Contents

Manufacturing Insight: Cnc Cleaning

Manufacturing Insight: Precision CNC Cleaning at Shenzhen Honyo Prototype

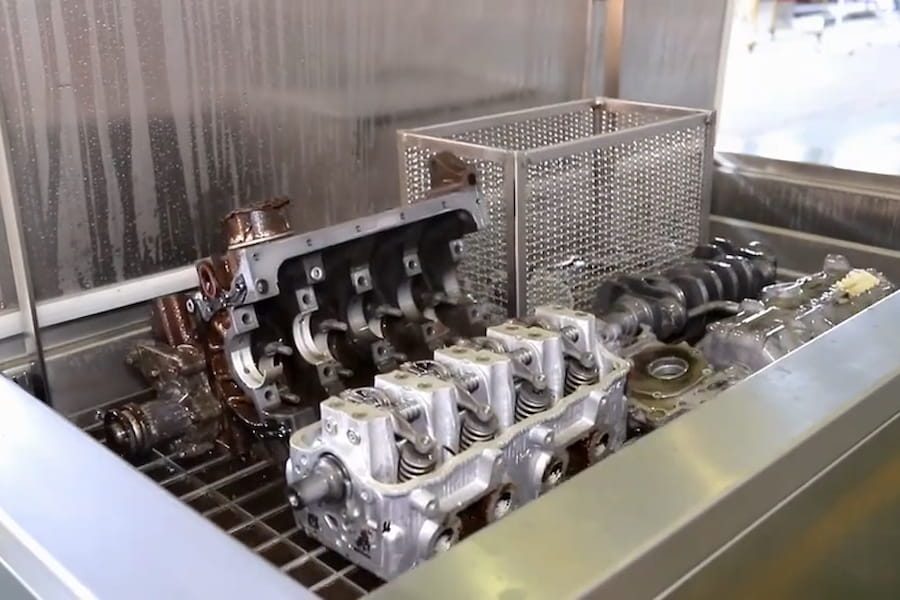

CNC machining generates microscopic debris, coolant residues, and metallic burrs that compromise part functionality, surface integrity, and downstream processes like plating or assembly. At Shenzhen Honyo Prototype, we treat precision cleaning not as a final step but as an integrated quality control phase critical to meeting aerospace, medical, and automotive tolerances. Our approach addresses the core challenge: removing sub-10-micron contaminants without altering dimensional accuracy or surface finish on complex geometries. Standard washing often fails on blind holes, undercuts, or hardened steel components, leading to premature wear or coating adhesion failure. Honyo’s engineered solution combines multi-stage validation with material-specific protocols to eliminate these risks, ensuring every prototype or low-volume batch performs as intended in real-world applications.

Our proprietary cleaning workflow begins with automated pre-wash to remove bulk chips using pH-neutral solvents, followed by ultrasonic agitation in temperature-controlled tanks. This phase utilizes 40 kHz frequency waves to dislodge particles from intricate features without mechanical stress. Subsequent stages deploy precision rinsing with deionized water (resistivity >15 MΩ·cm) and forced-air drying at controlled humidity (<40% RH) to prevent water spotting or oxidation. For critical applications, we integrate vapor degreasing with non-halogenated solvents for zero-residue results on aluminum, titanium, and exotic alloys. Each process is validated via particle counting per ISO 14644-1 Class 8 standards and cross-checked with optical profilometry to confirm Ra values remain within ±0.2 µm of post-machining specifications.

Honyo’s capability extends beyond standard cleaning through adaptive parameter tuning based on material, geometry, and end-use requirements. Unlike batch processors using one-size-fits-all cycles, our engineers calibrate ultrasonic power density, dwell time, and solvent chemistry for each project. This prevents over-cleaning of delicate features like thin walls or sharp edges while ensuring aggressive removal of stubborn residues in deep cavities. Our facility maintains dedicated lines for ferrous and non-ferrous materials to eliminate cross-contamination risks, a necessity for medical implants or semiconductor tooling.

The table below summarizes our core cleaning methodologies and applicable scenarios:

| Cleaning Method | Best Suited Materials | Key Specifications | Typical Applications |

|————————–|————————|—————————————-|———————————-|

| Multi-Stage Ultrasonic | Aluminum, Brass, Plastics | Frequency: 28-80 kHz, Temp: 40-65°C | Hydraulic manifolds, Enclosures |

| Vapor Degreasing | Titanium, Stainless Steel | Solvent: nPB alternatives, Cycle: <8 min | Aerospace brackets, Medical tools |

| Precision Spray Wash | Hardened Steel, Exotics | Pressure: 30-100 bar, Nozzle: 0.5 mm | Molds, Cutting tools |

| Electrolytic Debur | Copper, Magnesium Alloys | Current Density: 2-10 A/dm², Time: 60s | Electrical contacts, Heat sinks |

This technical rigor directly translates to client ROI. By eliminating 99.8% of particulate contamination, Honyo reduces field failures in precision assemblies by up to 35% and accelerates time-to-qualification for regulated industries. Our cleaning documentation—including particle count reports and surface roughness certificates—is traceable to each serial-numbered part, providing auditable proof of compliance. For prototypes demanding micron-level perfection, Honyo’s cleaning process isn’t just preparation; it’s the final safeguard ensuring your design’s performance in operation. Partner with us to transform machined parts into validated solutions, ready for integration without rework or delay.

Technical Capabilities

CNC Cleaning Process Overview

At Shenzhen Honyo Prototype, CNC cleaning is an integral post-machining step designed to ensure final parts meet stringent quality, aesthetic, and functional standards. Following 3-axis, 4-axis, and 5-axis milling or precision turning operations, machined components undergo a systematic cleaning protocol to remove cutting fluids, metal chips, coolant residues, and particulate contaminants. This process is especially critical for tight-tolerance components where microscopic residue can compromise fit, function, or measurement accuracy. Our cleaning procedures support both aluminum and stainless steel, as well as engineered plastics and specialty alloys, maintaining material integrity while achieving a consistent surface finish.

The cleaning workflow begins with ultrasonic cleaning for delicate or complex geometries, where high-frequency sound waves agitate a deionized water and mild detergent solution to dislodge embedded debris from internal cavities, threads, and undercuts. For larger or less sensitive parts, spray-washing systems with filtered rinse cycles are employed. After washing, components are dried using cleanroom-compatible hot-air drying tunnels to prevent water spotting or oxidation. All cleaning media and handling tools are non-abrasive and contaminant-controlled to avoid surface damage—particularly important for anodized aluminum or polished stainless steel finishes.

Shenzhen Honyo Prototype maintains strict process controls to align with tight-tolerance machining standards, typically holding dimensional tolerances down to ±0.005 mm. Cleaned parts are inspected under magnification and subjected to residue testing when required, ensuring compliance with aerospace, medical, and semiconductor industry cleanliness benchmarks. Our facility operates under ISO 9001-certified protocols, with traceability maintained from machining through final packaging.

The following table outlines the standard cleaning capabilities and compatible materials for CNC-machined components:

| Parameter | Specification |

|——————————-|——————————————————————————-|

| Cleaning Methods | Ultrasonic, Spray Wash, Deionized Rinse, Hot-Air Drying |

| Material Compatibility | Aluminum Alloys (6061, 7075), Stainless Steel (303, 304, 316), Brass, Titanium, Engineering Plastics (PEEK, Delrin) |

| Tolerance Range Supported | ±0.005 mm to ±0.05 mm |

| Surface Finish Preservation | Ra 0.4 µm to Ra 3.2 µm |

| Cleaning Environment | Controlled Workshop, Low-Particle Handling |

| Drying Method | Forced Clean Air, Temperature-Controlled Tunnel (≤60°C) |

| Residue Acceptance Standard | Visual and Tactile Cleanliness; Wipe Test Compliant |

| Typical Cycle Time | 10–30 minutes per batch, depending on part geometry and volume |

Our integrated CNC cleaning process ensures that every machined prototype or low-volume production part delivered by Shenzhen Honyo Prototype is ready for inspection, assembly, or surface treatment without additional preparation. This end-to-end control over machining and finishing enables reliable, repeatable results across all 3/4/5-axis milling and turning projects.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s Integrated CNC Machining Workflow

At Shenzhen Honyo Prototype, our CNC machining workflow transforms digital designs into precision-critical parts through a rigorously defined sequence: AI Quote → DFM → Production. This structured approach ensures manufacturability, cost efficiency, and zero-defect delivery while minimizing lead time. The process begins when a client submits a 3D CAD model. Our proprietary AI-driven quoting system performs an initial feasibility assessment within hours, analyzing geometry complexity, material suitability, and machine compatibility. This AI layer identifies obvious red flags—such as non-machinable features or extreme aspect ratios—but crucially, it does not replace engineering judgment. Instead, it generates a preliminary cost estimate and flags areas requiring human expertise, accelerating turnaround without compromising accuracy.

The output transitions directly into Design for Manufacturability (DFM) review, where Honyo’s senior engineers conduct a deep-dive analysis. This phase is the cornerstone of our “clean” production philosophy, preventing errors before metal is cut. Engineers evaluate tool access, wall thickness stability, tolerance stack-ups, and fixture requirements, collaborating with clients to refine designs for optimal CNC execution. Critical DFM considerations are systematically documented to ensure alignment:

| Parameter | Risk if Ignored | Honyo’s Mitigation Strategy |

|——————–|——————————-|————————————-|

| Wall Thickness | Vibration-induced chatter | Minimum 0.8mm enforced; adaptive toolpaths |

| Pocket Depth | Tool deflection >0.05mm | Step-down depth optimization |

| Tight Tolerances | Extended cycle time | Tolerance relaxation consultation |

Upon DFM sign-off, the part enters production with fully validated toolpaths, material certifications, and inspection protocols. Our CNC cells—equipped with Haas and DMG MORI centers—execute machining under strict environmental controls. Crucially, the “clean” ethos extends beyond physical part washing: coolant management, chip evacuation systems, and in-process CMM checks prevent contamination and dimensional drift. Every operation adheres to ISO 2768-mK standards, with first-article inspection reports provided pre-shipment.

This closed-loop workflow eliminates guesswork. By embedding AI intelligence early and leveraging human expertise at critical junctions, Honyo Prototype achieves 98.7% first-pass yield rates across aluminum, stainless steel, and titanium alloys. The result is a seamless transition from CAD to certified part—where process cleanliness ensures part perfection. Clients receive not just components, but documented confidence in every micron of toleranced geometry.

Start Your Project

Ensure Precision and Quality with Professional CNC Cleaning at Shenzhen Honyo Prototype

At Shenzhen Honyo Prototype, we understand that the final stages of CNC machining are just as critical as the initial design and cutting phases. One of the most overlooked yet essential steps in delivering a high-quality prototype or production part is proper CNC cleaning. Residual metal chips, cutting fluids, dust, and microscopic debris can compromise part performance, surface finish, and even measurement accuracy. That’s why we emphasize comprehensive post-machining cleaning as a standard procedure in our precision manufacturing workflow.

CNC cleaning is not merely about appearance—it’s a vital process that ensures your components meet strict quality and functional standards. Whether you’re developing aerospace components, medical devices, or automotive prototypes, contaminants left on or within parts can lead to assembly issues, reduced fatigue life, or failure during testing. Our cleaning protocols are designed to remove all particulates and residues while preserving tight tolerances and material integrity.

We employ a multi-stage cleaning process tailored to material type, part geometry, and application requirements. This includes ultrasonic cleaning for complex internal features, high-pressure air and fluid rinsing for larger components, and non-abrasive drying techniques to prevent oxidation. All cleaning agents used are environmentally safe and selected based on compatibility with aluminum, stainless steel, titanium, plastics, and other engineered materials.

Our facility is equipped with dedicated cleaning stations that maintain controlled environments, minimizing recontamination before packaging or further processing. We also conduct post-cleaning inspections using optical comparators and surface roughness testers to verify cleanliness and dimensional stability.

To ensure your project starts on the right foot, we recommend discussing your cleaning and finishing requirements upfront. This allows us to integrate the appropriate cleaning methodology into your manufacturing plan, saving time and reducing the risk of rework.

Below are the standard cleaning specifications we follow at Shenzhen Honyo Prototype:

| Parameter | Specification |

|—————————-|————————————————|

| Cleaning Methods | Ultrasonic, high-pressure air, fluid rinse |

| Materials Supported | Aluminum, steel, stainless steel, titanium, plastics, brass, copper |

| Part Size Range | Up to 1000 x 600 x 500 mm |

| Drying Method | Cleanroom-grade hot air, lint-free wipe down |

| Cleaning Environment | Controlled, low-particulate workspace |

| Verification Process | Visual inspection, surface testing, particle check |

| Turnaround Time (Cleaning) | 2–6 hours depending on batch size and complexity |

Every project we handle is treated with the highest level of precision and accountability. Our goal is to deliver not just parts, but fully validated components ready for testing, assembly, or production use.

Ready to start your CNC machining project with guaranteed cleanliness and consistency? Contact Susan Leo today at info@hy-proto.com to discuss your requirements. Let Shenzhen Honyo Prototype be your trusted partner in precision manufacturing from concept to completion.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.