Contents

Manufacturing Insight: Cnc Turning Machine

CNC Turning Technology and Honyo Prototype’s Precision Manufacturing Capabilities

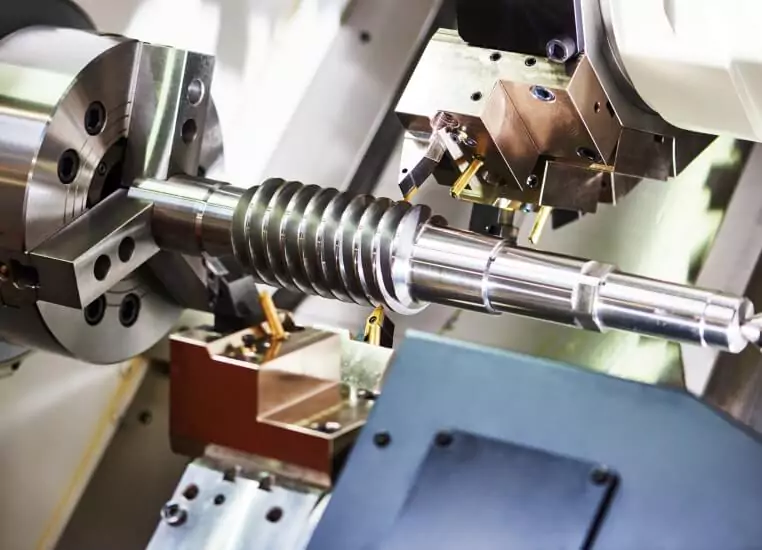

CNC turning represents a foundational subtractive manufacturing process where a workpiece rotates against a stationary cutting tool to create precise cylindrical geometries. Controlled by computer numerical code (G-code), modern CNC lathes execute complex operations—including facing, boring, grooving, threading, and parting—with exceptional repeatability and tight tolerances unattainable via manual methods. This technology is indispensable for producing high-integrity rotational components across aerospace, medical, automotive, and industrial sectors, where dimensional accuracy, surface finish, and material integrity are non-negotiable. At Shenzhen Honyo Prototype, we leverage advanced CNC turning not merely as a production step, but as a core enabler for rapid, high-fidelity prototyping and low-to-mid volume production of mission-critical parts.

Honyo Prototype specializes in transforming complex engineering designs into functional metal and plastic prototypes and end-use components through optimized CNC turning workflows. Our engineering team collaborates closely with clients during the design-for-manufacturability (DFM) phase to identify potential machining constraints, recommend material selections, and refine geometries for optimal turnability—reducing lead times and minimizing costly iterations. We excel in machining challenging materials such as titanium alloys, inconel, brass, aluminum 7075, and engineering plastics like PEEK, maintaining stringent quality control throughout the process. Our facility integrates turning with complementary processes like milling, drilling, and surface finishing, enabling single-setup completion of complex multi-feature parts that would otherwise require multiple vendors.

Our CNC turning capabilities are anchored by a modern fleet of multi-axis lathes equipped with live tooling and Y-axes, supporting intricate mill-turn operations. Key technical specifications defining our production envelope include:

| Parameter | Specification | Significance for Prototyping |

| :——————— | :——————— | :————————————— |

| Max Turning Diameter | Ø 200 mm | Accommodates medium-sized complex parts |

| Max Turning Length | 350 mm | Supports extended shafts and housings |

| Spindle Speed | 6,000 RPM | Enables fine finishes on diverse materials |

| Tool Capacity | 12-30 Stations | Reduces setups for complex geometries |

| Typical Tolerance | ±0.005 mm | Meets stringent aerospace/medical specs |

| Supported Materials | Metals, Plastics, Composites | Broad application coverage |

Quality assurance is systematically embedded within our CNC turning process. Each operation undergoes in-process inspection using calibrated CMMs, optical comparators, and surface roughness testers, with full first-article inspection (FAI) reports provided per AS9102 or client-specific requirements. Our ISO 9001-certified quality management system ensures traceability from raw material certification through final packaging, with real-time process monitoring to detect and correct deviations before they impact output. This disciplined approach allows Honyo Prototype to consistently deliver precision-turned components with lead times up to 40% faster than industry averages for complex prototypes. For engineering teams requiring rapid validation of rotational part designs, Honyo provides the technical expertise, agile manufacturing infrastructure, and uncompromising quality focus to accelerate your path from CAD model to functional hardware.

Technical Capabilities

CNC Turning Machine Technical Capabilities – Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC turning machines are engineered to deliver high-precision components for industries requiring tight tolerances, complex geometries, and rapid turnaround times. Our advanced 3-axis, 4-axis, and 5-axis CNC turning centers integrate live tooling and multi-tasking capabilities, enabling seamless transition between turning and milling operations. These machines support a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics, ensuring versatility across diverse prototyping and low-to-mid volume production applications.

Our 3-axis CNC lathes are optimized for high-speed, high-accuracy turning of cylindrical and symmetric parts. Equipped with programmable tool changers and rigid spindle designs, they maintain ±0.005 mm tolerance on critical dimensions. For more complex components requiring off-axis features such as cross-drilled holes, milled flats, or contour slots, our 4-axis and 5-axis turning centers provide enhanced flexibility. These machines incorporate Y-axis milling and B-axis rotary tooling, allowing simultaneous turning and milling in a single setup—reducing cycle time and improving positional accuracy.

Tight tolerance machining is a core competency at Honyo. Our CNC turning systems are maintained under strict environmental controls and calibrated monthly using laser interferometers and touch-probe inspection systems. We consistently achieve tolerances down to ±0.003 mm on critical diameters and ±0.02 mm on non-critical features, depending on part geometry and material. Surface finishes as fine as Ra 0.8 µm are standard, with optional polishing and grinding available for ultra-smooth surfaces.

All CNC turning operations are supported by full-process quality assurance. In-process inspections using coordinate measuring machines (CMM) and optical comparators ensure dimensional compliance throughout production. Our team of certified manufacturing engineers develops optimized toolpaths using Mastercam and Siemens NX, ensuring efficient material removal and minimal tool wear.

The table below outlines our standard machining tolerances and compatible materials:

| Feature | Standard Tolerance | High-Precision Capability |

|——–|——————–|—————————-|

| Linear Dimensions | ±0.02 mm | ±0.003 mm |

| Diameter Tolerance | ±0.01 mm | ±0.005 mm |

| Concentricity | 0.02 mm | 0.005 mm |

| Surface Finish (Typical) | Ra 3.2 µm | Ra 0.8 µm |

| Positional Tolerance | ±0.02 mm | ±0.005 mm |

| Material Category | Examples | Max Part Length | Max Diameter |

|——————|———|—————-|————–|

| Aluminum Alloys | 6061, 7075, 2024 | 500 mm | 300 mm |

| Stainless Steel | 303, 304, 316, 17-4 PH | 450 mm | 280 mm |

| Carbon Steel | 1018, 1045 | 400 mm | 250 mm |

| Brass & Copper | C36000, C11000 | 500 mm | 300 mm |

| Titanium Alloys | Grade 2, Grade 5 (Ti-6Al-4V) | 300 mm | 200 mm |

| Engineering Plastics | POM, PEEK, Nylon | 600 mm | 350 mm |

Shenzhen Honyo Prototype leverages state-of-the-art CNC turning technology to deliver precision-machined parts with repeatable quality and fast lead times. Our technical capabilities are backed by ISO 9001-certified processes and a commitment to engineering excellence in every project.

From CAD to Part: The Process

CNC Turning Production Process: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC turning workflow is engineered for speed, accuracy, and cost-effectiveness, transforming your digital design into a high-integrity physical component. This structured process minimizes risk and maximizes efficiency from initial inquiry through final inspection. Central to our approach is the seamless integration of advanced digital tools with rigorous manufacturing expertise, ensuring your prototype or low-volume production part meets exact specifications on time.

The journey begins with the AI-Powered Quoting System. Upon receiving your CAD file (STEP, IGES, or native formats preferred), our proprietary AI engine performs an instant preliminary analysis. It assesses geometric complexity, material requirements, feature recognition, and potential manufacturability flags. This enables Honyo to generate a highly accurate, detailed quote within hours—not days—providing transparent cost breakdowns and realistic lead time estimates based on actual machine capabilities and current shop floor load. This rapid feedback loop allows for immediate project validation and faster decision-making.

Following quote acceptance, the critical Design for Manufacturability (DFM) Review commences. Our senior manufacturing engineers conduct a thorough, hands-on analysis of your CAD model, moving beyond the AI’s initial scan. We identify potential issues such as non-optimal wall thicknesses, problematic undercuts, unnecessarily tight tolerances, or features requiring complex secondary operations. Crucially, we evaluate material utilization and toolpath efficiency specific to turning processes. Honyo provides actionable, collaborative DFM feedback before programming starts, suggesting practical design refinements that enhance part quality, reduce machining time, and lower overall costs—often preventing costly revisions later. Client approval of the DFM report is mandatory prior to production.

Production Execution leverages Honyo’s state-of-the-art CNC turning centers and stringent process controls. Approved CAD data drives CAM programming, generating optimized G-code for efficient material removal and surface finish. Skilled machinists meticulously set up the selected machine, verifying tooling, workholding (chucks, collets), and offsets against the engineering drawing. Production runs include rigorous in-process inspections using calibrated CMMs, optical comparators, and surface roughness testers at defined intervals to ensure conformance to all geometric dimensioning and tolerancing (GD&T) requirements. Final inspection provides comprehensive documentation, including first-article reports for critical features, before parts are carefully packaged and shipped.

Honyo Prototype maintains dedicated CNC turning capacity optimized for prototyping and low-volume production. Key machine capabilities include:

| Parameter | Capability Range |

|——————–|————————————–|

| Maximum Turning Diameter | Ø2mm to Ø300mm |

| Maximum Turning Length | Up to 500mm |

| Spindle Speed | 50 – 6,000 RPM (variable) |

| Typical Tolerances | ±0.005mm (standard), ±0.001mm (precision) |

| Common Materials | Aluminum, Steel, Stainless, Brass, Plastics (PEEK, Delrin) |

| Axis Configuration | 2-axis (basic), Y-axis, C-axis, Live Tooling (mill-turn) |

This integrated workflow—AI quoting for speed, expert DFM for cost and quality assurance, and precision production with robust quality control—ensures Honyo delivers CNC turned parts that consistently meet the demanding requirements of engineering prototypes and functional components. We transform your design intent into reality with minimal waste and maximum reliability.

Start Your Project

Start Your CNC Turning Project with Precision and Confidence

At Shenzhen Honyo Prototype, we specialize in high-precision CNC turning services designed to meet the exacting demands of modern manufacturing. Whether you’re developing a single prototype or scaling up to low-volume production, our advanced CNC turning capabilities ensure tight tolerances, superior surface finishes, and rapid turnaround times. Our facility is equipped with state-of-the-art CNC lathes, including multi-axis turning centers capable of handling complex geometries with automated bar feeding and live tooling integration. With over a decade of experience in precision machining, we support industries ranging from aerospace and medical devices to automotive and industrial equipment.

Starting your project with Honyo Prototype is simple and efficient. We understand that every component has unique requirements, which is why our engineering team collaborates closely with clients from the initial design phase through final production. Our process begins with a thorough review of your technical drawings and material specifications. We support a wide range of materials, including aluminum, stainless steel, brass, titanium, and engineering plastics, ensuring optimal performance for your application. Once we receive your design, our team performs a Design for Manufacturability (DFM) analysis to identify potential improvements in cost, lead time, and part functionality—helping you avoid costly revisions down the line.

Our CNC turning machines operate with micron-level accuracy and are monitored through real-time quality control systems. We maintain strict compliance with ISO 9001 standards and provide full traceability, first-article inspections, and comprehensive inspection reports upon request. From simple turned shafts to complex, multi-feature components, our machines deliver consistent repeatability and exceptional part quality.

To ensure seamless project execution, we offer competitive pricing, fast quoting, and transparent communication throughout the manufacturing cycle. Our goal is to become your trusted partner in bringing innovative ideas to life—on time and to specification.

CNC Turning Capabilities Overview

| Parameter | Specification |

|————————-|———————————————-|

| Maximum Turning Diameter| 300 mm |

| Maximum Turning Length | 600 mm |

| Tolerance | ±0.005 mm typical |

| Spindle Speed | Up to 8,000 RPM |

| Axis Configuration | 2-axis to 7-axis (including live tooling) |

| Materials Supported | Aluminum, Steel, Stainless Steel, Brass, Titanium, Plastics |

| Finishing Options | As-machined, Anodizing, Plating, Powder Coating, Passivation |

| Lead Time | As fast as 3–7 days for prototypes |

Ready to move forward? Contact Susan Leo today to discuss your CNC turning requirements. We provide fast, detailed quotes and expert technical support to help you make informed decisions. Email us at info@hy-proto.com with your CAD files or technical drawings, and let our team turn your concept into a high-precision reality. At Honyo Prototype, precision isn’t just a standard—it’s our promise.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.