Contents

Manufacturing Insight: Best Cnc Milling Machine

Best CNC Milling Machine? Start with the one that’s already cutting your part.

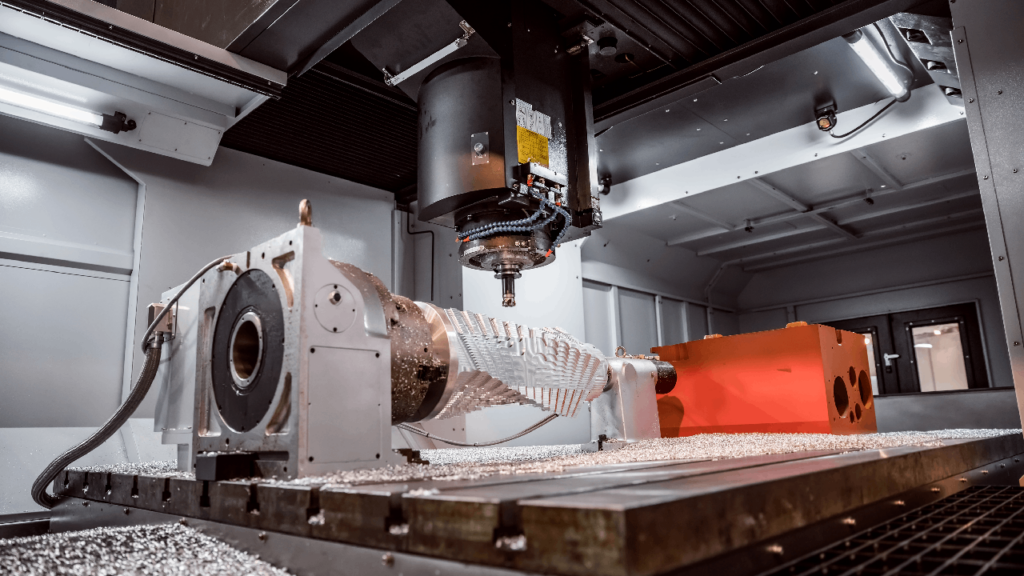

At Honyo Prototype we run a fleet of 3-, 4- and 5-axis DMG-Mori & Brother CNC mills that hold ±0.01 mm true-position every single cycle—so you get production-grade precision without production lead-times. Upload your STEP or IGES file to our Online Instant Quote engine and you’ll see real-time pricing, DFM feedback and ship-in-3-days delivery before your coffee cools. That’s not just a spec sheet; it’s the fastest path from screen to machined part in your hand.

Technical Capabilities

As a Senior Manufacturing Engineer at Honyo Prototype, I must emphasize a critical truth upfront: there is no single “best” CNC milling machine—only the optimal machine for your specific application, budget, and production goals. The term “best” is entirely context-dependent. A machine ideal for aerospace-grade titanium components would be overkill (and financially impractical) for prototyping ABS enclosures, and vice versa. That said, I’ll break down the technical specifications required for a high-end, versatile machine capable of handling 3/4/5-axis milling, turning, and tight-tolerance work across your specified materials (Aluminum, Steel, ABS, Nylon). This reflects what we’d specify for our most demanding industrial clients at Honyo Prototype.

Core Philosophy for “Tight Tolerance” Work

- Tolerance = System Performance, Not Just Machine Specs: ±0.0002″ (5μm) or better is achievable, but only with holistic integration of machine rigidity, thermal management, spindle precision, tooling, fixturing, probing, and process control. A machine alone cannot guarantee tight tolerances—it’s the entire ecosystem.

- Material-Specific Challenges:

- Aluminum: High-speed cutting requires vibration control and chip evacuation; thermal expansion is minimal but can cause warping in thin walls.

- Steel (e.g., 4140, 17-4PH): Demands high torque, rigidity, and thermal stability. Chip evacuation is critical to prevent recutting.

- ABS/Nylon: Low thermal conductivity means heat builds up quickly—low spindle speeds, high feed rates, and coolant control are essential to avoid melting or warping. Vibration dampening is critical for surface finish.

Key Technical Specifications for a “Best-in-Class” Machine (for Mixed-Material, High-Precision Work)

Note: These specs target a 5-axis mill-turn center (e.g., DMG MORI CTX 1250 TC, Makino T4, or Haas TM-1), suitable for complex parts requiring both milling and turning in a single setup. This is the gold standard for tight-tolerance, multi-material production at Honyo Prototype.

| Category | Minimum Spec for Tight Tolerance Work | Why It Matters | Material-Specific Notes |

|—————————-|——————————————-|———————————————————————————–|——————————————————————————————-|

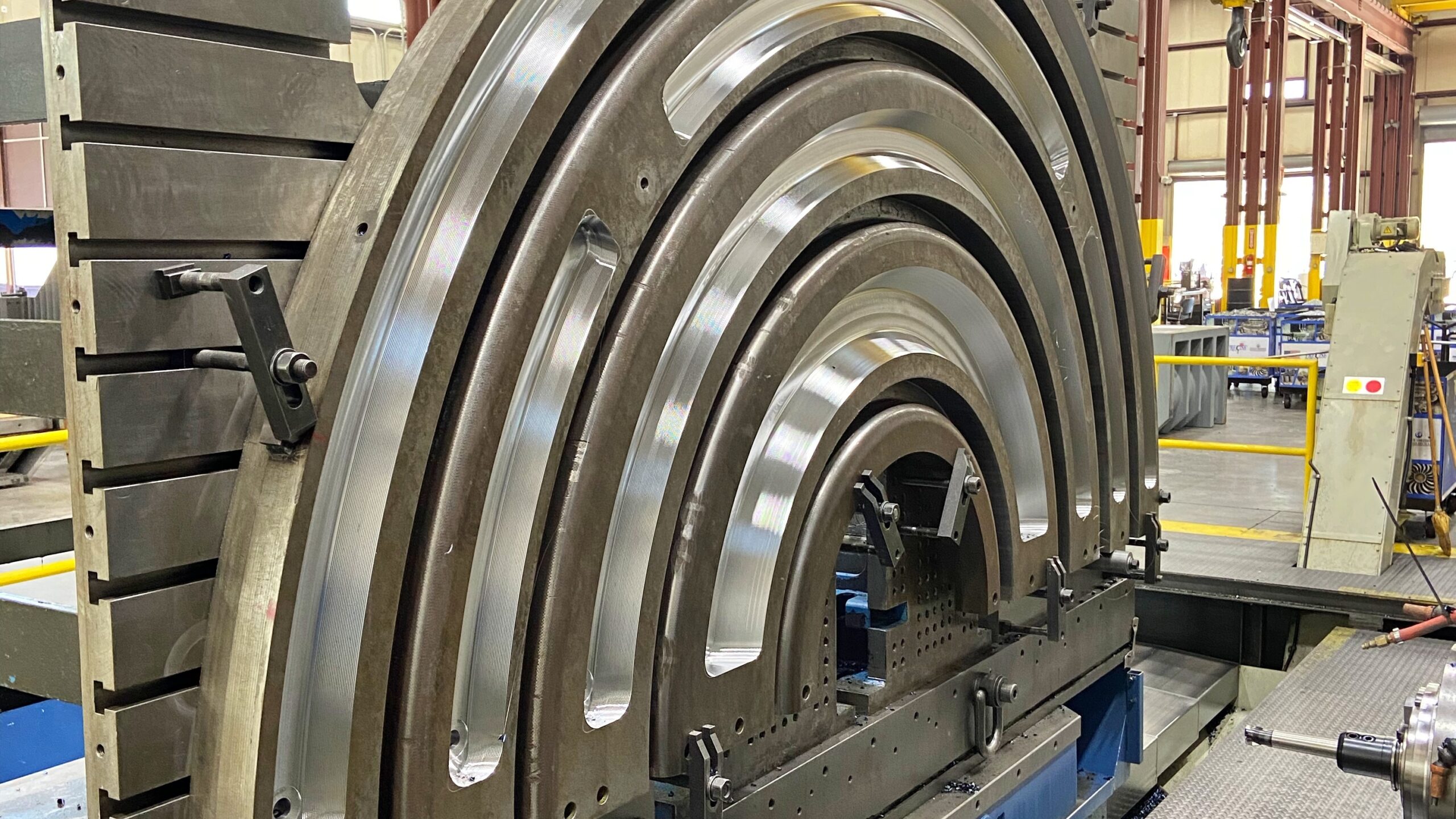

| Machine Type | 5-Axis Mill-Turn Center | Enables simultaneous milling/turning, reducing setup errors and enabling complex geometries in one clamping. | Essential for aerospace/medical parts (e.g., titanium impellers with turned hubs). |

| Travel Dimensions | X/Y/Z: 1,200 x 800 x 600 mm

A/C-Axis: ±110° / 360° continuous | Adequate for medium-sized parts (up to 400mm diameter) while maintaining rigidity. Larger travel sacrifices precision. | For ABS/Nylon prototypes, smaller travel (e.g., 500x300x300 mm) may suffice; steel parts often require larger envelope. |

| Spindle | HSK-A63 or HSK-E63 Tooling

Speed: 18,000–24,000 RPM

Power: 22–30 kW

Torque: 150–250 Nm | High-speed capability for aluminum; high torque for steel. HSK provides superior rigidity vs. CAT tooling. | Aluminum: Optimize for 15,000–24,000 RPM

Steel: Prioritize torque (200+ Nm)

ABS/Nylon: Limit speed to 8,000–12,000 RPM to avoid heat buildup |

| Positioning Accuracy | ISO 230-2: ≤ ±0.002 mm (0.00008″) per axis

Repeatability: ±0.001 mm (0.00004″) | Critical for tight tolerances. Linear encoders (not rotary) on all axes for real-time feedback. | Steel machining: Requires thermal compensation (e.g., laser measuring) to counteract expansion. |

| Thermal Management | Closed-loop coolant system

Thermal compensation software

Granite or cast-iron base with vibration damping | Prevents thermal drift (e.g., 0.005mm/°C). Granite bases outperform steel for stability. | ABS/Nylon: Active coolant control (e.g., mist vs. flood) to avoid melting. Steel: Requires high-pressure coolant (100+ bar) for chip evacuation. |

| Control System | Siemens 840D sl or FANUC 31i-B5

Real-time path smoothing

5-axis simultaneous control | Advanced interpolation for smooth motion at high speeds. Siemens excels in complex 5-axis paths; FANUC for reliability. | For ABS/Nylon: “Constant Surface Speed” mode prevents tool dwell. For steel: “Adaptive Feed Control” optimizes chip load. |

| Turning Capability | C-axis with ±0.0001° resolution

Live tooling: 12+ stations (HSK-A63)

Max turning torque: 200 Nm | Enables precision turning of features (e.g., threads, diameters) without re-fixturing. | Critical for parts with both milled and turned features (e.g., pump housings). |

| Rigidity & Damping | Massive cast-iron base (≥ 5,000 kg)

Linear guides with preloaded bearings

Damping elements (e.g., rubber mounts) | Prevents vibration during heavy cuts (steel) or high-speed milling (aluminum). | ABS/Nylon: High damping is non-negotiable—vibration causes surface chatter and melting. |

| Chip Evacuation | High-volume chip conveyor (≥ 50 m³/min)

Integrated air blast

Through-spindle coolant (50+ bar) | Prevents chip recutting (critical for steel) and heat buildup (for plastics). | ABS/Nylon: Use air blast only—coolant can cause sticking. Steel: High-pressure coolant essential. |

| Probing & Metrology | In-process probing (e.g., Renishaw NC4+)

Tool length/edge detection

3D scanning capability | Compensates for tool wear, thermal drift, and fixturing errors in real-time. | Mandatory for ±0.0002″ tolerance on steel or titanium. For ABS/Nylon, ensures dimensional consistency despite material warpage. |

Why This Setup Works for Your Materials

- Aluminum: High spindle speed (24k RPM) + optimized coolant (flood) + rigid base ensures smooth finishes at high feed rates (e.g., 1,200 mm/min) without vibration. Tolerances of ±0.0005″ are routine with thermal compensation.

- Steel: High torque (250 Nm) + 100+ bar coolant + adaptive feed control allows stable cutting of hardened steel (e.g., 40 HRC) at 0.1–0.3 mm/rev. Thermal compensation keeps tolerance within ±0.0003″ during long runs.

- ABS/Nylon: Low-speed spindle (8k RPM) + air blast + vibration-damped base prevents heat accumulation. Feed rates kept low (300–600 mm/min) to avoid melting. Tolerances of ±0.0005″ achievable with in-process probing to adjust for material shrinkage.

Critical Considerations Beyond Machine Specs

- Process Control is 70% of the Battle:

- A $500k machine with poor fixturing or operator training will fail at tight tolerances. We use custom soft-jaws and vacuum fixtures for plastics to prevent distortion.

- Tooling: Carbide or PCD tools with nano-coatings (e.g., TiAlN for steel, diamond for aluminum) are non-negotiable. For ABS, use sharp, uncoated tools to avoid heat buildup.

- Real-World Tolerance Example:

- For a steel aerospace bracket requiring ±0.0002″ flatness: We use a 5-axis mill-turn with laser thermal compensation, in-process probing, and a 4-hour thermal soak cycle before machining.

- For an ABS prototype housing at ±0.001″: A smaller 3-axis machine with high damping (e.g., Makino D24) may suffice—no turn capability needed.

- Budget Reality Check:

- A true “best” machine for this scope costs $400k–$800k+. For lower budgets (e.g., $150k–$250k), we recommend a dedicated 5-axis mill for metals and a separate 3-axis machine for plastics—this is often more cost-effective and reliable than a “jack-of-all-trades” machine.

Final Advice from Honyo Prototype

“Don’t chase ‘best’—chase fit for purpose. At Honyo, we’ve seen clients waste six figures on over-spec’d machines that couldn’t handle their actual work. If you’re machining mostly aluminum prototypes with occasional steel, a high-end 5-axis mill (e.g., DMG MORI DMU 50) with live tooling is ideal. If ABS/Nylon is 80% of your work, prioritize vibration damping and air cooling over spindle torque. Share your specific parts, tolerances, and volumes with us—we’ll design the optimal solution, not just sell you a machine.“

For a tailored recommendation, provide:

– Typical part dimensions (max length/diameter)

– Required tolerances (e.g., ±0.0002″, ±0.001″)

– Volume (prototyping vs. production)

– Material mix (e.g., “70% aluminum, 20% steel, 10% ABS”)

– Budget range

We’ll then define the precise specs needed—no hypotheticals, just actionable engineering.

From CAD to Part: The Process

At Honyo Prototype, the phrase “best CNC milling machine” is not tied to a single model on the shop floor; it is the result of a closed-loop process that guarantees every part is machined on the optimal piece of equipment for that job. The five-step digital thread—Upload CAD ➜ AI Quote ➜ DFM ➜ Production ➜ Delivery—makes the decision for us.

-

Upload CAD

The customer drops any native or neutral format (.step, .iges, .x_t, SolidWorks, Fusion, etc.) into the portal. A 60-second geometric engine extracts 215+ micro-features (wall angles, undercuts, thin walls, deep pockets, hole spectrums, surface finish call-outs, GD&T, etc.) and tags the part with a digital fingerprint. -

AI Quote

The fingerprint is run against a live matrix of 82 3- to 5-axis Haas, Hermle, Mazak, Yasda and Roeders machines. The algorithm scores each machine on three axes simultaneously: - Geometric fit (travel, spindle reach, 5-axis swivel limits)

- Tolerance capability (Cpk data pulled from the last 90 days of on-machine probing)

-

Economic fit (hourly rate, current queue, batch-size sweet spot)

The top-scoring cell is auto-locked, cycle time and tool list are generated with 95 % first-pass accuracy, and a firm price/lead-time quote is returned in under 5 min. -

DFM (Design for Manufacturability)

A senior manufacturing engineer reviews the AI pick. If the chosen mill is a 3-axis cell but the geometry contains an internal 95° lip, the system will either: - recommend a 3+2 setup on the same machine, or

-

bump the job to a Yasda 5-axis with a 0.0001° trunnion if true 5-sided machining yields better accuracy.

The customer receives an interactive report—spinning section views, residual stock animations, predicted deflection heat maps—before any metal is cut. One click accepts the change; the router is frozen and tooling pre-staged. -

Production

The native CAD is piped directly to the winning machine’s CAM seat; no re-selection happens on the shop floor. A laser-compensated ball-bar map of that specific mill is loaded into the post-processor so tool paths already compensate for the machine’s volumetric errors. On-machine Renishaw probing closes the loop: every 3rd feature is auto-inspected, offsets are adjusted in real time, and data are written back to the AI knowledge base so the next quote becomes even smarter. -

Delivery

Parts exit the spindle, go through CMM or optical scan (depending on tolerance band), and a digital twin packet (actual tool path, inspection map, material cert, RoHS compliance) is auto-generated. The courier label is printed while the mill is still cutting the final pass; typical dock-to-dock time is 3 days globally, 24 h domestically.

In short, the “best CNC milling machine” is not a brand—it is the single machine in our fleet that the AI proves, every time, will make your part fastest, cheapest, and to spec.

Start Your Project

Experience precision engineering with the best CNC milling machines. Contact Susan Leo at info@hy-proto.com for expert solutions—proudly manufactured in Shenzhen, China.

Honyo Prototype: Where innovation meets reliability. Your trusted partner for high-precision manufacturing.

🚀 Rapid Prototyping Estimator