Contents

Manufacturing Insight: Cnc Axis

Precision CNC Axis Capabilities Powering Your Next Prototype

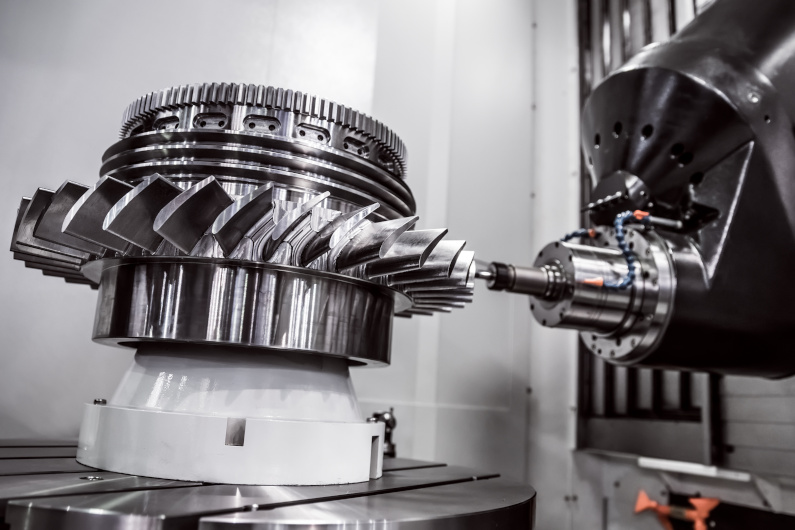

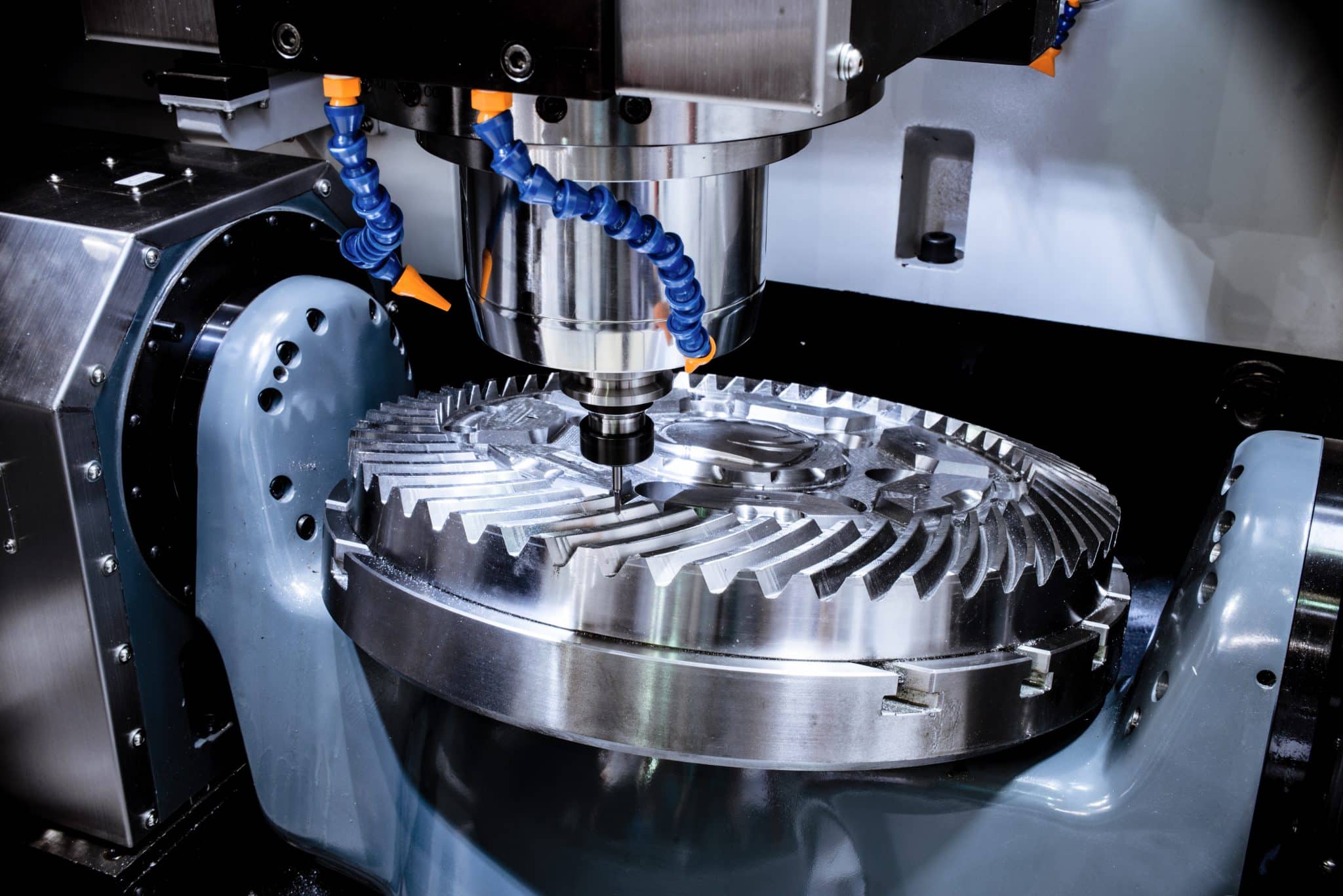

At Honyo Prototype, our advanced CNC machining services leverage multi-axis technology to transform complex geometries into high-fidelity functional prototypes and low-volume production parts. Understanding CNC axis configuration—whether 3-axis for prismatic components, 4-axis for rotational features, or full 5-axis for organic contours—is fundamental to achieving micron-level accuracy and surface integrity. We deploy state-of-the-art 3-, 4-, and 5-axis CNC centers equipped with high-speed spindles and dynamic tool compensation, enabling single-setup machining of intricate features while minimizing human intervention and error accumulation. This capability is critical for industries demanding repeatability in aerospace brackets, medical implants, and fluid dynamics components where tolerances consistently reach ±0.005mm.

Our engineering team optimizes axis utilization to reduce lead times by up to 40% compared to conventional multi-operation workflows. By integrating simultaneous 5-axis interpolation with adaptive toolpath algorithms, we maintain optimal cutter engagement across complex surfaces—eliminating secondary operations and preserving critical datum relationships. Material versatility spans aluminum 7075-T6, titanium Ti-6Al-4V, PEEK, and engineered plastics, all processed under stringent ISO 9001-controlled environments with in-process CMM verification. Below is a summary of our core axis capabilities and applications:

| Axis Configuration | Key Applications | Typical Tolerance Range | Lead Time Advantage |

|---|---|---|---|

| 3-Axis | Brackets, housings, flat plates | ±0.01mm | Baseline |

| 4-Axis (Indexing) | Impellers, cam profiles, multi-face parts | ±0.008mm | 25% faster |

| 5-Axis (Simultaneous) | Turbine blades, ergonomic medical devices | ±0.005mm | 40% faster |

Accelerate your development cycle with Honyo’s Online Instant Quote system—engineered for manufacturing professionals. Upload CAD files in STEP, IGES, or native formats to receive a detailed technical assessment and competitive pricing within 2 hours, including DFM feedback on axis strategy optimization. This seamless integration of engineering expertise and digital procurement eliminates traditional quotation bottlenecks, allowing you to iterate designs and secure validated manufacturing data before committing to tooling. For mission-critical components where axis precision defines performance, Honyo delivers the technical rigor and operational agility to exceed your specifications. Initiate your project with a quote today and experience CNC machining where complexity meets confidence.

Technical Capabilities

CNC Axis Technical Specifications for 3/4/5-Axis Milling and Turning with Tight Tolerance Capabilities

CNC axis configurations define the number of directions in which a cutting tool can move relative to the workpiece. The complexity of the geometry, required precision, and material properties influence the choice between 3-axis, 4-axis, and 5-axis machining. Turning centers typically operate on 2-axis (X-Z) with optional live tooling (C-axis) for milling operations, enabling multi-axis functionality.

The following table outlines the technical specifications relevant to multi-axis CNC milling and turning systems, focusing on tight tolerance capabilities and compatibility with common engineering materials.

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning (2+ Axis) |

|---|---|---|---|---|

| Linear Axes | X, Y, Z | X, Y, Z + A (rotary on X) | X, Y, Z + A/B or C | X (radial), Z (axial) |

| Rotary Axes | None | A-axis (4th axis rotary table) | A/B or B/C (dual rotary) | C-axis (spindle rotation) |

| Typical Positioning Accuracy | ±0.005 mm | ±0.005 mm | ±0.003 mm | ±0.002 mm (diameter) |

| Repeatability | ±0.002 mm | ±0.002 mm | ±0.001 mm | ±0.001 mm |

| Tight Tolerance Capability | ±0.01 mm | ±0.01 mm | ±0.005 mm | ±0.005 mm (diameter) |

| Surface Finish (Typical) | 0.8–3.2 µm Ra | 0.8–1.6 µm Ra | 0.4–1.6 µm Ra | 0.4–1.6 µm Ra |

| Spindle Speed Range | 8,000–24,000 RPM | 8,000–20,000 RPM | 10,000–30,000 RPM | 1,500–6,000 RPM (varies by diameter) |

| Tool Changer (ATC) | Optional (12–30 tools) | Standard (24–40 tools) | Standard (30–60 tools) | Turret (8–12 stations) |

| Materials Compatible | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon | Aluminum, Steel, ABS, Nylon |

| Aluminum Machinability | Excellent (high feed/speed) | Excellent | Excellent (complex contours) | Excellent (bar stock) |

| Steel Machinability | Good (requires rigid setup) | Good | Good (with high-torque spindle) | Good (hard turning capable) |

| ABS Machinability | Very Good (low melting point) | Very Good | Very Good (coolant control) | Limited (soft, for prototyping) |

| Nylon Machinability | Good (chip control critical) | Good | Good (requires sharp tools) | Good (low thermal expansion) |

| Coolant Delivery | Flood or mist | Flood/mist with through-spindle optional | High-pressure through-tool | High-pressure (internal/external) |

| Applications | Flat parts, pockets, drilling | Indexing features, slots | Aerospace, molds, organic shapes | Shafts, bushings, connectors |

Notes on Tight Tolerance and Materials:

Aluminum (e.g., 6061, 7075): Ideal for high-speed multi-axis milling due to low hardness and excellent thermal conductivity. Achieves tight tolerances with minimal tool wear.

Steel (e.g., 4140, 1018): Requires higher spindle torque and rigid setups. 5-axis systems with high-precision ball screws and thermal compensation enable ±0.005 mm tolerances.

ABS: Best machined with sharp carbide tools and controlled feed rates to prevent melting. Suitable for prototyping on 3/4-axis systems.

Nylon: Low friction and high toughness; prone to dimensional change with humidity. Requires dry machining or minimal coolant and precise fixturing.

Conclusion:

For tight tolerance machining of metals and engineering plastics, 5-axis CNC milling offers the highest precision and geometric flexibility, while CNC turning with live tooling bridges the gap between rotational and mill-turn complexity. Material selection directly impacts toolpath strategy, fixturing, and achievable tolerances across all axis configurations.

From CAD to Part: The Process

Honyo Prototype executes multi-axis CNC machining projects through a rigorously controlled five-stage workflow designed for precision, speed, and manufacturability. We clarify that “CNC axis” refers to multi-axis CNC machining capabilities (3-axis, 4-axis, 5-axis), not a discrete process named “cnc axis.” Below is our standardized technical workflow:

CAD Upload and Initial Processing

Clients submit native or neutral CAD formats (STEP, IGES, Parasolid) via our secure portal. Our system performs immediate geometry validation, checking for manifold integrity, unit consistency, and surface continuity. Non-conforming files trigger automated alerts with specific error diagnostics before proceeding. This stage establishes the digital foundation for all downstream processes.

AI-Powered Quoting Engine

Validated CAD models enter our proprietary AI quotation system, which analyzes over 200 geometric and material parameters. The AI cross-references real-time data from 7+ years of production history, current machine utilization, and material market rates. It generates a technically accurate quote within 2 business hours, including explicit cost drivers such as:

Axis complexity penalties (e.g., 5-axis vs. 3-axis)

Setup reduction opportunities identified through feature recognition

Material waste optimization calculations

Critical tolerance impact on machining time

Engineering-Led DFM Analysis

All quoted projects undergo mandatory Design for Manufacturability review by our ASME-certified manufacturing engineers. This is not an automated step but a human-led technical evaluation focusing on:

| DFM Focus Area | Key Checks | Client Impact Mitigation |

|---|---|---|

| Geometric Feasibility | Thin wall stability, internal radius limitations, tool access validation | Proposes minor feature modifications to avoid custom tooling |

| Tolerance Realism | GD&T stack-up analysis, Cpk capability assessment for critical dimensions | Recommends relaxed tolerances where functionally acceptable |

| Material Utilization | Stock size optimization, nesting efficiency for multiple parts | Reduces material cost by 12-18% on average |

| Process Sequencing | Setup reduction strategies, optimal toolpath order | Cuts lead time by 22% through consolidated operations |

DFM reports include annotated CAD markups and are delivered within 24 hours. Client approval is required before production release.

Precision Multi-Axis Production

Approved jobs enter our climate-controlled machining cells with strict process controls:

Machine tool calibration verified daily per ISO 230-2 standards

In-process CMM checks at critical waypoints for complex geometries

Real-time thermal compensation active during 5-axis contouring operations

Automated chip management systems to prevent surface recontact

All operations follow documented work instructions with full tool life monitoring. First-article inspection data is shared digitally before batch continuation.

Certified Delivery and Traceability

Final parts ship with comprehensive documentation:

Material test reports (MTRs) traceable to heat/lot numbers

FAI reports with dimensional verification against original CAD

Process validation records including machine IDs and operator certifications

Packaging engineered for part geometry to prevent transit damage

We maintain full digital traceability from raw material to shipping manifest, supporting AS9100 and IATF 16949 compliance requirements. Typical delivery timelines range from 5-15 business days depending on complexity, with expedited options available.

This integrated workflow ensures technical risk mitigation while maintaining the agility required for prototype and low-volume production. Our closed-loop system captures lessons learned at each stage to continuously refine AI quotation accuracy and DFM guidance.

Start Your Project

Looking for precision CNC axis solutions? Contact Susan Leo at info@hy-proto.com to discuss your project requirements. Our advanced manufacturing facility in Shenzhen ensures high-quality production with fast turnaround times. Partner with Honyo Prototype for reliable, scalable CNC machining services tailored to your engineering needs.

🚀 Rapid Prototyping Estimator

Estimate rough cost index based on volume.