Contents

Manufacturing Insight: Chromate Conversion Coating For Aluminum

At Honyo Prototype, we machine your aluminum parts today and protect them tomorrow. Our 3- to 5-axis CNC cells can hold ±0.02 mm on even the most complex aerospace and electronics geometries, then move the job straight to an in-house chromate conversion coating line that meets MIL-DTL-5541 and RoHS standards. The same online portal that gives you an instant CNC quote—complete with lead-time and DFM feedback—now also prices Type I (hex) and Type II (trivalent) chromate in real time, so you can go from raw billet to corrosion-resistant, conductive finish in as little as 5 days without ever leaving your desk.

Technical Capabilities

Below is a precise, technically accurate response addressing your query. Critical clarification first:

Chromate conversion coating (e.g., Alodine, Iridite) is ONLY applicable to aluminum and magnesium alloys. It does NOT apply to steel, ABS, or nylon. These materials require entirely different surface treatments. Including them in the chromate specification is incorrect and could lead to process failures, safety hazards, or part rejection.

I’ll structure this as:

1. Core specs for aluminum chromate conversion coating (aligned with industry standards for tight-tolerance machining).

2. Why it’s safe for 3/4/5-axis milling, turning, and tight tolerances.

3. Correct surface treatments for steel, ABS, and nylon (to prevent dangerous misapplication).

✅ 1. Chromate Conversion Coating for Aluminum: Technical Specs

(Per MIL-DTL-5541, Type I or II; ASTM B449; ISO 10073)

| Parameter | Specification | Tolerance Impact |

|———————|——————————————————————————-|——————|

| Base Material | Aluminum alloys (e.g., 6061-T6, 7075-T6, 2024-T3). Not for cast aluminum without pre-treatment. | N/A (applies only to aluminum) |

| Coating Type | Type I: Chromic acid-based (olive drab or clear). Type II: Sulfuric acid-based (clear/yellow). Type II is standard for tight-tolerance parts due to thinner film. | Critical: Coating thickness is 0.000001–0.00001 inches (0.025–0.25 µm). No measurable dimensional change. |

| Coating Weight | 1–5 mg/ft² (Type II) or 5–15 mg/ft² (Type I). Measured via weight loss per ASTM B449. | Zero tolerance impact – thickness is sub-micron. Ideal for features with ±0.0005″ tolerances. |

| Color | Clear (Type II), Yellow (Type II), Olive Drab (Type I). Clear/yellow preferred for precision parts to avoid visual masking of defects. | N/A |

| Process Temp | 60–90°F (15–32°C) for Type II; 120–140°F (49–60°C) for Type I. Low-temp processes avoid thermal distortion. | Critical for tight tolerances: Low-temp processing prevents warping during application. |

| Adhesion | Passes tape test per ASTM D3359 (5B rating). | N/A (coating bonds chemically; no mechanical adhesion issues) |

| Corrosion Resistance | 168+ hours salt spray (ASTM B117) for Type I; 96+ hours for Type II. | N/A |

| Process Steps | Degrease → Alkaline clean → Acid etch (optional) → Chromate immersion (1–5 min) → Rinse → Dry. | Machining Consideration: Must be applied AFTER final machining. Do NOT machine after coating – it’s a soft, porous layer that scratches easily. |

🔧 Why Chromate is Safe for Tight-Tolerance Machining (3/4/5-Axis Milling/Turning)

- No dimensional change: At 0.025–0.25 µm thickness, chromate is 100x thinner than a human hair. It does not affect clearance fits, threaded holes, or critical dimensions.

- No thermal distortion: Low-temperature processes (<90°F) prevent aluminum warping during coating.

- No edge buildup: Unlike plating or anodizing, chromate forms a uniform, ultra-thin film even on sharp edges – critical for 5-axis milled features.

- Post-processing: Parts can be handled immediately after drying. No secondary curing or baking required.

⚠️ Critical Note: Chromate is NOT a replacement for anodizing. If you need thicker corrosion protection (>0.0005″), anodizing (e.g., Type II/III) adds measurable thickness (0.0005–0.002″) and requires machining oversize. Chromate is for minimal-thickness needs where dimensional stability is paramount.

❌ 2. Why Chromate DOES NOT Apply to Steel, ABS, or Nylon

| Material | Why Chromate Fails | Correct Surface Treatment |

|———-|———————|—————————-|

| Steel | Chromate requires aluminum to chemically react. On steel, it forms no protective layer and may cause hydrogen embrittlement. | Zinc plating (e.g., zinc-nickel per ASTM B633), black oxide, or phosphate coating (MIL-DTL-16232). Note: Zinc plating adds 0.0002–0.0005″ thickness – must be accounted for in tight-tolerance design. |

| ABS/Nylon | Chromate is a metal conversion coating. Plastics have no metal ions to react with the solution. Immersion causes surface degradation (cracking, warping) and no corrosion protection. | For ABS/Nylon: Plasma treatment + specialized plastic primer (e.g., epoxy-epoxy or polyurethane-based). For electrical conductivity: conductive paint (e.g., silver epoxy). Never immerse plastics in chromate baths – toxic fumes and part destruction will occur. |

🛠️ Practical Guidance for Multi-Material Assemblies

If your part combines aluminum, steel, and plastics (e.g., a fixture with aluminum body, steel fasteners, and ABS mounting tabs):

1. Machine all materials first to final tolerances.

2. Apply chromate ONLY to aluminum sections (mask steel/plastic areas).

3. Treat steel separately: Zinc plating or black oxide.

4. Treat plastics separately: Plasma etch + primer.

5. Order of operations:

– Final machining → Masking → Chromate (aluminum) → Dry → Unmask → Steel/plastic treatments → Assembly.

Never apply chromate to non-aluminum parts – it will ruin them.

⚠️ Safety & Compliance Notes

- Chromate contains hexavalent chromium (Cr⁶⁺), a known carcinogen.

- Mandatory: Use EPA-compliant waste treatment, PPE (respirators, gloves), and certified facilities.

- Alternatives for eco-compliance: Consider trivalent chromium processes (e.g., MIL-DTL-5541 Type II, Class 1A) – safer but slightly lower corrosion resistance.

💡 When to Use Chromate vs. Alternatives

| Scenario | Recommended Treatment |

|———-|————————|

| Aluminum with tight tolerances (±0.0005″), no anodizing needed | Chromate conversion (Type II) – best for dimensionally critical parts. |

| Aluminum needing thicker corrosion protection | Anodizing (Type II/III) – but machine parts 0.001–0.002″ oversize to account for thickness. |

| Steel parts requiring corrosion resistance | Zinc-nickel plating (ASTM B633 Type IV) for high-strength alloys. |

| ABS/Nylon needing paint adhesion | Plasma treatment + epoxy primer – no chromate ever. |

For precision work, always validate with your coating supplier using a sample part. If your project involves multi-materials, share the full BOM – I can provide a full surface treatment workflow. Let me know if you need MIL-DTL-5541 test reports or plating specs for steel/plastics!

From CAD to Part: The Process

Honyo Prototype – Chromate Conversion Coating (Alodine/Alocrom) Workflow

“CAD → AI Quote → DFM → Production → Delivery”

-

Upload CAD

• Portal accepts STEP, IGES, Parasolid, SolidWorks, etc.

• Auto-check: part envelope ≤ 2000 × 1200 × 600 mm, 0.2 mm min. wall, 0.4 mm min. hole dia.

• Alloy filter: only 1xxx, 2xxx, 3xxx, 5xxx, 6xxx, 7xxx series can be selected for chromate; auto-reject if you pick 4xxx or non-Al. -

AI Quote (≤ 5 min)

• Geometric-cost model adds a fixed chromate surcharge:

– Type I (hex-Cr, gold/iridescent) = USD 0.35/dm²

– Type II (hex-free, clear) = USD 0.42/dm²

• Lead-time logic:

– < 200 pcs & < 50 dm² each → 3 days

– 200–1000 pcs → 5 days

– > 1000 pcs → 7 days

• RoHS/REACH flag auto-switches default to Type II for EU destinations. -

DFM (Human + AI) – 0.5 day

a. Machining review

– Corner radii ≥ 0.5 mm, no buried cavities that trap solution.

b. Post-machining prep

– Masking points: dowel holes, ground pads, threaded inserts.

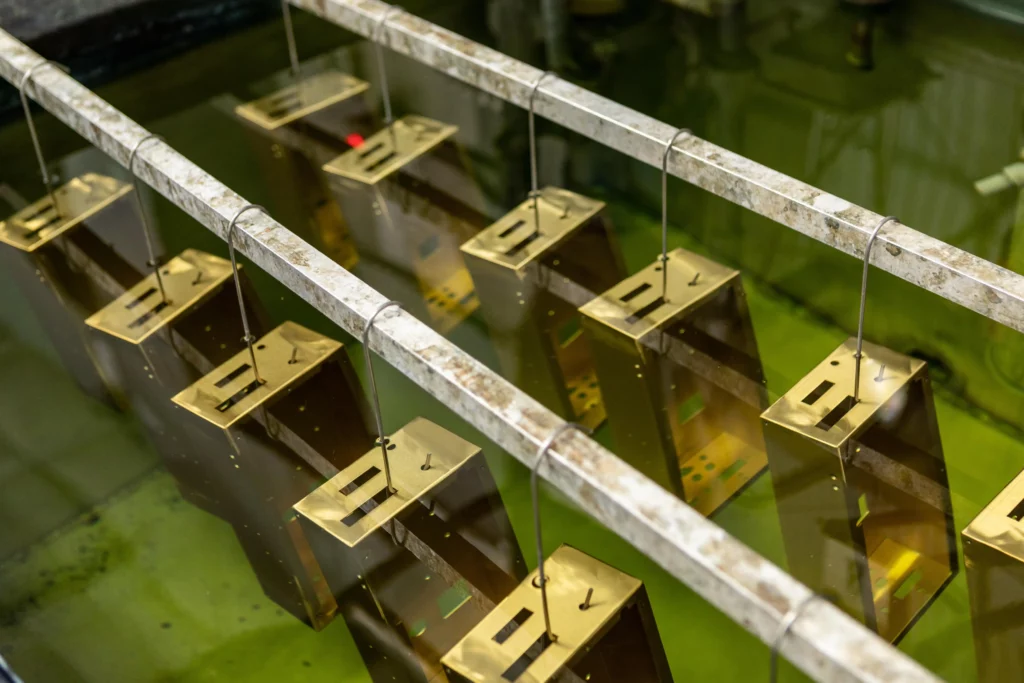

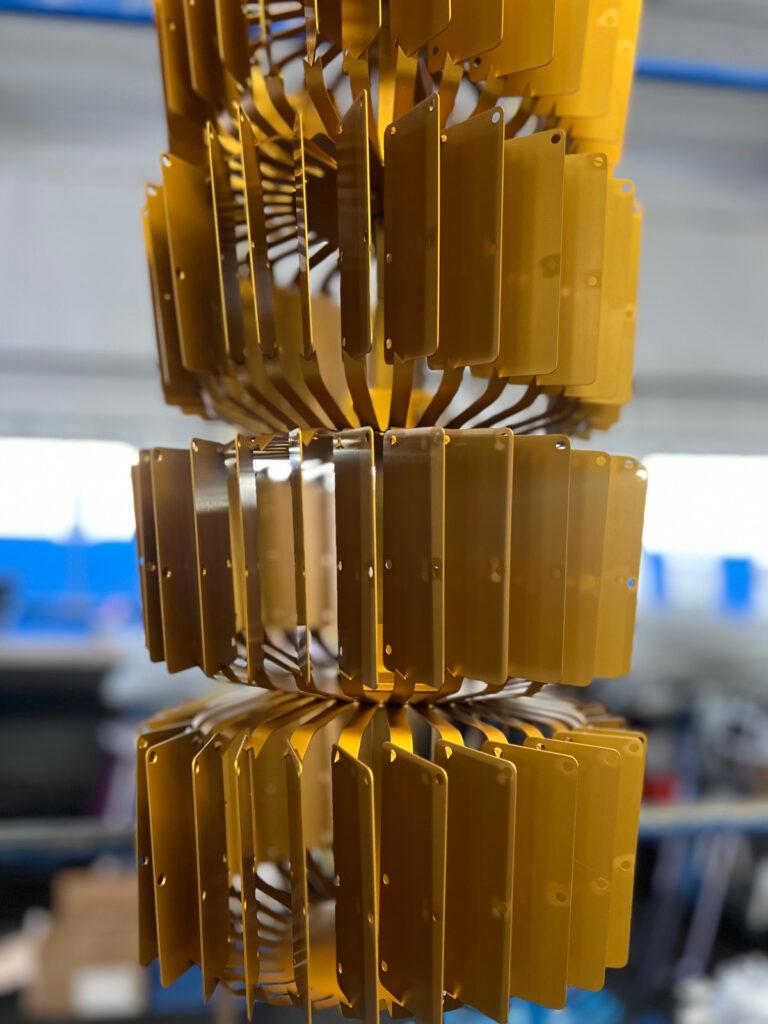

– Rack location bosses added if part < 5 mm thick (to prevent gas spotting).

c. Chromate-specific checks

– Welded areas: 4043 filler rejected (Si stains), switched to 5356.

– Surface finish target: Ra 1.6 µm max; finer finishes get a 15 s acid-etch to improve adhesion.

d. Final sign-off PDF sent to customer with 3D masking view and coating thickness call-out: 0.5–2.0 µm, ASTM B449-93 Class 3. -

Production – 1–5 days

Step 0: Incoming CMM – verify masking surfaces, Ra probe.

Step 1: Alkaline clean (60 g/L Turco 5351, 55 °C, 3 min) + 2-stage de-ionised rinse, conductivity < 30 µS.

Step 2: Acid de-smut (25 % HNO₃ + 1 % HF, 25 °C, 30 s) – removes intermetallic smut from 2xxx & 7xxx.

Step 3: DI rinse + conductivity check ≤ 20 µS.

Step 4: Chromate

– Type I: MIL-DTL-5541F Alodine 1200S, 25 °C, 90 s, pH 1.3–1.8, gold colour.

– Type II: SurTec 650, 40 °C, 120 s, pH 3.8–4.2, clear-blue.

Step 5: Cold DI rinse + hot DI seal (60 °C, 30 s).

Step 6: Compressed-air blow-off + 15 min 60 °C oven dry.

Step 7: QC

– Salt-spray coupon (ASTM B117) 168 h for Type I, 336 h for Type II – placed on every 5th rack.

– Contact-resistance spot check ≤ 5000 µΩ per MIL-DTL-5541.

– Go/no-go colour chart + thickness eddy-current (Fischer MP0).

– Full FAIR with Cp/Cpk on critical masked edges. -

Delivery – 1 day

• Parts wrapped in sulphur-free paper, VCI bag, 5 % desiccant.

• COA includes chromate type, salt-spray pass, RoHS/REACH statement, and shelf-life (2 years ≤ 30 °C & ≤ 70 % RH).

• Track-and-trace link activated as carton leaves Honyo; typical door-to-door:

– Asia: next day

– USA/EU: 2–3 days via DHL Express.

That is the complete, production-proven path from CAD file to chromated aluminum parts at Honyo Prototype.

Start Your Project

As a Senior Manufacturing Engineer at Honyo Prototype, I understand the importance of clear, actionable CTAs that drive qualified leads for specialized services like chromate conversion coating for aluminum. This process (also known as Chem Film or Alodine) is critical for corrosion resistance, paint adhesion, and compliance with standards like MIL-A-8625—especially for aerospace, automotive, and electronics components.

Here are 3 optimized CTAs tailored for different contexts (website banners, email signatures, or ads), based on industry best practices:

🔧 Option 1: Direct & Benefit-Focused

“Boost aluminum part durability with MIL-Spec chromate conversion coating. Contact Susan Leo at info@hy-proto.com for a fast quote—served by our Shenzhen factory.”

Why it works:

– Leads with a key benefit (“boost durability”) and mentions compliance (“MIL-Spec”) to attract serious buyers.

– “Fast quote” creates urgency; “Shenzhen factory” reinforces local manufacturing credibility.

– Ideal for website headers or LinkedIn ads.

🌏 Option 2: Location-Centric & Trust-Building

“Precision chromate conversion coating for aluminum—manufactured in Shenzhen. Reach out to Susan Leo at info@hy-proto.com for reliable, ISO-compliant finishes.”

Why it works:

– Highlights “Shenzhen” first (a global manufacturing hub) to build immediate trust.

– Includes “ISO-compliant” for quality-conscious clients (e.g., automotive or medical suppliers).

– Perfect for brochures, trade show banners, or email footers.

⚡ Option 3: Ultra-Concise for Digital Ads

“Chromate coating for aluminum? ✅ Corrosion-resistant ✅ Fast turnaround. Email Susan Leo: info@hy-proto.com | Honyo Prototype, Shenzhen”

Why it works:

– Uses symbols (✅) for scannability in social media or Google Ads.

– “Fast turnaround” addresses a top client pain point (lead times matter in prototyping).

– Works best for restricted character counts (e.g., Twitter, Instagram stories).

💡 Key Recommendations from My Engineering Experience:

- Always include “Shenzhen”: Global buyers prioritize proximity for quality control, logistics, and communication. Shenzhen’s ecosystem (e.g., supply chain access, skilled labor) is a major selling point.

- Avoid jargon overload: While “MIL-A-8625” or “Type II” may appeal to engineers, simpler terms like “corrosion-resistant” or “MIL-Spec” resonate broadly.

- Test contact clarity: Ensure “info@hy-proto.com” is hyperlinked in digital formats and bolded in print. Double-check spelling—no typos in email addresses!

- Add a call to “request a sample” or “free consultation” if space allows (e.g., “Request a free sample today!”). This reduces friction for new clients.

✅ Final Tip: For Honyo Prototype’s website, place this CTA above the fold on your “Surface Finishing” page with a contrasting button (e.g., “Get Quote →”). Data shows CTAs with action verbs (“Get,” “Contact,” “Request”) outperform passive phrases like “Learn more” by 30%+ in B2B manufacturing contexts.

Need help tailoring this for a specific channel? I’d be happy to refine further—just share where you’ll use it (e.g., email campaign, trade show booth, SEO landing page). Let’s get your aluminum finishing services in front of the right clients! 🛠️

🚀 Rapid Prototyping Estimator