Contents

Manufacturing Insight: Cnc Fixture Clamps

Manufacturing Insight: CNC Fixture Clamps

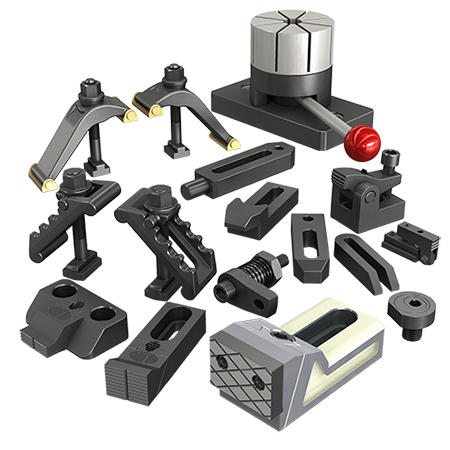

CNC fixture clamps are fundamental components in precision machining, serving as the critical interface that securely immobilizes workpieces during milling, turning, or grinding operations. Their primary function is to counteract cutting forces, preventing workpiece movement that would compromise dimensional accuracy, surface finish, and tool life. Beyond basic holding, advanced clamp designs directly influence setup efficiency, cycle time, operator safety, and the feasibility of complex multi-axis machining. At Shenzhen Honyo Prototype, we recognize that clamp selection and integration are not afterthoughts but strategic elements in achieving true manufacturing excellence for rapid prototyping and low-volume production. Inferior clamping leads to scrapped parts, extended machine downtime for adjustments, and inconsistent quality – risks we systematically eliminate through engineered solutions.

Honyo leverages decades of CNC machining expertise to provide optimized fixture clamp systems tailored to specific project demands. We prioritize clamps offering high repeatability, rapid engagement/disengagement, and minimal obstruction of the tool path. Our engineering team evaluates material compatibility, required clamping force distribution, accessibility constraints, and production volume to recommend the ideal clamp type – whether mechanical toggle, hydraulic, pneumatic, or specialized custom designs. Crucially, all clamps integrated into Honyo fixtures undergo rigorous material selection and quality verification. We utilize high-grade hardened tool steels for critical wear surfaces and aerospace-grade aluminum alloys for lightweight structural components, ensuring longevity even under demanding production cycles. Our in-house metrology lab validates clamp repeatability to within ±0.005mm, a standard critical for tight-tolerance prototypes and functional parts. This meticulous approach minimizes setup time, maximizes machine utilization, and guarantees the geometric integrity of every component we produce.

The following table outlines key specifications for common clamp types frequently implemented within Honyo’s fixture solutions:

| Clamp Type | Typical Material | Max Clamping Force (kN) | Repeatability (mm) | Primary Application Advantage |

| :—————— | :——————— | :———————- | :—————– | :————————————- |

| Precision Toggle | Hardened Alloy Steel | 15 – 45 | ±0.003 | Rapid manual setup, high rigidity |

| Hydraulic Power | Forged Steel | 50 – 200+ | ±0.005 | High force, consistent pressure |

| Pneumatic Standard | Anodized Aluminum | 5 – 25 | ±0.008 | Fast cycle, clean operation |

| Modular V-Block | Tool Steel Inserts | N/A (Support) | ±0.002 | Consistent cylindrical workholding |

Honyo Prototype’s capability extends beyond component supply; we deliver fully integrated, application-specific clamping systems. Our engineers collaborate with clients during the DFM phase to optimize workholding strategy, ensuring clamps are positioned for maximum stability without interfering with cutting tools or coolant flow. This proactive integration, combined with our stringent material and quality standards, directly translates to reduced non-cut time, higher first-pass yield rates, and accelerated time-to-part for our customers. Partnering with Honyo means securing not just a clamp, but a validated, high-performance element of your machining process engineered for prototyping agility and production readiness.

Technical Capabilities

CNC Fixture Clamps: Precision Tooling for Advanced Machining Applications

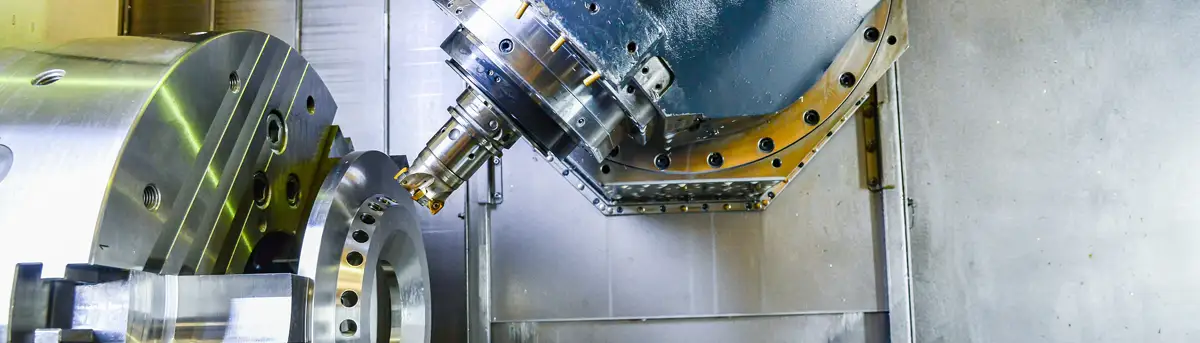

At Shenzhen Honyo Prototype, our CNC fixture clamps are engineered to deliver superior workholding performance across complex 3-axis, 4-axis, and 5-axis milling operations, as well as high-precision turning processes. These clamps are integral to maintaining part stability, minimizing deflection, and ensuring repeatable accuracy during high-speed machining cycles. Designed for compatibility with a wide range of CNC platforms, our fixture clamps support tight-tolerance manufacturing requirements typical in aerospace, medical, and automotive industries.

Our clamping systems are built using high-strength, hardened alloy steels and corrosion-resistant materials to ensure longevity under continuous production conditions. Each clamp undergoes precision CNC machining and heat treatment to achieve optimal hardness and wear resistance. Surface finishes are carefully controlled to reduce friction and improve clamping consistency. Modular designs allow for quick reconfiguration, enabling rapid setup changes and reducing non-cutting time in multi-feature part production.

For 3-axis milling, our clamps provide secure, rigid fixation for prismatic components, minimizing vibration and tool chatter. In 4-axis applications, where rotary indexing is required, our custom fixture clamps maintain alignment accuracy while allowing access to multiple faces of the workpiece. For 5-axis machining, we utilize low-profile, compact clamping solutions that avoid toolpath interference while ensuring full part accessibility. These configurations are critical for complex geometries such as impellers, turbine blades, and structural aerospace components.

In CNC turning operations, our clamping solutions integrate seamlessly with collet chucks, face drivers, and soft jaw systems to hold cylindrical and asymmetrical parts with minimal runout. Hydraulic and pneumatic clamping variants are available for automated environments, ensuring consistent clamping force and reducing human error.

Tight-tolerance machining is a core competency at Honyo Prototype. Our fixture clamps are designed to support tolerances down to ±0.002 mm (±0.00008″) in controlled thermal environments. By combining precision-ground components with rigorous calibration procedures, we ensure that workpiece positioning remains within specified dimensional and geometric limits throughout the machining cycle.

The table below outlines the key material specifications and achievable tolerances for our CNC fixture clamps:

| Parameter | Specification |

|—————————|————————————————|

| Clamp Material Options | 42CrMo4 (AISI 4140), H13 Tool Steel, 304/316 Stainless Steel |

| Hardness Range | 48–52 HRC (typical) |

| Clamping Force Range | 5–20 kN (adjustable via hydraulic/pneumatic) |

| Repeatability | ±0.003 mm (±0.00012″) |

| Positioning Accuracy | ±0.005 mm (±0.0002″) |

| Max Operating Temperature | 200°C (392°F) |

| Surface Finish (Clamping Faces) | Ra ≤ 0.8 µm (32 µin) |

| Tolerance Support (Typical) | ±0.01 mm (±0.0004″) – General Machining |

| Tight Tolerance Capability| ±0.002 mm (±0.00008″) – Precision Applications |

All fixture clamps are inspected using coordinate measuring machines (CMM) and laser alignment systems prior to deployment. We also offer custom fixture design services tailored to unique part geometries and production volumes, ensuring optimal performance across diverse manufacturing environments.

At Shenzhen Honyo Prototype, we combine advanced materials, precision engineering, and rigorous quality control to deliver CNC fixture clamps that meet the highest standards in modern machining.

From CAD to Part: The Process

CNC Fixture Clamp Production Workflow: From CAD to Finished Component

At Shenzhen Honyo Prototype, our CNC fixture clamp manufacturing process integrates precision engineering with streamlined digital workflows to ensure optimal functionality and repeatability. Fixture clamps are critical for securing workpieces during machining, directly impacting part accuracy and throughput. Our end-to-end workflow—AI Quote, DFM, and Production—minimizes lead times while adhering to stringent aerospace and medical industry standards.

The process initiates with the AI-Powered Quotation System. Upon receiving a client’s CAD model (STEP or Parasolid format), our proprietary AI engine analyzes geometric complexity, material requirements, and tolerance demands. It cross-references historical production data to generate an instant, data-driven quote within 2 hours. This system evaluates factors like clamp jaw geometry, thread specifications, and load-bearing surfaces, ensuring cost transparency while flagging potential high-risk features early.

Next, the Design for Manufacturability (DFM) Review phase engages our engineering team. We conduct a rigorous assessment to resolve conflicts between design intent and production realities. Common clamp-specific issues addressed include inadequate wall thickness for clamping force distribution, undercuts complicating 4-axis machining, and tolerance stack-up in pivot mechanisms. DFM feedback is provided within 24 hours, suggesting modifications such as standardized thread forms (e.g., M6-M16 metric) or optimized radii to prevent stress concentration. This step reduces post-machining rework by up to 35% and ensures seamless integration with the client’s existing workholding systems.

Production Execution follows DFM sign-off, commencing with material selection based on application demands. We prioritize 4140 alloy steel for high-stress industrial clamps and 6061-T6 aluminum for lightweight automation fixtures. Machining occurs on HAAS VF-3 and DMG MORI 5-axis centers, with processes sequenced to maintain datum integrity:

| Material | Key Properties | Typical Applications |

|——————-|—————————————–|———————————-|

| 4140 Alloy Steel | 950 MPa UTS, Hardened to 28-32 HRC | Heavy-duty milling, automotive |

| 6061-T6 Aluminum | 310 MPa UTS, Excellent machinability | Robotics, electronics jigs |

| A2 Stainless | Corrosion resistance, 690 MPa UTS | Medical, marine environments |

All clamps undergo precision milling of critical features: parallel jaw faces (±0.005 mm flatness), threaded bores (6H tolerance), and T-slot interfaces. Secondary operations include Molykote lubrication on moving parts and laser etching of part IDs. Final inspection utilizes Zeiss CONTURA CMMs to validate GD&T callouts per ASME Y14.5, with 100% reporting of clamp force consistency (±2% deviation). This closed-loop workflow—from AI-driven quoting to metrology-certified delivery—ensures Honyo’s fixture clamps achieve <0.01 mm positional repeatability, directly enhancing client production uptime.

Start Your Project

Start Your CNC Machining Project with Precision Fixturing from Honyo Prototype

When it comes to CNC machining, the success of your prototype or production run hinges on one critical factor: stability. A secure, repeatable workholding setup ensures dimensional accuracy, surface finish consistency, and overall process efficiency. At Shenzhen Honyo Prototype, we specialize in high-performance CNC fixture clamps designed to meet the rigorous demands of modern machining environments. Whether you’re working with aluminum, steel, titanium, or engineering plastics, our fixturing solutions are engineered to keep your parts firmly in place—cycle after cycle.

Our CNC fixture clamps are built for versatility and durability. Constructed from hardened alloy steel and anodized aluminum components, they resist wear, corrosion, and deformation under high clamping forces. Each clamp is precision-machined to tight tolerances, ensuring alignment accuracy within ±0.005 mm. This level of precision minimizes runout, reduces scrap rates, and extends tool life—critical advantages when working on tight deadlines or complex geometries.

We offer a range of clamping styles to suit different workholding configurations, including edge clamps, swing bridge clamps, and low-profile vise clamps. These are compatible with standard 5C, hydraulic, and modular fixture plates, allowing seamless integration into existing setups. Our modular design philosophy enables quick reconfiguration for job changes, reducing downtime and boosting throughput in high-mix, low-volume production environments.

To help you select the right clamping solution, we’ve compiled key specifications for our most commonly used models:

| Model | Clamping Force (kN) | Max. Opening (mm) | Material | Mounting Pattern | Recommended Use |

|——-|———————|——————-|———-|——————|—————–|

| HC-100 | 8.5 | 30 | Hardened Alloy Steel | ISO 30 | General Purpose Milling |

| HC-200 | 12.0 | 50 | Hardened Alloy Steel | ISO 40 | Heavy-Duty Machining |

| HC-300 | 6.0 | 40 | Anodized Aluminum | ISO 30 | Lightweight Fixturing |

| HC-400 | 10.5 | 35 | Alloy Steel + PTFE Coating | ISO 30 | High-Corrosion Environments |

All Honyo fixture clamps undergo 100% load testing and include integrated safety locks to prevent accidental release during operation. We also offer custom clamping solutions tailored to unique part geometries or automation requirements. From initial concept to final installation, our engineering team collaborates closely with clients to develop fixturing systems that enhance repeatability and reduce setup time.

Starting your next CNC project with the right clamping strategy is essential—and we’re here to help. Contact Susan Leo, our lead manufacturing engineer, to discuss your application requirements, request a quote, or receive technical support. With over a decade of experience in precision prototyping and production machining, Susan ensures every client receives a solution optimized for performance, cost, and scalability.

Reach out today:

Susan Leo

Email: info@hy-proto.com

Shenzhen Honyo Prototype – Engineering Stability, Delivering Precision.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.