Contents

Manufacturing Insight: Atc In Cnc

Manufacturing Insight: Automatic Tool Changers in CNC Machining

Automatic Tool Changers (ATC) represent a foundational advancement in Computer Numerical Control (CNC) machining, enabling seamless transitions between multiple cutting tools during a single operational cycle. At Shenzhen Honyo Prototype, we leverage ATC technology to eliminate manual tool interventions, significantly reducing non-cutting time and enhancing throughput for complex prototypes and low-volume production runs. This capability is critical in modern precision manufacturing, where part geometries often demand diverse tooling strategies—from roughing mills to micro-diameter drills—within a unified machining sequence. By integrating ATC systems, our CNC centers achieve higher machine utilization rates, tighter process control, and consistent dimensional accuracy, directly addressing client needs for accelerated time-to-market without compromising quality.

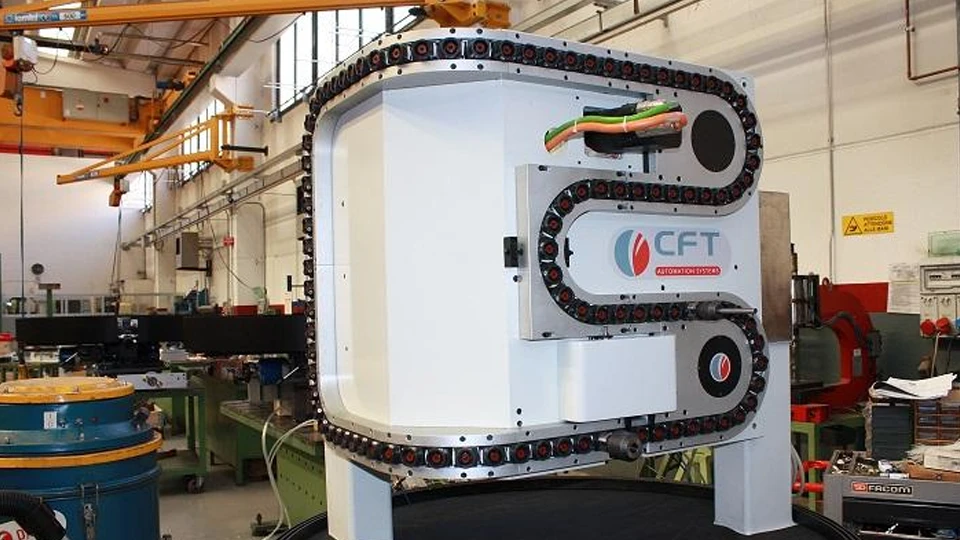

Honyo deploys ATC-equipped CNC machining centers across our facility, optimized for the stringent demands of rapid prototyping and bridge production. Our systems utilize high-speed carousel or chain-type tool magazines, engineered for rapid indexing and minimal vibration during tool exchange. Each ATC system undergoes rigorous calibration to maintain repeatability within ±0.001 mm, ensuring tool-to-tool alignment integrity critical for multi-operation features like deep cavities or intricate contours. We prioritize compatibility with industry-standard tooling interfaces (HSK-63, CAT-40) and implement predictive maintenance protocols to sustain >99.5% ATC operational reliability. This focus minimizes unplanned downtime and supports unattended machining cycles—essential for delivering prototypes in 24–72 hours while maintaining Honyo’s ISO 9001-certified quality standards.

Our ATC implementation directly translates to client value through reduced lead times and expanded design flexibility. Engineers can specify consolidated operations—such as simultaneous milling, drilling, and tapping—without manual setup breaks, enabling single-setup completion of parts that previously required multiple machine transfers. This capability is particularly advantageous for aerospace, medical, and robotics prototypes where geometric complexity and material diversity (e.g., aluminum 7075, PEEK, titanium) are common. Furthermore, our ATC systems integrate with in-process probing and tool length sensors, allowing real-time compensation for thermal drift or tool wear, thereby ensuring first-article conformance to tight tolerances (±0.005 mm).

Honyo’s current ATC-enabled CNC capabilities are summarized below:

| Parameter | Specification | Application Impact |

|————————-|—————————————-|—————————————-|

| Max Tool Capacity | 30–60 tools (machine-dependent) | Supports multi-operation complex parts |

| Avg. Tool Change Time | 1.8–3.2 seconds | Reduces non-cutting time by 35–50% |

| Positioning Accuracy | ±0.001 mm | Ensures feature alignment integrity |

| Compatible Machines | 3/4/5-axis vertical machining centers | Enables full 5-axis contouring |

| Maintenance Interval | 1,000 hours (monitored via IoT sensors)| Maximizes uptime for urgent projects |

By embedding ATC technology within our core manufacturing workflow, Honyo Prototype transforms CNC machining from a sequential task into a continuous, intelligent process. This strategic capability allows us to deliver technically ambitious prototypes with the speed and precision required in today’s competitive development cycles, reinforcing our commitment to engineering excellence in every component we produce.

Technical Capabilities

Advanced Tool Changer Integration in CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining capabilities are enhanced by the integration of Automatic Tool Changers (ATC) across 3, 4, and 5-axis milling platforms, as well as multi-axis turning centers. The ATC system enables seamless, high-precision tool exchanges during complex machining cycles, significantly improving efficiency, accuracy, and repeatability. This capability is especially critical when producing intricate geometries, deep cavities, or components requiring multiple operations without manual intervention.

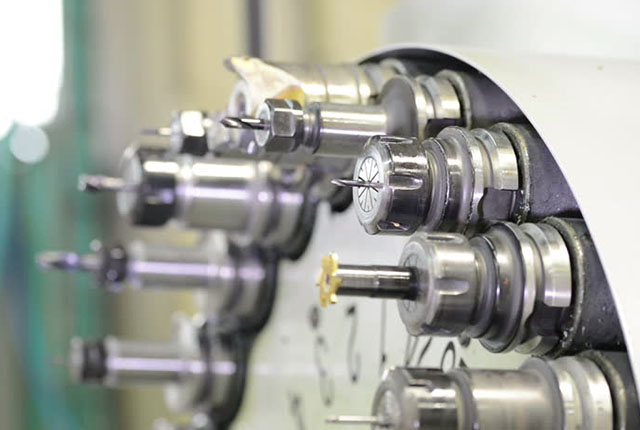

Our 3-axis CNC milling machines utilize ATC systems with tool magazine capacities ranging from 12 to 30 tools, allowing for uninterrupted processing of prismatic parts with tight tolerance requirements. Transitioning to 4-axis and 5-axis configurations, the ATC supports continuous indexing and simultaneous multi-face machining, essential for aerospace, medical, and automotive prototypes where complex contours and undercuts are common. In multi-axis turning with live tooling, the ATC ensures rapid switching between turning, drilling, tapping, and milling operations, reducing cycle times and maintaining dimensional consistency.

Tight tolerance machining is a core strength at Honyo Prototype. With ATC-enabled CNC systems, we maintain tolerances as tight as ±0.005 mm on critical dimensions. The closed-loop tool management system verifies tool length and diameter prior to engagement, minimizing thermal and mechanical deviations. Additionally, our machines are equipped with high-frequency spindles (up to 24,000 RPM) and real-time tool wear compensation, ensuring consistent surface finishes and geometric accuracy throughout production runs.

We support a broad range of engineering materials, from standard aluminum and stainless steel to exotic alloys and high-performance plastics. The ATC system allows for optimized tool paths using material-specific cutters, enhancing edge definition and minimizing burring. Each material is machined with dedicated tooling strategies to maintain integrity and meet stringent industry standards.

Below is an overview of our standard tolerance capabilities and compatible materials:

| Material Category | Example Materials | Standard Tolerance (mm) | Tight Tolerance (mm) | Max Part Size (mm) |

|——————-|——————-|————————–|————————|——————–|

| Aluminum Alloys | 6061, 7075, 2024 | ±0.010 | ±0.005 | 600 x 400 x 300 |

| Stainless Steel | 303, 304, 316, 17-4 PH | ±0.010 | ±0.008 | 500 x 350 x 250 |

| Tool Steels | A2, D2, H13 | ±0.010 | ±0.008 | 450 x 300 x 200 |

| Titanium Alloys | Ti-6Al-4V, Grade 2 | ±0.010 | ±0.008 | 400 x 300 x 200 |

| Engineering Plastics | PEEK, Delrin, Nylon | ±0.025 | ±0.015 | 600 x 500 x 300 |

| Brass & Copper | C36000, C11000 | ±0.010 | ±0.008 | 550 x 400 x 250 |

All ATC operations are monitored via integrated CNC diagnostics, ensuring traceability and process stability. At Shenzhen Honyo Prototype, we combine advanced automation with precision engineering to deliver high-complexity components that meet exacting client specifications.

From CAD to Part: The Process

From CAD to Precision Part: Honyo Prototype’s ATC CNC Production Workflow

At Shenzhen Honyo Prototype, transforming your CAD model into a high-precision CNC machined component is a rigorously defined process leveraging advanced automation, including Automatic Tool Changer (ATC) systems for optimal efficiency. Our workflow ensures technical accuracy and manufacturability from initial inquiry to final delivery, specifically optimized for complex geometries requiring multi-tool operations.

The process commences with your CAD model submission. Our AI-Powered Quoting System immediately analyzes the 3D geometry, material selection, and specified tolerances. This AI engine cross-references extensive historical production data and real-time machine capabilities, including ATC-equipped centers, to generate a highly accurate technical and commercial quotation within hours. This initial assessment factors in critical parameters like potential tool count, estimated machining time considering automatic tool changes, and fixture requirements, providing immediate transparency on feasibility and cost drivers.

Following quote acceptance, the model enters our mandatory Design for Manufacturability (DFM) review stage. Our senior manufacturing engineers conduct a deep technical analysis, focusing intensely on how the design interacts with ATC functionality. We scrutinize features requiring multiple cutting tools, undercuts, tight tolerances across different operations, and overall part orientation. Key DFM considerations include verifying that the sequence of operations can be efficiently managed by the ATC, ensuring tool clearances during automatic changes, and optimizing the tool library to minimize non-cutting time. Any potential issues impacting ATC utilization or causing manual intervention are identified and resolved collaboratively with the client before programming begins. This stage is critical for leveraging ATC benefits and preventing costly delays.

Upon DFM sign-off, production initiates on our state-of-the-art CNC machining centers equipped with high-speed ATCs. The CAM programming phase generates optimized toolpaths specifically structured to maximize ATC efficiency, sequencing operations to minimize tool change frequency and spindle downtime. During machining, the ATC autonomously selects and loads the required tool from the carousel (typically holding 24-60 tools) based on the programmed sequence. This eliminates manual tool changes, drastically reducing non-productive time and enabling uninterrupted machining of complex, multi-feature parts in a single setup. Rigorous in-process inspections and final quality control against the original CAD model and specifications ensure dimensional accuracy and surface finish meet stringent requirements.

The integration of ATC technology is fundamental to our production capability for intricate components. The table below highlights key performance advantages of utilizing ATC-equipped machining centers for multi-operation parts compared to manual tool change setups:

| Parameter | Manual Tool Change Setup | ATC-Equipped Machining Center | Typical Reduction with ATC |

| :———————– | :———————– | :—————————- | :———————– |

| Non-Cutting Time per Part | High (5-15+ minutes) | Very Low (Seconds) | 70-90% |

| Max Practical Tool Count | Limited (5-10 tools) | High (24-60+ tools) | N/A |

| Setup Changes per Part | Multiple | Often Single | 50-100% |

| Complex Feature Feasibility | Low | High | Significant Improvement |

| Production Throughput | Low | High | 30-60%+ |

This seamless integration of AI-driven quoting, expert DFM analysis focused on ATC optimization, and precision ATC production enables Honyo Prototype to deliver complex CNC machined prototypes and low-volume production parts with exceptional speed, accuracy, and technical reliability, meeting the demanding requirements of modern manufacturing.

Start Your Project

Start Your Project with Precision CNC Machining at Shenzhen Honyo Prototype

When it comes to high-precision CNC machining, integrating an Automatic Tool Changer (ATC) system is a decisive factor in achieving efficiency, accuracy, and scalability in modern manufacturing. At Shenzhen Honyo Prototype, we specialize in advanced CNC solutions equipped with ATC technology, enabling seamless tool transitions, reduced downtime, and consistent part quality across complex production runs. Whether you’re developing prototypes or scaling to low-volume production, our capabilities are engineered to meet the rigorous demands of industries such as aerospace, medical devices, automotive, and industrial equipment.

An ATC-equipped CNC machine enhances productivity by automatically selecting and changing tools during the machining cycle. This eliminates manual intervention, reduces cycle times, and ensures tighter tolerances through uninterrupted operations. At Honyo Prototype, our CNC machining centers are outfitted with reliable ATC systems capable of managing multi-operation workflows—from milling and drilling to tapping and contouring—all within a single setup. This integration not only improves dimensional accuracy but also significantly cuts down on human error and setup inconsistencies.

Our team of experienced manufacturing engineers works closely with clients from the initial design phase through to final production. We leverage state-of-the-art 3-, 4-, and 5-axis CNC machines with ATC functionality to deliver complex geometries with micron-level precision. Material versatility is another cornerstone of our service, supporting aluminum, stainless steel, titanium, brass, engineering plastics, and other high-performance alloys.

To ensure your project meets both technical and timeline requirements, we offer comprehensive DFM (Design for Manufacturability) analysis, real-time progress tracking, and strict quality control in accordance with ISO 9001 standards. Every component undergoes rigorous inspection using CMM, optical comparators, and surface finish testers to guarantee compliance with your specifications.

Below is an overview of our CNC machining capabilities with ATC integration:

| Specification | Details |

|——————————-|————————————————————————-|

| Machine Types | 3-axis, 4-axis, 5-axis CNC with ATC systems |

| Tool Capacity (ATC) | Up to 30 tools (configurable based on machine model) |

| Maximum Work Envelope | 1200 x 600 x 500 mm (5-axis); up to 2000 x 1000 x 800 mm (3-axis) |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported Materials | Aluminum, Steel, Stainless Steel, Titanium, Brass, Plastics (PEEK, etc.) |

| Lead Times | As fast as 5–7 days for prototypes; production runs scalable |

| Quality Standards | ISO 9001:2015 compliant, full inspection reporting |

Starting your project at Honyo Prototype is simple. We prioritize clear communication, technical transparency, and rapid turnaround to keep your development on track. If you’re ready to move forward with a CNC machining solution powered by ATC technology, contact Susan Leo at info@hy-proto.com. She will guide you through the quoting process, review your CAD files, and provide expert recommendations to optimize your design for manufacturing. Partner with a team that combines precision engineering with responsive service—choose Shenzhen Honyo Prototype for your next CNC project.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.