Contents

Manufacturing Insight: Cnc Engine Block Machining

Manufacturing Insight: CNC Engine Block Machining

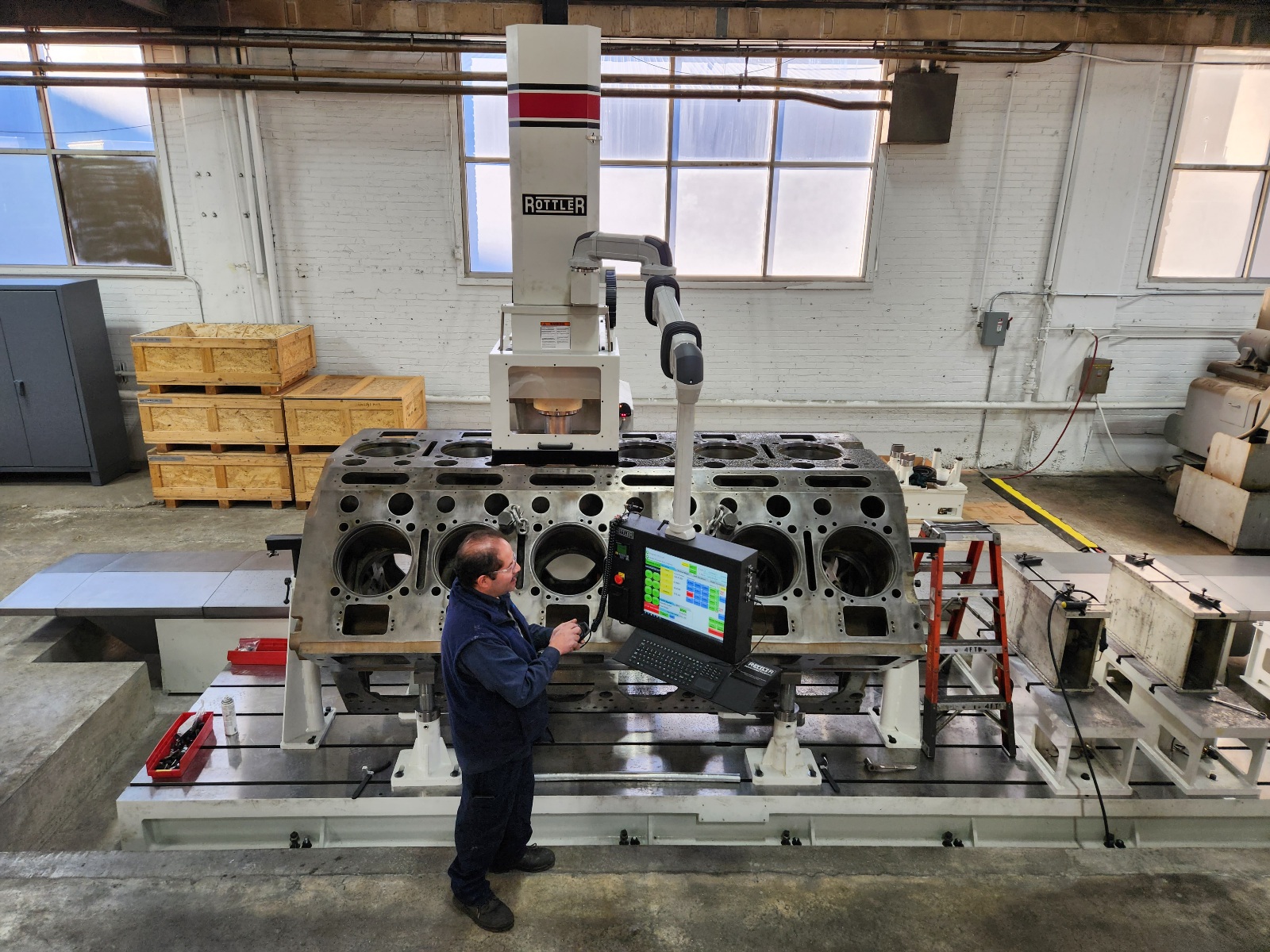

Engine blocks represent one of the most demanding components in powertrain manufacturing, requiring exceptional precision, structural integrity, and thermal stability. Modern CNC machining is the cornerstone technology enabling the production of these complex cast iron or aluminum components, transforming raw castings into dimensionally accurate, high-performance foundations for internal combustion engines. The intricate network of cylinder bores, coolant passages, oil galleries, and mounting surfaces demands multi-axis coordination, stringent thermal management, and sophisticated process control far beyond basic milling or turning operations. At Shenzhen Honyo Prototype, we leverage deep expertise in high-precision CNC machining to meet these exacting challenges for prototyping and low-to-mid volume production runs.

Our core capability centers on advanced multi-axis CNC machining centers, specifically configured for powertrain component complexity. We utilize state-of-the-art 5-axis machining platforms alongside specialized horizontal boring mills and dedicated cylinder honing equipment. This integrated approach allows for near-net-shape machining of critical features—such as cylinder bores, deck surfaces, main bearing caps, and valve train components—in minimal setups, significantly enhancing geometric accuracy and reducing cumulative error. Managing thermal distortion during prolonged machining cycles is critical; our processes incorporate controlled coolant strategies, optimized cutting parameters, and in-process metrology to ensure dimensional stability throughout the operation. Material selection expertise spans common gray cast iron (e.g., GJL-250), ductile iron, and high-silicon aluminum alloys (e.g., 319, 356), with machining strategies tailored to each material’s abrasiveness and thermal properties.

Honyo Prototype delivers comprehensive engine block machining solutions from initial casting to final inspection. Our Shenzhen facility integrates advanced technology with rigorous quality systems to ensure every component meets or exceeds OEM specifications. Key technical capabilities are summarized below.

| Parameter | Specification | Application Benefit |

| :——————— | :————————————- | :————————————————— |

| Machine Platforms | 5-Axis Vertical Machining Centers, Horizontal Boring Mills, CNC Honing Machines | Complete feature machining in minimal setups; complex geometry capability |

| Typical Tolerances | ±0.005 mm (critical bores/deck), ±0.02 mm (general features) | Ensures piston ring sealing, bearing alignment, and assembly integrity |

| Material Expertise | Gray Cast Iron (GJL-250/GJL-300), Ductile Iron, Aluminum Alloys (319/356) | Optimized tooling and parameters for material-specific challenges |

| Max Work Envelope | 800 mm x 600 mm x 500 mm | Accommodates most passenger car and light-duty engine blocks |

| In-Process Metrology | On-machine probing, CMM verification (0.0005″ accuracy) | Real-time error correction; traceable dimensional validation |

Robust quality assurance is non-negotiable in engine block production. Honyo implements comprehensive inspection protocols utilizing calibrated Coordinate Measuring Machines (CMM) for full geometric dimensioning and tolerancing (GD&T) verification, including critical cylinder bore roundness, cylindricity, and cross-hole relationships. Surface roughness analysis ensures optimal sealing surfaces for head gaskets and main bearings. Our AS9100-aligned quality management system provides full traceability from raw material certification through final inspection documentation, offering clients confidence in component reliability and performance. By combining cutting-edge CNC technology, material science understanding, and uncompromising quality control, Shenzhen Honyo Prototype provides engine manufacturers with a trusted partner for precision-machined engine blocks that form the reliable core of high-performance powertrains.

Technical Capabilities

CNC Engine Block Machining – Technical Capabilities

Shenzhen Honyo Prototype specializes in high-precision CNC machining of engine blocks for automotive, aerospace, and industrial applications. Our advanced 3, 4, and 5-axis milling centers, combined with precision turning capabilities, enable us to produce complex engine block geometries with exceptional accuracy and repeatability. Engine blocks demand tight tolerances, robust material integrity, and intricate coolant and oil passage machining—requirements we meet through state-of-the-art equipment and rigorous process control.

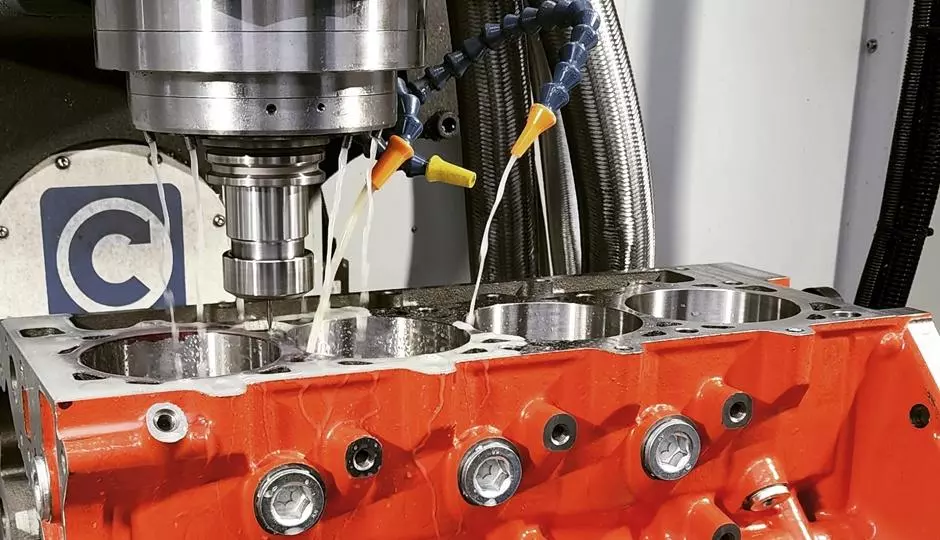

Our 5-axis simultaneous machining technology allows for complete part accessibility, minimizing setup changes and ensuring optimal feature alignment. This is critical for cylinder bore positioning, deck surface flatness, and main bearing bore concentricity. With 4-axis indexing and 3-axis milling options available, we offer scalable solutions for prototyping, low-volume production, and high-mix manufacturing. All milling operations are performed using high-rigidity CNC machines equipped with through-spindle coolant, high-precision spindle probes, and tool length presetters to maintain dimensional consistency.

In addition to multi-axis milling, our CNC turning centers are employed for machining crankshaft journals, cam bores, and other rotational features when integrated into a hybrid manufacturing process. These turning operations support both external and internal diameter machining with sub-micron repeatability. Our engineers utilize advanced CAM software to optimize toolpaths, reduce cycle times, and prevent tool deflection—particularly important when machining deep cylinder bores or thin-walled sections.

Tight tolerance machining is a core competency. We consistently achieve tolerances down to ±0.005 mm on critical features such as cylinder bores, deck surfaces, and main bearing caps. Surface finishes are tightly controlled, with typical values ranging from Ra 0.8 µm to 3.2 µm depending on functional requirements. All engine blocks undergo comprehensive CMM inspection, including GD&T validation, to ensure compliance with design specifications.

We work with a wide range of materials suited for high-stress, high-temperature environments. Our production experience includes aluminum alloys (e.g., A380, A356, 6061), cast iron (gray and ductile), and high-strength steel alloys used in performance and diesel engine applications.

| Material Type | Common Grades | Tolerance Capability (± mm) | Typical Surface Finish (Ra, µm) | Key Applications |

|———————|———————|——————————|———————————-|——————————-|

| Aluminum Alloys | A380, A356, 6061-T6 | 0.005 – 0.012 | 0.8 – 1.6 | Performance, prototype blocks |

| Cast Iron (Gray) | G1800, G2500 | 0.010 – 0.025 | 1.6 – 3.2 | Diesel, industrial engines |

| Ductile Iron | QT400, QT500 | 0.010 – 0.020 | 1.6 – 2.4 | High-load gasoline engines |

| Alloy Steel | 4140, 4340 | 0.008 – 0.015 | 0.8 – 1.6 | Racing, heavy-duty blocks |

All engine block machining projects are supported by full process documentation, first-article inspection reports, and material traceability. At Shenzhen Honyo Prototype, we combine technical precision with agile manufacturing to deliver engine blocks that meet the highest performance and reliability standards.

From CAD to Part: The Process

CNC Engine Block Machining: Production Process Workflow

At Shenzhen Honyo Prototype, precision engine block manufacturing demands a rigorously defined workflow from digital design to finished component. Our process integrates advanced automation with engineering expertise to ensure dimensional accuracy, structural integrity, and rapid turnaround for prototyping and low-volume production. The sequence begins with AI-driven quoting, progresses through Design for Manufacturability (DFM) optimization, and culminates in high-precision CNC machining.

The AI Quote Phase initiates upon client CAD submission. Our proprietary AI system analyzes geometric complexity, material requirements (typically A356-T6 aluminum or cast iron), and critical tolerances to generate an instant cost and lead-time estimate. This system cross-references historical machining data, toolpath simulation outcomes, and material waste metrics, reducing quoting time by 70% while identifying potential high-risk features like thin cylinder walls or intersecting coolant passages. Clients receive actionable feedback within hours, enabling rapid design iteration before formal order placement.

DFM Analysis follows quote acceptance, where our engineering team collaborates with clients to refine the design for manufacturability. We prioritize minimizing setups, avoiding non-machinable undercuts, and optimizing feature sequencing to reduce cycle time. Critical considerations include thermal stress management during machining and ensuring datum accessibility for inspection. Key DFM adjustments are documented below:

| DFM Parameter | Standard Adjustment | Impact on Production |

|————————|—————————————–|———————————|

| Wall Thickness | Minimum 4.5 mm for cylinder bores | Prevents distortion during milling |

| Draft Angles | 1.5° added to non-critical cavities | Eliminates secondary EDM steps |

| Datum Selection | Primary datums on deck surface & main bore | Enables single-setup CMM validation |

| Coolant Passage Design | Radius > 1.2 mm at intersections | Reduces tool breakage risk |

Production Execution leverages 5-axis simultaneous machining centers (DMG MORI NTX 1000 series) with dynamic tool compensation. The process begins with rough milling of external features using indexable face mills, followed by precision boring of cylinder bores to ±0.025 mm tolerance. Critical phases include thermal stress relief via controlled slow cooling after roughing and final honing of bearing bores. All operations occur in temperature-stabilized environments (20±0.5°C) to mitigate thermal drift. In-process probing verifies critical dimensions after each major operation, with final validation via Zeiss CONTURA CMM against ASME Y14.5 GD&T specifications.

| Production Specification | Value | Verification Method |

|————————–|—————————|—————————|

| Positional Tolerance | ±0.015 mm (cylinder bores)| On-machine probing + CMM |

| Surface Finish (Deck) | Ra 0.8 µm | Portable profilometer |

| Cycle Time (Per Block) | 18.5 hours | MES time-tracking system |

| Material Utilization | 82% | Nesting software analytics |

This integrated workflow ensures Honyo delivers engine blocks with zero rework rates for critical sealing surfaces while maintaining 15-day average lead times. Our closed-loop system—from AI quoting through DFM collaboration to precision machining—provides clients with predictable quality and accelerated development cycles for demanding powertrain applications.

Start Your Project

Start Your CNC Engine Block Machining Project with Precision and Confidence

When it comes to high-performance engine development, the foundation lies in precision-engineered components. At Shenzhen Honyo Prototype, we specialize in CNC engine block machining that meets the exacting standards of automotive engineers, motorsport teams, and R&D departments worldwide. Whether you’re developing a prototype for a next-generation powertrain or refining an existing design for enhanced durability and efficiency, our advanced CNC machining capabilities ensure every cylinder bore, coolant passage, and mounting surface is executed with micron-level accuracy.

Our state-of-the-art 5-axis CNC machining centers are equipped to handle complex geometries and tight tolerances inherent in modern engine block designs. We work with a wide range of materials, including aluminum alloys (such as 356, 6061, and A380), cast iron, and high-strength composites, tailoring the machining process to your performance requirements. From raw billet blocks to near-net-shape castings, we deliver fully machined, surface-finished, and inspection-certified engine blocks ready for assembly and testing.

What sets Honyo Prototype apart is our end-to-end engineering support. Our team collaborates with clients from the initial design review through to final production, offering DFM (Design for Manufacturability) analysis to optimize part geometry, reduce cycle time, and minimize material waste. With integrated CAD/CAM workflows and real-time in-process inspection using CMM and laser probing, we ensure dimensional consistency across single prototypes or low-volume production runs.

We understand that engine development timelines are aggressive. That’s why we offer rapid turnaround without compromising quality—typical lead times range from 7 to 15 days depending on complexity and finishing requirements. Every project is managed by a dedicated engineering coordinator to ensure seamless communication and full traceability.

Below are standard specifications for our CNC engine block machining services:

| Specification | Details |

|————–|——–|

| Maximum Work Envelope | 1200 mm × 800 mm × 600 mm |

| Positioning Accuracy | ±0.005 mm |

| Repeatability | ±0.002 mm |

| Surface Finish (Typical) | Ra 0.8–3.2 µm (adjustable per requirement) |

| Materials Supported | Aluminum alloys, Cast Iron, Ductile Iron, Composites |

| Tolerances | IT6–IT8 (standard), IT5 on critical features |

| Finishing Options | As-machined, Bead-blasted, Anodized (Type II/III), Powder Coating |

| Quality Certification | ISO 9001:2015, Full First Article Inspection (FAI) reports available |

Partnering with Honyo Prototype means gaining access to a manufacturing team that speaks the language of performance engineering. We don’t just machine parts—we help bring high-stakes engine innovations to life.

Ready to start your project? Contact Susan Leo, Customer Project Manager at Shenzhen Honyo Prototype, to discuss your engine block specifications, material preferences, and timeline expectations. Let us help you accelerate from concept to combustion.

Email: info@hy-proto.com

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.