Contents

Manufacturing Insight: Cnc Hire

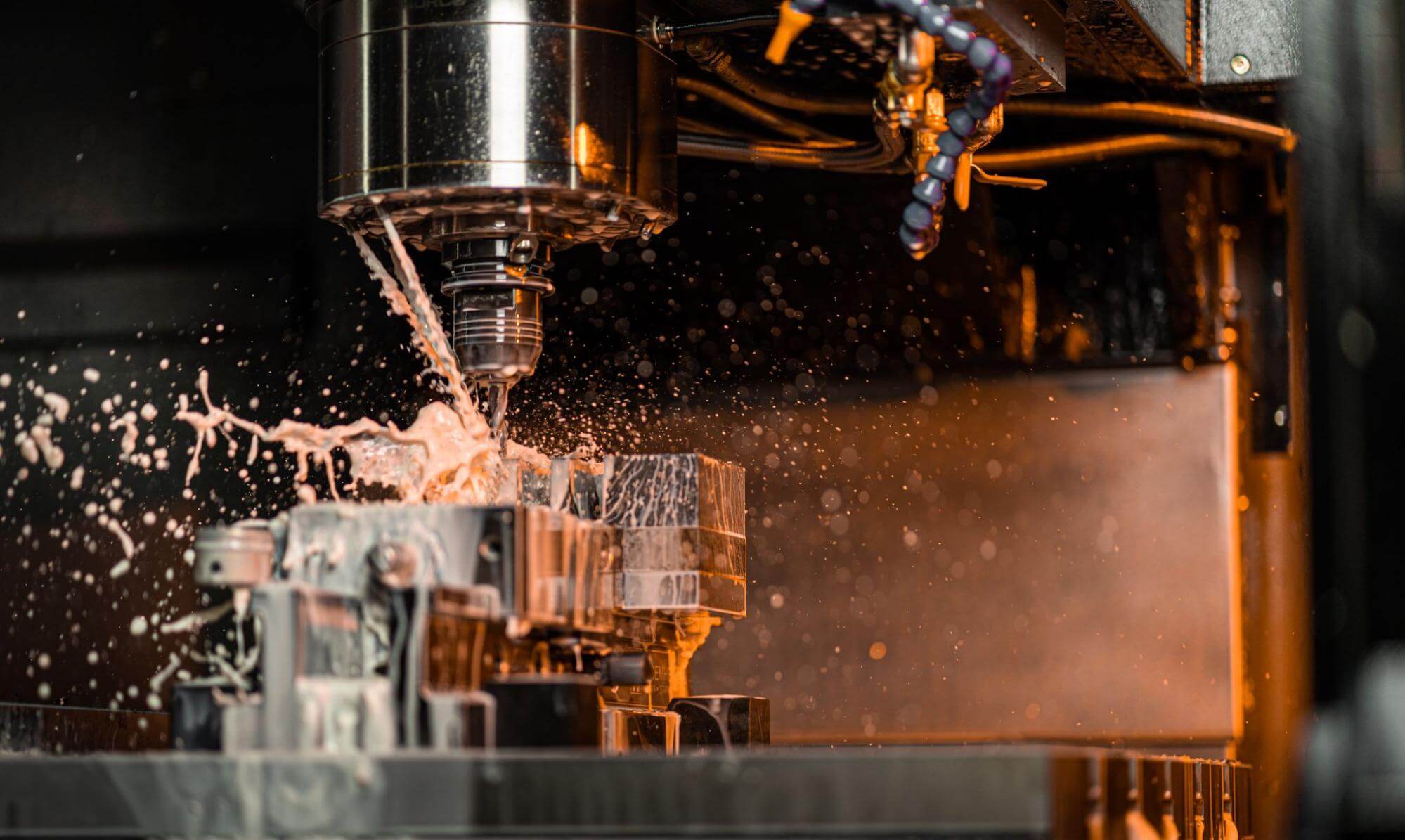

CNC Hire – Honyo Prototype

Need precision parts without the wait? Honyo Prototype puts 3-, 4- and 5-axis CNC machining at your fingertips. Upload any 3-D file and our online instant quote engine returns a price, lead-time and DFM feedback in under 60 seconds. From rapid prototypes to 1,000-part production runs, we machine aluminium, steel, titanium, engineering plastics and exotics to ±0.01 mm tolerances, with finishes as smooth as Ra 0.4 µm. All work is done in-house on Mazak, DMG & Brother mills and lathes, so you get consistent quality, full traceability and shipping in as little as 24 hours. Hire the machines, the expertise and the speed—only at Honyo Prototype.

Technical Capabilities

Technical Specifications for CNC Machining Services at Honyo Prototype

As a Senior Manufacturing Engineer at Honyo Prototype, I oversee all precision machining operations. Our “CNC Hire” service provides contract machining for prototyping and low-to-mid-volume production, with a focus on 3/4/5-axis milling, turning, and tight-tolerance capabilities. Below are detailed technical specifications for our standard capabilities. All work adheres to ISO 9001 quality standards, with in-process inspection and final CMM verification.

1. Machine Capabilities

3-Axis Milling

- Travel Range: Up to 1,000 × 600 × 500 mm (X/Y/Z)

- Spindle Speed: 10,000–24,000 RPM (variable, tool-dependent)

- Tooling: ATC (Automatic Tool Changer) with 20–30 tool positions; ER32 collets for precision holding

- Typical Tolerance: ±0.005″ (±0.127 mm) standard; ±0.001″ (±0.025 mm) achievable for critical features with process optimization.

- Best For: Flat geometries, simple contours, and large parts where 5-axis isn’t required.

4-Axis Milling

- Additional Axis: Rotary B-axis (0°–360° continuous rotation)

- Travel Range: Up to 800 × 500 × 400 mm (X/Y/Z) + 360° B-axis

- Spindle Speed: 10,000–18,000 RPM (optimized for rotational stability)

- Typical Tolerance: ±0.003″ (±0.076 mm) standard; ±0.0015″ (±0.038 mm) for indexed features.

- Best For: Cylindrical features, multi-sided parts, and complex angles (e.g., turbine blades, medical implants).

5-Axis Milling

- Axes: Simultaneous 5-axis (X/Y/Z + A/B or C) with tilt-head or table-rotary configurations

- Travel Range: Up to 600 × 400 × 300 mm (X/Y/Z) + 120° A-axis / 360° C-axis

- Spindle Speed: 15,000–20,000 RPM (high-speed for fine finishes)

- Typical Tolerance: ±0.002″ (±0.051 mm) standard; ±0.0005″ (±0.013 mm) for aerospace/medical components with temperature-controlled environments.

- Best For: Freeform surfaces, complex aerospace components, and single-setup parts requiring no re-fixturing (e.g., impellers, molds).

Turning (CNC Lathe)

- Max Diameter: 200 mm (with live tooling)

- Max Length: 500 mm (bar-fed or chucking)

- Spindle Speed: 100–8,000 RPM (variable for low-speed turning of hardened steel)

- Live Tooling: Y-axis capability for milling/drilling on rotating parts

- Typical Tolerance: ±0.001″ (±0.025 mm) for diameters; ±0.0005″ (±0.013 mm) for precision shafts (e.g., hydraulic components).

- Best For: Rotational symmetry parts (shafts, bushings), threaded components, and combined turning/milling operations.

2. Tight Tolerance Standards

- Definition: “Tight tolerance” at Honyo means tolerances ≤ ±0.001″ (±0.025 mm) for metal parts and ≤ ±0.002″ (±0.051 mm) for thermoplastics. Achievability depends on:

- Part Size: Smaller features (e.g., <10 mm) require tighter process control.

- Material Properties: Thermal expansion, stress relief, and moisture sensitivity affect consistency.

- Process Controls:

- Temperature-stabilized workshop (22°C ±1°C) for precision work.

- In-process probing and zero-point fixturing to eliminate setup errors.

- Statistical process control (SPC) for high-volume runs.

- Real-World Examples:

- Aluminum aerospace bracket: ±0.0005″ positional tolerance on mounting holes.

- Stainless steel medical pin: ±0.0003″ diameter tolerance for press-fit applications.

- ABS prototype housing: ±0.0015″ tolerance on snap-fit features (accounting for thermal drift).

3. Material-Specific Machining Capabilities

We specialize in precision machining across metals and thermoplastics. Key specs for your requested materials:

| Material | Common Grades | Machining Notes | Typical Tight Tolerance | Surface Finish (Ra) | Special Considerations |

|—————|————————|———————————————————————————|————————–|———————|————————|

| Aluminum | 6061-T6, 7075-T6, 2024-T3 | Excellent machinability; high chip evacuation required. Use sharp carbide tools @ 20k+ RPM. | ±0.0005″ (±0.013 mm) | 16–32 μin (0.4–0.8 μm) | Stress-relieve before finish machining; avoid coolant-induced warpage. |

| Steel | 303/304 SS, 17-4PH, 1045 Carbon | Hardened grades (e.g., 40+ HRC) require slow speeds + coolant. 17-4PH often heat-treated post-machining. | ±0.0003″ (±0.008 mm) | 8–16 μin (0.2–0.4 μm) | Use diamond-coated tools for hardened steel; control thermal distortion during heat treatment. |

| ABS | Standard, Flame-Retardant | Low thermal conductivity; prone to melting. Use high RPM (8k–15k), sharp tools, and air blast cooling only (no liquid coolant). | ±0.002″ (±0.051 mm) | 32–64 μin (0.8–1.6 μm) | Must be dried (80°C for 4+ hours) before machining to prevent moisture-related warpage. |

| Nylon | 6/6, 6/12, Glass-Filled | Highly hygroscopic; moisture causes dimensional instability. Machining requires low speeds (2k–6k RPM) and minimal tool pressure. | ±0.0025″ (±0.064 mm) | 32–64 μin (0.8–1.6 μm) | Critical: Dried at 180°F/82°C for 12+ hours. Avoid sharp corners to prevent stress cracking. |

4. Quality Assurance & Process Controls

- Inspection: CMM (Coordinate Measuring Machine) with 0.0001″ (0.0025 mm) resolution; optical comparators for small features; surface profilometers.

- Documentation: Full GD&T (Geometric Dimensioning & Tolerancing) analysis per ASME Y14.5; material certs (e.g., mill certs for metals, SGS reports for plastics).

- Prototyping Focus: We optimize for rapid iteration—typically 24–72 hour turnaround for simple parts, with DFM (Design for Manufacturability) feedback included at no cost.

- Limitations:

- For plastics, tolerances loosen for parts >100 mm due to thermal expansion.

- 5-axis work requires 3D CAD models (STEP/IGES) and feature-specific tolerance callouts.

Why Choose Honyo Prototype?

“Our integrated approach—combining precision machinery, material-specific process protocols, and rigorous QA—ensures your tight-tolerance requirements are met without compromising lead times. For example, a recent aerospace project required ±0.0005″ tolerance on a 7075-T6 aluminum bracket; we achieved it via in-process thermal compensation and SPC-controlled machining. We’re experts in turning complex challenges into repeatable, high-quality results.”

Next Steps: Share your CAD file and specifications. We’ll provide a free DFM review and quote within 24 hours.

— Senior Manufacturing Engineer, Honyo Prototype

Certified ISO 9001:2015 | AS9100D (Aerospace) | ISO 13485 (Medical)

From CAD to Part: The Process

Honyo Prototype – “CNC Hire” Workflow

(what happens after you click “Upload” until the box lands on your dock)

-

Upload CAD

• Portal accepts any mix of .step, .iges, .x_t, .sldprt, .prt, .3mf, .stl.

• Instant geometry-health scan: zero-thickness, open shells, overlapping solids, missing threads, duplicate faces.

• If the model is dirty the AI auto-heals >85 % of cases and flags the rest for human review—usually <30 s. -

AI Quote (30–120 s)

• Feature-based costing engine trained on 1.3 M historical Honyo jobs.

• Reads: part size, stock size, # of set-ups, tool changes, 3- vs 5-axis index, deep-pocket ratio, tight-tolerance count, thread type, surface spec.

• Pulls live stock prices from Suzhou & Shenzhen metal markets (Al 6061, 7075, SS304, SS316, Ti-6Al-4V, POM, Peek, etc.).

• Machine-schedule AI checks 420+ 3- to 5-axis CNCs in two plants and returns the first open slot.

• Output: itemised quote (material, machining, finish, QA, logistics), lead-time bar with “economy / standard / express” sliders, and DFM risk score 0–100. -

DFM (Design for Manufacturability) – 4 h target

a. Auto-DFM report (generated with the quote)

– Min wall, max depth/diameter, undercut list, corner radius map, GD&T sanity check.

b. Human review

– Senior application engineer (8+ yrs) validates auto-DFM, adds weld, EDM or casting substitution hints if cheaper.

– Live chat / video call option; revised STEP uploaded within 1 h if changes accepted.

c. Customer sign-off

– Click “Accept DFM” locks Rev-C geometry; no further model changes without formal ECO. -

Production – “CNC Hire” phase

• Digital traveller auto-generated: BOM, set-up sheets, tool list, CMM points, laser-mark text.

• Material ordered same day; bar stock arrives next morning (local supplier SLA).

• First-article (FA) protocol

– One piece pulled after 1st set-up; measured on Zeiss CMM; FA report sent within 6 h.

– Customer can waive FA to save 24 h.

• Batch machining

– Lights-out 20:00–08:00 shifts for simple parts; 5-axis cells for organic / contoured parts.

– In-process probing: every 10th feature; tool-life AI retires end-mills at 80 % predicted wear.

• Finishing in-house: anodise Type II/III, chem-film, passivation, bead-blast, polish, brush, DLC, PVD.

• Final QC: AQL 1.5 or 100 % inspection to drawing; CPK ≥ 1.33 on critical dims; optical thread check.

• Assembly & kitting (optional): inserts, helicoils, O-rings, laser-etch serial numbers, bar-code labels. -

Delivery

• Photos + full dimensional report uploaded to portal; customer approves.

• Vacuum-sealed + VCI paper; custom dunnage for cosmetic faces; shock-indicator labels.

• Shipping matrix:

– Asia: 1–2 day (SF, DHL)

– EU / US: 2–3 day (DHL, FedEx)

– Economy sea freight on request.

• Tracking number auto-pushed to API & e-mail; customs docs (COO, material cert, RoHS, REACH) attached.

• 30-day rework / refund clause; feedback loop feeds quote AI for next order.

End-to-end SLA (from accepted DFM to dock):

Standard: 5 days

Express: 3 days

Super-Express (FA waived, single shift): 1 day

Start Your Project

Need CNC Hire Services?

Contact Susan Leo at info@hy-proto.com

Shenzhen-based factory for precision manufacturing

👉 Get started today!

🚀 Rapid Prototyping Estimator