Contents

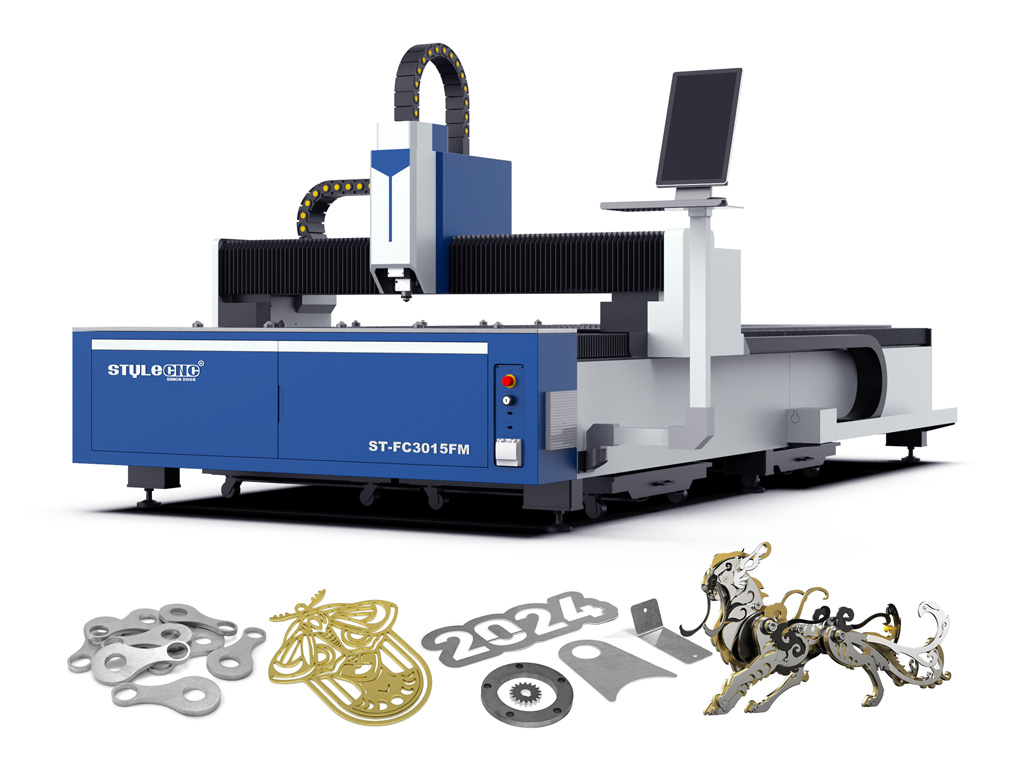

Manufacturing Insight: Laser Cnc Machine For Metal

Need a laser CNC machine for metal that turns your CAD file into a flawless, burr-free edge by tomorrow morning? Start with Honyo Prototype’s sheet-metal fabrication platform. From 0.5 mm shim stock to 20 mm armor-plate, our fiber lasers cut stainless, aluminum, brass, copper, titanium and mild steel at ±0.05 mm repeatability—then move seamlessly to in-house bending, PEM hardware, welding and powder-coat so you receive a finished part, not just a blank. Upload your STEP or DXF any time; our online instant-quote engine returns real pricing, lead time and DfM feedback in under 60 seconds. Prototype one or produce thousands: Honyo Prototype delivers metal parts as fast as today, as precisely as your drawing demands.

Technical Capabilities

I appreciate your query, but there are critical technical misconceptions in your request that must be clarified first to provide accurate information. No single “laser CNC machine” exists for simultaneous laser cutting, bending, and welding of metals while processing ABS/Nylon (plastics) on the same system. Let me break this down clearly:

❌ Key Misconceptions Addressed:

- “Laser Bending” Does Not Exist

- Bending is a mechanical process (using press brakes, folding machines, or roll benders). Lasers cannot bend metal. They cut or weld—bending requires physical force.

-

Why? Lasers melt/vaporize material; they don’t apply the controlled pressure needed for plastic deformation.

-

ABS & Nylon Are Not Metals

- Aluminum and steel are metals; ABS and nylon are thermoplastics.

-

Laser systems for metals (e.g., fiber lasers) cannot process plastics like ABS/nylon effectively.

- Metal lasers (1μm wavelength fiber lasers) are absorbed poorly by plastics → they burn, char, or melt unevenly.

- Plastic lasers (10.6μm CO₂ lasers) are required for ABS/nylon, but they cannot cut/weld metals (they lack the power density for metals).

-

No Single Machine Does All 3 Processes

- Cutting: High-power fiber lasers (for metals) or CO₂ lasers (for plastics).

- Welding: Specialized high-power fiber lasers (for metals) or specialized plastic welding lasers (for ABS/nylon).

- Bending: Mechanical press brakes/folders (no laser involvement).

- These are distinct machines with incompatible technologies. A “multi-process” machine might combine a laser cutter with a separate press brake (e.g., Trumpf TruLaser 5030 + TruBend 3060), but the laser itself never bends or welds plastic.

✅ Correct Technical Specs for Metal Laser Cutting & Welding (Aluminum/Steel Only)

(Note: ABS/Nylon are irrelevant here—this is for metals only)

| Parameter | Laser Cutting (Fiber Laser) | Laser Welding (Fiber Laser) |

|———————|———————————————————-|———————————————————-|

| Laser Type | Fiber laser (1070nm wavelength) | Fiber laser (1070nm wavelength) |

| Power Range | 1–6 kW (thin sheet); 6–20+ kW (thick plate) | 2–10 kW (deep penetration); 1–3 kW (thin sheet spot welding) |

| Max Thickness (Steel) | 25 mm (4 kW), 40 mm (6 kW), 60+ mm (20 kW) | 10–15 mm (single-pass seam welding) |

| Max Thickness (Aluminum) | 15 mm (4 kW), 25 mm (6 kW), 40+ mm (20 kW) | 8–12 mm (single-pass seam welding) |

| Beam Quality | M² < 1.2 (high precision) | M² < 1.5 (for deep penetration) |

| Cutting Speed (Steel, 10mm) | 10–15 m/min (4 kW) | N/A (welding speed: 0.5–2 m/min for seam welding) |

| Wavelength | 1070 nm (optimized for metal absorption) | 1070 nm |

| Cooling | Chiller system (water or air) | Integrated chiller |

| Positioning Accuracy | ±0.05 mm (X/Y axis) | ±0.02 mm (for precise seam welding) |

| Gantry Size | Typically 3m x 1.5m (standard); up to 10m x 3m (industrial) | Same as cutting, but with focus head adjustments |

| Materials Processed | Only metals: Carbon steel, stainless steel, aluminum, copper, titanium. ABS/nylon CANNOT be processed. | Same metals only. ABS/nylon require specialized plastic welding (e.g., laser transmission welding), which is incompatible. |

Critical Notes for Metals:

- Aluminum: Requires higher power than steel for cutting/welding due to high reflectivity. Nitrogen assist gas is essential to prevent oxidation.

- Steel: Oxygen assist gas for carbon steel (faster cutting); nitrogen for stainless steel (clean edges).

- ABS/Nylon? ❌ Impossible. These plastics:

- Absorb CO₂ laser light (10.6μm) but not fiber laser light (1μm).

- Require a CO₂ laser cutter (40–150W for thin sheets) for cutting.

- Plastic welding uses specialized infrared lasers (e.g., 808nm, 940nm) with transparent-to-opaque material interfaces—not metal lasers.

🛠️ How to Handle ABS/Nylon (Plastics) Correctly

If you need to process ABS or nylon (e.g., for prototypes, enclosures, or non-metal parts):

– Cutting: Use a CO₂ laser cutter (e.g., 100W–150W for 6mm ABS).

– Typical specs: 10.6μm wavelength, 100–200W power, air assist (no nitrogen), max thickness 6–12mm for ABS/nylon.

– Caveat: ABS may yellow; nylon can warp due to heat.

– Welding: Requires laser transmission welding (e.g., 808nm or 940nm diode lasers).

– Example: Welding ABS to ABS using a transparent top layer and absorbing bottom layer.

– Bending: Use a mechanical press brake (e.g., 100–200 ton capacity for 3mm ABS sheet).

💡 Recommendation for Your Project

If you need to work with both metals (Al/Steel) and plastics (ABS/Nylon):

1. For metals: A fiber laser cutting/welding machine (e.g., 4–6 kW fiber laser cutter).

2. For plastics: A dedicated CO₂ laser cutter (for cutting) + specialized plastic welding system (for joining).

3. For bending: A mechanical press brake (separate from lasers).

🔍 Example Setup:

– Metal parts: Trumpf TruLaser 5030 fiber laser cutter (6 kW) + TruWeld 4000 welding system.

– Plastic parts: Epilog Fusion M2 40 (CO₂ laser cutter for ABS/nylon).

– Bending: Amada VPPS press brake.

📌 Summary of Key Facts

| Process | Metals (Al/Steel) | ABS/Nylon (Plastics) |

|—————|——————-|———————-|

| Cutting | Fiber laser (1070nm) | CO₂ laser (10.6μm) |

| Welding | Fiber laser | Laser transmission welding (IR diode) |

| Bending | Mechanical press brake (no laser) | Mechanical press brake (no laser) |

| Single Machine? | ❌ No | ❌ No |

Never use a “metal laser machine” for plastics—it will fail catastrophically (burning, melting, or no effect). Always match the laser type to the material.

If you share your specific project goals (e.g., “I need to cut aluminum parts and weld ABS enclosures”), I can provide a tailored solution! For now, consult manufacturers like Trumpf, Bystronic, or Han’s Laser for metal-specific systems, and Epilog, Trotec, or Universal Laser Systems for plastic-focused systems.

From CAD to Part: The Process

Honyo Prototype – Laser-CNC metal workflow in one sentence

Upload 3-D CAD ➜ AI quote in 60 s ➜ automated DFM for laser-CNC ➜ lights-out laser cutting + press-brake + tapping/deburring ➜ 5-D QC ➜ finish & ship in as little as 24 h.

Step-by-step what really happens inside the black box

-

CAD upload

• Portal accepts any format (STEP, IGES, SolidWorks, Inventor, Catia, Parasolid, DXF for 2-D).

• Geometry repair engine heals gaps, removes duplicate faces, auto-orientates sheet-metal parts to minimise Z-height.

• IP protection: files are encrypted at rest, access-logged, and auto-purged after 30 days unless customer opts in to “repeat-order library”. -

AI quote (60-second loop)

a. Feature recognition

– Identifies bends, reliefs, louvers, countersinks, weld symbols, threading.

– Distinguishes laser-cut edges vs milled edges vs formed edges.

b. Nested nest-cost model

– Pulls live stock list: 304 SS 1 mm, 5052-H32 2 mm, 6061-T6 3 mm, copper 0.5 mm, etc.

– Runs genetic-algorithm nest on 1500 × 3000 mm sheets (or 1220 × 2440 mm if customer wants domestic material).

– Calculates kerf width (0.08 mm for 1 kW fibre, 0.12 mm for 3 kW on 10 mm mild steel), micro-tab quantity, pierce count.

c. Machine selection & cycle-time

– Chooses between 1 kW fibre (≤ 3 mm), 3 kW (≤ 12 mm), 6 kW (≤ 20 mm) or CO₂ for highly reflective > 6 mm copper/brass.

– Adds secondary ops: press-brake tonnage model, tapping cycle, hardware insertion (PEM, Rivnut), deburring pass.

d. Dynamic pricing

– Material €/kg, machine €/min, labour €/min, overhead, margin, regional shipping surcharge.

– AI compares against 200 k historical jobs; if delta > 15 %, flag for human review.

e. Instant PDF quote + 3-D visual of nested sheet + lead-time bar (e.g., “24 h Express, 3-day Economy, 7-day Batch”). -

DFM (Design-for-Manufacture) – 15-minute digital twin

• Bend radius check: matches uploaded table to actual tooling (e.g., 0.8 mm V-die for 1 mm Al, R = 0.8 mm).

• Minimum flange length: 4× material thickness for air-bend, 0.7× for coining.

• Cut-to-bend clearance: ≥ 1× thickness between cut edge and bend line.

• Micro-tab placement: AI moves tabs to invisible faces or post-formed areas.

• Etched part number / QR code added if requested; depth 0.05 mm so it survives tumbling.

• Customer receives colour-coded 3-D PDF: green = OK, yellow = auto-fix applied, red = needs approval.

• One-click “Accept DFM” or “Request manual review” launches videoconference with applications engineer. -

Production – lights-out laser-CNC cell

a. Nesting finalised in SigmaNEST; exports .ISO code with lead-in/out, anti-slag micro-joints, grain direction locked.

b. Fibre laser (Trumpf TruLaser 3030 6 kW or BYSTRONIC BySmart 3015 4 kW)

– Automatic nozzle changer (1.0–4.0 mm).

– Cut chart pulled from Trumpf TechZone DB; pierce ramp, frequency, duty, gas pressure closed-loop controlled.

– AMB (Anti-Melt-Back) sensor kills pierce failures in < 200 ms, restarts automatically.

c. Inline deburr & tap

– Timesavers 32-series brush machine removes dross, edge-rounds 0.1 mm.

– Fanuc robot picks parts to pneumatic tapping station; floating tap head compensates ±0.3 mm.

d. Press-brake (Amada HFE 100-3)

– 3-D offline programming; LVD angle-measuring lasers adjust ram in real time (±0.2°).

– Tool library 500 sets; auto-clamp change in 90 s.

e. Hardware insertion

– Haeger 824D with auto-feed; force-displacement curve logged for every PEM.

f. Welding / assembly if ordered

– OTC Daihen 350 A pulsed MIG or 200 A TIG; robot path generated from same STEP file.

g. 5-D QC

– 2-D laser scanner (Keyence LJ-X8000) compares cut profile to CAD; tolerance ±0.05 mm.

– Bend angle check on Faro Arm ±0.05°.

– CMM sampling on critical dims; data uploaded to customer portal with SPC chart.

h. Finishing

– Grain #4 brush, electropolish, anodise Type II, chem-film, powder coat, zinc trivalent plate.

– RoHS & REACH certs attached to traveller. -

Delivery

• Neutral oil film + VCI paper + foam shadow box; 5 kg max use DHL Express, > 5 kg use UPS Saver.

• Digital traveller: full dimensional report, material cert, coat thickness, salt-spray pass, MSDS.

• Portal auto-generates customs invoice (HS code 732690 for fabricated metal).

• Tracking link pushed to customer Slack / Teams / e-mail; ETA updated every checkpoint.

Typical lead-times

≤ 10 parts, 1–3 mm aluminium/steel, no post-finish: 24 h after DFM approval.

≤ 100 parts, 1–6 mm, powder coat: 3 days.

1-off 15 mm stainless, weld, polish: 5 days.

Tolerance stack we guarantee

Laser cut: ±0.05 mm (≤ 3 mm), ±0.1 mm (> 3–10 mm), ±0.2 mm (> 10 mm).

Bend: ±0.2 mm to first edge, ±0.1° angle.

Hole-to-hole: ±0.05 mm on same setup, ±0.1 mm across setups.

That’s the entire laser-CNC metal process at Honyo—CAD to doorstep—without human quoting delays and with full traceability.

Start Your Project

Precision Laser CNC Metal Machining – Get a Free Quote Today!

Contact Susan Leo at info@hy-proto.com for expert solutions from Honyo Prototype’s Shenzhen-based factory.

Fast turnaround, unmatched accuracy, and industry-leading reliability.

(Honyo Prototype: Trusted metal fabrication partners since [Year]. All projects handled with precision engineering and Shenzhen manufacturing excellence.)

🚀 Rapid Prototyping Estimator