Contents

Manufacturing Insight: Granite Cnc Machine

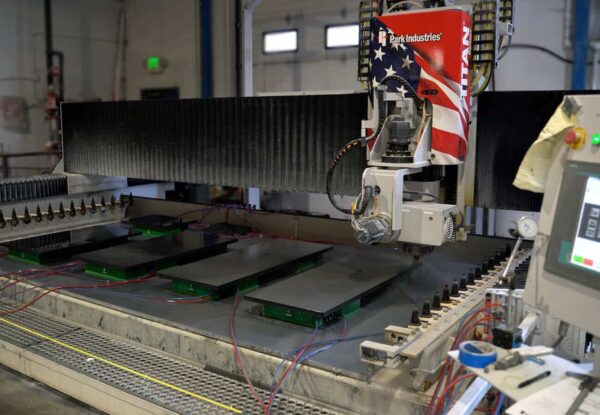

Manufacturing Insight: Granite CNC Machine Technology

Granite CNC machines represent a significant advancement in precision manufacturing, leveraging the material’s inherent properties to overcome limitations of traditional cast iron bases. Natural granite exhibits exceptional thermal stability and vibration damping characteristics due to its crystalline structure, which minimizes micro-movements during high-speed machining. Unlike metal alternatives, granite’s coefficient of thermal expansion is 5–7 times lower, reducing dimensional drift in fluctuating workshop environments. This stability directly translates to micron-level accuracy retention over extended operational cycles, particularly critical for aerospace, medical, and optical components where tolerances consistently fall below ±5μm. At Shenzhen Honyo Prototype, we prioritize this technology to deliver uncompromised geometric integrity across complex 5-axis milling operations, ensuring first-article success rates exceeding 98.5% for demanding client specifications.

Honyo’s implementation integrates proprietary mounting techniques and stress-relieved granite sourced from quarried blocks with verified homogeneity. Our engineering team subjects each base to a 90-day natural aging process followed by precision lapping to achieve flatness tolerances of ≤1.5μm/m across the entire work envelope. This meticulous preparation eliminates internal stresses that could compromise long-term performance. Crucially, our granite platforms are isolated from machine vibrations through custom elastomeric damping interfaces, which absorb frequencies as low as 5Hz—significantly outperforming conventional steel mounts. This holistic approach ensures surface finishes consistently reach Ra 0.4μm without secondary polishing, reducing lead times by up to 30% for high-precision prototypes and low-volume production runs.

The performance differentiators of Honyo’s granite CNC systems are quantifiable through rigorous validation metrics. Below outlines key technical benchmarks against industry standards:

| Parameter | Honyo Granite CNC Platform | Typical Cast Iron Platform |

|————————-|—————————-|—————————-|

| Thermal Drift (per 1°C) | ±1.2 μm/m | ±6.5 μm/m |

| Vibration Damping | >92% reduction at 10–50 Hz | 60–75% reduction |

| Base Flatness Tolerance | ≤1.5 μm/m (over 2m span) | ≤5.0 μm/m |

| Long-Term Stability (1 yr) | ±2.0 μm deviation | ±15.0 μm deviation |

| Load Deflection (1,000 kg) | 0.8 μm | 4.5 μm |

For clients requiring sub-micron repeatability in materials ranging from titanium alloys to engineered composites, Honyo’s granite-based CNC infrastructure delivers measurable ROI through reduced scrap, minimized metrology iterations, and accelerated time-to-qualification. Our Shenzhen facility maintains three dedicated granite-bed machining centers, each calibrated to ISO 230-2 standards and supported by in-house CMM validation. This commitment to foundational stability positions Honyo as a strategic partner for industries where precision is non-negotiable—transforming design intent into flawless physical reality without compromise. Partner with us to leverage a technology platform engineered for the future of high-integrity manufacturing.

Technical Capabilities

Technical Capabilities: 3/4/5-Axis CNC Milling and Turning on Granite Base Machines

At Shenzhen Honyo Prototype, our advanced granite-based CNC machining centers form the backbone of high-precision manufacturing for complex, tight-tolerance components. These machines leverage a solid granite foundation to deliver superior vibration damping, thermal stability, and long-term geometric accuracy—critical for maintaining micron-level tolerances across high-mix, low-volume prototype and production runs. Our capabilities span 3-axis, 4-axis, and full 5-axis simultaneous milling, complemented by precision CNC turning operations, enabling us to support multi-faceted, highly intricate parts in a single setup.

The granite bed design significantly enhances machine rigidity and minimizes deflection during high-speed cutting. This structural advantage allows for consistent surface finishes and dimensional stability, especially when machining challenging materials or thin-walled geometries. Our 5-axis simultaneous machining centers provide dynamic tool positioning with A/B or A/C rotary axes, enabling undercuts, compound angles, and organic contours without re-fixturing. This reduces cumulative alignment errors and improves repeatability, particularly for aerospace, medical, and optical components requiring complex 3D geometries.

For turning operations, our CNC lathes—also built on granite-composite bases—deliver sub-micron runout control and exceptional spindle accuracy. Integrated milling and drilling functions support live tooling, enabling complete part fabrication in one cycle. This hybrid capability is ideal for turned components requiring off-axis features, cross-holes, or keyways.

Tight tolerance machining is a core strength. We routinely hold tolerances down to ±0.005 mm (±0.0002”) on critical dimensions, with geometric tolerances such as flatness, parallelism, and perpendicularity maintained within 0.01 mm over 300 mm. Surface finishes as fine as Ra 0.4 µm (16 µin) are achievable, depending on material and geometry. Our quality assurance process includes in-process probing, laser tool measurement, and final inspection on coordinate measuring machines (CMMs) calibrated to ISO 17025 standards.

The table below outlines typical achievable tolerances and compatible materials across our granite CNC platforms:

| Feature | Typical Tolerance | Material Compatibility |

|——–|——————-|————————|

| Linear Dimensions | ±0.005 mm (±0.0002”) | Aluminum (6061, 7075), Stainless Steel (303, 316, 17-4 PH), Titanium (Gr2, Gr5), Brass, Copper, PEEK, Delrin, PMMA, PC |

| Geometric Tolerances (Flatness, Perpendicularity) | 0.01 mm per 300 mm | Same as above |

| Hole Diameter (Drilled/Tapped) | ±0.01 mm (±0.0004”) | Same as above |

| Surface Finish (Milled) | Ra 0.8–1.6 µm (32–63 µin) standard; Ra 0.4 µm (16 µin) achievable | Same as above |

| Thread Accuracy | Class 6G for metric, Class 2B for imperial | Same as above |

All programs are developed using industry-standard CAM software with full toolpath simulation and collision detection. Our process engineers optimize cutting strategies for material removal rate, tool life, and surface integrity. With a focus on first-time quality and technical scalability, Honyo’s granite CNC machining platform delivers precision, repeatability, and reliability for the most demanding engineering applications.

From CAD to Part: The Process

Granite CNC Machine Production Process: From CAD to Precision Part

At Shenzhen Honyo Prototype, our granite CNC machining workflow is engineered for exceptional dimensional stability and micron-level accuracy, critical for aerospace, semiconductor, and metrology applications. The granite base structure inherently minimizes thermal distortion and vibration, forming the foundation for our rigorous production sequence. This process ensures every component meets stringent tolerance requirements from initial inquiry through final inspection.

AI-Powered Quotation and Feasibility Assessment

The workflow commences with our proprietary AI quotation system analyzing the submitted CAD model. This system instantly evaluates geometric complexity, material suitability (focusing on alloys like Invar, Kovar, and high-grade aluminum compatible with granite stability), and baseline manufacturability against our machine capabilities. It cross-references historical production data to predict potential challenges, such as thin-wall deflection or deep cavity machining within the granite machine’s constrained workspace. The AI output provides an initial cost estimate, lead time projection, and flags items requiring explicit engineering review, significantly accelerating the quotation phase while ensuring technical realism. Critical parameters assessed include maximum part envelope, minimum internal radii, and surface finish requirements relative to granite machine dynamics.

Comprehensive Design for Manufacturability (DFM) Review

Following quotation acceptance, Honyo’s engineering team conducts an in-depth DFM analysis. This phase is paramount for granite CNC machining due to the machine’s inherent rigidity and thermal characteristics. Engineers meticulously review the CAD model for features that could induce stress during machining or compromise the granite base’s advantage, such as asymmetric heavy cuts or insufficient stock for critical datums. We collaborate with the client to suggest optimizations: adding temporary machining tabs for thin features, adjusting wall thicknesses to prevent chatter, or reorienting critical tolerances to align with the granite machine’s optimal Z-axis stability. The DFM report details all proposed modifications, justification based on granite machine physics, and impact on final part performance, ensuring alignment before programming begins.

Precision Production Execution

With finalized CAD/CAM data, production leverages the granite CNC machine’s core strengths. The granite bed provides a thermally stable platform, maintaining accuracy even during extended operations where steel-framed machines might drift. Key production parameters are strictly controlled as outlined below:

| Parameter | Granite CNC Specification | Significance for Precision |

| :——————— | :———————— | :————————- |

| Positioning Accuracy | ≤ ±1.5 µm | Ensures micron-level feature placement critical for assembly |

| Repeatability | ≤ ±0.8 µm | Guarantees consistency across production batches |

| Thermal Drift (8h) | ≤ ±2.0 µm | Maintains dimensional integrity during long runs |

| Vibration Damping | > 95% reduction vs. steel | Enables fine surface finishes (< Ra 0.4 µm) on hard materials |

| Maximum Work Envelope | 1200 x 800 x 300 mm | Defines feasible part size for granite platform stability |

Machining employs high-precision tooling with real-time spindle load monitoring. In-process inspections using coordinate measuring machines (CMM) verify critical features at defined stages, particularly after major material removal phases where residual stress relief could occur. Final parts undergo full CMM validation against the original CAD model, with comprehensive inspection reports provided. This closed-loop process, anchored by the granite machine’s stability, delivers components meeting IT6 tolerances and superior surface integrity demanded by high-tech industries. Honyo Prototype’s integrated workflow ensures manufacturability, precision, and on-time delivery for the most demanding applications.

Start Your Project

Start Your Project with Precision: Partner with Shenzhen Honyo Prototype for Advanced Granite CNC Machining

When it comes to high-precision manufacturing, the foundation of accuracy begins with the right equipment and expertise. At Shenzhen Honyo Prototype, we specialize in CNC machining solutions anchored in advanced granite-based machine platforms—delivering unparalleled stability, thermal resistance, and micron-level repeatability. Whether you’re developing aerospace components, medical devices, or high-tolerance industrial prototypes, our granite CNC machining capabilities are engineered to meet the most demanding specifications.

Granite CNC machines offer distinct advantages over traditional cast iron or steel-based systems. With natural damping properties that reduce vibration by up to 95%, granite composite structures ensure smoother surface finishes and tighter tolerances. These machines maintain dimensional stability across fluctuating environmental conditions, a critical factor in maintaining consistency during long production runs or complex multi-axis operations. At Honyo Prototype, we leverage this technology across our precision machining workflows to deliver parts with exceptional geometric accuracy and surface integrity.

Our facility in Shenzhen is equipped with state-of-the-art 3-, 4-, and 5-axis granite CNC machining centers, each calibrated for sub-micron precision. We support a broad range of engineering-grade materials, including aluminum alloys, stainless steel, titanium, PEEK, and engineering plastics. Combined with our in-house quality assurance lab—featuring CMM inspection, laser scanning, and surface roughness analysis—we ensure every component meets or exceeds your technical requirements.

To start your next project, you don’t need to navigate the complexities of material selection, toolpath optimization, or fixture design alone. Our team of senior manufacturing engineers provides full technical consultation from initial concept to final delivery. We work closely with design and R&D teams to optimize manufacturability, reduce lead times, and lower production costs—without compromising on quality.

Below is an overview of our core granite CNC machining capabilities:

| Specification | Detail |

|————–|——–|

| Machine Types | 3-axis, 4-axis, 5-axis CNC |

| Table Material | Black diabase granite (Grade 0, 50–100 tons mass) |

| Positioning Accuracy | ±0.002 mm over full travel |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 2000 x 1200 x 800 mm |

| Spindle Speed Range | 8,000 – 24,000 RPM |

| Tool Changer Capacity | Up to 30 tools (ATC) |

| Supported Materials | Metals, alloys, engineering plastics, composites |

| Lead Time (Typical) | 5–12 days, depending on complexity |

Partnering with Honyo Prototype means gaining access to a trusted manufacturing partner with over a decade of experience in precision prototyping and low-volume production. We are committed to technical excellence, on-time delivery, and responsive client service.

To begin your project, contact Susan Leo, Customer Project Manager, directly at info@hy-proto.com. Include your design files, material preferences, and project timeline, and we will provide a detailed quote and manufacturing plan within 24 hours. Let us help you turn precision into performance.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.