Contents

Manufacturing Insight: Cnc Camshaft

Manufacturing Insight: CNC Camshaft Production at Honyo Prototype

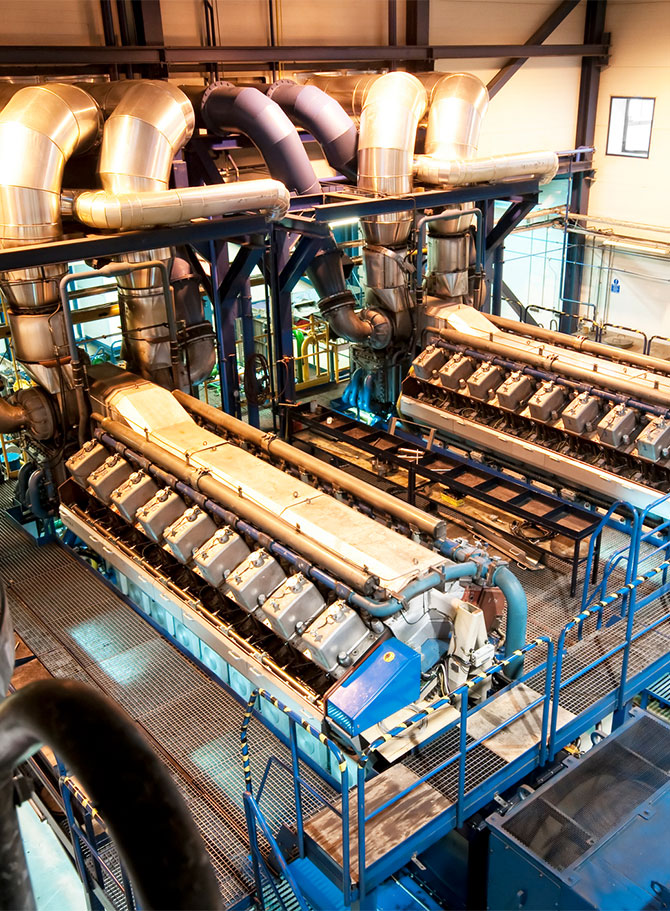

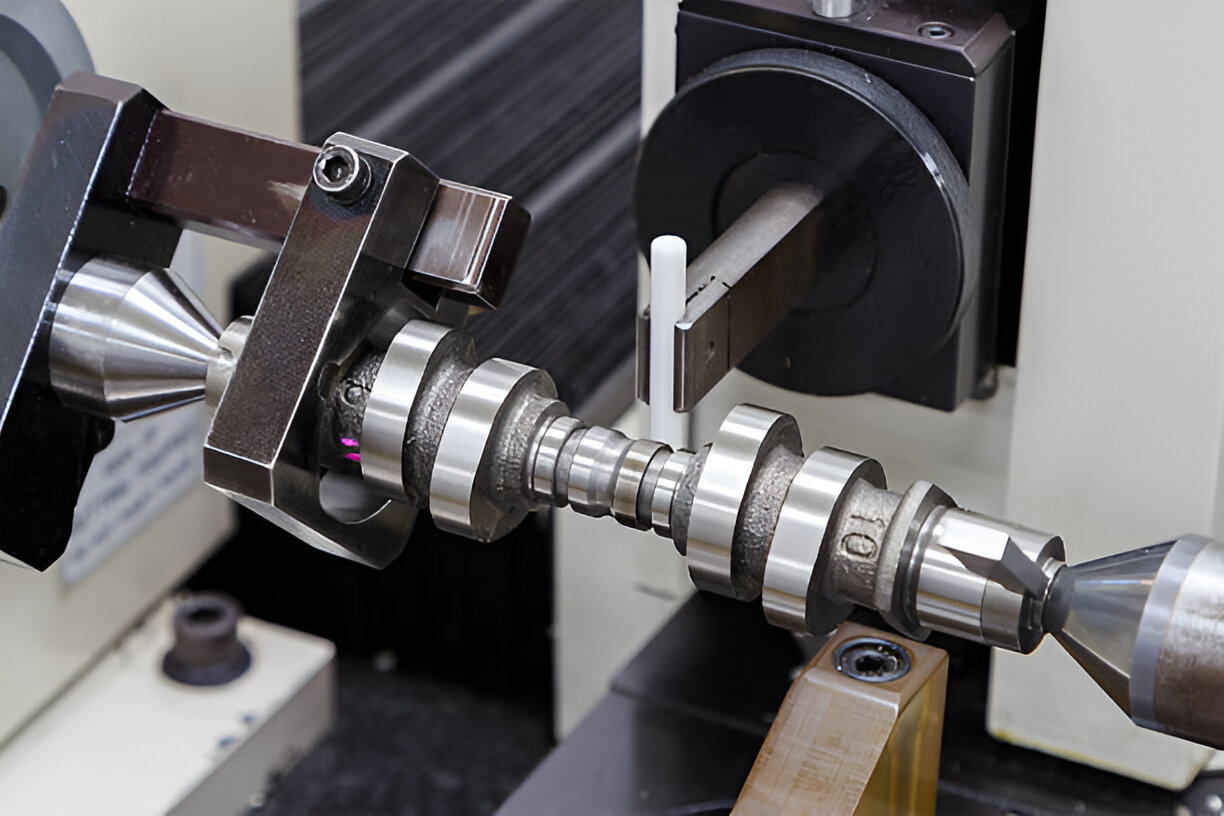

Camshafts represent a critical component in high-performance internal combustion systems, demanding exceptional kinematic precision, material integrity, and surface finish to ensure optimal valve timing, engine efficiency, and longevity. The complex geometry of lobes, journals, and drive features, coupled with stringent tolerances, presents significant manufacturing challenges. Traditional methods often struggle with consistency and geometric accuracy, particularly for prototyping and low-to-mid volume production runs. CNC machining, specifically advanced multi-axis milling and turning, has become the indispensable solution for producing camshafts that meet modern performance and reliability standards. At Shenzhen Honyo Prototype, we leverage our specialized CNC capabilities to transform demanding camshaft designs from concept to high-fidelity functional prototype or bridge production part with unmatched precision and speed.

Our dedicated camshaft manufacturing process utilizes state-of-the-art 5-axis CNC machining centers equipped with high-precision spindles, thermal compensation systems, and advanced probing. This technology enables the complete machining of complex lobe profiles, eccentric journals, and keyways in minimal setups, drastically reducing cumulative error and ensuring perfect geometric relationships between critical features. We excel in machining a wide range of camshaft materials, including induction-hardened 4140/4340 alloy steels, cast irons (such as CGI), and specialized alloys, applying optimized cutting strategies and coolant management to maintain dimensional stability and prevent thermal distortion during the critical finishing operations. Rigorous in-process inspection, utilizing high-accuracy Coordinate Measuring Machines (CMM) and optical comparators, verifies lobe profile accuracy, base circle runout, journal concentricity, and overall form to micron-level tolerances before final surface treatments like induction hardening or nitriding are applied.

Honyo Prototype delivers comprehensive camshaft manufacturing capabilities tailored to the prototyping and low-volume production needs of engine developers and motorsport teams. Our core specifications consistently meet or exceed industry demands for precision components.

| Parameter | Industry Typical Requirement | Honyo Prototype Standard Capability |

| :—————– | :————————— | :———————————- |

| Material Range | 4140, 4340, Cast Irons | 4140, 4340, 8620, CGI, Tool Steels, Custom Alloys |

| Lobe Profile Tolerance | ±0.010 mm | ±0.005 mm |

| Journal Runout | ≤ 0.015 mm | ≤ 0.008 mm |

| Surface Finish (Ra) | 0.8 – 1.6 μm | 0.4 – 0.8 μm (pre-heat treat) |

| Max. Part Length | Varies | 1200 mm |

| Min. Batch Size | Often high | 1 pc (Prototype) |

Quality assurance is embedded throughout our workflow. Every camshaft undergoes full geometric dimensioning and tolerancing (GD&T) verification against the client’s digital model, including comprehensive lobe profile analysis and dynamic balancing checks where required. Our Shenzhen-based facility provides agile project management, rapid iteration cycles based on test feedback, and seamless integration with downstream processes like surface hardening partners. By combining advanced CNC technology, deep material science understanding, and stringent metrology, Honyo Prototype ensures your camshaft prototypes perform with the precision necessary for accurate engine validation and accelerated development timelines, significantly de-risking the path to production. Partner with us for camshaft manufacturing where uncompromising accuracy meets prototype agility.

Technical Capabilities

Shenzhen Honyo Prototype delivers precision CNC machining solutions for complex components, including high-performance camshafts used in automotive, aerospace, and industrial engine systems. Our advanced 3-axis, 4-axis, and 5-axis CNC milling centers, combined with multi-axis turning and mill-turn technology, enable the production of camshafts with intricate lobe profiles, precise lift curves, and superior surface finishes. Our in-house capabilities support end-to-end manufacturing—from prototype development to low-to-mid volume production—ensuring consistent quality, repeatability, and compliance with stringent industry standards.

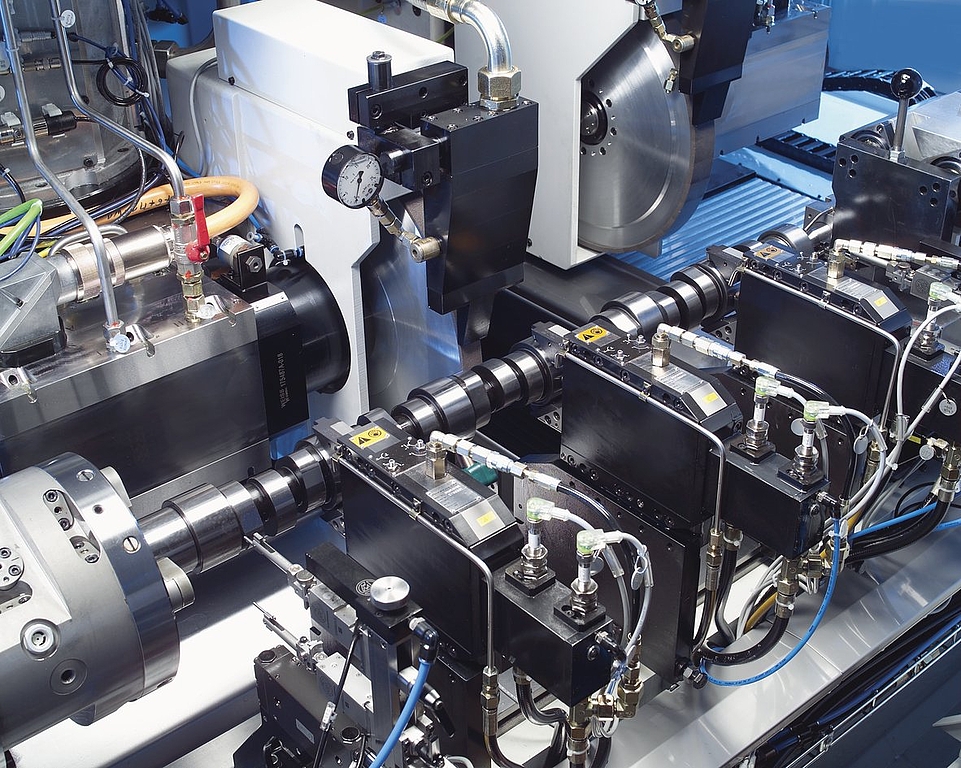

Our 5-axis simultaneous machining platforms provide the flexibility and accuracy required for generating complex cam profiles without re-fixturing, minimizing cumulative errors and improving geometric consistency. With high-speed spindles, dynamic tool compensation, and real-time probing systems, Honyo achieves micron-level control over critical features such as base circle runout, lobe symmetry, and journal concentricity. For applications requiring tight tolerance grinding or superfinishing, we integrate secondary operations with strict process validation to meet OEM specifications.

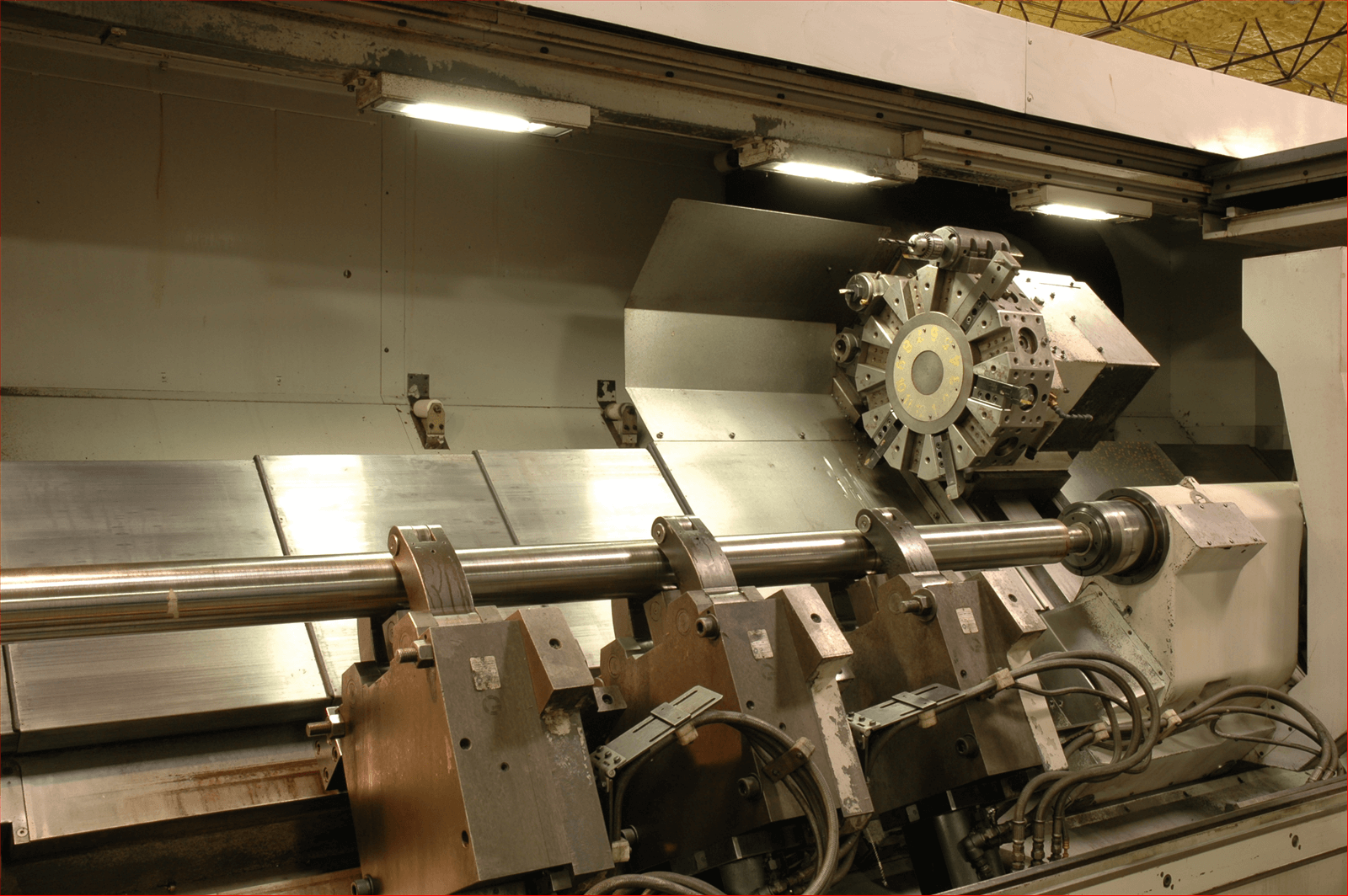

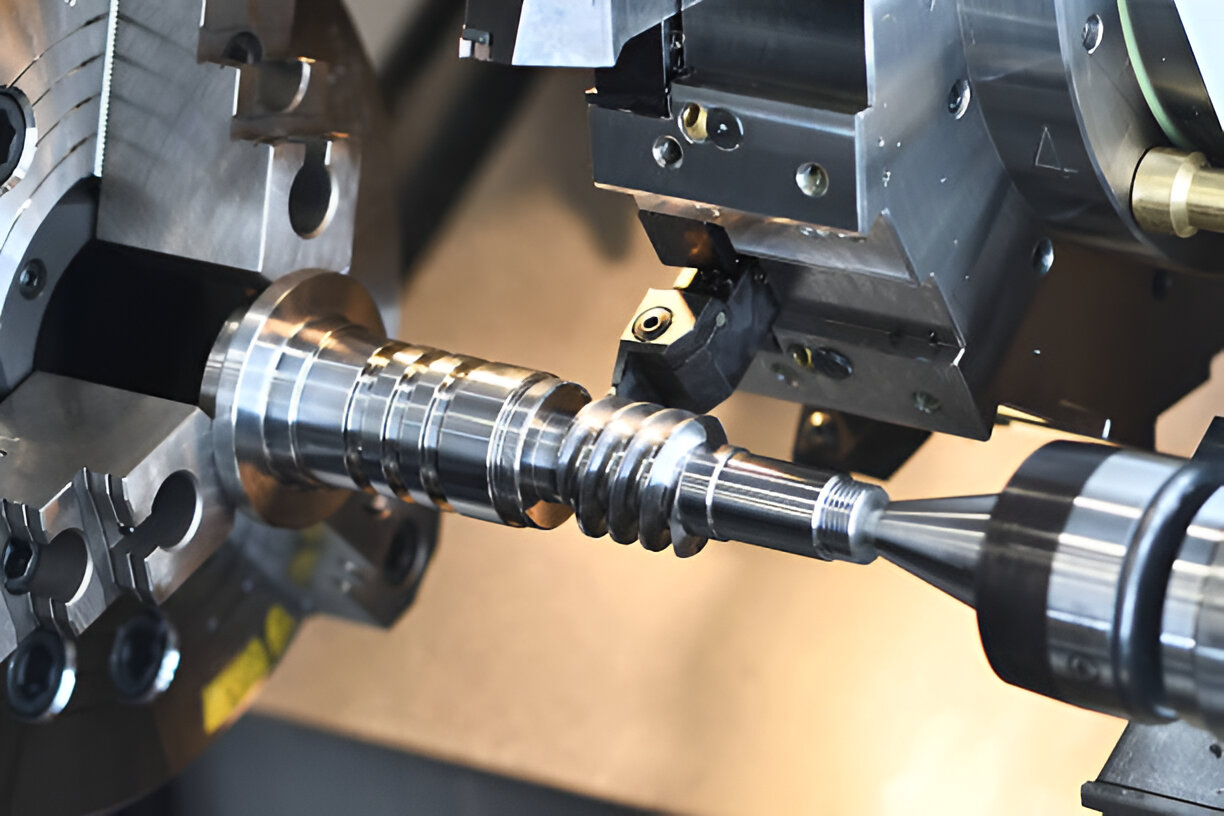

Turning operations are performed on precision CNC lathes equipped with live tooling and dual spindles, allowing complete machining of camshaft journals, flanges, and drive features in a single setup. This reduces handling and ensures excellent cylindricity and axial alignment. Our process planning includes thermal stability protocols and in-process metrology to maintain dimensional integrity across batch runs.

The following table outlines the typical material options and geometric tolerances achievable for CNC-machined camshafts at Honyo Prototype:

| Material Category | Common Alloys | Tolerance Range (mm) | Surface Finish (Ra, µm) | Key Applications |

|——————-|—————|————————|————————–|——————|

| Alloy Steel | 4140, 4340, 5140 | ±0.005 (lobe profile), ±0.01 (journal) | 0.8 – 1.6 | High-strength automotive, racing |

| Cast Iron | Nodular Iron (QT600), Gray Iron | ±0.01 (profile), ±0.015 (shaft) | 1.6 – 3.2 | Industrial engines, compressors |

| Stainless Steel | 17-4 PH, 420 SS | ±0.008 (critical zones) | 0.8 – 1.2 | Corrosion-resistant environments |

| Tool Steel | H13, D2 | ±0.005 (after hardening) | 0.4 – 0.8 (ground finish) | High-wear, high-temperature |

| Specialty Alloys | Inconel 718, Titanium Ti-6Al-4V | ±0.01 (standard), ±0.005 (with fixturing) | 1.6 – 2.5 | Aerospace, performance motorsports |

Geometric tolerances are verified using coordinate measuring machines (CMM), roundness testers, and optical contour measuring systems. Typical tolerances include lobe lift accuracy within ±0.005 mm, journal concentricity ≤ 0.01 mm TIR, and lobe angular positioning within ±0.1°. Surface treatments such as nitriding, induction hardening, and chrome plating are available through certified partners to enhance wear resistance and fatigue life.

At Shenzhen Honyo Prototype, we combine advanced CNC technology with rigorous quality control to deliver camshafts that meet functional, durability, and performance requirements across demanding industries.

From CAD to Part: The Process

CNC Camshaft Production Workflow: From CAD to Precision Component

At Shenzhen Honyo Prototype, our CNC camshaft manufacturing leverages an integrated digital workflow designed for speed, accuracy, and manufacturability assurance. This process transforms client CAD models into high-performance, engine-ready components through three rigorously defined phases, ensuring optimal outcomes for demanding automotive and industrial applications.

The workflow initiates with our AI-Powered Quoting Engine. Upon receipt of the client’s native CAD file (STEP, IGES, or native CAD formats preferred), proprietary algorithms perform instantaneous geometric analysis. This system evaluates critical factors including material volume, feature complexity, required tolerances, and surface finish specifications. Crucially, it identifies potential manufacturing constraints early, such as undercuts or thin sections prone to deflection. The output is a highly accurate, data-driven quotation delivered within hours, not days, detailing cost, lead time, and preliminary process recommendations based on actual machining time calculations and material requirements. This transparency eliminates guesswork and accelerates project initiation.

Subsequent to quote acceptance, the Design for Manufacturability (DFM) review becomes paramount. Our senior manufacturing engineers conduct a meticulous analysis, focusing specifically on camshaft challenges. We assess lobe profile geometry for toolpath feasibility, journal spacing for chucking stability, and base circle diameter for secure fixturing during high-precision milling. Material selection (typically 4140, 1045, or specialty alloys per client spec) is validated against required hardness and wear resistance. Potential issues like excessive stock removal causing thermal distortion or inadequate clearance for lobe profiling cutters are proactively resolved. Client collaboration during this phase is essential; we provide actionable feedback to refine the design, optimizing it for CNC efficiency without compromising functional intent, ultimately reducing cycle times and part cost.

Production commences only after DFM sign-off. Utilizing state-of-the-art multi-axis CNC milling and turning centers (primarily 5-axis vertical machining centers and precision CNC lathes with live tooling), the process sequence is strictly controlled. Initial operations involve precision turning of journals and flanges on a CNC lathe. The core lobe profiling occurs on dedicated 5-axis mills, employing high-speed steel or carbide form cutters with C-axis interpolation for exact lobe contour generation. Critical in-process inspection via Coordinate Measuring Machine (CMM) verifies lobe lift, duration, and base circle runout after milling. Final operations typically include precision grinding of bearing journals to achieve mirror finishes, dynamic balancing to stringent OEM standards, and comprehensive final inspection against all geometric dimensioning and tolerancing (GD&T) requirements. Throughout production, real-time process monitoring ensures dimensional stability and surface integrity.

The following table summarizes key production specifications consistently achieved for precision camshafts:

| Parameter | Requirement | Verification Method |

| :——————— | :————————— | :———————— |

| Lobe Profile Tolerance | ±0.005 mm (max deviation) | 5-Axis CMM Scanning |

| Journal Surface Finish | Ra 0.4 µm (max) | Portable Surface Tester |

| Journal Runout (Total) | ≤ 0.010 mm | Precision Dial Indicator |

This structured workflow—AI Quote for speed and accuracy, rigorous DFM for manufacturability, and precision-controlled Production—ensures Shenzhen Honyo Prototype delivers CNC camshafts that meet the most stringent performance and reliability demands, directly contributing to our clients’ engine efficiency and longevity goals.

Start Your Project

Start Your CNC Camshaft Project with Precision Engineering at Shenzhen Honyo Prototype

When it comes to high-performance engine systems, the camshaft plays a pivotal role in controlling valve timing and optimizing engine output. At Shenzhen Honyo Prototype, we specialize in the precision CNC machining of custom camshafts tailored to your exact specifications. Whether you’re developing a prototype for performance tuning, OEM validation, or industrial engine applications, our advanced manufacturing capabilities ensure superior accuracy, durability, and consistency.

Our CNC camshaft machining process leverages state-of-the-art 5-axis milling and turning centers, combined with rigorous quality control protocols. We work with a wide range of materials—including alloy steels, cast iron, and specialty alloys—to deliver components that meet tight tolerances and demanding surface finish requirements. From single prototype units to low-volume production runs, Honyo Prototype provides scalable solutions without compromising on precision or lead time.

We understand that every camshaft design presents unique challenges, from lobe profile geometry to journal concentricity and dynamic balancing. That’s why our engineering team collaborates closely with clients during the initial design phase to ensure manufacturability, recommend material optimizations, and identify potential cost-saving opportunities—all before machining begins.

Below are the key technical specifications we support for CNC-machined camshafts:

| Specification | Capability |

|————–|———–|

| Maximum Length | 800 mm |

| Maximum Diameter | 120 mm |

| Tolerance | ±0.005 mm (lobe profile), ±0.01 mm (journals) |

| Surface Finish | Ra 0.4 µm (typical on journals and lobes) |

| Materials | 1045, 4140, 4340, EN40B, Cast Iron, Nitriding Steels |

| Machining Axes | 5-axis simultaneous CNC machining |

| Secondary Processes | Grinding, Nitriding, Dynamic Balancing, Polishing |

| Quality Inspection | CMM, Roundness Tester, Surface Profiler, Full First Article Inspection Report |

All camshafts undergo comprehensive metrology verification to ensure compliance with design intent. We provide detailed inspection reports and are fully equipped to support PPAP documentation for automotive and industrial clients.

Starting your project is simple. Reach out to our lead manufacturing engineer, Susan Leo, who will guide you through the quoting process, material selection, and design review. With decades of combined experience in precision CNC machining, our team ensures your camshaft not only meets but exceeds performance expectations.

Contact Susan Leo today at info@hy-proto.com to begin your CNC camshaft project. Include your CAD files, material preferences, and any applicable performance requirements, and we’ll deliver a competitive quote within 24 hours. At Shenzhen Honyo Prototype, we turn precision concepts into high-performance reality—partner with us for CNC-machined camshafts you can trust.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.