Contents

Manufacturing Insight: 12L14 Steel Material Properties

Manufacturing Insight: 12L14 Steel Material Properties for Precision CNC Machining

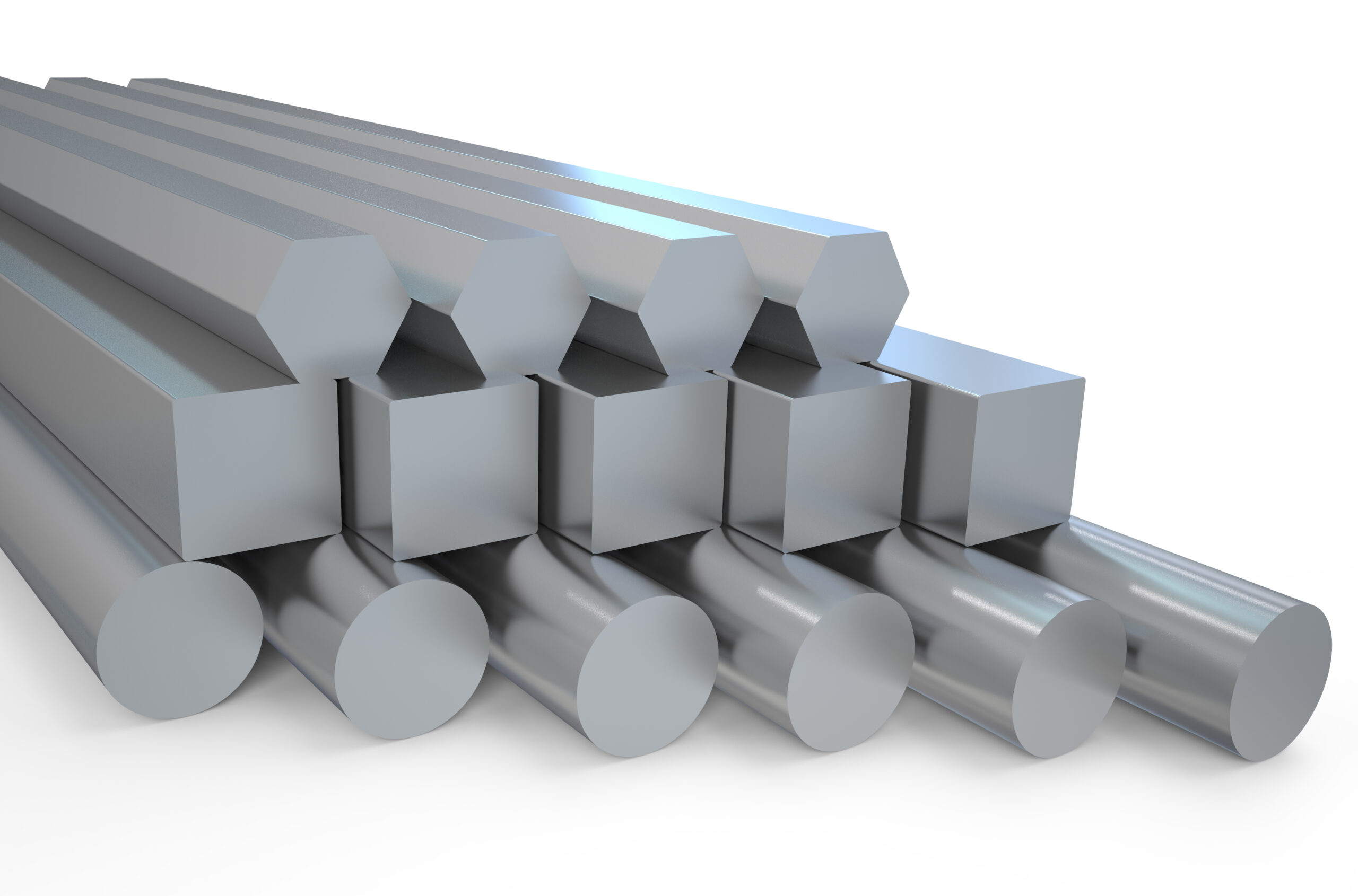

12L14 steel represents a cornerstone material within high-volume precision CNC machining, particularly for complex turned components demanding exceptional machinability and tight tolerances. As a resulfurized and rephosphorized free-machining carbon steel containing a precisely controlled lead addition (0.15-0.35%), 12L14 is engineered to optimize chip formation and reduce tool wear during high-speed operations. This inherent machinability, significantly superior to 1018 or 1215 steel, translates directly into reduced cycle times, extended tool life, superior surface finishes, and lower overall production costs for manufacturers. Its primary application lies in industries requiring vast quantities of precision parts, such as automotive fuel systems, hydraulic connectors, valve components, fasteners, and intricate machinery fittings where consistent dimensional accuracy and reliable thread quality are non-negotiable. While not intended for critical structural applications requiring high strength or weldability due to its lead content and lower ductility, 12L14 excels in high-volume production environments where machining efficiency and part consistency are paramount.

Understanding the core mechanical and physical properties of 12L14 is essential for effective process planning and quality assurance in CNC operations. The lead inclusion acts as a chip breaker and lubricant at the tool-workpiece interface, enabling higher cutting speeds and feeds without compromising surface integrity. However, this also necessitates careful consideration during secondary operations like welding or applications requiring through-hardening, as lead can cause porosity or weaken heat-affected zones. The material responds well to standard finishing processes such as plating, painting, and passivation. Critical properties for CNC machining planning include its relatively low tensile and yield strengths compared to higher-carbon steels, moderate hardness in the as-machined condition, and excellent cold formability for features like knurling or light coining. The following table summarizes key specifications relevant to precision machining:

| Property | Typical Value | Test Standard |

| :———————— | :——————— | :———— |

| Carbon (C) | 0.15% max | ASTM A29 |

| Manganese (Mn) | 0.85-1.15% | ASTM A29 |

| Phosphorus (P) | 0.04-0.09% | ASTM A29 |

| Sulfur (S) | 0.26-0.35% | ASTM A29 |

| Lead (Pb) | 0.15-0.35% | ASTM A29 |

| Tensile Strength | 57,000 psi (393 MPa) | ASTM A370 |

| Yield Strength (min) | 40,000 psi (276 MPa) | ASTM A370 |

| Brinell Hardness (HB) | 140 | ASTM E10 |

| Machinability Rating | 180% (100% = B1112) | – |

| Density | 0.283 lb/in³ (7.83 g/cm³) | ASTM A370 |

At Shenzhen Honyo Prototype, we leverage deep expertise in machining 12L14 steel to deliver exceptional value for production-volume components. Our advanced CNC turning and milling centers, coupled with optimized tooling strategies specifically calibrated for free-machining steels, ensure maximum throughput while maintaining micron-level tolerances and superior surface finishes. We implement rigorous in-process inspection protocols, including CMM verification and surface roughness testing, to guarantee every part meets stringent dimensional and quality requirements. Our material sourcing adheres strictly to ASTM A121 and AISI specifications, ensuring consistent lead distribution and machinability. By combining precise process control with our focus on material science understanding, Honyo transforms the inherent advantages of 12L14 steel into reliable, cost-effective, and high-quality components for our global manufacturing partners, minimizing lead times and eliminating production bottlenecks.

Technical Capabilities

12L14 Steel Material Properties for Precision CNC Machining at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining of free-machining steels, with 12L14 steel being a preferred material for components requiring excellent machinability, tight tolerances, and high production efficiency. 12L14 steel is a leaded modification of 12L13, formulated to optimize chip breaking and reduce tool wear during high-speed machining operations. This material is particularly well-suited for complex parts produced via 3-axis, 4-axis, and 5-axis milling, as well as precision turning applications.

The chemical composition of 12L14 steel includes approximately 0.15% carbon, 0.85–1.15% manganese, 0.25–0.35% sulfur, and 0.04–0.09% lead, with the remainder being iron and trace elements. The addition of lead enhances lubricity at the tool-chip interface, significantly improving surface finish and dimensional consistency. This makes 12L14 ideal for manufacturing threaded fasteners, bushings, shafts, gears, and other intricate components where both geometric precision and functional reliability are critical.

Mechanically, 12L14 steel typically exhibits a tensile strength of 55,000–75,000 psi and a Brinell hardness of 140–170 HB. While it is not recommended for applications requiring high strength or through-hardening due to its low carbon content and lack of hardenability, it performs exceptionally in cold working and threading operations. The material is not suitable for welding or high-temperature environments but excels in ambient-condition mechanical assemblies.

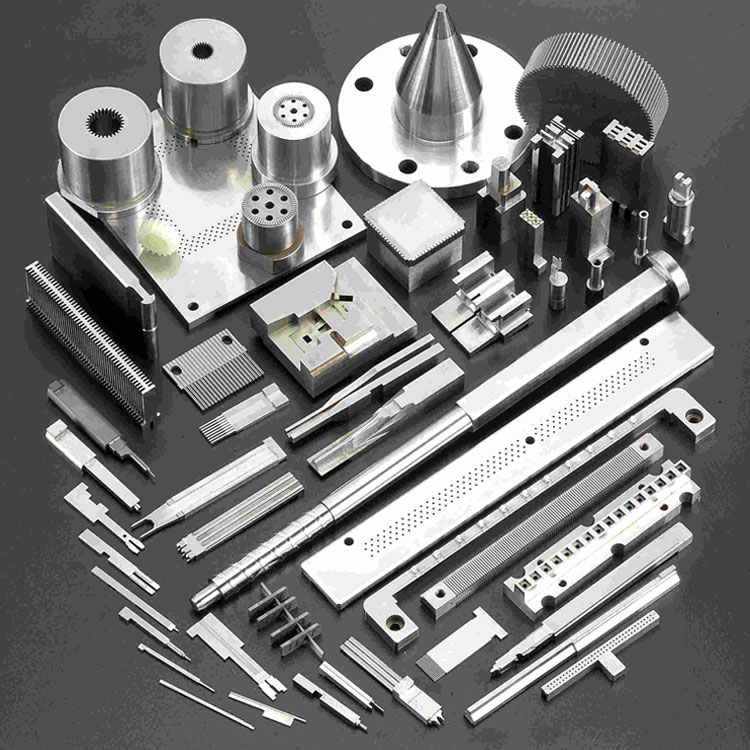

Our CNC machining capabilities support tight-tolerance production across all axes. For 3-axis milling, we maintain tolerances down to ±0.0005″ (±0.013 mm) on critical dimensions. With 4-axis and 5-axis configurations, we achieve angular precision of ±0.1° and positional tolerances of ±0.001″ (±0.025 mm), enabling the fabrication of complex geometries with minimal setup changes. Turning operations on 12L14 steel consistently achieve roundness within 0.0002″ (0.005 mm) and surface finishes as fine as 32 RMS.

The following table outlines key material properties and achievable tolerances for 12L14 steel in our CNC machining processes:

| Property | Specification |

|———|—————|

| Material Grade | AISI 12L14 |

| Carbon Content | 0.15% |

| Manganese | 0.85–1.15% |

| Sulfur | 0.25–0.35% |

| Lead | 0.04–0.09% |

| Tensile Strength | 55,000–75,000 psi |

| Brinell Hardness | 140–170 HB |

| Machinability Rating | 170% (relative to 100% for AISI 1212) |

| Typical Applications | Fasteners, shafts, bushings, gears, fittings |

| 3-Axis Milling Tolerance | ±0.0005″ (±0.013 mm) |

| 4/5-Axis Milling Tolerance | ±0.001″ (±0.025 mm) |

| Angular Accuracy | ±0.1° |

| Turning Roundness | 0.0002″ (0.005 mm) |

| Surface Finish (Typical) | 32–64 RMS |

Shenzhen Honyo Prototype leverages advanced CNC controls, in-process probing, and rigorous quality inspection to ensure that every 12L14 steel component meets exacting engineering standards. This material’s predictable behavior and superior machinability make it a cost-effective choice for high-volume and prototype production alike.

From CAD to Part: The Process

From CAD to Part: 12L14 Steel CNC Machining Workflow at Honyo Prototype

Understanding 12L14 free-machining steel’s unique properties is fundamental to optimizing the CNC production process at Honyo Prototype. This leaded steel offers exceptional machinability due to its lead inclusions, significantly reducing cutting forces and improving surface finish compared to non-leaded grades like 1215. However, its lower ductility and specific environmental handling requirements necessitate a structured workflow from initial inquiry to final part delivery. Our process ensures precision, efficiency, and adherence to material-specific best practices.

The workflow begins with the AI-Powered Quotation Phase. Upon receiving a CAD model, our proprietary AI system instantly analyzes geometry, material specification (12L14), and requested tolerances. It cross-references this data against our extensive database of 12L14 machining parameters, historical production times, and material cost fluctuations. Crucially, the AI flags potential issues inherent to 12L14, such as the risk of chip welding on internal features or the need for specific coolant types to manage lead dust. This generates a preliminary quote and lead time estimate within minutes, providing immediate value to the client while identifying early-stage material considerations.

Following client approval, the project enters the Critical DFM (Design for Manufacturability) Review. Honyo’s senior manufacturing engineers meticulously evaluate the CAD model specifically for 12L14’s characteristics. Key focus areas include verifying adequate wall thicknesses to prevent deformation given the material’s lower ductility, ensuring sufficient draft angles for easy ejection in secondary operations, and confirming that specified tolerances align with 12L14’s typical machining capabilities. Engineers assess feature geometry to minimize long, stringy chips – a non-issue with 12L14 due to its lead content promoting small, broken chips – and recommend optimal tool paths to leverage its high-speed machining potential. Any necessary design modifications to enhance producibility or reduce cost while maintaining function are proposed and discussed with the client.

Only after DFM sign-off does Precision CNC Production commence. Our Haas and DMG MORI centers are configured with parameters optimized for 12L14, as validated during DFM. Dedicated tooling strategies employing sharp, positive-rake carbide inserts maximize the material’s free-machining advantage. Strict adherence to recommended speeds and feeds ensures surface integrity and dimensional stability, while specialized coolant filtration systems manage lead particulate in compliance with environmental regulations. In-process inspections verify critical dimensions against the finalized DFM-approved drawing. Post-machining, parts undergo thorough deburring and final inspection per ASME Y14.5 standards before shipment. Throughout production, real-time data on machine performance and part quality is fed back to continuously refine our 12L14 machining parameters.

Typical Optimized CNC Machining Parameters for 12L14 Steel

| Parameter | Turning (Roughing) | Milling (Slotting) | Typical Tolerance (mm) | Surface Finish (Ra µm) |

| :—————– | :—————– | :—————– | :——————— | :——————— |

| Spindle Speed (SFM) | 350 – 500 | 250 – 400 | ±0.025 | 0.8 – 1.6 |

| Feed Rate (IPR/IPM) | 0.015 – 0.025 | 0.004 – 0.008 | (ISO 286-1 h7/m6) | (32 – 63 µin) |

| Depth of Cut (in) | 0.080 – 0.150 | Full Diameter | | |

This integrated workflow, deeply informed by 12L14’s material science, enables Honyo Prototype to deliver high-precision machined components rapidly while mitigating the specific challenges and maximizing the advantages of this essential free-machining steel for prototyping and low-volume production.

Start Your Project

Optimize Your CNC Machining Projects with 12L14 Steel – Partner with Honyo Prototype

When precision, efficiency, and reliability are critical in CNC machining, 12L14 steel stands out as a premier choice for high-volume production and complex components. At Shenzhen Honyo Prototype, we specialize in leveraging the unique properties of 12L14 steel to deliver machined parts that meet exacting industry standards. Whether you’re developing automotive components, hydraulic fittings, or precision fasteners, understanding the material fundamentals and partnering with an experienced manufacturer can dramatically reduce lead times and improve part performance.

12L14 steel is a resulfurized and rephosphorized free-machining carbon steel, engineered specifically to enhance machinability. The addition of sulfur and phosphorus creates inclusions that act as chip breakers during cutting operations, resulting in smoother finishes, reduced tool wear, and faster machining cycles. This makes 12L14 ideal for high-speed CNC turning, milling, and threading operations—especially in automated setups where consistency and throughput are paramount.

Below are key mechanical and chemical properties of 12L14 steel that make it a preferred material in precision manufacturing:

| Property | Value |

|——–|——-|

| Tensile Strength | 77,000 psi (531 MPa) |

| Yield Strength | 58,000 psi (400 MPa) |

| Elongation at 2″ | 10% |

| Reduction in Area | 35% |

| Brinell Hardness | 170 HB |

| Machinability Rating | 170% (relative to AISI 1212) |

| Density | 0.284 lb/in³ (7.85 g/cm³) |

| Chemical Composition (Weight %) | |

|——————————-|–|

| Carbon (C) | 0.15–0.20% |

| Manganese (Mn) | 0.85–1.15% |

| Sulfur (S) | 0.26–0.35% |

| Phosphorus (P) | 0.08–0.13% |

| Iron (Fe) | Balance |

While 12L14 offers exceptional machinability, it is not recommended for welding or cold forming due to its high sulfur and phosphorus content, which can lead to cracking under thermal or mechanical stress. Additionally, it cannot be through-hardened effectively, limiting its use in high-stress or high-wear environments unless surface treatments are applied.

At Honyo Prototype, our CNC machining experts evaluate each project for material suitability, dimensional complexity, and end-use requirements to ensure optimal results. We utilize advanced CNC lathes and milling centers equipped with tool monitoring and automated inspection to maintain tight tolerances—down to ±0.0002” when required.

Starting your next project with 12L14 steel is simple. Contact Susan Leo at info@hy-proto.com to discuss your design specifications, volume needs, and timeline. Our team provides rapid quoting, material sourcing, and DFM feedback within 12 hours of receiving your CAD files. With ISO 9001-certified processes and a focus on agile prototyping and low-to-mid volume production, Honyo Prototype is your trusted partner in precision manufacturing.

Let us help you transform your designs into high-quality, cost-effective components—on time and to specification. Reach out today and experience the Honyo difference.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.