Contents

Manufacturing Insight: Best 5 Axis Cnc

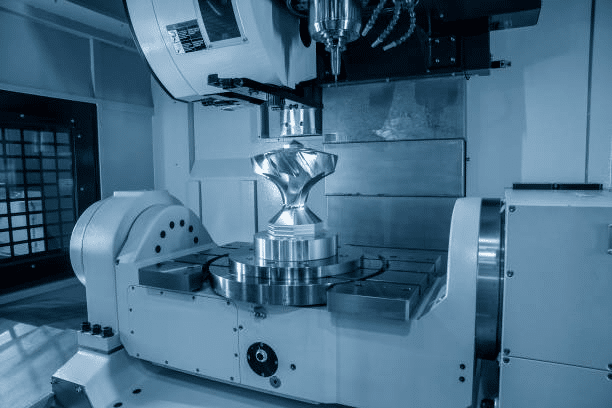

Mastering Geometric Complexity: 5-Axis CNC at Honyo Prototype

Five-axis CNC machining represents the pinnacle of precision manufacturing for complex, high-integrity components, particularly within demanding prototyping and low-volume production environments. Unlike traditional 3-axis systems constrained to movement along X, Y, and Z linear axes, 5-axis CNC integrates two additional rotational axes (typically A and B, rotating around X and Y). This simultaneous multi-directional capability allows the cutting tool to approach the workpiece from virtually any angle in a single, continuous operation. The critical advantage lies in eliminating the need for multiple manual setups. For intricate geometries—such as organic aerospace turbine blades, sculpted medical implants, or complex fluid dynamics housings—this translates directly into superior dimensional accuracy, exceptional surface finishes, significantly reduced lead times, and the ability to machine features previously requiring specialized, costly fixtures or even being deemed non-manufacturable. The technology inherently minimizes human intervention error and optimizes tool life through consistent optimal tool engagement angles.

Shenzhen Honyo Prototype leverages state-of-the-art 5-axis CNC platforms specifically selected for the rigorous demands of rapid prototyping and precision engineering validation. Our fleet prioritizes machines offering the optimal balance of rigidity, accuracy, and dynamic performance essential for producing functional prototypes that accurately reflect final production intent. Key machine specifications underpinning our capability include:

| Parameter | Specification Range | Significance for Prototyping |

| :—————– | :———————— | :———————————————– |

| Positioning Accuracy | ±0.003 mm (±0.0001″) | Ensures critical prototype dimensions meet tight engineering tolerances |

| Repeatability | ±0.002 mm (±0.00008″) | Guarantees consistency across multiple prototype iterations |

| Work Envelope (X) | Up to 1000 mm (39.4″) | Accommodates medium-sized complex assemblies |

| Spindle Speed | 24,000 RPM | Enables high-speed machining of hard materials with fine finishes |

| Materials Handled | Aluminum, Titanium, Inconel, Steel, Plastics, Composites | Supports diverse application requirements from aerospace to medical |

Honyo Prototype’s engineering team possesses deep expertise in programming and executing sophisticated 5-axis toolpaths using industry-leading CAM software. We specialize in transforming complex CAD models into optimized machining strategies that maximize efficiency while preserving critical surface integrity and geometric fidelity. Our process integrates rigorous in-process inspection using coordinate measuring machines (CMMs) and advanced probing systems directly on the machine tool, ensuring dimensional compliance is verified during the machining cycle, not just as a final check. This proactive quality control is paramount for prototypes intended for functional testing or regulatory submission.

By deploying advanced 5-axis technology within a disciplined manufacturing framework focused on precision and rapid iteration, Honyo Prototype empowers design engineers to confidently realize their most ambitious concepts. We transform complex digital designs into physically accurate, fully functional prototypes faster and with greater confidence in their performance characteristics, accelerating the critical path from concept validation to production readiness.

Technical Capabilities

Technical Capabilities: Advanced 5-Axis CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our precision 5-axis CNC machining services are engineered to deliver complex, high-integrity components with exceptional accuracy and surface finish. Our state-of-the-art machining centers support full 3-axis, 4-axis, and simultaneous 5-axis milling operations, enabling us to produce intricate geometries that are unattainable with conventional 3-axis systems. These capabilities are complemented by advanced CNC turning with live tooling, allowing for complete machining of rotational parts with secondary mill features in a single setup.

Our 5-axis CNC systems utilize high-speed spindles with RPMs up to 24,000, ensuring fine surface finishes and efficient material removal across a broad spectrum of engineering materials. The integration of rotary and tilting tables enables tool access from multiple angles, significantly reducing setup times and improving part accuracy by minimizing repositioning errors. This is particularly beneficial for aerospace, medical, and automation components that feature undercuts, deep cavities, or organic contours.

A cornerstone of our machining service is our commitment to tight-tolerance production. We consistently achieve tolerances down to ±0.005 mm (±0.0002″) for critical dimensions, with geometric tolerances maintained through continuous on-machine probing and post-process inspection using coordinate measuring machines (CMMs). Our quality control system is ISO 9001:2015 certified, ensuring full traceability and repeatability across production batches.

We support a wide range of materials, from standard aluminum and stainless steel to exotic alloys and engineering plastics. Each material is machined using optimized toolpaths, cutting parameters, and tooling strategies to prevent warping, maintain dimensional stability, and achieve the required surface integrity. Our in-house material verification and first-article inspection processes ensure compliance with customer-specified material standards.

The following table outlines our standard tolerance capabilities and supported materials for 3/4/5-axis CNC machining:

| Feature | Typical Tolerance | Notes |

|——–|——————-|——-|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Achievable on critical features |

| Hole Diameter | +0.005 / -0.000 mm | Reamed or precision bored |

| Positional Tolerance | ±0.010 mm (±0.0004″) | GD&T controlled |

| Surface Roughness (Ra) | 0.4 – 3.2 µm (16 – 125 µin) | Adjustable per requirement |

| Angular Accuracy | ±0.05° | Simultaneous 5-axis motion |

| Material Category | Examples | Machinability Notes |

|——————|———|——————–|

| Aluminum Alloys | 6061, 7075, 2024 | High speed, excellent finish |

| Stainless Steel | 303, 304, 316, 17-4 PH | Coolant-through tools, slow feeds |

| Carbon & Alloy Steel | 4140, 4340 | Stress-relieved pre-machining |

| Titanium Alloys | Ti-6Al-4V (Grade 5) | Low RPM, high torque, strict chip control |

| Engineering Plastics | PEEK, Delrin, Nylon | Non-stick tooling, low heat buildup |

| Exotic Alloys | Inconel 718, Monel, Hastelloy | Specialized tooling and programming |

Our technical team works closely with design and engineering partners to optimize part manufacturability, reduce lead times, and ensure compliance with functional and inspection requirements. Whether producing one-off prototypes or low-volume production runs, Honyo Prototype delivers precision, reliability, and technical excellence across every 5-axis CNC project.

From CAD to Part: The Process

From CAD to Precision Part: Honyo Prototype’s 5-Axis CNC Production Workflow

At Shenzhen Honyo Prototype, our advanced 5-axis CNC machining services deliver complex, high-precision components efficiently. Our rigorously defined workflow ensures optimal manufacturability, quality, and speed from initial design to final part delivery, leveraging integrated digital systems throughout the process.

The journey begins with the AI-Powered Quoting Engine. Upon receiving your CAD model, our proprietary AI system performs an instant, multi-faceted analysis. It assesses geometric complexity, identifies potential undercuts or challenging features, estimates machine time based on toolpath simulation, and evaluates material utilization. This deep analysis generates a highly accurate, data-driven quote within hours, not days, providing immediate cost and timeline visibility while flagging any initial red flags requiring client consultation before proceeding.

Following quote acceptance, the project enters the critical Design for Manufacturability (DFM) Review phase. Our senior manufacturing engineers conduct a hands-on evaluation of the CAD data, focusing specifically on optimizing the design for efficient 5-axis machining. We scrutinize wall thicknesses, internal radii, feature accessibility, and tolerance stack-ups. Crucially, we assess opportunities to minimize setups by leveraging the simultaneous 5-axis motion capabilities, potentially eliminating secondary operations. This collaborative stage often involves direct dialogue with the client to suggest refinements that maintain functional intent while significantly reducing cost, lead time, and risk of machining errors. Approved DFM feedback is formally documented before programming commences.

Production Execution utilizes state-of-the-art 5-axis CNC centers under strict process control. Based on the finalized DFM-approved design, our programmers generate optimized toolpaths using Mastercam and Siemens NX, fully exploiting continuous 5-axis interpolation for complex contours and deep cavities. Machine setup employs precision modular fixturing and rigorous workpiece alignment via Renishaw probes. Production runs incorporate in-process inspections at critical stages using on-machine probing and dedicated CMM verification against the original CAD model, ensuring dimensional accuracy and surface finish meet stringent tolerances. Material waste is minimized through efficient nesting and adaptive clearing strategies. Final parts undergo comprehensive first-article inspection and full dimensional reporting before shipment.

The technical capabilities enabling this workflow are defined by our core machine specifications:

| Parameter | Specification | Relevance to Production |

| :——————— | :——————————– | :—————————————— |

| Axis Configuration | Simultaneous 5-Axis (XYZABC) | Enables single-setup machining of complex geometries |

| Typical Travel Range | 800 x 600 x 500 mm (X,Y,Z) | Accommodates medium to large aerospace/medical components |

| Spindle Speed | 24,000 RPM | Supports high-speed machining of hard alloys and composites |

| Positioning Accuracy | ±0.003 mm | Ensures tight tolerance compliance on critical features |

| Repeatability | ±0.0015 mm | Guarantees consistent part quality across batches |

| Control System | Siemens 840D sl / Heidenhain TNC | Provides robust platform for complex 5-axis toolpath execution |

This integrated CAD-to-Part workflow, underpinned by AI efficiency, expert DFM insight, and precision 5-axis execution, allows Honyo Prototype to transform the most demanding designs into high-integrity components with exceptional reliability and reduced time-to-market for our B2B partners.

Start Your Project

Start Your Next Precision Project with Honyo’s 5-Axis CNC Machining Expertise

At Shenzhen Honyo Prototype, we specialize in delivering high-precision, complex components through advanced 5-axis CNC machining. Whether you’re developing aerospace components, medical devices, or industrial prototypes, our state-of-the-art manufacturing capabilities ensure superior accuracy, faster turnaround, and repeatable quality. If you’re ready to bring your most challenging designs to life, now is the time to partner with a team that combines technical excellence with responsive service.

Our 5-axis CNC technology allows for simultaneous movement across five axes, enabling the machining of intricate geometries in a single setup. This reduces human error, improves surface finish, and significantly cuts down production time—critical advantages when prototyping or scaling to low-volume production. With a focus on materials ranging from aluminum and titanium to high-performance plastics and hardened steels, we support diverse engineering requirements without compromising on tolerances or consistency.

We understand that every project begins with a vision. That’s why our engineering team collaborates closely with clients from the initial design review phase, offering DFM (Design for Manufacturability) feedback to optimize part geometry, material selection, and toolpath strategy. This proactive approach ensures manufacturability, cost-efficiency, and performance—all before a single chip is cut.

To get started, simply reach out to Susan Leo, our dedicated manufacturing coordinator. With over 12 years of experience in precision CNC operations, Susan serves as your direct point of contact to guide you through the quoting process, material sourcing, and production scheduling. Her technical insight and client-focused approach ensure your project moves seamlessly from CAD model to finished part with minimal friction.

Share your 3D model or technical drawing, and we’ll provide a detailed quote within 24 hours, including lead time, material options, surface treatments, and any recommended design adjustments. Whether you need a single prototype or batch production up to 500 units, Honyo Prototype is equipped to support your timeline and quality standards.

Below are the core specifications of our 5-axis CNC machining capabilities:

| Specification | Detail |

|————–|——–|

| Machine Types | DMG MORI, Hermle, and Makino 5-axis vertical machining centers |

| Axis Configuration | 3 linear (X, Y, Z) + 2 rotary (A, C) for full 5-axis simultaneous machining |

| Maximum Work Envelope | 1,200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Material Compatibility | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Grade 5), Brass, PEEK, PC, POM, and more |

| Typical Tolerances | ±0.01 mm (standard), down to ±0.005 mm (tight-tolerance features) |

| Surface Finish | As low as Ra 0.4 µm (polished), standard Ra 3.2 µm |

| Secondary Operations | Deburring, anodizing, powder coating, passivation, laser engraving |

Don’t let design complexity slow down your innovation. Contact Susan Leo today at info@hy-proto.com to start your project with Honyo Prototype—where precision meets performance in 5-axis CNC machining.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.