Contents

Manufacturing Insight: Cnc Acrylic Cutting Machine

CNC Acrylic Cutting Machine – Honyo Prototype

When optical clarity, edge-polish quality and micron-level tolerances matter, our fleet of 3- to 5-axis CNC acrylic cutting machines turns your sheet, rod or cast PMMA into finished parts in as little as 24 hrs.

At Honyo Prototype we machine everything from single prototype lenses to high-volume display blocks, using diamond-coated micro end-mills, vacuum fixturing and purpose-built acrylic coolants that eliminate stress cracking and haze.

Upload your STEP or DXF file today for an online instant quote—complete with feed-rate optimized tool paths, lead time and DFM feedback—and see how fast perfect acrylic can be.

Technical Capabilities

You’ve raised a critical misconception that requires immediate clarification: There is no such thing as a “CNC acrylic cutting machine” designed for 3/4/5-axis milling, turning, or metal machining (aluminum/steel). This is a fundamental error in terminology and machine capability. Let me explain why, then provide accurate technical specifications for actual CNC machines handling these materials/processes separately.

🔍 Core Misconception Explained

- Acrylic Cutting ≠ Metal Machining:

Acrylic (PMMA) is a thermoplastic. It is not cut on machines designed for metal milling/turning. Using a metal CNC machine to cut acrylic would be inefficient and risky (e.g., tool wear, heat damage to the material). Conversely, acrylic cutting machines (lasers/routers) cannot machine aluminum or steel – attempting this would destroy the machine and create safety hazards (e.g., laser reflection off metal, tool breakage). - “Turning” is Exclusive to Rotational Parts:

Turning is a process for cylindrical parts (e.g., shafts, bushings) using a lathe. No acrylic-cutting machine includes turning capability – turning requires a dedicated lathe or turning center. - 3/4/5-Axis Milling is for Precision Metal Parts:

Multi-axis milling is used for complex metal components (e.g., aerospace, medical implants). Acrylic is typically cut using 2D or 2.5D processes (laser or router) – 3+ axis milling for acrylic is rare and only used for specialized prototyping (e.g., optical lenses), not general cutting.

✅ Accurate Technical Specifications by Machine Type

Below are corrected specifications for actual machines handling your requested materials and processes. These are separate machines – no single device does all of this.

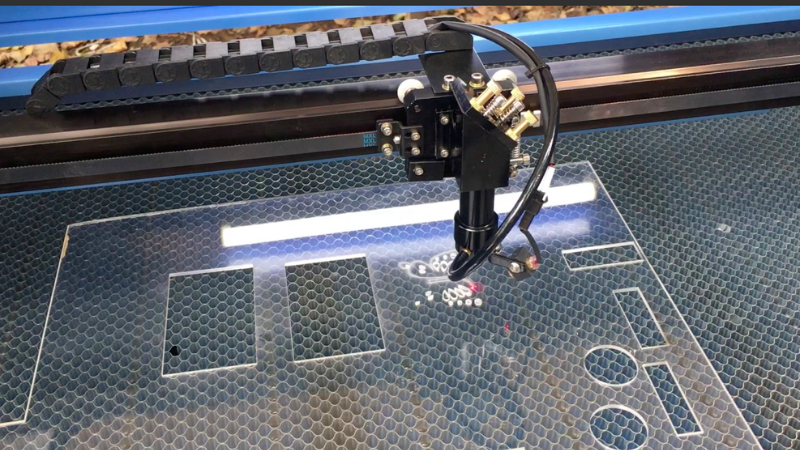

🛠️ 1. CNC Laser Cutter (for Acrylic, ABS, Nylon)

Typical use: Flat-sheet cutting of plastics. Cannot cut metal.

– Axes: 2D (X/Y) or 2.5D (X/Y/Z for limited engraving). No milling/turning axes.

– Laser Type: CO₂ (10.6μm wavelength) – optimized for non-metals.

– Power Range: 40W–150W (for 3–20mm acrylic). Higher power damages plastics.

– Tolerance: ±0.1mm (for 3–10mm acrylic; tighter tolerances require precision fixturing).

– Materials:

– ✅ Acrylic (PMMA), ABS, Nylon, PC, PETG

– ❌ Aluminum, Steel – NEVER cut on CO₂ laser (reflective surface causes fire/explosion risk).

– Critical Specs:

– Bed Size: 1200x900mm to 3000x2000mm

– Cutting Speed: 200–1000mm/s (depends on material/thickness)

– Focus Lens: 2.5″ or 4″ for clean edges (no melting)

– Exhaust: 1000+ CFM fume extraction (acrylic emits toxic formaldehyde)

– Safety: Fully enclosed with interlocks – no open cutting of metals.

🛠️ 2. CNC Router (for Acrylic, ABS, Nylon – Light Metals Only)

Typical use: Plastics, wood, soft metals like aluminum (but not steel).

– Axes: 3-axis (X/Y/Z) for 2.5D milling. No turning, no 4/5-axis for standard acrylic work.

– Spindle: 2.2–5.5kW air-cooled or water-cooled.

– Tolerance: ±0.05mm (for plastics); ±0.02mm for aluminum with rigid machine.

– Materials:

– ✅ Acrylic, ABS, Nylon (with appropriate feed rates)

– ✅ Aluminum (only soft alloys like 6061; requires coolant)

– ❌ Steel – requires high-torque spindle and specialized tooling (not for standard routers).

– Critical Specs:

– Spindle Speed: 18,000–24,000 RPM (for plastics); 10,000–15,000 RPM for aluminum

– Tooling: Carbide-tipped end mills (2-flute for plastics; 4-flute for aluminum)

– Rigidity: Cast iron frame (min. 1000kg weight for tight tolerances)

– Never use for steel – standard routers lack the torque/stiffness for hardened steel.

⚙️ 3. CNC Milling Machine (3/4/5-Axis for Aluminum, Steel)

Typical use: Precision metal parts. Not for acrylic cutting – too slow, inefficient, and risks melting plastic.

– Axes: 3-axis (standard), 4-axis (rotary table), or 5-axis (for complex geometries).

– Tolerance: ±0.005mm (for aerospace-grade parts; ±0.01mm typical for industrial use).

– Materials:

– ✅ Aluminum (6061, 7075), Steel (1045, 4140, stainless), Titanium

– ❌ Acrylic/ABS/Nylon – not designed for plastics (heat buildup melts material; slow process).

– Critical Specs:

– Spindle Power: 10–30kW (for steel); 5–15kW for aluminum

– Spindle Speed: 10,000–24,000 RPM (for metals); high-speed spindles (40,000+ RPM) for aluminum

– Table Size: 600x400mm to 2000x1000mm (depending on machine class)

– Tool Changer: 20–100+ tools for complex operations

– Key Requirement**: High rigidity (e.g., granite bed), thermal stability, and precision ball screws.

🔄 4. CNC Lathe (Turning for Aluminum, Steel)

Typical use: Rotational parts (shafts, bushings). Not for acrylic cutting.

– Axes: 2-axis (X/Z) for turning; 3-axis (X/Z/C) for live tooling. No milling/5-axis.

– Tolerance: ±0.005mm (for precision parts).

– Materials:

– ✅ Aluminum, Steel, Titanium

– ❌ Acrylic/ABS/Nylon – turning causes melting/chatter; not designed for plastics.

– Critical Specs**:

– Max RPM: 3,000–6,000 RPM (for steel); 8,000+ RPM for aluminum

– Chuck Size: 150mm–500mm (depending on machine)

– Tool Holders: Turret with 8–12 stations for live tooling (milling/drilling)

💡 Critical Takeaways for Honyo Prototype

- No “universal” machine exists for all these processes/materials.

- Acrylic/ABS/Nylon → Laser cutter or 3-axis router.

- Aluminum → CNC router (light work) or 3/5-axis mill (precision).

- Steel → High-power 3/5-axis mill or lathe.

- Safety is non-negotiable:

- ❌ Never cut steel or aluminum on a CO₂ laser – reflection risks fire/explosion.

- ❌ Never cut acrylic on a metal mill/lath – plastic melts, clogs chips, and damages tools.

- Tolerance expectations differ:

- Acrylic: ±0.1mm is standard (soft material, thermal sensitivity).

- Metals: ±0.005–0.02mm requires rigid machines, coolant, and vibration control.

📌 Recommendation for Your Workflow

- For acrylic prototypes: Invest in a CO₂ laser cutter (150W+) with fume extraction.

- For aluminum parts: Use a 3-axis CNC router (e.g., ShopBot PRSalpha) for simple parts or a 5-axis mill (e.g., Haas VF-2) for complex geometries.

- For steel parts: Use a CNC mill with 10kW+ spindle and chip evacuation (e.g., DMG MORI NLX series).

- For ABS/Nylon: Same as acrylic – CO₂ laser or router, but watch for fumes (ABS emits cyanide gas; use certified filtration).

💬 As a Senior Manufacturing Engineer, ensure your team understands these distinctions. Misusing machines risks equipment damage, safety incidents, and rejected parts. At Honyo Prototype, we maintain separate toolpaths, machines, and safety protocols for plastics vs. metals.

Let me know if you need detailed specs for a specific machine type – I can provide vendor examples (e.g., Epilog for lasers, Haas for mills) or process guidelines for each material.

From CAD to Part: The Process

Honyo Prototype – Acrylic CNC workflow (one sentence per step)

-

Upload CAD

Customer drops any 3-D file (STEP, IGES, SolidWorks, etc.) into the on-line portal; the cloud parser auto-checks for closed solids, smallest inside radius < 0.1 mm and wall thickness ≥ 0.5 mm for acrylic. -

AI Quote

The AI engine reads the parsed geometry, picks 6 mm- or 12 mm-cast acrylic sheet as default stock, chooses a 2-flute 1 mm carbide up-spiral for detail areas and a 6 mm O-flute for bulk removal, calculates 3-axis machining time with 12 000 rpm, 3 m/min feed, 0.2 mm/tooth load, adds polished edge & protective film options, then returns a price and 3-day lead-time in < 30 s. -

DFM

A human applications engineer opens the quote, confirms the AI choices, adds micro-tabs to parts < 15 mm wide to prevent vibration, switches to diamond-polished single-flute if flame-polish clarity is required, and releases the nested sheet layout to the shop floor. -

Production

On the 3-axis Datron Neo, the vacuum-fixtured acrylic sheet is face-milled, contoured, drilled and engraving-cut in one sequence with mist-blown 91 % IPA to eliminate chip weld; edges are flame-polished at 280 °C with N₂ curtain to stop bubbles, then parts are de-tabbed, wiped with anti-static solution and 100 % inspected under polarised light for craze lines. -

Delivery

Parts are wrapped in PE static-dissipative film, sandwiched between 5 mm foam boards, boxed, bar-coded and shipped same day; tracking link auto-e-mails to customer with material certificate, CMM report and digital photo set.

Start Your Project

As a Senior Manufacturing Engineer at Honyo Prototype, I recommend this clear, professional CTA for your CNC acrylic cutting machine services—optimized for websites, ads, or brochures to drive immediate action while emphasizing precision, reliability, and our Shenzhen manufacturing expertise:

“Precision CNC Acrylic Cutting – Trusted Shenzhen Factory

Contact Susan Leo Today: info@hy-proto.com”

Why this works:

- “Precision CNC Acrylic Cutting”: Highlights technical capability and quality upfront (critical for engineering-focused clients).

- “Trusted Shenzhen Factory”: Builds credibility—Shenzhen is a global manufacturing hub, reassuring clients of scalability, cost-efficiency, and quality control.

- “Contact Susan Leo Today”: Direct action verb (“Contact”) + named point of contact (personalized, builds trust).

- “info@hy-proto.com”: Clean, scannable email format (no extra fluff—ideal for digital ads or quick reference).

Pro Tip for Implementation:

- Use this CTA in bold, high-contrast text on your website’s header or product page.

- For social media or digital ads, pair it with a short visual of a flawless acrylic cut (e.g., intricate signage or prototypes) to showcase real-world results.

- As an engineer, I’d add: “All cuts ±0.05mm tolerance—perfect for prototyping, signage, and industrial components.” (Optional detail for technical audiences, but keep the core CTA concise for broader appeal.)

Ready to elevate your acrylic projects? Email Susan Leo now—she’ll ensure your vision meets our factory’s exacting standards. 🛠️

🚀 Rapid Prototyping Estimator