs, undercuts or non-standard threads we either:

– Recommend geometry tweaks (with editable STEP sent back), or

– Add jig cost for 5-axis or wire-EDM secondary ops.

• You approve the final DFM packet—this locks the geometry revision and tolerance stack. -

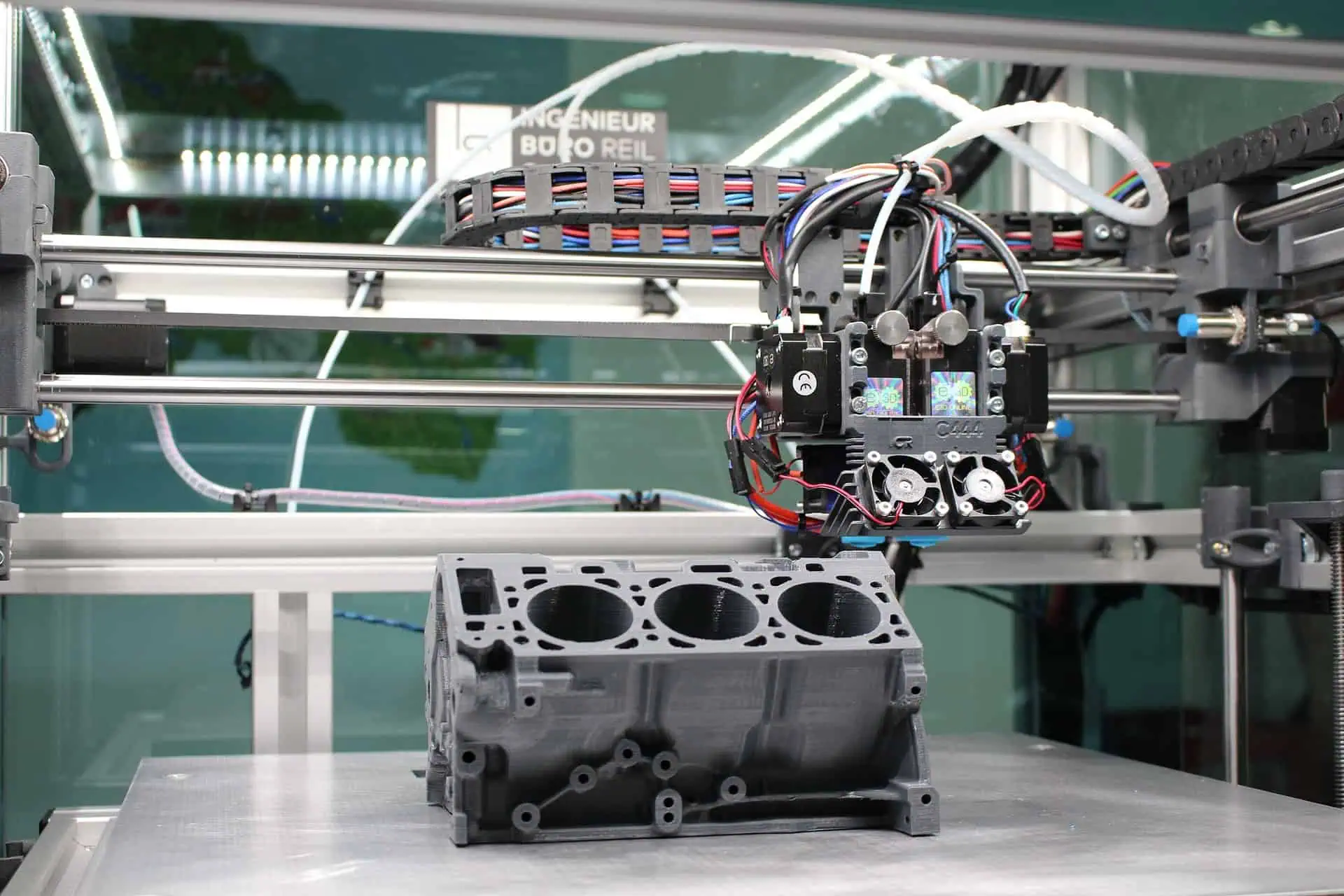

Production

• CAM is auto-generated from the approved solid; no re-drawing.

• Blank material is pre-machined on 3-axis routers for near-net shape, then finished on 5-axis Mikron or Hermle cells.

• In-cycle probing (Renishaw) compensates tool wear so the first article is already on-spec; no separate “setup part”.

• Finishing ops: anodise Type II/III, chem-film, passivate, bead-blast, silk-screen, all in-house.

• CMM report + dimensional colour map uploaded to the same portal link. -

Delivery

• Parts vacuum-sealed with VCI paper, boxed with custom foam CNC-cut from the same STL to guarantee zero transit damage.

• DHL/UPS/FedEx pre-cleared; Asian customers can opt for our same-day Shenzhen van service.

• Digital traveller (PDF + raw CMM data) travels with the shipment; scan the QR code on the box and you see the exact tool list, operator, and inspection results.

From STL upload to dock, standard lead-time is 5 days; expedite down to 72 h if material is in stock.

Start Your Project

3D STL CNC Machining – Contact Susan Leo at info@hy-proto.com.

Honyo Prototype | Shenzhen Factory | Precision Manufacturing for Your Designs

👉 Need fast, accurate CNC parts from STL files?

Reach out today for a quote! 🚀

🚀 Rapid Prototyping Estimator