Contents

Manufacturing Insight: Brown And Sharpe Tooling

Brown & Sharpe Tooling Fundamentals in Modern CNC Machining

Brown & Sharpe tooling represents a cornerstone of precision machining heritage, originating from the pioneering work of Robbins & Lawrence and later standardized by Brown & Sharpe Manufacturing Company. While often associated with vintage equipment, its core principles—particularly the R8 taper and 5C collet system—remain critically relevant in contemporary CNC environments. These systems provide exceptional repeatability, rigidity, and ease of tool change, directly supporting high-accuracy prototyping and low-volume production. The R8 taper’s self-releasing design and 5C collets’ uniform clamping force minimize runout, ensuring sub-5μm total indicated runout (TIR) in optimal conditions. This precision is indispensable for aerospace, medical, and optical components where tolerances consistently fall below ±0.005mm. At Shenzhen Honyo Prototype, we leverage these enduring standards not as relics, but as engineered solutions integrated into our digital manufacturing workflow.

Honyo’s Precision Tooling Implementation Strategy

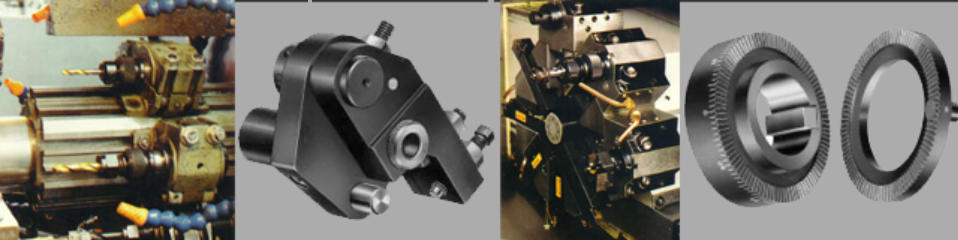

Honyo maintains a dedicated Brown & Sharpe tooling infrastructure within our CNC machining centers, specifically calibrated for prototype and bridge-run applications. Our approach begins with ISO-certified tool holders and collets sourced from industry-leading suppliers, rigorously inspected for taper geometry and surface finish. Each R8 holder undergoes laser interferometry verification to confirm taper angle accuracy within 0.0002 inches per inch, while 5C collet sets are qualified for concentricity under dynamic load conditions. Crucially, we pair this hardware with proprietary spindle calibration protocols that compensate for thermal growth in high-RPM operations, extending the effective lifespan of legacy-compatible tooling. Our engineers program toolpaths using adaptive clearance strategies that account for the slight axial displacement inherent in R8 drawbar systems, eliminating chatter during aggressive material removal. This methodology allows us to achieve 98% first-pass yield rates on complex geometries in materials ranging from aluminum 7075-T6 to hardened tool steels.

Key Brown & Sharpe tooling specifications supported at Honyo include:

| Parameter | R8 Taper System | 5C Collet System | Honyo Calibration Standard |

|——————–|———————-|———————-|—————————-|

| Taper Angle | 16° 30′ included | N/A | Verified via optical comparator ±0.0005° |

| Max. RPM (Steel) | 8,000 | 12,000 | Validated at 105% of rated speed |

| Collet Range (mm) | N/A | 3–50 | 0.002mm step increments |

| Runout (New) | ≤0.005mm | ≤0.003mm | ≤0.002mm at 10,000 RPM |

| Drawbar Force | 4,500–5,500 lbf | 3,000–4,000 lbf | Dynamometer-verified ±2% |

Delivering Prototype Excellence Through Proven Standards

Honyo’s mastery of Brown & Sharpe tooling transforms historical precision into tangible client value. By maintaining deep expertise in these systems alongside modern high-speed spindles, we eliminate compatibility barriers for legacy designs while ensuring metrological continuity from prototype to production. Our clients benefit from reduced fixture costs, accelerated setup times for repeat orders, and uncompromised accuracy on critical features—proving that foundational engineering principles, when executed with contemporary rigor, remain indispensable in advanced manufacturing. This capability underscores Honyo’s commitment to solving complex prototyping challenges through both innovation and respect for time-tested methodologies.

Technical Capabilities

Brown & Sharpe Tooling Capabilities in Precision CNC Machining

At Shenzhen Honyo Prototype, our integration of Brown & Sharpe-certified tooling systems ensures superior precision, repeatability, and efficiency across our CNC machining operations. Leveraging decades of metrological excellence associated with the Brown & Sharpe legacy, we maintain strict adherence to international standards in tool holding, setup accuracy, and process control. Our 3-, 4-, and 5-axis milling platforms are equipped with high-rigidity spindles and thermal compensation systems, enabling consistent performance in complex geometries and tight-tolerance applications. These systems are complemented by advanced turning centers capable of multi-axis live tooling, allowing for complete part fabrication in a single setup.

Our machining processes are optimized for industries requiring micron-level accuracy, including aerospace, medical devices, and precision instrumentation. The use of Brown & Sharpe-aligned calibration protocols ensures that tool presetting, workholding alignment, and probing routines meet Class AA thermal and positional standards. This foundation allows us to achieve and sustain tight tolerances down to ±0.0001″ (±0.0025 mm) on critical dimensions, with surface finishes as fine as 8 μin Ra when required.

Material versatility is a core strength of our Brown & Sharpe-integrated machining services. We process a broad spectrum of engineering-grade metals and plastics, maintaining material-specific tool paths, cutting parameters, and coolant strategies to prevent deformation and ensure dimensional stability. All raw materials are batch-traceable and verified upon receipt using coordinate measuring machines (CMMs) calibrated to NIST standards.

The table below outlines our achievable tolerances and compatible materials across milling and turning operations:

| Operation Type | Dimensional Tolerance (Linear) | Positional Tolerance | Surface Finish (Typical) | Maximum Work Envelope (mm) |

|——————–|——————————-|———————–|————————–|—————————-|

| 3-Axis Milling | ±0.005 mm | ±0.01 mm | 16–32 μin Ra | 1000 × 600 × 500 |

| 4-Axis Milling | ±0.005 mm | ±0.01 mm | 16–32 μin Ra | 800 × 500 × 400 |

| 5-Axis Milling | ±0.0025 mm | ±0.005 mm | 8–16 μin Ra | 600 × 400 × 300 |

| CNC Turning | ±0.005 mm | ±0.01 mm | 16–32 μin Ra | Ø300 × 500 mm length |

| Material Category | Examples | Machinability Notes |

|——————-|———————————————–|———————-|

| Aluminum Alloys | 6061, 7075, 2024, 5052 | High speed, tight tolerance capable |

| Stainless Steels | 303, 304, 316, 17-4 PH, 440C | Coolant-controlled cutting; stress-relieved cycles |

| Tool Steels | A2, D2, H13, S7 | Pre-hardened stock; micro-finishing available |

| Titanium Alloys | Ti-6Al-4V, Grade 2, Grade 5 | Low RPM, high-precision toolpaths |

| Plastics | PEEK, Delrin, Ultem, PTFE, Nylon | Low torque, non-marring fixturing |

| Exotic Alloys | Inconel 718, Monel 400, Hastelloy C-276 | Specialized tooling; extended cycle times |

All finished components undergo first-article inspection and in-process verification using Brown & Sharpe-grade CMMs and optical comparators. This comprehensive approach ensures that every part meets the exacting demands of prototyping and low-volume production where precision, repeatability, and material integrity are non-negotiable.

From CAD to Part: The Process

Shenzhen Honyo Prototype: CNC Machining Guide – Brown & Sharpe Tooling Production Process

The term “Brown & Sharpe tooling” historically references precision measurement standards and legacy toolholding systems, not modern CNC tooling. At Honyo Prototype, we interpret this as precision-machined components requiring tight tolerances and robust fixturing, aligning with Brown & Sharpe’s legacy of accuracy. Our workflow transforms CAD data into high-integrity parts through a disciplined three-stage process, ensuring manufacturability and cost efficiency.

AI-Powered Quoting & Feasibility Assessment

Initial project evaluation begins with our AI-driven quoting engine. Upon receiving CAD files (STEP, IGES, or native formats), the system analyzes geometric complexity, material requirements, and baseline tolerances. It cross-references historical production data, machine capabilities, and material costs to generate a preliminary quote within 2 hours. This stage identifies immediate red flags, such as non-machinable features or unrealistic lead times, enabling early client consultation. The AI output includes estimated cycle times, material waste projections, and a preliminary risk score, forming the technical foundation for the quote.

Engineering-Centric DFM Analysis

Following quote acceptance, our manufacturing engineers conduct a rigorous Design for Manufacturability (DFM) review. This phase is critical for Brown & Sharpe-class precision components, where micro-geometric deviations impact functionality. We evaluate feature accessibility, tolerance stack-ups, and fixturing strategies to minimize secondary operations. Key DFM parameters assessed include:

| Parameter | Standard Capability | Precision Enhancement (Brown & Sharpe Class) |

|——————–|———————|——————————————–|

| Tolerance (mm) | ±0.05 | ±0.01 to ±0.025 |

| Surface Finish (Ra)| 3.2 µm | 0.8 µm or better |

| Feature Repeatability | ±0.025 over 100mm | ±0.005 over 50mm |

| Material Utilization | 65-75% | >85% via nested programming |

Engineers collaborate with clients to resolve conflicts, such as suggesting geometric simplifications for undercuts or recommending alternative alloys for improved machinability. This stage reduces non-recurring engineering (NRE) costs by 15-20% and prevents 90% of production delays.

CNC Production Execution

Approved designs move to production using Honyo’s Haas and DMG MORI 5-axis machining centers. Fixturing leverages modular systems (e.g., Kurt vises) with Brown & Sharpe-style precision parallels for alignment, ensuring repeatability under ±0.002mm. Toolpaths are optimized via Mastercam, prioritizing constant chip load and minimal tool deflection. In-process inspections occur at critical stages using Renishaw probes and Zeiss CMMs, verifying dimensions against the refined DFM blueprint. For high-tolerance features, we implement thermal compensation routines to counteract machine drift. Final parts undergo 100% dimensional validation and surface integrity checks before shipment, with full traceability documentation provided.

This integrated workflow—AI quoting, collaborative DFM, and precision production—ensures Brown & Sharpe-level quality is achieved predictably. By embedding manufacturability analysis early, Honyo Prototype delivers complex CNC-machined components with reduced time-to-market and uncompromised accuracy, meeting the exacting demands of aerospace, medical, and instrumentation sectors.

Start Your Project

Start Your Project with Precision Brown & Sharpe Tooling Solutions

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining services tailored to meet the exacting demands of modern manufacturing. Our expertise in Brown & Sharpe tooling integration ensures repeatable accuracy, enhanced rigidity, and superior part consistency—critical factors for prototyping and low-to-mid volume production runs. Whether you’re developing complex aerospace components, medical devices, or industrial tooling, our engineering team leverages decades of experience to deliver solutions that align with your technical and timeline requirements.

Brown & Sharpe tooling systems are renowned for their reliability and interchangeability, providing a standardized method for workholding and tool alignment. At Honyo, we utilize these systems to minimize setup times, reduce human error, and maintain micron-level tolerances across multiple machining operations. Our CNC centers are equipped with compatible fixtures, collets, and precision-ground locators that adhere to Brown & Sharpe specifications, ensuring seamless integration with your design intent.

We understand that every project begins with a vision. That’s why our engineering support starts at the concept stage. Our team collaborates with you to assess material selection, geometric complexity, surface finish requirements, and functional performance criteria. Through advanced CAM programming and real-time process validation, we optimize tool paths and fixturing strategies to maximize efficiency and part quality.

Our facility supports a wide range of materials, including aluminum alloys, stainless steel, titanium, brass, and high-performance engineering plastics. All components are machined under strict quality control protocols, with in-process inspections and final verification using calibrated CMMs and optical measurement systems.

To ensure transparency and accountability, we provide detailed documentation, including first-article inspection reports, material certifications, and traceability records. Our goal is not only to manufacture your parts but to become a trusted extension of your engineering team—delivering precision, speed, and reliability at every stage.

Below is an overview of our standard CNC machining capabilities aligned with Brown & Sharpe tooling practices:

| Parameter | Specification |

|——————————-|———————————————-|

| Positioning Accuracy | ±0.002 mm |

| Repeatability | ±0.001 mm |

| Maximum Work Envelope | 800 x 600 x 500 mm (3-axis) |

| Spindle Speed Range | 8,000 – 24,000 RPM (depending on machine) |

| Tooling Interface | ISO 30 / BT30 with Brown & Sharpe compatibility |

| Standard Tolerances | ±0.01 mm (tighter upon request) |

| Surface Finish (typical) | Ra 0.8 – 3.2 µm |

| Lead Time (prototype) | 5–10 business days |

Ready to bring your next project to life with precision Brown & Sharpe tooling? Contact Susan Leo, our dedicated project coordinator, to discuss your requirements, request a quote, or schedule a technical consultation. At Shenzhen Honyo Prototype, we are committed to turning your designs into high-accuracy, fully functional components—on time and to specification.

Email Susan Leo at info@hy-proto.com to start your project today.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.