Contents

Manufacturing Insight: Injection Molding Machine Parts

Manufacturing Insight: Injection Molding Machine Parts

Understanding the distinction between injection molding machines and the parts produced by injection molding is fundamental for effective rapid tooling partnerships. This insight focuses specifically on the high-precision components manufactured using injection molding technology – the end-product parts critical to your assemblies, enclosures, and functional components. These parts demand rigorous attention to material science, geometric complexity, and dimensional stability, directly impacting final product performance and manufacturability.

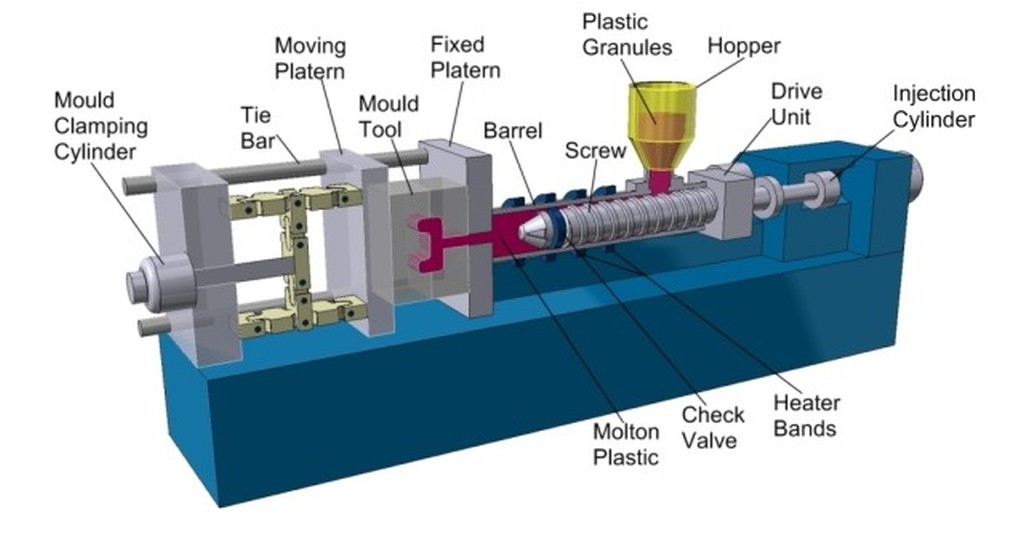

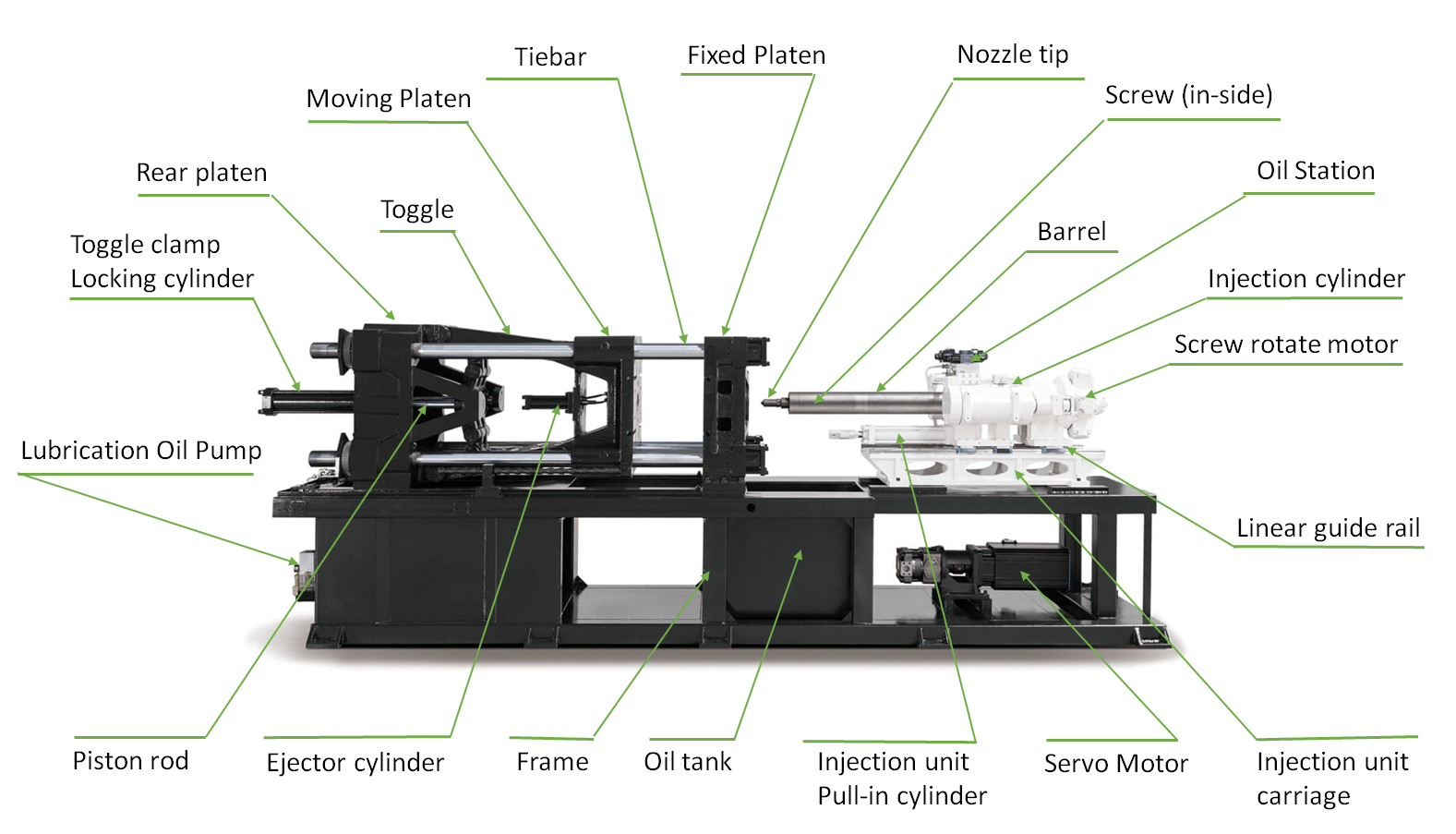

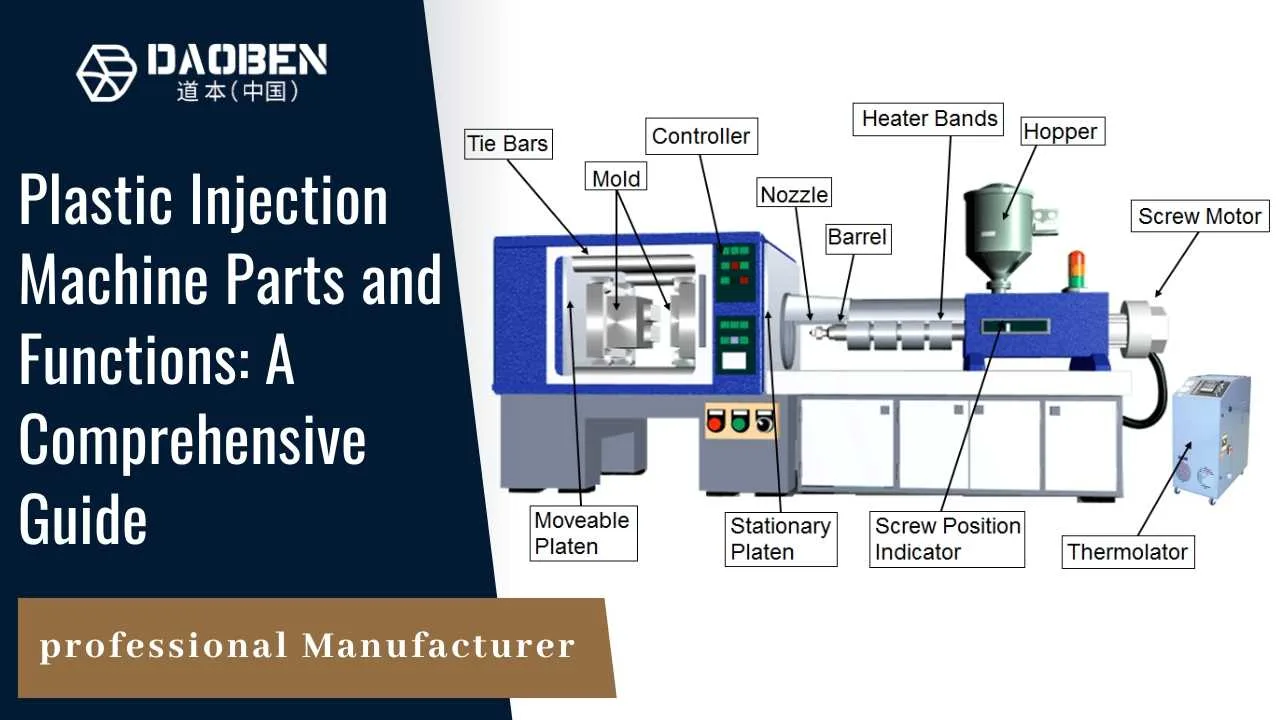

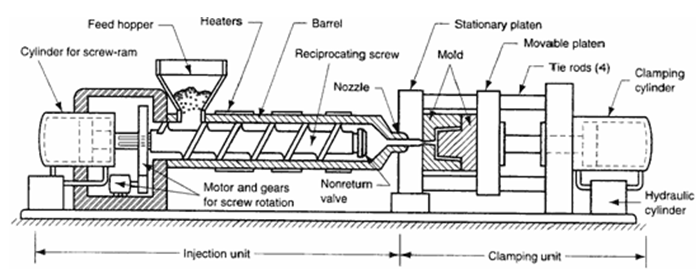

Injection molding excels at producing complex, net-shape plastic parts with exceptional repeatability and surface finish. The process involves melting thermoplastic pellets and injecting the viscous material under high pressure into a precision-machined mold cavity. Key factors influencing part quality include precise temperature control across barrel zones and the mold itself, optimized injection speed and pressure profiles, controlled cooling rates to minimize warpage, and sophisticated ejection system design. Material selection is paramount, spanning commodity resins like ABS and PP to high-performance engineering plastics such as PEEK, PPS, and LCP, each requiring specific processing parameters. Gate type and location significantly affect fill patterns, weld lines, and residual stress. Achieving tight tolerances, especially for features like snap-fits, living hinges, or optical surfaces, necessitates advanced mold design and meticulous process validation.

Shenzhen Honyo Prototype leverages extensive experience in rapid tooling and production injection molding to deliver complex, high-integrity parts efficiently. Our Shenzhen-based facility utilizes modern, well-maintained machinery capable of handling diverse material requirements and part geometries. We specialize in bridging the gap between prototype development and low-to-mid volume production, ensuring seamless scalability without compromising on quality. Our engineering team collaborates closely with clients during the design for manufacturability (DFM) phase, identifying potential issues like sink marks, knit lines, or ejection challenges early, optimizing part geometry, material selection, and gate strategy to minimize cost and accelerate time-to-market. We implement rigorous in-process quality control, including first article inspection (FAI) and statistical process control (SPC), to guarantee parts consistently meet stringent dimensional and functional specifications for precision-critical applications.

Our core machine capabilities support a wide range of project scales and complexities:

| Machine Parameter | Range Offered at Honyo Prototype | Key Application Benefit |

| :———————- | :—————————-: | :———————————————– |

| Clamping Force | 50 to 1,200 Tonnage | Supports small intricate parts to large structural components |

| Shot Size (Max) | 1 to 1,500 cm³ (approx) | Accommodates micro-parts up to substantial housings |

| Material Compatibility | Commodity to High-Performance | Processes standard ABS/PP/PC through PEEK, PPSU, Liquid Crystal Polymers |

| Precision Tolerance | ±0.02 mm to ±0.05 mm | Achieves tight tolerances for critical interfaces and assemblies |

Honyo Prototype provides the technical expertise, advanced equipment, and process rigor required to transform your injection molded part designs into high-quality, reliable components. We focus on delivering robust manufacturing solutions that balance speed, cost, and precision, ensuring your parts perform as intended within your final product assembly. Partner with us for rapid tooling and injection molding execution where engineering precision meets manufacturing agility.

Technical Capabilities

Technical Capabilities: Injection Molding Machine Parts at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers high-precision injection molding machine parts through advanced rapid tooling techniques, combining speed, accuracy, and material versatility to meet demanding production timelines and quality standards. Our technical capabilities are engineered to support both prototyping and low-to-mid volume manufacturing, with a focus on steel and aluminum molds that balance durability, thermal performance, and cost-efficiency. Central to our service offering is the ability to deliver T1 samples within 7 days of mold completion, enabling rapid design validation and accelerated product development cycles.

Our mold fabrication processes leverage CNC machining, EDM, and precision polishing to achieve tight tolerances and superior surface finishes. We specialize in constructing molds from a range of tool steels—including P20, 718H, H13, and S136—for applications requiring high wear resistance and extended service life. For rapid prototyping and lower volume runs, we utilize high-grade aluminum alloys such as 7075 and 6061, which offer excellent machinability, thermal conductivity, and reduced lead times without compromising part quality.

All molds are built to withstand standard injection molding parameters and are compatible with a wide range of thermoplastics, including ABS, PC, PP, PE, PA (nylon), POM, and PMMA. Mold bases are designed using industry-standard configurations, and we integrate hot runner systems, lifters, side actions, and ejection mechanisms as required by part geometry. Each mold undergoes rigorous quality inspection, including mold flow analysis and first-article inspection (FAI), to ensure dimensional accuracy and functional performance.

The following table outlines key technical specifications for our injection molding capabilities:

| Parameter | Specification |

|——————————-|——————————————————————————-|

| Mold Materials | P20, 718H, H13, S136 (Steel); 7075, 6061 (Aluminum) |

| Mold Lifetime | 50,000–100,000+ cycles (Steel); 5,000–10,000 cycles (Aluminum) |

| Part Tolerances (Typical) | ±0.05 mm (Standard); ±0.02 mm (Tight Tolerance) |

| Surface Finishes | SPI Finish A1–A3, B1–B3, C1–C3; Textured, Matte, Glossy, As-Machined |

| Maximum Part Size | 500 mm × 400 mm × 300 mm |

| Minimum Wall Thickness | 0.6 mm (for most engineering plastics) |

| Lead Time (T1 Sample) | 7 days from mold completion (after final design approval) |

| Compatible Resins | ABS, PC, PP, PE, PA6/66, POM, PMMA, PBT, PET, TPE, and more |

| Secondary Operations | Ultrasonic welding, pad printing, painting, annealing, assembly |

We maintain full in-house control over mold design, fabrication, and molding operations, ensuring seamless communication and rapid iteration. Our engineering team collaborates closely with clients to optimize part and mold design for manufacturability (DFM), minimizing defects such as warpage, sink marks, and flash. With a dedicated focus on precision, speed, and repeatability, Shenzhen Honyo Prototype provides a reliable gateway from concept to functional injection-molded parts.

From CAD to Part: The Process

Production Process: From CAD to Final Part at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers precision injection molded machine components through a rigorously defined workflow, ensuring optimal quality, cost efficiency, and accelerated time-to-market. Our integrated process seamlessly transitions from initial design data to certified production parts, leveraging advanced digital tools and deep manufacturing expertise. This structured approach minimizes risk and maximizes first-pass yield for demanding industrial applications.

The workflow commences with the AI-Powered Quoting Engine. Upon receipt of validated CAD geometry and material specifications, our proprietary AI system analyzes part complexity, anticipated tooling requirements, and material consumption. It cross-references this data against our extensive historical production database and current machine utilization metrics. This generates a statistically validated preliminary quote within hours, providing clients with highly accurate cost and lead time projections before formal engineering commitment. This initial step eliminates quoting ambiguities and establishes a transparent foundation for the project.

Critical refinement occurs during the Design for Manufacturability (DFM) Analysis phase. Our senior manufacturing engineers conduct a comprehensive, collaborative review of the CAD model. This is not a passive checklist but an active engineering dialogue focused on optimizing the design for injection molding realities. Key parameters are scrutinized to prevent defects and ensure robust, repeatable production. The core DFM verification focuses on the following critical aspects:

| Parameter | Critical Range | Verification Method | Honyo Standard |

| :—————– | :——————- | :———————— | :———————- |

| Wall Thickness | 1.0mm – 4.0mm | CAD Section Analysis | Uniformity ±0.1mm |

| Draft Angles | ≥ 1° per side | Surface Vector Analysis | ≥ 1.5° for critical surfaces |

| Gate Location | Project Specific | Moldflow Simulation | Minimized witness mark |

| Ejection Force | Calculated Max Load | Structural Simulation | 20% safety margin |

| Tolerance Capability | ISO 2768-mK | GD&T Feasibility Study | Cpk ≥ 1.33 achievable |

Following DFM sign-off, the project transitions to Precision Production. Our certified technicians utilize state-of-the-art all-electric and hybrid injection molding presses (50T – 1000T), selected based on part size and complexity. Production runs commence only after rigorous mold validation, including cavity pressure monitoring and first-article inspection against the approved DFM report and client specifications. Real-time process control systems continuously monitor critical parameters like melt temperature, injection pressure, and cooling time. Every component undergoes 100% visual inspection and statistically significant dimensional verification using calibrated CMMs and optical comparators against the original CAD model. Final parts are meticulously packaged to prevent transit damage, accompanied by full material certifications and first-article inspection reports.

This disciplined CAD-to-Part workflow—AI Quote enabling speed, DFM ensuring manufacturability, and controlled Production guaranteeing quality—forms the cornerstone of Shenzhen Honyo Prototype’s rapid tooling and injection molding service. We transform complex machine component designs into high-integrity production parts with unmatched reliability and efficiency.

Start Your Project

Start Your Injection Molding Project with Confidence at Shenzhen Honyo Prototype

When it comes to precision manufacturing of injection molding machine parts, time, accuracy, and reliability are non-negotiable. At Shenzhen Honyo Prototype, we specialize in rapid tooling and injection molding solutions that help you move quickly from concept to production-ready components—without compromising on quality. Whether you’re developing new machinery components or replacing worn parts, our advanced capabilities in CNC machining, mold design, and plastic injection molding ensure your project is executed with engineering excellence.

Our team leverages state-of-the-art equipment and decades of experience in rapid prototyping and low-to-mid volume production to deliver fully functional, high-tolerance parts tailored to your specifications. We understand the critical role that injection molding components play in maintaining machine performance, and we engineer each part to meet strict durability and fit requirements. From ejector pins and sprue bushes to cavity inserts and runner systems, every component is manufactured using premium materials and validated through rigorous quality checks.

One of the key advantages of partnering with Honyo is our integrated approach. We combine rapid tooling with real-time design feedback, enabling faster iterations and reduced lead times. Our in-house capabilities allow us to control every stage of production—material selection, mold fabrication, trial runs, and final part delivery—ensuring consistency and traceability across batches.

We support a wide range of engineering thermoplastics and reinforced materials, including ABS, PC, POM, PBT, and nylon-based composites, ensuring compatibility with demanding operational environments. Our molding machines range from 50 to 300 tons, allowing flexibility in part size and complexity. All molds are built to ISO 9001 standards and designed for long service life, even under high-cycle production conditions.

Below is an overview of our core injection molding capabilities:

| Specification | Detail |

|————-|——–|

| Clamping Force Range | 50–300 tons |

| Shot Weight Capacity | Up to 2,000 grams (PS) |

| Tolerance | ±0.02 mm standard, ±0.005 mm on request |

| Mold Materials | NAK80, S136, 2344, 2738, 718H |

| Surface Finishes | SPI-S1 to SPI-A1, texture, polish, coating |

| Lead Time (Prototype Tooling) | 7–15 days |

| Production Volume | 100–100,000+ parts per mold |

| Secondary Operations | Ultrasonic welding, insert molding, assembly |

Starting your project is simple. Share your CAD files, material preferences, and volume requirements, and our engineering team will provide a detailed manufacturability analysis and quotation within 24 hours. We support STEP, IGES, SolidWorks, and PDF formats.

Ready to move forward? Contact Susan Leo, our dedicated Project Coordinator, to discuss your injection molding needs. With her technical expertise and commitment to client success, Susan ensures smooth communication and on-time delivery.

Email: info@hy-proto.com

Let’s build precision parts, together.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.