Contents

Manufacturing Insight: Desktop 5 Axis Cnc Milling Machine

Manufacturing Insight Desktop 5 Axis CNC Milling Technology at Honyo Prototype

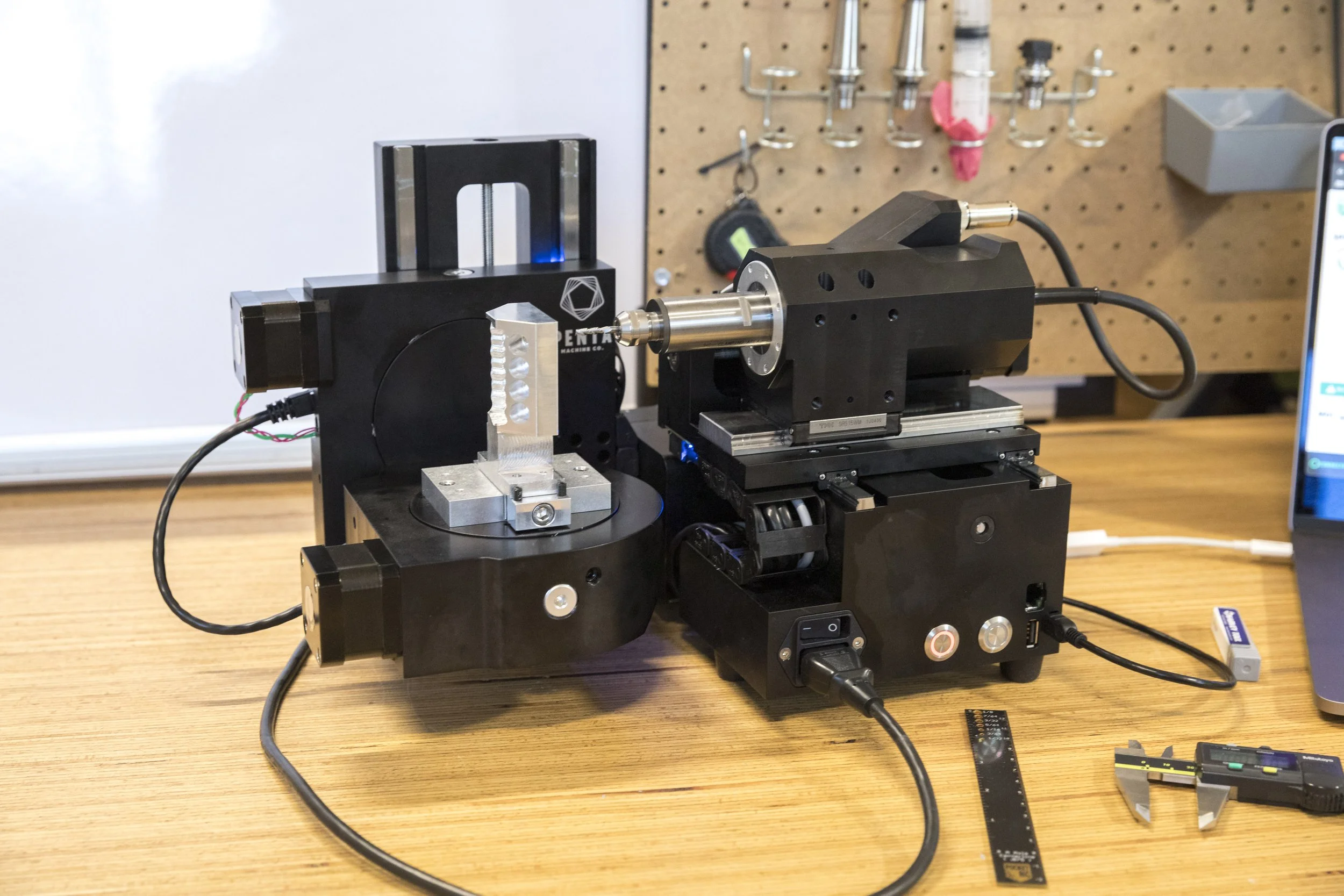

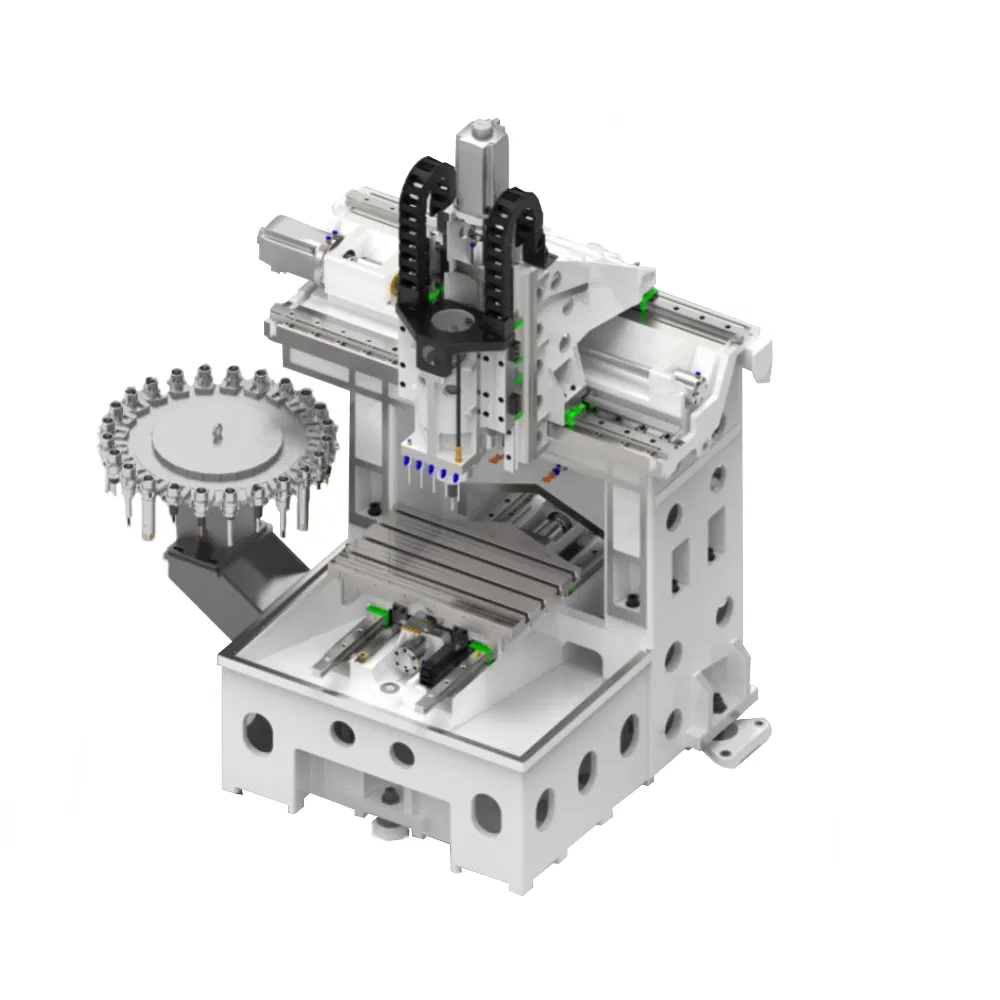

Shenzhen Honyo Prototype integrates advanced desktop 5-axis CNC milling technology as a cornerstone of our rapid prototyping and low-volume production capabilities. This technology fundamentally transforms the machining of complex geometries by enabling simultaneous movement across three linear axes (X, Y, Z) and two rotational axes (typically A and B), allowing the cutting tool to approach the workpiece from virtually any angle in a single setup. For engineering teams developing intricate components—such as medical device housings, aerospace brackets, or fluid dynamics models—this capability eliminates the constraints and cumulative errors inherent in multi-setup 3-axis processes. The result is significantly enhanced part accuracy, superior surface finishes on contoured surfaces, and drastically reduced lead times critical for accelerating product development cycles.

The core advantage of our desktop-scale 5-axis systems lies in their ability to machine complex features—undercuts, deep cavities, organic shapes—in one operation. This eliminates the need for custom fixtures, secondary operations, and manual repositioning, directly reducing non-recurring engineering costs and potential scrap rates. While maintaining the compact footprint suitable for agile prototyping environments, these machines deliver precision unattainable with traditional methods. At Honyo, we leverage this technology specifically for high-value, geometrically challenging prototypes and bridge production runs where design fidelity and speed-to-part are paramount. Our engineers program optimized toolpaths using advanced CAM software, ensuring minimal tool deflection and maximum material removal efficiency even on demanding alloys like titanium or high-temp plastics.

Honyo Prototype’s implementation focuses on maximizing the technology’s value for client projects. We utilize these systems for rapid iteration of functional prototypes requiring tight tolerances on complex surfaces, eliminating weeks from development schedules. The reduced setup complexity translates directly to lower costs for clients compared to traditional multi-axis outsourcing, while our in-house process control guarantees consistent quality. This capability is particularly transformative for sectors like robotics and consumer electronics, where component integration demands seamless multi-faceted machining.

Key technical specifications of our production-grade desktop 5-axis milling platforms are summarized below:

| Parameter | Specification |

|————————|———————————–|

| Linear Travel (X/Y/Z) | 300 mm / 250 mm / 250 mm |

| Rotary Axis Range (A/B)| ±110° / 360° continuous |

| Max Spindle Speed | 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Max Workpiece Size | Ø200 mm x 200 mm height |

| Control System | Fanuc 31i-B5 with 5-axis interpolation |

By embedding desktop 5-axis milling into our core manufacturing workflow, Honyo Prototype delivers unparalleled geometric capability without sacrificing the agility expected in rapid prototyping. We transform complex CAD models into high-precision physical parts faster and with greater fidelity, empowering your engineering team to validate designs with confidence. Contact our manufacturing engineering team to discuss how this technology can streamline your next prototyping project from concept to functional validation.

Technical Capabilities

Technical Capabilities: Desktop 5-Axis CNC Milling Machine

Shenzhen Honyo Prototype utilizes advanced desktop 5-axis CNC milling machines to deliver high-precision components for prototyping and low-volume production. These compact yet powerful systems are engineered to support complex geometries, tight tolerances, and multi-sided machining in a single setup. Our 5-axis platforms integrate simultaneous motion across X, Y, Z, A, and B axes, enabling unparalleled access to intricate features and undercuts that are unattainable with conventional 3-axis systems.

Our capabilities span 3-axis, 4-axis, and full 5-axis milling operations, as well as integrated milling-turning for hybrid components. The desktop format allows for rapid deployment, reduced footprint, and energy-efficient operation without compromising machining performance. Each machine is equipped with high-speed spindles (up to 60,000 RPM), precision linear guides, and closed-loop servo control to ensure repeatability and surface finish accuracy. The use of advanced CNC controllers with tool path optimization ensures smooth interpolation and minimal vibration during high-speed contouring.

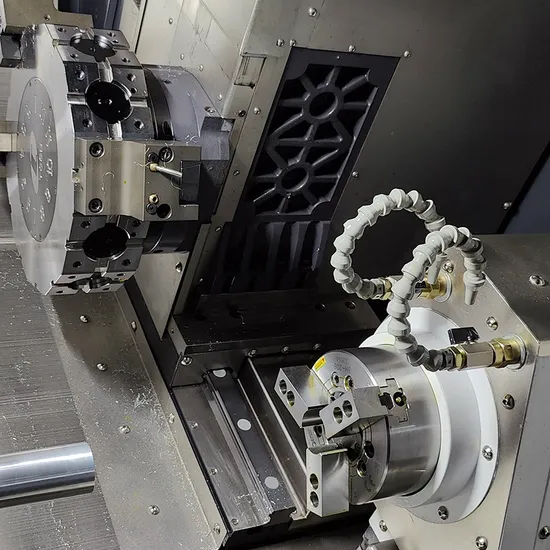

For turning operations, our mill-turn configurations support live tooling and C-axis rotation, enabling the production of turned-milled parts such as impellers, fittings, and medical connectors. This hybrid capability reduces secondary operations and improves overall dimensional consistency.

All machining processes are supported by in-house CAD/CAM programming using industry-standard software (SolidWorks, Mastercam, Fusion 360), ensuring optimal tool paths and collision avoidance. We also employ on-machine probing for automated workpiece alignment and first-article inspection, enhancing process reliability and reducing setup errors.

Tight tolerance machining is a core strength. Our desktop 5-axis systems consistently achieve tolerances down to ±0.005 mm for critical dimensions and surface finishes as fine as Ra 0.4 µm. These capabilities are maintained through rigorous environmental controls, regular machine calibration, and real-time tool wear compensation.

The following table outlines typical achievable tolerances and compatible materials:

| Feature | Standard Tolerance | Precision Capability |

|——–|——————–|————————|

| Linear Dimensions | ±0.025 mm | ±0.005 mm |

| Hole Diameter | ±0.015 mm | ±0.008 mm |

| Positional Tolerance | ±0.020 mm | ±0.005 mm |

| Surface Finish (Milled) | Ra 1.6 µm | Ra 0.4 µm |

| Angular Tolerance | ±0.1° | ±0.05° |

| Material Category | Compatible Materials |

|——————-|————————|

| Metals | Aluminum 6061, 7075; Stainless Steel 303, 316; Titanium Grade 2, 5; Brass C360; Inconel 718 |

| Plastics | ABS, POM (Delrin), PC, Nylon, PEEK, PMMA |

| Composites | Carbon Fiber Reinforced Polymers, G10, FR4 |

These technical capabilities enable Shenzhen Honyo Prototype to serve industries requiring high precision and rapid turnaround, including aerospace, medical devices, robotics, and R&D. Our desktop 5-axis CNC milling platform combines flexibility, accuracy, and scalability to meet the evolving demands of modern prototyping and precision manufacturing.

From CAD to Part: The Process

From CAD to Finished Part: Desktop 5-Axis CNC Production Workflow at Honyo Prototype

At Shenzhen Honyo Prototype, our desktop 5-axis CNC milling process transforms digital designs into high-precision physical components through a rigorously defined workflow. This integrated approach ensures manufacturability, efficiency, and exceptional part quality, starting from the initial CAD model submission and culminating in a verified finished part. The sequence leverages proprietary AI tools and expert engineering analysis to minimize lead times and maximize first-pass yield.

The process initiates with our AI-Powered Quoting Engine. Upon receiving a customer’s 3D CAD model, the system performs an immediate automated analysis. It assesses geometric complexity, identifies potential undercuts or thin walls, estimates machine time based on feature density and material, and calculates material requirements. This rapid evaluation generates a highly accurate preliminary quote within hours, not days, providing clear cost and timeline expectations while flagging any obvious geometric constraints requiring early attention. This step significantly accelerates the commercial phase and sets realistic project parameters.

Subsequent to quote acceptance, the Design for Manufacturability (DFM) review becomes critical. Our senior manufacturing engineers conduct a detailed technical assessment of the CAD model, focusing specifically on the capabilities and limitations of our desktop 5-axis platforms. We evaluate optimal workholding strategies, potential collision risks during complex multi-axis moves, tool accessibility for all features, minimum wall thicknesses relative to tool diameters, and surface finish requirements achievable within practical cycle times. This phase is inherently collaborative; we provide actionable feedback and suggested design modifications to the client, resolving potential production issues before programming begins. This proactive DFM step is fundamental to avoiding costly delays, scrap, and rework during actual machining.

Production commences only after DFM sign-off. The approved CAD model is imported into our CAM software, where experienced programmers develop optimized 5-axis toolpaths. Key considerations include strategic workpiece orientation to minimize setups, selection of specialized small-diameter tools suitable for intricate desktop machining, precise control of stepovers for surface finish, and meticulous simulation to verify no collisions occur between the tool, holder, part, and machine components. The machine setup phase involves meticulous workpiece fixturing using modular vise systems or custom soft jaws, precise tool length and diameter measurement via touch probes, and thorough machine calibration. During the milling operation, the desktop 5-axis system executes complex simultaneous motions, enabling the creation of organic contours, deep cavities, and precision features from a single setup. Real-time monitoring ensures process stability. The final stage is comprehensive inspection using coordinate measuring machines (CMM) or optical comparators against the original CAD nominal dimensions, verifying geometric accuracy and surface integrity before part shipment.

This structured workflow – AI Quote enabling speed, collaborative DFM ensuring feasibility, and precision 5-axis execution guaranteeing quality – is core to Honyo Prototype’s value proposition for rapid, complex desktop CNC machining.

Key Desktop 5-Axis CNC Specifications at Honyo Prototype

| Parameter | Specification |

|——————–|———————————–|

| Maximum Travel (X) | 300 mm |

| Maximum Travel (Y) | 200 mm |

| Maximum Travel (Z) | 200 mm |

| Rotary Axis (B) | -30° to +120° |

| Rotary Axis (C) | Continuous 360° |

| Spindle Speed | 24,000 RPM |

| Typical Tolerance | ±0.005 mm (features < 50 mm) |

| Common Materials | Aluminum 6061/7075, Steels, Plastics, Composites |

Start Your Project

Start Your Project with Precision: Partner with Shenzhen Honyo Prototype

When it comes to high-precision prototyping and low-volume production, a desktop 5-axis CNC milling machine offers unmatched versatility and accuracy. At Shenzhen Honyo Prototype, we specialize in leveraging advanced 5-axis CNC technology to deliver complex, high-tolerance components across industries such as aerospace, medical devices, robotics, and consumer electronics. If your design demands intricate geometries, tight tolerances, and superior surface finishes, our desktop 5-axis milling capabilities are engineered to meet and exceed your expectations.

Our state-of-the-art facility integrates compact yet powerful desktop 5-axis systems that allow for simultaneous multi-directional cutting. This enables us to machine complex parts in a single setup, reducing lead times, minimizing human error, and ensuring dimensional consistency. Whether you’re developing a functional prototype or preparing for small-batch manufacturing, our team ensures your project benefits from optimized tool paths, advanced fixturing, and real-time process monitoring.

We understand that every project begins with a vision. That’s why we offer a seamless onboarding process designed to transform your CAD models into precision-engineered parts with minimal turnaround time. Our engineering team performs a comprehensive design for manufacturability (DFM) review to identify potential challenges early, recommend material selections, and suggest optimizations that enhance performance while reducing cost.

At Honyo Prototype, we support a wide range of engineering materials, including aluminum alloys, stainless steel, titanium, brass, PEEK, polycarbonate, and more. Our desktop 5-axis platforms are ideal for producing small to medium-sized components where precision and repeatability are non-negotiable.

To ensure clarity and alignment from the outset, we’ve outlined key specifications of our desktop 5-axis CNC milling capabilities:

| Specification | Detail |

|—————|——–|

| Machine Type | Desktop 5-Axis Simultaneous CNC Milling |

| Working Envelope | Up to 300 x 200 x 150 mm (X-Y-Z) |

| Spindle Speed | 24,000 RPM |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.003 mm |

| Supported File Formats | STEP, IGES, STL, X_T, SLDPRT, DWG, DXF |

| Typical Lead Time | 3–7 days (depending on complexity) |

| Surface Finish | As low as Ra 0.8 μm (polished finishes available) |

| Tolerances | ±0.01 mm standard, down to ±0.005 mm on critical features |

Starting your project with Honyo Prototype is simple. Share your 3D model and technical requirements, and our team will provide a detailed quotation, DFM feedback, and production timeline within 24 hours.

Ready to bring your design to life with precision 5-axis CNC milling? Contact Susan Leo today at info@hy-proto.com. Let’s discuss your project, material needs, and delivery goals. At Shenzhen Honyo Prototype, we’re not just a service provider—we’re your manufacturing partner committed to innovation, quality, and speed.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.