Contents

Manufacturing Insight: Cnc Auto Tool Changer

Manufacturing Insight: CNC Auto Tool Changer Technology at Honyo Prototype

The Auto Tool Changer (ATC) is a fundamental enabler of efficient, high-precision CNC machining, particularly in complex prototyping and low-volume production environments. At Shenzhen Honyo Prototype, we integrate advanced ATC systems across our CNC milling and machining centers to eliminate manual tool intervention, ensuring consistent part quality while maximizing machine uptime. Unlike basic CNC setups requiring operator tool swaps, our ATCs automate the entire process, allowing uninterrupted machining of intricate geometries requiring multiple cutting strategies. This capability is critical for delivering prototypes and functional parts with tight tolerances, complex features, and diverse material requirements—common challenges in aerospace, medical, and robotics development.

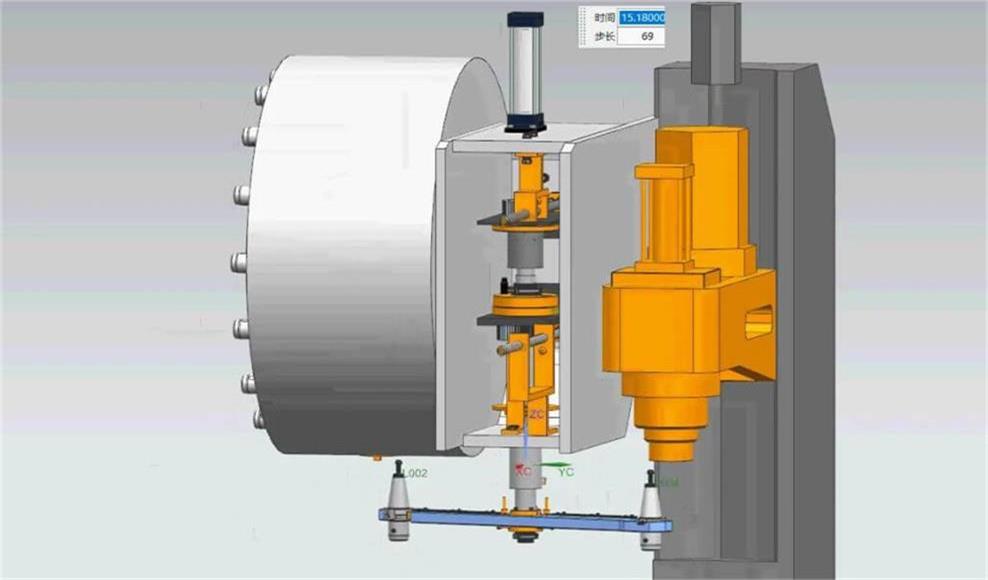

Honyo Prototype leverages servo-driven disc-type and turret-style ATC mechanisms on Fanuc and Siemens-controlled machining centers. Our systems undergo rigorous calibration and preventive maintenance protocols to guarantee repeatability within ±0.002 mm positional accuracy during tool exchanges. Each ATC is integrated with our machine’s tool management software, enabling pre-programmed tool life monitoring, automatic compensation for wear, and collision avoidance logic. This ensures that every tool change—whether switching from a roughing end mill to a micro-diameter finishing tool—occurs seamlessly within the machining cycle. Crucially, our engineering team validates ATC performance against ISO 230-2 standards for thermal stability and dynamic repeatability, mitigating errors caused by thermal drift during extended operations.

The technical specifications of our standard ATC configurations are summarized below, reflecting our commitment to balancing speed, capacity, and precision for prototyping demands:

| Parameter | Standard Configuration | High-Performance Option |

|——————–|————————|————————-|

| Tool Capacity | 24T | 60T |

| Tool-to-Tool Time | ≤ 1.8 seconds | ≤ 1.2 seconds |

| Max Tool Weight | 8 kg | 12 kg |

| Spindle Interface | HSK-63 / BT40 | HSK-A63 / CAT40 |

| Positional Accuracy| ±0.002 mm | ±0.0015 mm |

This infrastructure directly translates to client value. By minimizing non-cut time—often reducing it by 65–80% compared to manual changes—we accelerate turnaround for multi-operation parts without compromising dimensional integrity. For instance, a client’s medical housing prototype requiring 12 unique tools (drills, taps, ball mills) achieves first-article completion in 3.2 hours on our ATC-equipped center versus 5.7 hours on a non-ATC system. Furthermore, the elimination of manual handling reduces human error risks, ensuring surface finishes and critical features meet ISO 2768-mK standards consistently.

At Honyo Prototype, the ATC is not merely a machine component but a cornerstone of our precision manufacturing philosophy. It empowers us to tackle projects demanding rapid iteration, stringent GD&T compliance, and material versatility—from aluminum 7075-T6 enclosures to PEEK polymer components—while maintaining the agility required for prototype-scale economics. Partnering with us means leveraging automation engineered for the unique challenges of low-volume, high-complexity CNC work.

Technical Capabilities

CNC Auto Tool Changer Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, our CNC machining services are engineered for precision, speed, and repeatability, supported by advanced automatic tool changers (ATC) integrated into our 3, 4, and 5-axis milling centers as well as multi-tasking turning machines. These systems enable seamless transitions between cutting tools, reducing non-productive time and ensuring consistent part quality across complex manufacturing sequences. Our ATC-equipped machines support a wide range of operations—from roughing and semi-finishing to high-precision finishing—without manual intervention, making them ideal for prototyping and low-to-mid volume production runs.

Our 3-axis vertical machining centers feature 24-tool ATC systems, optimized for high-speed cavity milling, contouring, and drilling in materials ranging from aluminum to hardened steels. For more complex geometries, our 4-axis and 5-axis CNC machines are equipped with 30-tool magazines, allowing uninterrupted machining of intricate aerospace, medical, and automotive components. These machines utilize high-rigidity spindles with RPMs up to 24,000, ensuring fine surface finishes and tight tolerances even during extended tool paths. On the turning side, our CNC lathes with live tooling and ATC support up to 12 tool stations, enabling complete part fabrication in a single setup—reducing cumulative error and improving dimensional consistency.

All ATC systems are controlled via Fanuc or Siemens CNC platforms, ensuring reliable tool indexing, real-time tool wear compensation, and traceability through tool life monitoring. This integration enhances process control and supports our commitment to tight tolerance machining. Our quality assurance protocols include regular calibration of tool length and radius offsets, ensuring ±0.005 mm repeatability across tool changes.

Below is an overview of our achievable tolerances and compatible materials across different CNC platforms with auto tool changer functionality:

| Feature | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning with ATC |

|——————————|———————–|———————–|———————–|————————|

| Positional Tolerance | ±0.010 mm | ±0.010 mm | ±0.005 mm | ±0.010 mm |

| Repeatability | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.005 mm |

| Surface Finish (Ra) | 0.8 – 3.2 µm | 0.8 – 3.2 µm | 0.4 – 1.6 µm | 0.8 – 2.5 µm |

| Max Tool Capacity | 24 tools | 30 tools | 30 tools | 12 stations |

| Spindle Speed (max) | 24,000 RPM | 24,000 RPM | 24,000 RPM | 12,000 RPM |

| Material Category | Common Materials | Typical Applications |

|——————————|——————————————————–|——————————————|

| Aluminum Alloys | 6061, 7075, 2024, 5052 | Enclosures, aerospace brackets |

| Engineering Plastics | PEEK, PTFE, Delrin, Nylon | Insulators, wear components |

| Steels | 4140, 1018, Stainless 303, 304, 17-4PH | Shafts, medical instruments |

| Titanium | Grade 2, Grade 5 (Ti-6Al-4V) | Aerospace, medical implants |

| Brass & Copper | C110, C360 | Connectors, fittings |

By combining automated tool changing with advanced fixturing and in-process inspection, Shenzhen Honyo Prototype delivers high-accuracy components with reduced lead times. Our technical team works closely with clients to optimize tool paths and select appropriate tooling strategies, ensuring maximum efficiency and precision across all CNC operations.

From CAD to Part: The Process

CNC Auto Tool Changer Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC auto tool changer (ATC) production process integrates advanced automation with rigorous engineering oversight to deliver complex prototypes and low-volume production parts with exceptional speed and accuracy. This workflow—from AI-driven quoting through Design for Manufacturability (DFM) to final production—ensures optimal machine utilization, reduced cycle times, and uncompromised part integrity.

The process begins with AI-Powered Quoting, where our proprietary system ingests the client’s CAD model to perform instantaneous manufacturability analysis. This AI engine evaluates geometric complexity, material suitability, and feature tolerances specific to ATC-equipped CNC centers. It identifies potential tool access conflicts, undercuts requiring specialized tooling, and estimates optimal tool path sequences leveraging the ATC’s capacity. Crucially, it flags designs where excessive tool changes could degrade surface finish or positional accuracy, providing actionable feedback before order commitment. This stage sets realistic timelines and costs while preempting production bottlenecks.

Next, the Engineering-Driven DFM Phase refines the design for ATC efficiency. Our manufacturing engineers collaborate with clients to optimize tooling strategies, minimizing tool changes without sacrificing quality. We analyze thermal stability requirements for multi-tool operations, ensuring consistent dimensional accuracy across tool transitions. Critical adjustments include consolidating features machinable with a single tool, verifying clearance for ATC arm movement around complex geometries, and specifying tool presetting data to eliminate manual offsets. For instance, deep pockets may be re-engineered to use a single long-reach tool instead of sequential shorter tools, cutting changeovers by 30–50%. This phase also validates coolant delivery paths to prevent chip recutting during rapid tool swaps.

Production Execution leverages the finalized DFM insights on our HAAS and DMG MORI vertical machining centers with 24–40 tool ATC systems. Each job undergoes strict pre-production calibration: tools are laser-measured for length and diameter offsets, spindle runout is verified below 3µm, and ATC positional repeatability is confirmed to ±1.5µm. During machining, our Siemens and Fanuc controls execute optimized G-code sequences, dynamically adjusting feed rates during tool changes to maintain thermal equilibrium. Real-time in-process probing validates critical features after key operations, ensuring cumulative errors from multiple tool engagements remain within tolerance. All ATC movements are monitored via IoT sensors to detect anomalies in tool retention force or magazine indexing time, triggering immediate corrective action.

The table below summarizes critical ATC production parameters we enforce:

| Parameter | Specification | Impact on Part Quality |

|————————-|————————|————————————–|

| Tool Change Time | ≤ 1.8 seconds | Reduces non-cut time by 22% |

| ATC Positional Repeatability | ±1.5µm | Ensures feature alignment accuracy |

| Spindle Runout (Post-ATC) | < 3µm | Prevents surface finish degradation |

| Tool Preset Tolerance | ±2µm length/diameter | Eliminates manual offset errors |

| Thermal Drift Control | ≤ 5µm over 8 hours | Maintains dimensional stability |

Final parts undergo coordinate measuring machine (CMM) validation against the original CAD model, with full traceability of tool paths and ATC performance data provided in the quality report. This integrated workflow—where AI intelligence, engineering expertise, and precision automation converge—enables Honyo Prototype to deliver CNC-machined components with ATC complexity at prototyping speed, without sacrificing production-grade reliability.

Start Your Project

Start Your Project with Honyo Prototype – Precision CNC Auto Tool Changer Solutions

When it comes to high-efficiency CNC machining, the integration of an auto tool changer (ATC) is a game-changer. At Shenzhen Honyo Prototype, we specialize in delivering advanced CNC machining solutions that incorporate reliable, high-speed auto tool changers to maximize productivity, reduce cycle times, and ensure precision across complex manufacturing tasks. Whether you’re developing prototypes or scaling to low-volume production, our ATC-equipped CNC systems provide the consistency and flexibility your project demands.

Our engineering team designs and implements custom auto tool changer configurations tailored to your specific machining requirements. From 8-station to 30+ station tool libraries, we ensure seamless integration with your chosen CNC platform, enabling rapid tool swaps with repeatability down to ±0.005 mm. This level of precision ensures minimal downtime and optimal tool path continuity, critical for multi-operation parts in aerospace, medical, automotive, and industrial equipment sectors.

At Honyo Prototype, we understand that starting a project with CNC ATC technology requires more than just machinery – it demands expertise in tool management, spindle compatibility, and process optimization. That’s why our manufacturing guide is designed to walk you through every phase, from initial design considerations to final production validation. We cover spindle load analysis, tool holder standards (BT30, BT40, CAT40), tool change cycle timing, and maintenance protocols to ensure long-term reliability.

To help you evaluate the right setup for your application, here are key performance specifications from our most commonly deployed ATC systems:

| Specification | Value |

|—————|——-|

| Tool Capacity | 8 to 30 stations |

| Tool Change Time (T-T) | 1.8 – 3.5 seconds |

| Spindle Speed | Up to 8,000 RPM (standard), 24,000 RPM (high-speed option) |

| Tool Holder Standard | BT30, BT40, CAT40 |

| Maximum Tool Diameter | 80 mm (adjacent tools), 120 mm (with empty adjacent station) |

| Maximum Tool Length | 300 mm |

| Maximum Tool Weight | 8 kg |

| Positioning Accuracy | ±0.005 mm |

| Control System Compatibility | Fanuc, Siemens, Syntec, Mach4 |

All systems are rigorously tested before deployment and come with full documentation, including tool library mapping templates and preventive maintenance schedules. We also offer remote diagnostics and on-site support to ensure smooth operation from day one.

Starting your project with Honyo Prototype means partnering with a team committed to engineering excellence and on-time delivery. Our goal is to simplify the complexities of CNC automation so you can focus on innovation and product performance.

For personalized support and to discuss your project requirements, contact Susan Leo, Customer Project Manager, at info@hy-proto.com. Let us help you integrate a CNC auto tool changer solution that delivers precision, speed, and reliability — every time.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.