Contents

Manufacturing Insight: Laser Vs Cnc

Manufacturing Insight: Laser Cutting vs CNC Machining for Precision Prototyping

Selecting the appropriate subtractive manufacturing process is critical for achieving optimal prototype functionality, lead time, and cost efficiency. At Shenzhen Honyo Prototype, we frequently guide clients through the strategic choice between laser cutting and CNC machining—two foundational technologies serving distinct but occasionally overlapping roles in rapid prototyping. Understanding their core capabilities ensures your design intent translates accurately into physical form.

Laser cutting excels in high-speed, two-dimensional profiling of sheet materials. Utilizing focused thermal energy, it vaporizes material along programmed paths, making it ideal for intricate 2D geometries in acrylic, wood, fabric, and thin metals (typically under 6mm for stainless steel). However, its limitations become apparent with thicker sections, reflective metals, or any requirement for three-dimensional features. The inherent kerf width (material removal zone) introduces dimensional variance, and heat-affected zones can alter material properties near cut edges. Surface finish is generally smooth but may exhibit slight taper or recast layers on metals.

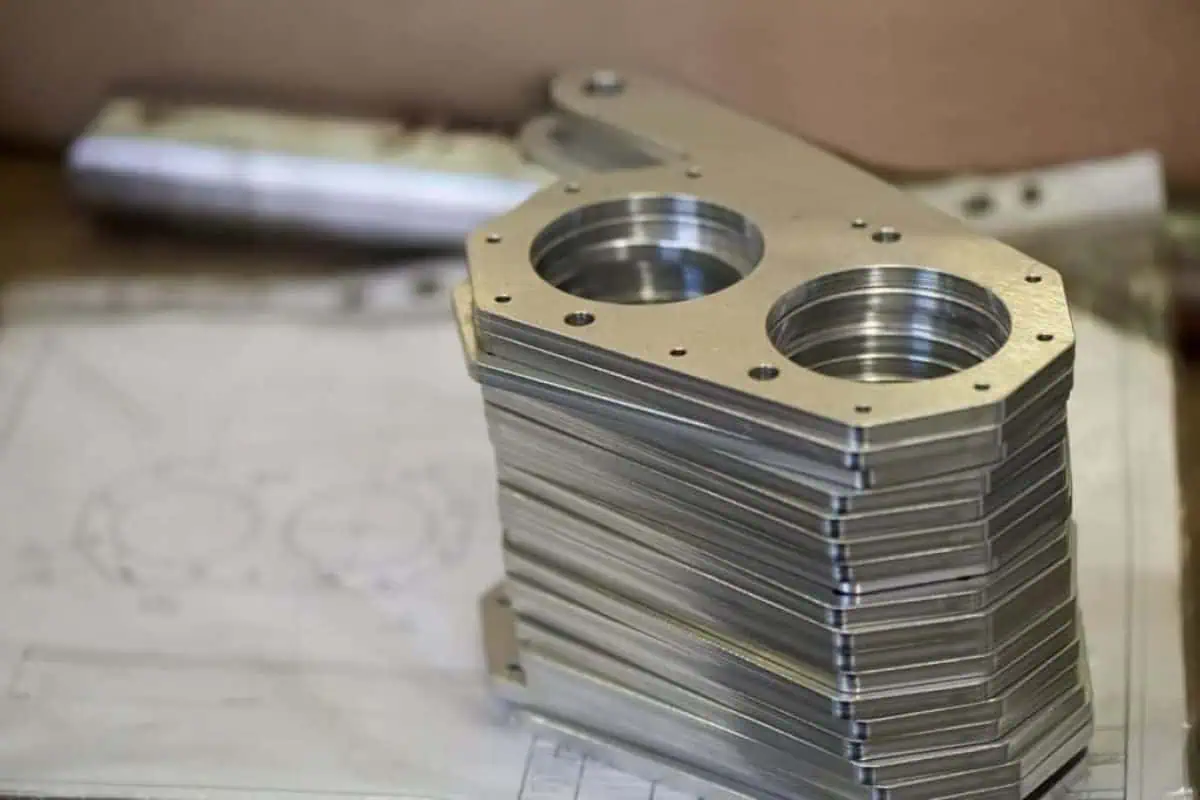

Conversely, CNC machining employs mechanically driven rotary cutters to remove material from solid billets or blocks. This process inherently supports complex 3D geometries, internal features, undercuts, and precise through-holes—impossible with 2D laser systems. Honyo leverages advanced 3-axis and 5-axis CNC centers capable of machining metals (aluminum, steel, titanium), engineering plastics (PEEK, Delrin), and composites with exceptional dimensional fidelity. Material thickness is constrained only by machine envelope (up to 300mm routinely), not process physics. Crucially, CNC achieves tighter tolerances and superior surface finishes without thermal distortion, directly impacting functional performance in demanding applications.

The following table summarizes key technical differentiators relevant to prototype development:

| Parameter | Laser Cutting | CNC Machining (Honyo Standard) |

|——————–|—————————–|——————————–|

| Max Material Thickness | 25mm (acrylic), 6mm (steel) | 300mm+ (aluminum), 150mm+ (steel) |

| Dimensional Tolerance | ±0.1mm – ±0.2mm | ±0.005mm – ±0.025mm |

| Surface Finish (Ra) | 3.2μm – 12.5μm | 0.8μm – 3.2μm |

| Geometry Complexity | 2D profiles only | Full 3D contours, cavities, threads |

| Material Versatility | Limited on thick/reflective metals | Metals, plastics, composites, ceramics |

| Lead Time (Simple Part) | Very fast (minutes) | Moderate (hours) |

Honyo Prototype specializes in high-precision CNC machining as the backbone of our rapid prototyping services. Our ISO-certified facility integrates Siemens-controlled mills and lathes with stringent in-process metrology, enabling us to consistently deliver functional prototypes meeting aerospace, medical, and industrial design specifications. While we utilize laser cutting for specific 2D sheet applications, CNC remains our primary recommendation for prototypes requiring mechanical integrity, tight tolerances, or true 3D complexity. We collaborate closely with engineering teams during DFM analysis to validate process selection, ensuring your prototype not only looks correct but performs as intended under real-world conditions. Partner with Honyo to leverage CNC’s unmatched versatility for prototypes that accelerate your path from concept to validated product.

Technical Capabilities

Laser vs CNC Machining: Technical Capabilities at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, precision manufacturing is driven by selecting the right process for the application. When comparing laser cutting to CNC machining—particularly multi-axis milling and turning—the distinction lies in dimensional accuracy, material compatibility, geometric complexity, and tolerance requirements. While laser processing excels in speed and 2D/2.5D profile cutting, CNC machining remains the definitive solution for high-precision, three-dimensional components requiring tight tolerances and superior surface integrity.

CNC machining, including 3-axis, 4-axis, and 5-axis milling, enables full toolpath control across multiple planes, allowing for complex contours, undercuts, and cavities that laser systems cannot achieve. Turning centers complement this by providing high-accuracy cylindrical geometries for shafts, bushings, and threaded components. In contrast, laser cutting is primarily limited to through-cutting or engraving planar surfaces, making it suitable for sheet-based prototypes but inadequate for functional parts requiring strict form and fit.

Tight tolerance machining is a core competency at Honyo. Our CNC platforms consistently achieve tolerances down to ±0.005 mm for critical dimensions, supported by on-machine probing, thermal compensation, and post-process CMM validation. Lasers, while capable of fine kerf widths (typically 0.1–0.3 mm), suffer from heat-affected zones (HAZ), taper effects, and material recast layers—factors that compromise edge quality and dimensional repeatability, especially in thicker sections.

Material selection further differentiates these technologies. CNC machining supports a broad range of engineering-grade metals, plastics, and composites in solid block or bar form, enabling full mechanical property retention. Laser cutting is constrained by material reflectivity and thermal behavior—materials like copper, aluminum, and clear polymers often require specialized laser types (e.g., green or UV lasers) and still yield inconsistent results.

The following table outlines key technical specifications for CNC and laser processes at Honyo Prototype:

| Parameter | 3/4/5-Axis CNC Milling | CNC Turning | Laser Cutting (Fiber/CO₂) |

|—————————-|——————————|—————————–|——————————-|

| Typical Tolerance | ±0.005 mm – ±0.025 mm | ±0.01 mm – ±0.02 mm | ±0.1 mm – ±0.2 mm |

| Surface Roughness (Ra) | 0.8 – 3.2 µm | 0.8 – 1.6 µm | 6.3 – 12.5 µm (with HAZ) |

| Max Work Envelope (mm) | 1000 × 600 × 500 | Ø300 × 500 length | 1500 × 3000 (sheet-based) |

| Materials | Aluminum, Steel, Titanium, Stainless, PEEK, Delrin, Nylon | Same as milling | Mild Steel, Stainless (thin), Acrylic; limited Al/Cu |

| Lead Time (Prototype) | 3–7 days | 3–6 days | 1–3 days |

| Best For | High-precision 3D parts, tight tolerance features, functional assemblies | Cylindrical components, threaded parts, high RPM rotors | Flat profiles, enclosures, non-critical brackets |

For clients demanding functional prototypes or end-use parts with exacting geometric and tolerance requirements, CNC machining—especially 5-axis milling and precision turning—is the optimal choice. Laser cutting serves best in early-stage design validation where speed and cost are prioritized over dimensional fidelity. At Honyo Prototype, we guide clients to the right technology based on part function, volume, and performance criteria.

From CAD to Part: The Process

Precision Manufacturing Workflow: CNC Machining from CAD to Part

At Shenzhen Honyo Prototype, our CNC machining process transforms digital designs into high-precision physical components through a rigorously optimized workflow. This sequence ensures manufacturability, cost efficiency, and adherence to engineering specifications, distinguishing CNC from alternative methods like laser cutting for complex geometries. Unlike laser systems—which excel in 2D sheet metal processing but struggle with 3D contours, tight tolerances, or non-metallic materials—CNC machining delivers superior versatility for functional prototypes and end-use parts requiring micron-level accuracy.

AI-Powered Quoting

The workflow initiates with our proprietary AI quoting engine. Upon CAD file upload (STEP, IGES, or native formats), the system instantly analyzes geometric complexity, material requirements, and dimensional tolerances. It cross-references real-time data on machine availability, tooling costs, and material waste to generate a precise cost and lead time estimate within minutes. This eliminates manual quoting delays and provides immediate feedback on design feasibility, setting clear expectations before DFM engagement.

Comprehensive DFM Analysis

Every design undergoes mandatory Design for Manufacturability (DFM) review by our engineering team. We scrutinize CAD models for CNC-specific constraints: tool access for deep pockets or undercuts, minimum wall thickness relative to material rigidity, and optimal stock dimensions to minimize machining time. Critical considerations include avoiding sharp internal corners (requiring specialty tooling) and ensuring features align with standard tool diameters. For instance, a 0.5mm internal radius may necessitate a costly 1mm ball end mill, whereas a 1.0mm radius allows efficient 2mm tool use. Material selection is validated against CNC capabilities—aluminum 6061-T6 achieves ±0.005mm tolerances, while POM (acetal) requires adjusted feeds to prevent melting. Laser alternatives are evaluated only for thin-sheet applications; CNC remains optimal for 3D forms, threaded features, or materials like titanium where laser thermal distortion is prohibitive.

CNC Production Execution

Approved designs proceed to production on Haas or DMG MORI 3-5 axis centers. Fixturing is optimized using modular vices or custom jigs to ensure zero runout. G-code is verified via simulation software to prevent collisions, followed by first-article inspection using CMMs to validate critical dimensions. For multi-part runs, in-process probing maintains consistency, while automated chip removal sustains surface integrity. This end-to-end control ensures repeatability unattainable with laser systems, which cannot machine enclosed cavities or achieve sub-0.1mm positional accuracy on complex prismatic parts.

Process Capability Comparison

| Parameter | CNC Machining | Laser Cutting |

|——————–|—————————–|—————————–|

| Max Material Thickness | 500mm (metals) | 25mm (metals) |

| Typical Tolerance | ±0.005mm – ±0.025mm | ±0.1mm – ±0.2mm |

| 3D Geometry | Full capability | Limited to 2D profiles |

| Material Range | Metals, plastics, composites | Primarily metals, thin sheets |

| Feature Complexity | Threads, undercuts, cavities | Simple contours only |

This workflow—AI quoting, engineering-led DFM, and precision CNC execution—ensures Shenzhen Honyo Prototype delivers robust, production-ready components with minimal iteration. By prioritizing CNC for multi-axis geometries and tight-tolerance applications, we eliminate the compromises inherent in laser-based alternatives, providing clients with functional accuracy that accelerates time-to-market.

Start Your Project

Start Your Project with Confidence: Choose the Right Manufacturing Process

When launching a new product development cycle, selecting the appropriate manufacturing method is one of the most critical decisions you’ll make. At Shenzhen Honyo Prototype, we specialize in high-precision CNC machining and advanced laser processing—two technologies that serve distinct purposes depending on your design requirements, material selection, and production goals. Understanding the differences between laser cutting and CNC machining helps ensure your prototype or low-volume production run achieves the desired accuracy, surface finish, and structural integrity.

CNC machining is a subtractive manufacturing process that uses rotating cutting tools to remove material from a solid block, offering exceptional dimensional accuracy and versatility across metals, plastics, and composites. It is ideal for complex 3D geometries, tight-tolerance components, and parts requiring superior mechanical strength. In contrast, laser cutting excels in high-speed, 2D profile cutting of sheet materials. It delivers clean edges on thin substrates and is commonly used for enclosures, brackets, and intricate patterns in materials like stainless steel, aluminum, and acrylic.

To help you make an informed choice, consider the following technical comparison:

| Feature | CNC Machining | Laser Cutting |

|————————–|———————————–|————————————|

| Dimensional Accuracy | ±0.005 mm – ±0.01 mm | ±0.1 mm |

| Material Thickness Range | Up to 500 mm | Typically up to 25 mm |

| Suitable Materials | Metals, Plastics, Composites | Sheet metals, Acrylic, Wood, Fabrics |

| Geometry Complexity | 3D shapes, undercuts, threads | 2D profiles, flat patterns |

| Surface Finish | Excellent, customizable | Smooth edge, possible heat tint |

| Tooling Requirements | End mills, drills, fixtures | No contact tooling |

| Lead Time (Prototype) | 3–7 days | 1–3 days |

While laser cutting offers speed and cost-efficiency for flat parts, CNC machining remains the gold standard for functional prototypes and end-use components demanding precision and durability. At Honyo Prototype, we support both processes with ISO-certified quality control, in-house engineering validation, and rapid turnaround times—ensuring your project moves seamlessly from CAD model to physical part.

Your design deserves the right manufacturing partner. Whether you’re evaluating process suitability, material performance, or scalability, our engineering team is ready to assist.

Contact Susan Leo today at info@hy-proto.com to discuss your project specifications, receive technical guidance, and obtain a competitive quote. With decades of experience in precision prototyping and low-volume production, Honyo Prototype is committed to delivering excellence—from concept to reality. Let us help you make the right choice between laser and CNC, tailored to your unique application.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.