Contents

Manufacturing Insight: 032 Aluminum Sheet Metal

Manufacturing Insight: 032 Aluminum Sheet Metal

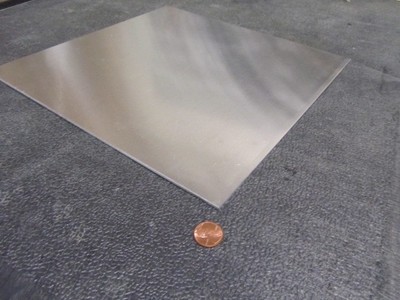

032 aluminum sheet metal, denoting a nominal thickness of 0.032 inches (0.81 mm), represents a critical material choice for precision prototypes and low-volume production in aerospace, electronics, and medical device sectors. At Honyo Prototype, we specialize in transforming this thin-gauge material into complex, high-integrity components where dimensional stability and surface finish are non-negotiable. Its popularity stems from an optimal balance of lightweight properties, moderate strength, and exceptional formability—yet its thin profile introduces unique manufacturing challenges, including warpage during cutting, springback in bending, and susceptibility to surface marring. Mastery of 032 aluminum demands rigorous process control, which defines Honyo’s engineering approach.

Material selection is foundational. While 032 refers strictly to thickness, common alloys include 5052-H32 for superior corrosion resistance in marine environments and 6061-T6 for enhanced structural rigidity. Honyo maintains strict inventory controls to ensure alloy consistency, directly impacting weldability and fatigue performance. Below are key specifications we adhere to for 032 aluminum fabrication:

| Parameter | Standard Tolerance | Honyo Enhanced Tolerance | Critical Impact |

|——————–|——————–|————————–|——————————————|

| Thickness | ±0.005 in (±0.13 mm) | ±0.002 in (±0.05 mm) | Prevents buckling in bending operations |

| Flatness | 0.015 in/ft | 0.005 in/ft | Ensures reliable fit for multi-part assemblies |

| Bend Radius (Min) | 0.5T | 0.3T | Enables tighter geometries without cracking |

| Hole Position | ±0.005 in | ±0.002 in | Critical for PCB alignment in enclosures |

Laser cutting 032 aluminum requires adaptive power modulation to minimize heat-affected zones that induce micro-warping. Honyo employs fiber lasers with nitrogen assist gas, achieving burr-free edges at speeds up to 40 m/min while maintaining ±0.003 in positional accuracy. For bending, our CNC press brakes utilize real-time feedback systems to counteract springback—adjusting tonnage dynamically based on material batch data. This precision ensures consistent 90° bends within 0.25° angular tolerance, even for intricate brackets under 2 in² surface area.

Surface integrity remains paramount. Honyo integrates automated deburring stations post-cutting to eliminate micro-burrs that compromise EMI shielding effectiveness in electronic housings. For finishing, we offer anodizing (Type II clear or black) with dye absorption controls specific to thin gauges, preventing uneven coloration. Our in-house metrology lab validates results using CMM and optical comparators, certifying conformance to ASME Y14.5 GD&T standards.

Honyo Prototype’s capability with 032 aluminum sheet metal extends beyond execution—it’s embedded in collaborative engineering. We partner with clients during DFM analysis to optimize bend sequences, recommend relief cuts for nested features, and simulate stress points using SolidWorks Simulation. This proactive approach reduces prototyping iterations by up to 40%, accelerating time-to-test while ensuring manufacturability at scale. When thin-gauge performance is non-negotiable, Honyo delivers engineered precision from blueprint to bench-ready component.

Technical Capabilities

Technical Capabilities: 0.032″ Aluminum Sheet Metal Fabrication

Shenzhen Honyo Prototype specializes in precision sheet metal fabrication for prototyping and low-volume production, with extensive capabilities in processing 0.032″ (0.813 mm) aluminum sheet stock. This thickness, commonly used in lightweight enclosures, brackets, and structural components, presents unique challenges and opportunities in laser cutting, bending, and welding. Our advanced manufacturing systems ensure consistent quality, tight tolerances, and high repeatability across all processes.

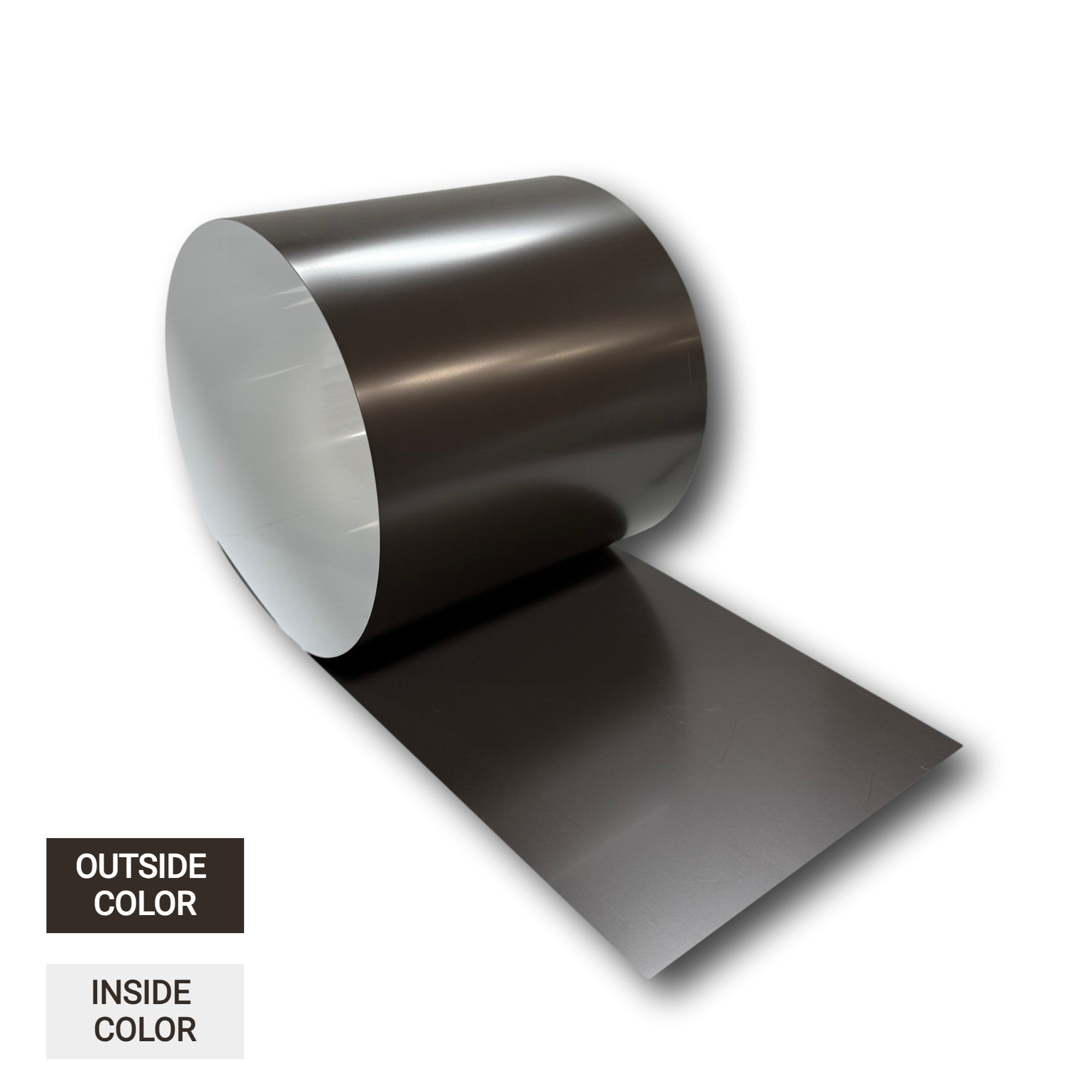

Laser cutting of 0.032″ aluminum is performed using high-precision fiber laser systems with a maximum cutting area of 1500 mm × 3000 mm. The thin gauge allows for clean, burr-free edges with minimal heat-affected zones when optimized parameters are applied. We utilize nitrogen-assisted cutting for oxide-free edges, ideal for parts requiring post-processing such as anodizing or painting. Edge squareness is maintained within ±0.1 mm across the cut profile, and feature positioning accuracy is held to ±0.05 mm.

Bending operations are executed on CNC press brakes equipped with precision-ground tools and automatic backgauging systems. Due to the thin section, springback is minimal in 5052 and 6061 aluminum alloys, allowing for accurate angular control. We recommend a minimum bend radius of 0.8 mm (1x material thickness) to prevent cracking or deformation at the bend line. Bend angles are controlled to ±0.5°, and part-to-feature location tolerance is maintained at ±0.1 mm. Specialized tooling is available for tight clearance bends and small flange geometries.

Welding of 0.032″ aluminum is performed using pulsed TIG and micro-laser welding techniques to minimize warpage and penetrate thin sections without burn-through. Pulsed TIG is ideal for short seams and structural joints, offering excellent control and weld bead aesthetics. Micro-laser welding is used for precision seams requiring minimal heat input and high cosmetic quality, particularly in visible enclosures. All welds are inspected per AWS D1.2 structural welding code for aluminum, with optional post-weld machining or grinding available.

We process the following aluminum alloys at 0.032″ thickness, each selected based on mechanical requirements, formability, and finish compatibility:

| Material | Typical Use | Formability | Weldability | Surface Finish Options |

|——–|————|————-|————-|————————|

| 5052-H32 | Enclosures, brackets | Excellent | Good | Bare, anodized, powder coat |

| 6061-T6 | Structural components | Moderate | Excellent | Anodized, chromate, paint |

| 3003-H14 | Non-structural panels | Excellent | Good | Painted, primed |

All fabricated components undergo first-article inspection and in-process quality checks to ensure compliance with engineering drawings and GD&T specifications. Shenzhen Honyo Prototype supports rapid turnaround for prototypes and scalable production runs, backed by full traceability and material certification.

From CAD to Part: The Process

Production Process: From CAD to Finished 032 Aluminum Sheet Metal Part

At Shenzhen Honyo Prototype, our manufacturing workflow for 032 aluminum sheet metal components ensures precision, efficiency, and adherence to client specifications from initial design through to final delivery. This structured process minimizes errors, optimizes cost, and guarantees part functionality. The journey begins immediately upon receipt of your CAD file and follows a rigorous three-stage sequence: AI-Powered Quoting, Comprehensive Design for Manufacturability (DFM) Analysis, and Controlled Production Execution.

The initial phase leverages our proprietary AI Quote System. Upon uploading your native CAD file (STEP, IGS, or native formats preferred), the system instantly analyzes geometric complexity, material requirements, and feature tolerances specific to 032 aluminum sheet. It calculates material yield through advanced nesting algorithms, estimates machine time for laser cutting, bending, and finishing operations, and factors in secondary processes. Crucially, it identifies potential high-cost drivers like excessive small features or tight tolerances early, providing an accurate, data-driven cost projection within minutes. This transparency allows for immediate design or specification adjustments before commitment.

Following quote acceptance, engineering rigor takes precedence during the mandatory DFM Analysis stage. Our senior manufacturing engineers conduct a detailed manual review, cross-referencing the AI findings with practical fabrication realities. We scrutinize bend allowances for 032 aluminum, verify minimum hole sizes and slot widths relative to material thickness, assess flange lengths for tool access, and evaluate hole-to-edge distances to prevent deformation. Critical attention is paid to grain direction implications for bending and potential springback compensation. Any identified manufacturability risks – such as features prone to burring, insufficient bend relief, or tolerance stacks exceeding process capability – are documented with specific, actionable recommendations provided directly to the client for collaborative resolution. This stage is non-negotiable for ensuring first-time-right production.

Only after DFM sign-off does Production Execution commence. Material procurement utilizes certified 6061-T6 aluminum sheet meeting strict thickness and flatness specifications. Components are nested optimally on the sheet using our CAM system, maximizing yield. Precision fiber laser cutting achieves clean edges with minimal heat-affected zone. CNC press brakes, programmed with material-specific springback compensation, form bends to the verified radii and angles. All formed parts undergo in-process inspection for critical dimensions and flatness. Final deburring and surface finishing (as specified: brushed, anodized, powder-coated) are applied. Rigorous first-article inspection against the approved drawing, including critical feature verification and material certification traceability, precedes full production run approval and shipment.

This integrated workflow, underpinned by AI efficiency and deep engineering expertise, guarantees that your 032 aluminum prototype transitions seamlessly from digital model to high-integrity physical part, meeting both functional requirements and project timelines.

| Critical Parameter | Specification for 032 Aluminum Sheet Metal |

| :————————– | :—————————————– |

| Material Grade | 6061-T6 (Standard) |

| Nominal Thickness | 0.32 mm (0.0126 inches) |

| Thickness Tolerance | ±0.05 mm |

| Min. Bend Radius | 0.32 mm (1x Material Thickness) |

| Min. Hole Diameter | 0.5 mm (for clean piercing) |

| Standard Surface Finish | Mill Finish (Deburred) |

| Key Process Capability | ±0.1 mm Linear Dimensional Tolerance |

Start Your Project

Start Your Project with High-Performance 032 Aluminum Sheet Metal

At Shenzhen Honyo Prototype, we specialize in precision sheet metal fabrication using high-grade materials tailored for demanding industrial and commercial applications. Our expertise with 032 aluminum sheet metal enables engineers, product designers, and OEMs to bring innovative concepts to life with confidence in material consistency, structural integrity, and manufacturability. Whether you’re developing enclosures, chassis components, heat shields, or custom brackets, starting your project with the right material is the first step toward success.

032 aluminum refers to a 0.032-inch thick aluminum sheet, typically fabricated from alloys such as 5052 or 6061, which are known for excellent corrosion resistance, weldability, and formability. This thickness strikes an ideal balance between rigidity and flexibility, making it suitable for applications requiring lightweight construction without sacrificing durability. At Honyo Prototype, we support low-volume prototyping and mid-volume production runs, ensuring seamless transition from design to delivery.

Our advanced fabrication capabilities include laser cutting, CNC bending, precision punching, and automated welding—all optimized for thin-gauge aluminum. We also offer comprehensive finishing services such as anodizing, powder coating, and brushed textures to meet both functional and aesthetic requirements. Every part is manufactured to strict quality standards, ensuring dimensional accuracy within ±0.005 inches and full compliance with customer-specified tolerances.

To ensure your project starts on solid ground, our engineering team provides Design for Manufacturability (DFM) feedback at no additional cost. We review your CAD files for bend allowances, grain direction, hole placement, and feature spacing to minimize material waste and reduce lead times. This proactive collaboration helps avoid costly revisions and accelerates time-to-market.

| Specification | Value |

|—————|——-|

| Material Type | Aluminum 5052-H32 or 6061-T6 |

| Sheet Thickness | 0.032 in (0.813 mm) |

| Tolerance | ±0.005 in (±0.127 mm) |

| Minimum Bend Radius | 1× material thickness |

| Max Part Size | 48 in × 96 in (1219 mm × 2438 mm) |

| Finishing Options | Anodizing, Powder Coating, Brushing, Passivation |

We understand that every project begins with a vision—and that vision deserves expert support from day one. If you’re working with 032 aluminum sheet metal or exploring its potential for your next design, connect with Susan Leo, our dedicated Client Engineering Manager. She will guide you through material selection, fabrication planning, and quoting to ensure your requirements are met with precision and efficiency.

Contact Susan Leo today at info@hy-proto.com to start your project. Include your design files or specifications, and our team will respond within 24 hours with a detailed quote and DFM report. At Shenzhen Honyo Prototype, we don’t just manufacture parts—we partner in innovation.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.