Contents

Manufacturing Insight: Best Cnc Milling Machine

Manufacturing Insight: Optimizing CNC Milling for Precision Prototyping

In high-stakes prototyping and low-volume production, selecting the right CNC milling technology is not merely a procurement decision—it directly impacts time-to-market, functional validation, and cost efficiency. CNC milling remains the cornerstone of precision metal and plastic part fabrication, leveraging computer-controlled rotary cutters to remove material from a workpiece with exceptional accuracy. Modern multi-axis systems (3-axis, 4-axis, and 5-axis) enable the creation of complex geometries impossible with manual machining, while advanced toolpath strategies minimize cycle times and maximize surface finish quality. For engineering teams demanding rapid iteration without compromising on dimensional integrity, the integration of high-performance milling centers with rigorous process control is non-negotiable.

At Shenzhen Honyo Prototype, we deploy a strategic fleet of industrial-grade CNC milling machines engineered specifically for the demanding requirements of functional prototyping and bridge production. Our approach transcends raw machine capability; it integrates machine performance with deep process expertise, metrology validation, and agile workflow management. We prioritize systems offering superior thermal stability, sub-micron positioning repeatability, and high-torque spindles capable of maintaining precision across diverse materials—from aerospace-grade aluminum and titanium to engineering plastics like PEEK and polycarbonate. This ensures consistent part accuracy even during extended machining runs essential for prototype batches. Crucially, our machines are maintained under strict calibration schedules per ISO 9001 standards, and every process parameter is documented and traceable.

The following table outlines the core specifications of our primary production milling platforms, reflecting our commitment to balancing speed, precision, and versatility for prototyping applications:

| Parameter | 3-Axis Vertical Machining Centers | 5-Axis Simultaneous Milling Centers |

|——————–|———————————–|————————————-|

| Positioning Accuracy | ±0.003 mm | ±0.005 mm |

| Repeatability | ±0.002 mm | ±0.003 mm |

| Spindle Speed | 24,000 RPM | 18,000 RPM |

| Rapid Traverse | 42 m/min | 36 m/min |

| Max Work Envelope | 800 x 500 x 500 mm | 600 x 500 x 400 mm |

| Typical Tolerance | ±0.01 mm | ±0.01 mm (complex features) |

| Material Focus | Aluminum, Steel, Plastics | Titanium, Inconel, High-temp Plastics |

These specifications translate directly into client value. Our 3-axis platforms deliver exceptional turnaround for high-volume prototype components requiring tight tolerances, while the 5-axis systems eliminate costly fixturing by accessing complex features in a single setup—critical for validating intricate fluid dynamics or structural components. Advanced probing systems integrated into all machines enable in-process measurement, reducing scrap and ensuring first-article quality. Combined with our proprietary adaptive machining strategies and 24/7 production capability, Honyo consistently achieves industry-leading lead times, often delivering precision-machined prototypes within 72 hours of CAD release. We understand that for engineers, the “best” machine is the one that reliably transforms design intent into physically validated reality—on schedule and within specification. Partner with Honyo to leverage CNC milling not just as a tool, but as a strategic accelerator for your product development lifecycle.

Technical Capabilities

Shenzhen Honyo Prototype leverages advanced CNC milling technology to deliver precision-engineered components for industries requiring high accuracy, complex geometries, and repeatable quality. Our technical capabilities center on 3-axis, 4-axis, and 5-axis CNC milling machines, complemented by CNC turning centers, enabling us to support a broad spectrum of prototyping and low-to-mid volume production applications. Each machine in our facility is maintained to OEM standards and operated by certified machinists with extensive experience in high-speed machining and tight-tolerance manufacturing.

Our 3-axis CNC milling systems are ideal for prismatic parts, flat surfaces, and features aligned along the X, Y, and Z axes. These machines offer rapid material removal and excellent surface finishes, making them suitable for tooling, jigs, and functional prototypes. For components requiring indexing or rotational features, our 4-axis platforms add a rotary A-axis, enabling continuous machining around a single rotational plane. This capability significantly reduces setup time and improves geometric consistency.

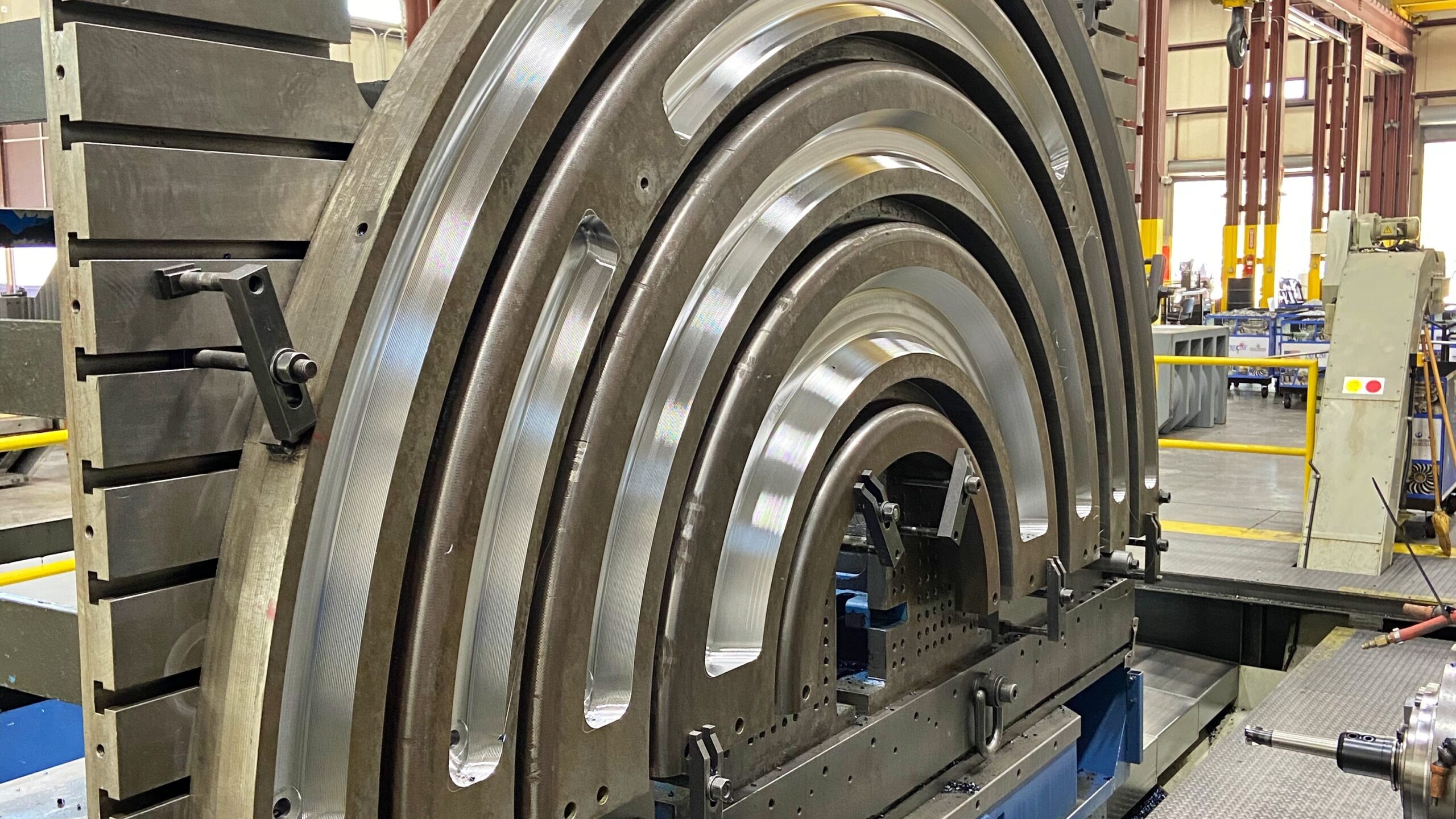

For the most complex geometries—such as impellers, aerospace brackets, and organic industrial design forms—our 5-axis simultaneous CNC milling centers provide unparalleled flexibility. These machines operate with fully interpolated motion across X, Y, Z, and two rotational axes (typically A and B), allowing tool access from nearly any angle in a single setup. This not only enhances precision but also minimizes human intervention, reducing the risk of alignment errors and improving throughput.

In addition to milling, our CNC turning centers support bar-fed and chucking operations for cylindrical and near-cylindrical components. We routinely machine shafts, fittings, and threaded parts with tight concentricity and surface finish requirements.

Tight tolerances are a hallmark of Honyo’s manufacturing process. We maintain standard tolerances of ±0.005 mm (±0.0002″) for linear dimensions, with critical features held to ±0.002 mm (±0.0001″) when required. Surface finishes can reach Ra 0.8 µm (32 µin) or better, depending on material and geometry. Our quality assurance process includes first-article inspection (FAI), in-process checks, and final CMM verification to ensure compliance with engineering drawings and industry standards.

Below is a summary of our standard machining tolerances and compatible materials:

| Feature | Standard Tolerance | Notes |

|——–|——————–|——-|

| Linear Dimensions | ±0.005 mm (±0.0002″) | Tighter tolerances down to ±0.002 mm achievable |

| Angular Features | ±0.1° | |

| Hole Diameter | +0.005 / -0.000 mm | Reamed or honed holes to ±0.002 mm |

| Surface Finish (Milled) | Ra 1.6 – 3.2 µm (63–125 µin) | As low as Ra 0.8 µm achievable |

| Surface Finish (Turned) | Ra 0.8 – 1.6 µm (32–63 µin) | |

| Material Category | Examples | Max Part Size (mm) |

|——————|———|——————-|

| Aluminum Alloys | 6061, 7075, 2024 | 1000 x 600 x 400 |

| Steels | 4140, 1018, Stainless 303/304/17-4PH | 800 x 500 x 350 |

| Plastics | POM (Delrin), Nylon, PEEK, PC | 1200 x 800 x 500 |

| Brass & Copper | C36000, C11000 | 600 x 400 x 250 |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | 500 x 400 x 300 |

Honyo’s investment in multi-axis CNC technology, combined with rigorous process control, ensures that every component meets the highest standards of dimensional accuracy and surface integrity.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s CNC Milling Workflow

At Shenzhen Honyo Prototype, our CNC milling process transforms digital designs into precision-engineered components through a rigorously defined workflow. This systematic approach ensures optimal efficiency, part integrity, and adherence to client specifications from initial inquiry to final delivery. The core stages—AI-Driven Quotation, Design for Manufacturability (DFM) analysis, and Production—form an integrated pipeline that minimizes risk and maximizes value for industrial clients.

AI-Driven Quotation

Upon receipt of a 3D CAD model (STEP, IGES, or native format), our proprietary AI quotation engine performs an instantaneous geometric and material analysis. This system evaluates critical factors including part complexity, feature density, stock requirements, and material grade against our machine capabilities and current shop floor load. Unlike manual quoting, the AI quantifies machining time with 95%+ accuracy by simulating toolpath strategies and identifying potential bottlenecks. Clients receive a detailed cost breakdown within 2 hours, including material costs, setup fees, and lead time—all derived from real-time production data. This transparency eliminates estimation errors and accelerates project kickoff.

Design for Manufacturability (DFM) Review

Before production begins, every design undergoes mandatory DFM scrutiny by our senior engineering team. This phase identifies manufacturability risks that could compromise quality or increase costs. Common issues addressed include inadequate wall thickness (<0.8mm for aluminum), problematic internal radii, excessive tolerance stacking (e.g., ±0.005mm on non-critical features), and suboptimal tool access. We provide actionable feedback with annotated CAD markups, suggesting geometric adjustments that maintain functional intent while enhancing machinability. For instance, recommending a 0.5mm corner radius instead of a sharp internal edge reduces cycle time by 15–20% and eliminates tool deflection risks. Client approval of the DFM report is required to ensure alignment before material procurement.

Precision Production Execution

Approved designs move to our climate-controlled production floor, where parts are machined on state-of-the-art CNC mills. Honyo utilizes a strategic mix of 3-axis, 4-axis, and 5-axis vertical machining centers optimized for tight-tolerance work. All machines undergo daily calibration checks, and critical processes employ in-process probing for real-time geometric deviation correction. Our standard production parameters ensure consistency across materials:

| Material Category | Max Tolerance (mm) | Surface Finish (Ra µm) | Typical Machines Used |

|——————-|———————|————————|————————|

| Aluminum Alloys | ±0.010 | 0.8–1.6 | DMG MORI CTX beta 1250 |

| Stainless Steel | ±0.008 | 0.4–0.8 | Haas UMC-750 |

| Titanium Alloys | ±0.012 | 1.6–3.2 | Makino D200Z |

Post-machining, parts undergo rigorous CMM inspection against the original CAD model, with full inspection reports provided. Non-destructive testing (e.g., dye penetrant) is applied for mission-critical aerospace or medical components. This closed-loop workflow—from AI-validated quoting to DFM-optimized production—ensures first-article approval rates exceeding 98% and reduces lead times by up to 30% compared to industry benchmarks. Clients receive not just a part, but a certified, traceable component engineered for seamless integration into their assemblies.

Start Your Project

Start Your Next Precision Project with Honyo Prototype’s Advanced CNC Milling Solutions

When it comes to high-precision prototyping and low-volume production, selecting the right CNC milling machine is only part of the equation. At Shenzhen Honyo Prototype, we understand that your project’s success depends not just on machinery, but on expertise, responsiveness, and a partner who’s committed to your timeline and quality standards. Our advanced CNC milling capabilities are engineered to meet the demands of industries ranging from aerospace and medical devices to consumer electronics and automotive innovation.

We operate state-of-the-art 3-axis, 4-axis, and 5-axis CNC milling machines, enabling us to handle complex geometries with tight tolerances as tight as ±0.005 mm. Whether you’re developing a functional prototype or preparing for small-batch manufacturing, our facility combines cutting-edge equipment with skilled machinists who bring decades of experience in material selection, toolpath optimization, and finish control.

Our process begins with a detailed review of your design files—available in STEP, IGES, SolidWorks, or other standard formats—followed by a rapid manufacturability analysis. We work with a wide range of materials, including aluminum alloys (6061, 7075), stainless steel (303, 316), titanium, brass, and engineering plastics such as PEEK, Delrin, and nylon. Surface finishes, anodizing, bead blasting, and custom coatings are available to meet both functional and aesthetic requirements.

To ensure transparency and speed, we provide real-time project updates and first-article inspection reports upon request. With a lead time as fast as 3–7 days for most machined parts, we’re built for agility without compromising precision.

Below is an overview of our core CNC milling capabilities:

| Feature | Specification |

|——–|—————|

| Machine Types | 3-axis, 4-axis, 5-axis CNC milling centers |

| Maximum Work Envelope | 1200 x 600 x 500 mm |

| Tolerance | ±0.005 mm (standard), tighter upon request |

| Materials | Aluminum, stainless steel, titanium, brass, plastics (PEEK, Delrin, etc.) |

| Spindle Speed | Up to 24,000 RPM |

| Positioning Accuracy | ±0.003 mm |

| Lead Time | 3–7 days (standard), expedited options available |

| File Formats Accepted | STEP, IGES, X_T, SolidWorks, PDF, DWG |

Your next breakthrough begins with a conversation. Contact Susan Leo, our dedicated project coordinator, to discuss your design requirements, material preferences, and delivery expectations. We offer free quotes within 4 business hours and are ready to support your project from concept to completion.

Email Susan Leo at info@hy-proto.com with your 3D model or technical drawing attached, and let Honyo Prototype bring your vision to life with precision, speed, and reliability.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.