Contents

Manufacturing Insight: Stone Cnc

Manufacturing Insight: Stone CNC Machining Capabilities

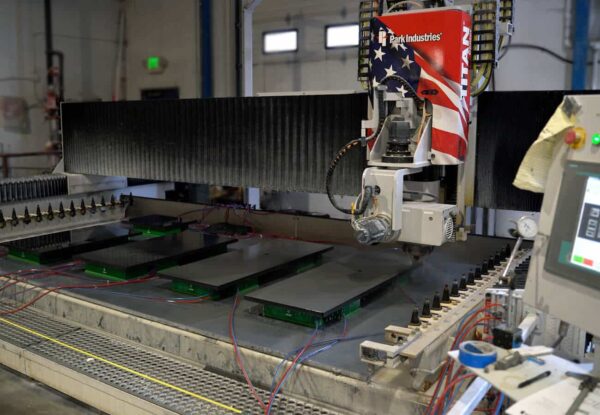

Stone CNC machining represents a specialized discipline within precision manufacturing, demanding exceptional control to overcome the inherent challenges of natural and engineered stone materials. Unlike metals or plastics, stone exhibits variable density, internal stresses, and brittleness, requiring tailored machining strategies to prevent chipping, cracking, or surface imperfections. At Shenzhen Honyo Prototype, we leverage advanced multi-axis CNC systems specifically configured for stone substrates, enabling the production of intricate architectural elements, high-end signage, countertops, and custom artistic components with micron-level fidelity. Our process integrates material science expertise with adaptive toolpathing algorithms to manage heat generation and vibration—critical factors in preserving stone integrity during high-speed milling, drilling, and contouring operations.

Honyo’s stone CNC workflow begins with rigorous material assessment to identify grain structure and potential flaws, ensuring optimal fixturing and tool selection. We utilize diamond-coated tooling engineered for stone abrasion resistance, paired with vacuum-assisted dust extraction systems that maintain workplace safety and component cleanliness. Our Shenzhen facility operates dedicated stone CNC centers featuring hydrostatic guideways for vibration damping and thermal stability, essential for achieving seamless finishes on materials like granite, marble, quartzite, and sintered stone composites. Crucially, we implement real-time spindle load monitoring to dynamically adjust feed rates, preventing tool deflection and material fracture during complex 3D profiling. This approach delivers repeatability unattainable with manual methods, supporting clients from prototyping through low-to-mid volume production with consistent surface quality and dimensional accuracy.

Key technical specifications underpinning our stone CNC service are detailed below:

| Parameter | Honyo Capability | Industry Standard Benchmark |

|———————–|—————————|—————————–|

| Max Work Envelope | 3000 x 2000 x 800 mm | 2500 x 1500 x 600 mm |

| Positioning Accuracy | ±0.01 mm | ±0.02 mm |

| Surface Finish (Ra) | 0.8–1.6 μm | 1.6–3.2 μm |

| Material Thickness | 5–150 mm | 10–100 mm |

| Spindle Power | 15 kW (Water-Cooled) | 10 kW |

Our commitment extends beyond machining to comprehensive finishing protocols, including automated edge polishing and controlled curing cycles that mitigate residual stress. This holistic methodology ensures components meet stringent architectural and design specifications while minimizing waste—a critical advantage given stone’s material cost. Honyo Prototype’s integration of German-engineered CNC platforms with localized material expertise positions us as a strategic partner for global clients requiring defect-free stone components at scale. We prioritize collaborative engineering engagement, offering DFM analysis early in the design phase to optimize manufacturability and cost-efficiency. For projects demanding the fusion of artistic vision and structural precision, our stone CNC capabilities deliver reliability where conventional methods fall short. Contact our Shenzhen engineering team to discuss your next stone fabrication challenge.

Technical Capabilities

Technical Capabilities: Stone CNC Machining at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype specializes in high-precision CNC machining for natural and engineered stone materials, delivering complex geometries and superior surface finishes for architectural, artistic, and industrial applications. Our advanced 3-axis, 4-axis, and 5-axis CNC stone milling systems are engineered to handle intricate contours, deep undercuts, and multi-faceted designs with exceptional accuracy and repeatability. These capabilities enable us to support prototyping and low-to-mid volume production runs with rapid turnaround and consistent quality.

Our 3-axis CNC stone machines are optimized for flat-surfaced and 2D profiling operations, ideal for countertops, signage, and relief carvings. For more complex components requiring rotational indexing and angled features, our 4-axis systems integrate a rotary fourth axis to enable continuous cutting around cylindrical or semi-curved stone forms. The 5-axis CNC stone machining centers represent the pinnacle of our technical capacity, allowing simultaneous movement across all five axes to produce highly detailed sculptures, freeform architectural elements, and precision-fitted joints without repositioning, minimizing human error and maximizing dimensional consistency.

In addition to multi-axis milling, we offer CNC stone turning for symmetrical cylindrical components such as columns, balusters, and ornamental pillars. Our stone lathes are equipped with diamond-tipped tooling and high-torque spindles capable of processing dense materials like granite and quartzite while maintaining surface integrity and geometric precision.

Tight tolerance machining is a core strength at Honyo Prototype. We consistently achieve tolerances as tight as ±0.02 mm on critical features, supported by in-process metrology, temperature-stable machining environments, and post-process inspection using coordinate measuring machines (CMM) and laser scanning. Our quality control protocols ensure that every component meets exact design specifications, particularly for assembly-critical or fitment-required applications.

We process a wide range of stone materials, each selected based on project requirements for durability, aesthetics, and machinability. Below is a summary of our standard material offerings and achievable tolerances:

| Material Type | Common Grades | Typical Tolerance (± mm) | Max Feature Size (L×W×H) | Notes |

|———————|———————————-|————————–|————————–|————————————|

| Natural Granite | Imperial Black, Kashmir White | 0.03 | 3000×1800×800 mm | High density, excellent durability |

| Natural Marble | Calacatta, Emperador, Carrara | 0.05 | 2800×1600×600 mm | Prone to micro-fractures; handled with care |

| Engineered Quartz | Caesarstone, Silestone types | 0.02 | 3200×1600×400 mm | Consistent composition, ideal for tight tolerances |

| Limestone | Indiana, Solnhofen | 0.05 | 2500×1500×500 mm | Softer; suitable for detailed carving |

| Sandstone | Brownstone, Cliffstone | 0.08 | 2400×1400×450 mm | Variable grain; moderate precision |

| Artificial Stone | Acrylic & Polyester-based | 0.02 | 3050×1450×300 mm | High machinability, seamless finishes |

All stone CNC operations are supported by proprietary fixturing solutions and dust-extraction systems to ensure operator safety and environmental control. At Shenzhen Honyo Prototype, we combine technical precision with material expertise to deliver stone components that meet the most demanding engineering and design standards.

From CAD to Part: The Process

Stone CNC Production Workflow: From CAD to Finished Part

At Shenzhen Honyo Prototype, our stone CNC machining process integrates advanced digital tools with deep material science expertise to transform client CAD models into precise, high-quality stone components. This structured workflow ensures efficiency, minimizes risk, and guarantees exceptional results for challenging stone materials like granite, marble, and engineered quartz. The process rigorously follows three critical phases: AI-Powered Quoting, Expert Design for Manufacturability (DFM) Review, and Precision Production.

The workflow initiates with our proprietary AI Quote Engine. Upon receiving a client’s 3D CAD model (STEP, IGES, or native formats preferred), the system performs rapid geometric analysis. It automatically calculates material volume, identifies complex features requiring specialized toolpaths, and estimates machine runtime based on historical data for specific stone types. Crucially, the AI factors in stone-specific variables such as material density, inherent brittleness, and typical tool wear rates. This generates a highly accurate preliminary quote and lead time within hours, providing immediate transparency on cost drivers like material waste potential and secondary operations.

Following client approval, the project enters the mandatory DFM review phase led by our senior stone machining engineers. This is not an automated step; it requires deep material-specific insight. Engineers meticulously analyze the CAD model for stone’s unique constraints: grain direction sensitivity, minimum wall thickness limitations to prevent breakage, optimal part orientation to minimize internal stresses during cutting, and feasibility of intricate details without chipping. We proactively identify potential issues like undercuts requiring specialized tooling or features prone to edge chipping and collaborate directly with the client to suggest robust, manufacturable design refinements. Physical sample verification of the specific stone batch is often recommended at this stage due to natural material variation.

Only after DFM sign-off does production commence on our specialized stone CNC platforms. We utilize high-torque, low-vibration machines equipped exclusively with diamond-coated tooling (sintered or brazed) capable of machining abrasive stone. Parameters are meticulously dialed in based on the confirmed stone type and DFM insights. Critical machining parameters are strictly controlled as shown below:

| Parameter | Typical Range for Stone | Critical Consideration |

| :—————– | :———————- | :—————————————– |

| Spindle Speed | 500 – 2,000 RPM | Low speed prevents heat buildup & chipping |

| Feed Rate | 100 – 500 mm/min | Slow, consistent feed minimizes fracture |

| Depth of Cut | 0.5 – 2.0 mm | Shallow cuts reduce tool load & vibration |

| Coolant/Lubrication| Non-corrosive Mist | Controls dust, cools tool, prevents staining |

Machining occurs in multiple controlled stages: roughing to remove bulk material, semi-finishing for accuracy, and fine finishing for critical surfaces. Post-machining, parts undergo thorough cleaning, meticulous deburring using stone-specific techniques, dimensional verification against the original CAD, and optional surface treatments like sealing as specified. This integrated, stone-centric workflow ensures Honyo delivers dimensionally accurate, structurally sound prototypes and low-volume production parts with minimal rework, leveraging technology where it adds value while relying on irreplaceable human expertise for material mastery.

Start Your Project

Start Your Stone CNC Machining Project with Shenzhen Honyo Prototype

When precision, durability, and aesthetic detail matter in architectural or decorative applications, CNC-machined stone components deliver unmatched quality. At Shenzhen Honyo Prototype, we specialize in high-accuracy stone CNC machining for prototypes, custom installations, and low-to-mid volume production runs. Whether you’re developing intricate stone facades, bespoke countertops, sculptural elements, or functional components for luxury interiors, our advanced CNC technology ensures dimensional accuracy, smooth surface finishes, and consistent repeatability.

Our stone CNC machining services support a wide range of natural and engineered materials, including granite, marble, limestone, quartz, and composite stone. Utilizing 3-, 4-, and 5-axis CNC routers equipped with diamond-tipped tooling, we achieve complex geometries, fine detailing, and tight tolerances down to ±0.05 mm. This level of control is essential for projects requiring seamless fit, structural integrity, and design fidelity—particularly in high-end architectural and design applications.

We understand that every stone project begins with a vision. That’s why our engineering team collaborates closely with clients from the initial concept stage through final production. By reviewing your CAD models, material specifications, and functional requirements early in the process, we can identify potential manufacturability challenges, recommend design optimizations, and ensure efficient machining strategies. This proactive approach minimizes revisions, reduces lead times, and lowers overall project costs.

Below are key technical capabilities of our stone CNC machining services:

| Specification | Detail |

|————–|——–|

| Material Types | Granite, Marble, Limestone, Quartz, Engineered Stone |

| Machine Axes | 3-axis, 4-axis, 5-axis CNC Routers |

| Maximum Work Envelope | 3000 mm × 2000 mm × 600 mm |

| Tolerance | ±0.05 mm typical |

| Surface Finish | As-machined, polished, brushed, or custom texture |

| Tooling | Diamond-coated end mills and core drills |

| Lead Time | 7–15 days (varies by complexity and volume) |

At Shenzhen Honyo Prototype, quality is embedded in every phase of production. Each stone component undergoes rigorous inspection using coordinate measuring machines (CMM) and laser scanning to verify dimensional accuracy and surface integrity. We also provide detailed inspection reports upon request, ensuring full traceability and compliance with your project specifications.

Starting your stone CNC project is simple. Share your design files in STEP, IGES, or DWG format, along with any material preferences and application requirements. Our team will provide a comprehensive manufacturability analysis, a detailed quotation, and expert recommendations tailored to your needs.

For immediate assistance, contact Susan Leo, our dedicated project coordinator. She will guide you through the onboarding process, answer technical questions, and ensure your project moves smoothly from concept to completion.

Contact Susan Leo

Email: info@hy-proto.com

Shenzhen Honyo Prototype – Precision Machining for Stone Innovation

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.