Contents

Manufacturing Insight: Alloy Steel Vs Carbon Steel Which Is Stronger

Manufacturing Insight: Alloy Steel vs Carbon Steel – Understanding Strength in CNC Machining Applications

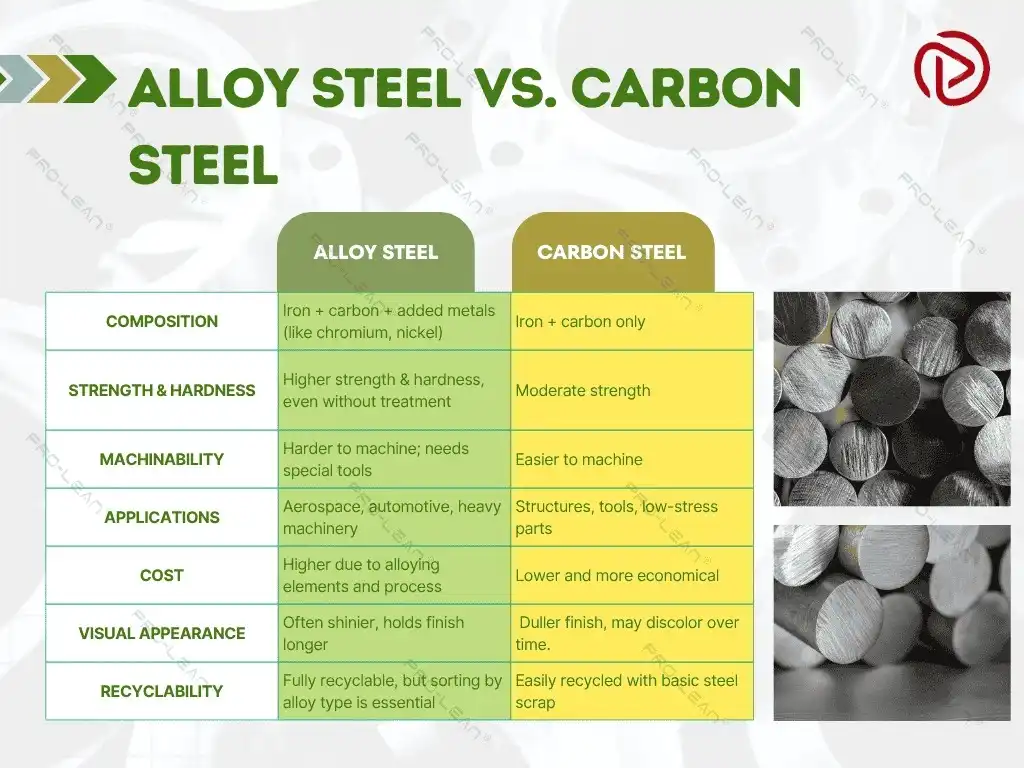

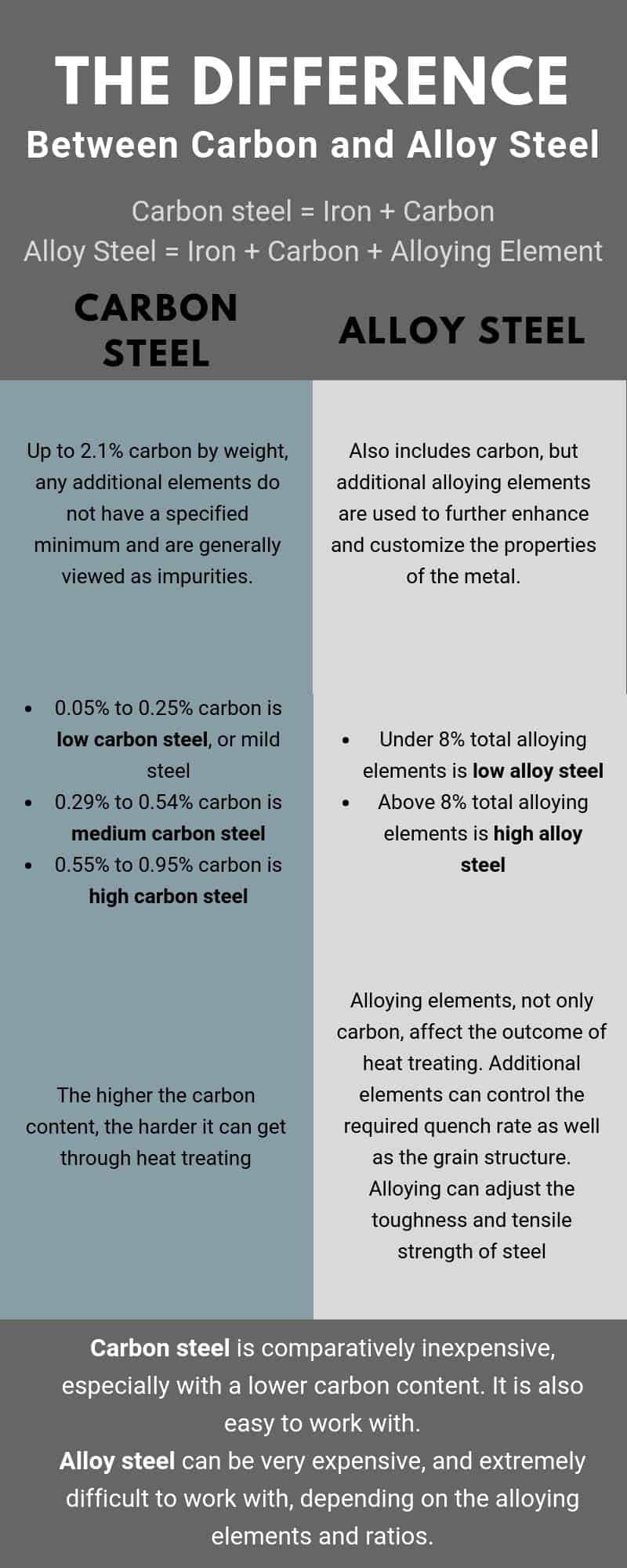

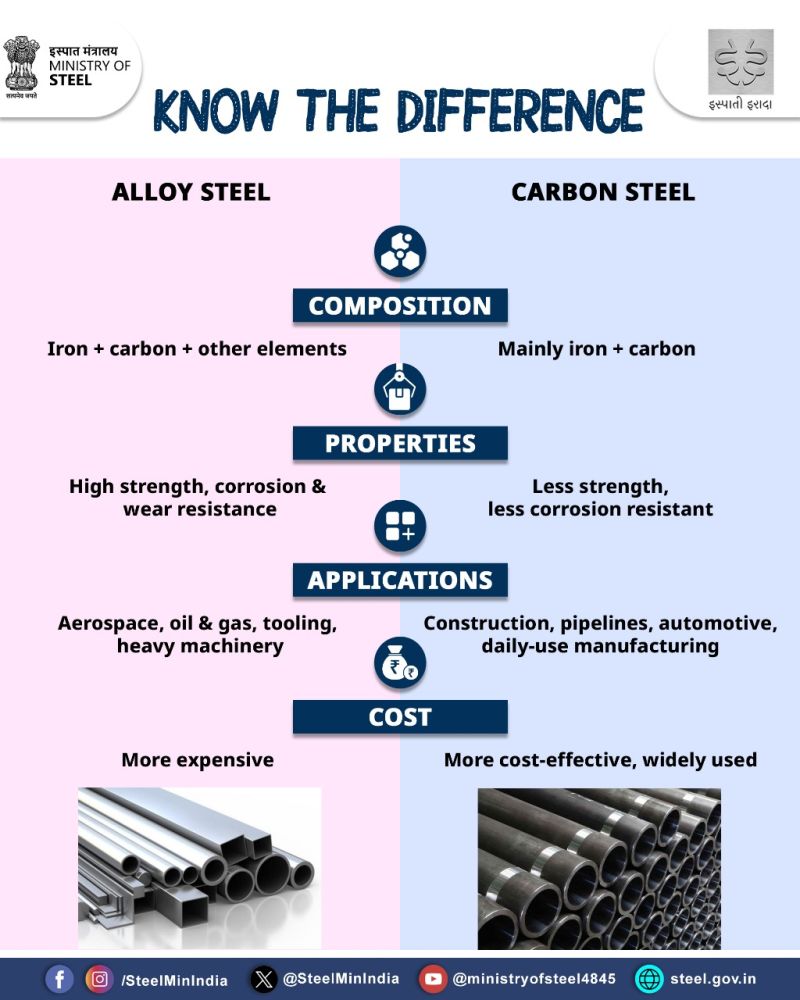

When selecting materials for precision CNC machined components, the question alloy steel vs carbon steel which is stronger frequently arises. The answer is not absolute but context-dependent, governed by specific alloying elements, heat treatment processes, and the mechanical property requirements of the end application. At Shenzhen Honyo Prototype, we emphasize that “strength” encompasses multiple metrics—including yield strength, tensile strength, fatigue resistance, and toughness—and material selection must align with the functional demands of the prototype or production part. Carbon steel, primarily composed of iron and carbon (typically 0.05% to 1.5% carbon), derives its strength largely from carbon content and cold working. Higher carbon grades like 1045 offer good hardness and wear resistance but exhibit limitations in hardenability and weldability. Alloy steel incorporates additional elements such as chromium, nickel, molybdenum, or vanadium, which significantly enhance hardenability, strength-to-weight ratios, and performance under stress or elevated temperatures. These elements enable superior response to heat treatment, allowing targeted strength optimization unattainable with plain carbon steels.

The fundamental distinction lies in how each material achieves and sustains strength. Carbon steel relies predominantly on carbon content for strength, but its hardenability is shallow, limiting effective section thickness for through-hardening. Alloy steel leverages synergistic interactions between carbon and alloying elements, enabling uniform strength properties even in larger cross-sections after heat treatment. Below is a comparative overview of key material properties:

| Material Type | Carbon Content Range | Typical Yield Strength Range (MPa) | Key Alloying Elements Beyond Carbon |

|———————|———————-|———————————-|————————————-|

| Carbon Steel | 0.05% – 1.5% | 300 – 700 | Manganese (trace), Silicon (trace) |

| Alloy Steel | 0.1% – 1.0% | 400 – 1200+ | Cr, Ni, Mo, V, Mn (significant) |

Heat treatment critically amplifies the performance gap. While carbon steel benefits from quenching and tempering, its hardenability constraints often result in a soft core in thicker sections. Alloy steels, exemplified by grades like 4140 or 4340, achieve deep, uniform hardening and retain strength at higher temperatures. The table below illustrates this divergence:

| Heat Treatment Process | Carbon Steel Effect | Alloy Steel Advantage |

|————————|—————————————–|————————————————|

| Quenching & Tempering | Limited hardening depth; core remains soft | Deep, uniform hardening; consistent core strength |

| High-Temperature Use | Rapid strength loss above 300°C | Maintains strength up to 500°C+ (depending on alloy) |

At Honyo Prototype, our CNC machining expertise extends beyond cutting parameters to deep material science integration. We leverage in-house metallurgical analysis and controlled heat treatment partnerships to select and process the optimal steel grade for your application’s specific strength, durability, and geometric requirements. Whether your project demands the cost efficiency of carbon steel for moderate-stress components or the enhanced performance envelope of alloy steel for high-load aerospace or automotive prototypes, our engineers provide data-driven material recommendations. We validate all selections through rigorous testing—ensuring yield strength, hardness, and fatigue life meet your functional specifications before final machining. This precision-driven approach guarantees that your prototype not only meets dimensional tolerances but also delivers the required mechanical performance in real-world conditions. Partner with Honyo to transform material science into manufacturing certainty.

Technical Capabilities

Alloy Steel vs Carbon Steel: Strength and Machinability in CNC Applications

When evaluating alloy steel versus carbon steel for CNC machining applications, understanding the mechanical properties, composition, and performance under stress is critical to selecting the optimal material for high-precision components. Both materials are widely used in industrial manufacturing, but their differences in strength, hardness, and machinability directly influence their suitability for 3-axis, 4-axis, and 5-axis milling, turning operations, and tight-tolerance production.

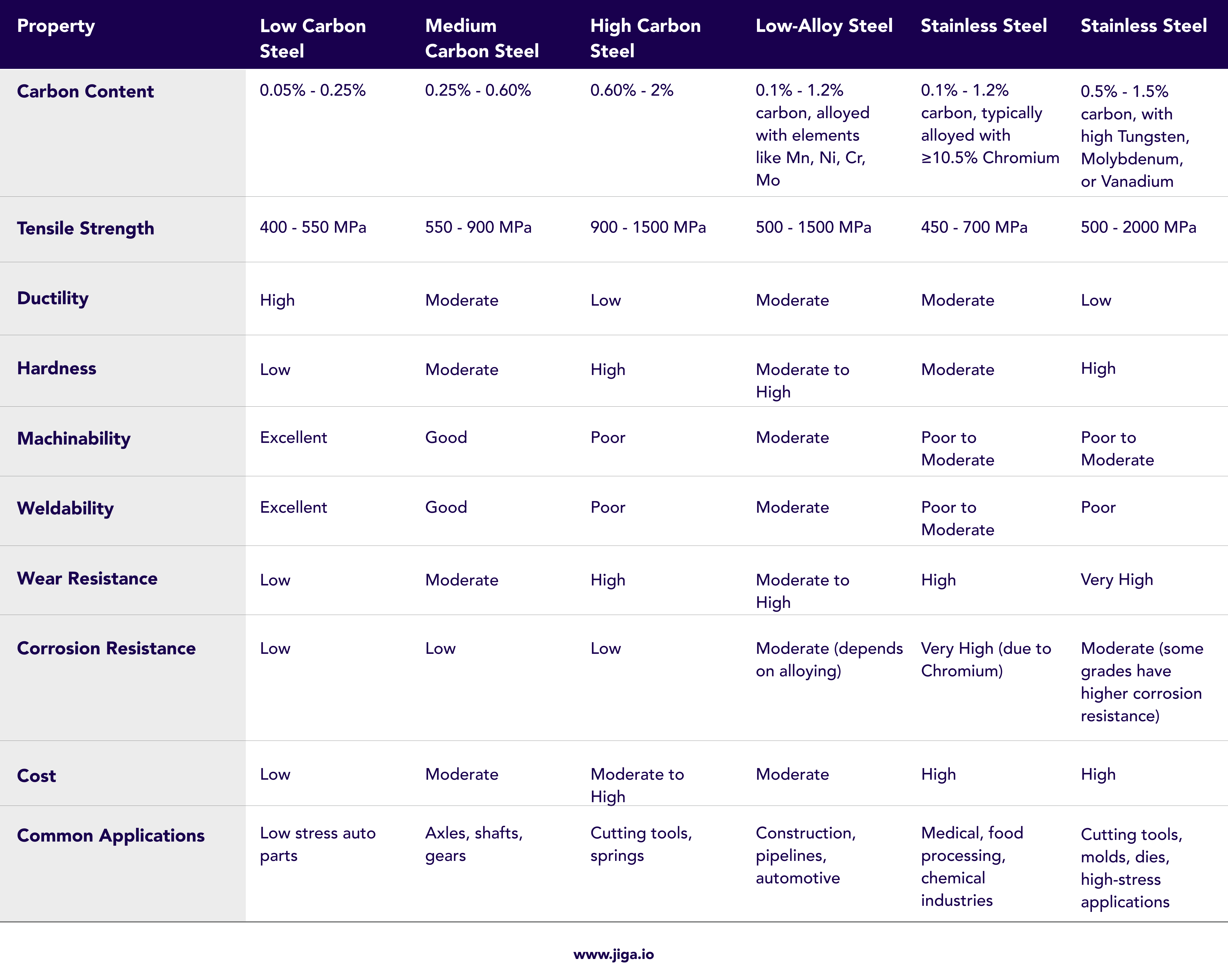

Carbon steel is primarily composed of iron and carbon, with carbon content typically ranging from 0.05% to 1.0%. Low-carbon steels (e.g., 1018) offer good machinability and weldability but exhibit lower tensile strength, making them suitable for non-critical structural parts. Medium-carbon steels (e.g., 1045) provide increased strength and moderate hardness, often used in gears and shafts. However, high-carbon variants can be challenging to machine due to reduced ductility and increased brittleness.

Alloy steel incorporates additional elements such as chromium, nickel, molybdenum, and vanadium, which enhance hardenability, wear resistance, and overall strength. Grades like 4140 and 4340 are common in aerospace, automotive, and tooling applications where high fatigue resistance and toughness are required. These alloys can achieve superior tensile strength—often exceeding 100,000 psi after heat treatment—compared to standard carbon steels. The inclusion of alloying elements also improves performance under extreme temperatures and dynamic loads.

In CNC machining, alloy steels generally require more advanced tooling and slower cutting speeds due to their increased hardness and abrasiveness. However, modern 5-axis milling systems and high-precision turning centers at Shenzhen Honyo Prototype are optimized to handle these demanding materials while maintaining tight tolerances. Carbon steels, while easier to machine, may not meet the structural demands of high-stress applications, limiting their use in performance-critical components.

The following table outlines key material properties and achievable tolerances for both steel types under precision CNC processing:

| Material | Tensile Strength (Typical) | Hardness (HB) | Machinability Rating | Typical Tolerance (Milling) | Typical Tolerance (Turning) | Common Applications |

|—————-|—————————–|—————|————————|——————————|——————————|——————————|

| 1018 Carbon Steel | 63,800 psi | 126 | 70% | ±0.005 mm | ±0.003 mm | Brackets, fixtures, shafts |

| 1045 Carbon Steel | 80,000 psi | 180 | 55% | ±0.005 mm | ±0.003 mm | Gears, spindles, couplings |

| 4140 Alloy Steel | 100,000 psi | 220 | 65% | ±0.003 mm | ±0.002 mm | Tooling, aerospace parts |

| 4340 Alloy Steel | 125,000 psi | 250 | 50% | ±0.002 mm | ±0.001 mm | High-stress shafts, landing gear |

At Shenzhen Honyo Prototype, our CNC machining capabilities support both carbon and alloy steels with strict adherence to dimensional accuracy and surface finish requirements. While alloy steels are inherently stronger and more durable, the choice between materials must balance performance needs with manufacturability and cost. For mission-critical components requiring maximum strength and fatigue resistance, alloy steel is the superior choice. For less demanding applications where cost and ease of machining are priorities, carbon steel remains a viable option.

From CAD to Part: The Process

From CAD to Part: CNC Production Workflow for Steel Components

At Shenzhen Honyo Prototype, our CNC machining workflow for steel components—from initial inquiry to finished part—is engineered to prioritize precision, cost efficiency, and material integrity. This process is particularly critical when selecting between carbon steel and alloy steel, as material properties directly impact machinability, tool wear, and final part performance. Below we detail the structured workflow ensuring optimal outcomes for your steel-based prototypes or production runs.

The process begins with the AI-Powered Quoting System. Clients upload CAD files (STEP, IGES, or native formats) to our portal, specifying material requirements—such as AISI 1045 carbon steel or 4140 alloy steel—and tolerances. Our AI engine cross-references geometric complexity, material grade, and volume against real-time machine capabilities and material costs. For steel selections, the system flags critical considerations: carbon steels (e.g., 1018, 1045) offer cost-effective machinability but lower hardenability, while alloy steels (e.g., 4140, 4340) provide superior strength and wear resistance at higher material and processing costs. Quotes include explicit notes on how material choice affects lead time and surface finish, ensuring informed client decisions before commitment.

Next, Design for Manufacturability (DFM) Analysis is conducted by our engineering team. This phase scrutinizes CAD models for steel-specific challenges. Carbon steels may require slower feed rates to prevent work hardening, whereas alloy steels often demand specialized tooling to manage abrasive carbides. Key DFM checks include:

Wall thickness validation to avoid distortion during heat treatment

Tolerance stack-up assessment for tight-tolerance features

Toolpath feasibility for deep cavities in high-strength alloys

Heat treatment sequencing recommendations (e.g., pre-hardened 4140 vs. through-hardened 1045)

DFM feedback is delivered within 24 hours, with actionable suggestions to reduce scrap risk—such as adjusting radii in 4340 steel to minimize stress concentrations.

Finally, CNC Production Execution leverages our 5-axis milling and turning centers. Material-specific protocols are applied:

Carbon steel parts use high-speed steel (HSS) tooling with flood coolant to manage gummy chips

Alloy steel runs employ carbide inserts with reduced RPM and optimized coolant pressure to combat tool wear

In-process CMM inspections verify critical dimensions after roughing, especially for alloy steels prone to residual stress

All steel components undergo final heat treatment per client specs (annealing, quenching, or tempering), followed by surface validation via roughness testers. For high-strength alloys, we implement stress-relief cycles to ensure dimensional stability.

This integrated workflow—AI quoting, steel-optimized DFM, and precision CNC execution—eliminates common pitfalls in steel machining. By aligning material science with process engineering, Honyo Prototype delivers parts that meet exact strength, durability, and geometric requirements, whether you select cost-driven carbon steels or performance-focused alloys. Clients receive not just a component, but a validated solution where material choice and manufacturing process are harmonized for success.

Note: Material selection guidance is based on ASTM/SAE standards. Final strength properties depend on heat treatment and part geometry.

Start Your Project

Alloy Steel vs Carbon Steel: Which Is Stronger for Your CNC Machining Project?

When selecting materials for precision CNC machining, the choice between alloy steel and carbon steel can significantly impact the performance, durability, and cost-effectiveness of your final part. At Shenzhen Honyo Prototype, we understand that material selection is not just about strength—it’s about matching mechanical properties, machinability, and application requirements to ensure optimal results.

Carbon steel, primarily composed of iron and carbon (typically up to 2.1% by weight), is known for its high tensile strength and hardness. It is widely used in structural components, automotive parts, and tooling due to its excellent wear resistance and straightforward machinability. However, its corrosion resistance is limited, and it may not perform well under extreme temperatures or high-stress cyclic loading without additional treatments.

Alloy steel, on the other hand, contains additional elements such as chromium, nickel, molybdenum, or vanadium, which enhance specific properties like toughness, hardenability, and resistance to heat and corrosion. These enhancements make alloy steel ideal for demanding applications in aerospace, defense, and high-performance machinery. While generally stronger and more durable than carbon steel, alloy steels can be more challenging to machine and may require specialized tooling and processes.

To help you make an informed decision, consider the following comparison of common grades used in CNC machining:

| Property | AISI 1045 (Carbon Steel) | AISI 4140 (Alloy Steel) |

|————————–|————————–|————————–|

| Tensile Strength (MPa) | 570 | 655 |

| Yield Strength (MPa) | 310 | 415 |

| Hardness (HB) | 170 | 197 |

| Machinability Rating | 72% | 65% |

| Common Applications | Shafts, bolts, gears | Aircraft components, tooling, high-stress parts |

While alloy steel typically offers superior strength and performance under extreme conditions, carbon steel remains a cost-effective solution for less demanding environments. The right choice depends on your project’s operational requirements, environmental exposure, and lifecycle expectations.

At Honyo Prototype, we specialize in high-precision CNC machining of both carbon and alloy steels, providing expert guidance from material selection to final production. Our advanced machining capabilities ensure tight tolerances, superior surface finishes, and rapid turnaround—whether you’re prototyping or moving into low-volume production.

Ready to start your project? Let our engineering team help you select the optimal material and process for your application. Contact Susan Leo today at info@hy-proto.com for a personalized consultation and free project quote. With Honyo Prototype, precision isn’t just a standard—it’s our commitment.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.