Contents

Manufacturing Insight: Cnc Hire

Manufacturing Insight: CNC Hire for Precision Prototyping

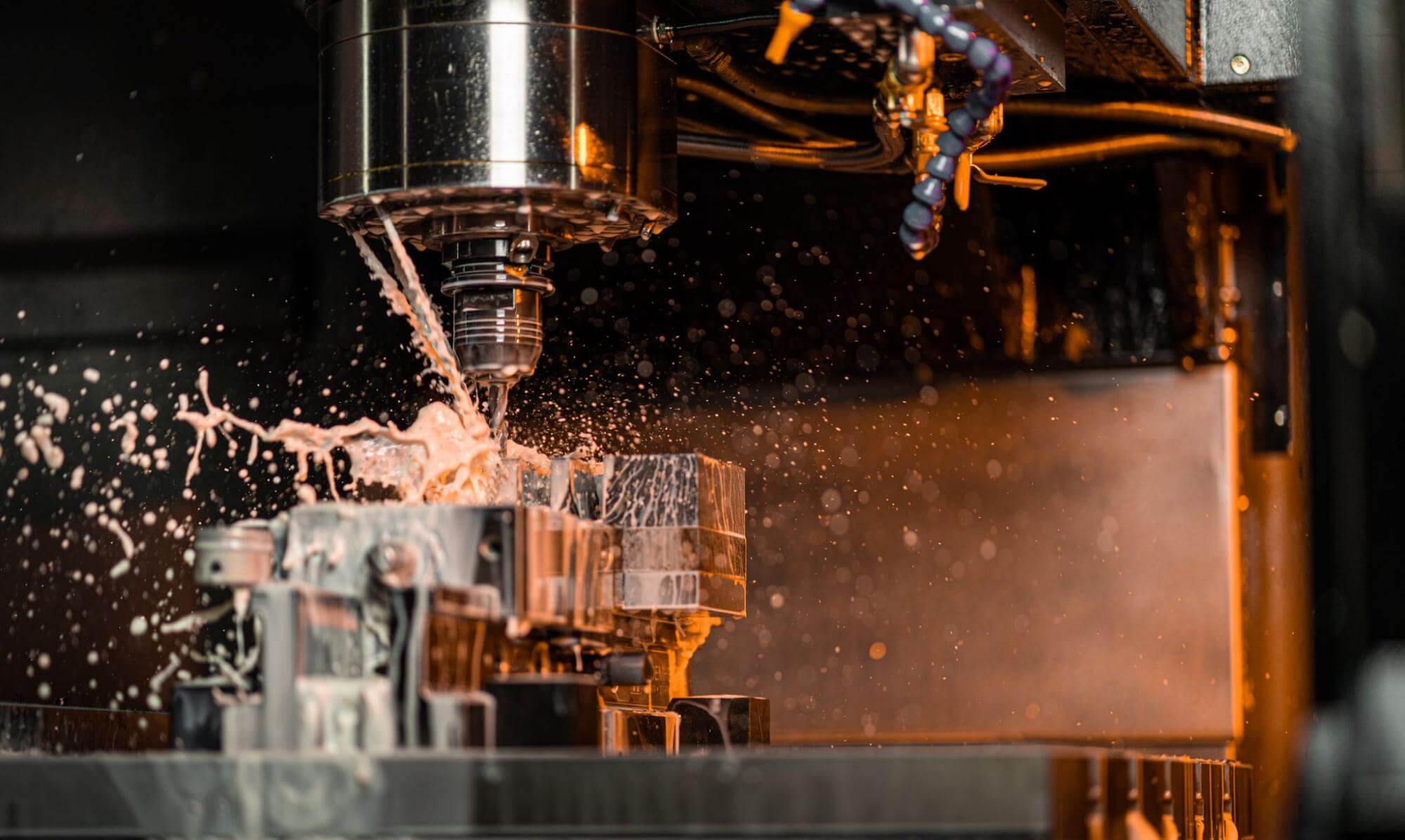

CNC machining remains the cornerstone of high-fidelity rapid prototyping, delivering unmatched precision, material versatility, and repeatability for engineering validation. At Shenzhen Honyo Prototype, we leverage advanced CNC technologies to transform complex 3D CAD models into functional, production-intent prototypes with rigorous adherence to geometric and dimensional specifications. Our focus extends beyond mere fabrication—we engineer solutions that de-risk product development cycles, accelerate time-to-market, and ensure seamless transition to volume manufacturing.

Honyo’s CNC capabilities are anchored in a modern fleet of multi-axis machining centers, integrated with stringent quality management systems compliant with ISO 9001:2015 standards. We specialize in tight-tolerance components (±0.005mm) across diverse engineering materials, including aerospace-grade aluminum alloys, medical stainless steels, titanium, and high-performance polymers. Our engineers optimize toolpaths using Mastercam and Siemens NX software, minimizing cycle times while maximizing surface finish quality—critical for prototypes requiring cosmetic validation or fluid dynamics testing. Unlike standard job shops, Honyo implements in-process gauging and first-article inspection (FAI) per AS9102 standards, ensuring dimensional compliance at every stage. This proactive quality control eliminates costly rework and aligns with the exacting demands of automotive, medical, and industrial clients.

Our strategic advantage lies in marrying technical depth with agile responsiveness. Shenzhen’s robust supply chain ecosystem enables same-day material sourcing for 95% of common alloys and plastics, while our 24/7 production cells support urgent prototypes in 3–5 business days without premium surcharges. We prioritize transparent collaboration: clients receive real-time machining progress updates, material certifications, and full inspection reports via our secure client portal. This operational transparency builds trust and reduces project uncertainty—a critical differentiator when validating designs for regulatory submission or investor review.

Honyo’s technical specifications demonstrate our commitment to precision engineering:

| Parameter | Capability | Application Impact |

|————————-|———————————————|———————————————|

| Machine Types | 3-axis, 4-axis, 5-axis simultaneous milling | Complex geometries, undercuts, organic forms |

| Tolerance Range | ±0.005mm to ±0.025mm | Fit/function validation, assembly testing |

| Material Range | Aluminum 6061/7075, SS303/316, Titanium Gr5, PEEK, Delrin | Functional testing in end-use environments |

| Max Work Envelope | 1000 x 600 x 500 mm | Large-scale structural prototypes |

| Surface Finish | Ra 0.8 μm to Ra 3.2 μm (as-machined) | Cosmetic approval, reduced post-processing |

Choosing Honyo for CNC hire means partnering with a team that treats your prototype as mission-critical. We understand that a single dimension out of tolerance can derail an entire product launch—this mindset drives our obsessive attention to detail. Our engineers proactively identify potential manufacturability issues during DFM reviews, offering actionable feedback to optimize designs for both prototyping and future production. By combining Shenzhen’s manufacturing agility with uncompromising technical rigor, Honyo transforms conceptual designs into precision-engineered reality, empowering your innovation with confidence. Partner with us to navigate prototyping complexities with expertise that delivers results, not just parts.

Technical Capabilities

Technical Capabilities – CNC Machining at Shenzhen Honyo Prototype

Shenzhen Honyo Prototype delivers high-precision CNC machining services tailored for rapid prototyping, low-volume production, and functional testing across aerospace, medical, automotive, and industrial sectors. Our advanced CNC capabilities include 3-axis, 4-axis, and 5-axis milling, as well as multi-axis turning with live tooling, enabling complex geometries and superior surface finishes. We specialize in tight-tolerance machining, consistently achieving ±0.005 mm on critical features, supported by in-house metrology and process validation.

Our 3-axis milling centers are ideal for prismatic parts with straightforward geometries, offering fast turnaround and high repeatability. When increased complexity is required, our 4-axis and 5-axis CNC machines provide simultaneous multi-directional cutting, reducing setup times and enabling single-setup production of intricate components such as impellers, turbine blades, and ergonomic housings. The use of 5-axis technology ensures optimal tool approach angles, improved surface finish, and minimized tool wear, especially on freeform surfaces.

For rotational components, our CNC turning centers integrate live tooling and Y-axis capabilities, allowing for milling, drilling, and tapping operations during the turning process. This enables complete machining of complex turned parts without secondary operations, improving accuracy and reducing lead times. All machines are maintained to stringent standards and operated by experienced technicians using high-rigidity workholding and precision tooling systems.

Tight-tolerance machining is a core strength at Honyo. We implement full process control, including pre-machining material stress relief, in-process inspection, and final CMM verification. Our quality management system is ISO 9001-compliant, ensuring traceability and consistency across all production runs.

We support a wide range of engineering materials, including aluminum alloys, stainless steels, titanium, brass, engineering plastics, and exotic alloys. Material selection is optimized based on application requirements such as strength, corrosion resistance, thermal stability, and machinability.

The following table outlines our standard machining tolerances and compatible materials:

| Feature | Standard Tolerance | Typical Materials |

|——–|——————–|——————|

| Linear Dimensions (Milling) | ±0.01 mm | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Titanium (Gr2, Gr5), Brass (C3604), PEEK, ABS, PC |

| Linear Dimensions (Turning) | ±0.01 mm | Same as above |

| Hole Diameter | ±0.012 mm | Aluminum, Stainless Steel, Brass, Plastics |

| Positional Tolerance | ±0.005 mm | All machined components |

| Surface Roughness (Ra) | 0.8 – 3.2 µm (standard), down to 0.4 µm (polished) | All metals and rigid plastics |

| Angular Features (5-axis) | ±0.02° | Complex aerospace and medical components |

| Threading | ISO Metric, UN/UNC/UNF, NPT | Internal and external threads per ISO/ASME standards |

All tolerances are achievable under standard production conditions. Tighter tolerances down to ±0.002 mm are available upon engineering review. We work directly with design and engineering teams to optimize part manufacturability, ensuring that components meet functional and regulatory requirements without unnecessary cost.

From CAD to Part: The Process

CNC Machining Production Workflow: From CAD to Precision Part

At Shenzhen Honyo Prototype, our CNC machining process transforms client CAD models into high-precision physical components through a rigorously defined sequence. This structured workflow ensures efficiency, quality, and adherence to specifications from initial inquiry to final delivery. The core stages—AI-Powered Quoting, Comprehensive DFM Analysis, and Precision Production—form an integrated system minimizing delays and maximizing first-time-right outcomes.

The process initiates when a client submits a 3D CAD model via our online portal. Our proprietary AI quoting engine instantly analyzes the geometry, material selection, required tolerances, and surface finish specifications. This system cross-references real-time machine availability, tooling requirements, and material costs against historical production data, generating an accurate cost and lead time estimate within minutes. This immediate feedback allows for rapid project validation and iteration before formal commitment, significantly accelerating the path to production compared to manual quoting methods.

Following quote acceptance, the CAD file undergoes mandatory Design for Manufacturability (DFM) review by our senior manufacturing engineering team. This critical stage identifies potential production challenges before programming begins, preventing costly errors and rework. Our engineers perform detailed validation against fundamental CNC machining constraints. Key parameters scrutinized include geometric complexity, feature accessibility, minimum wall thicknesses, hole depth-to-diameter ratios, and tolerance feasibility. The table below outlines common DFM considerations we evaluate:

| DFM Parameter | Critical Threshold | Honyo Resolution Strategy |

| :——————— | :————————– | :——————————————– |

| Minimum Wall Thickness | < 0.8mm (Aluminum) | Recommend design modification or alternative process |

| Hole Depth | > 6x Diameter | Propose step drilling or alternative solutions |

| Tight Tolerances | < ±0.025mm over large spans | Confirm metrology capability or adjust spec |

| Undercuts / Cavities | Non-standard tool access | Suggest redesign or specialized tooling path |

Upon DFM sign-off, the approved CAD model transitions to CAM programming. Our technicians generate optimized toolpaths using industry-leading software (Mastercam, Fusion 360), meticulously selecting cutting tools, spindle speeds, feed rates, and coolant strategies tailored to the specific material and geometry. Program simulation verifies collision avoidance and path efficiency. Physical production commences on our modern Haas and DMG MORI machining centers, featuring multi-axis capabilities and high-precision spindles. Throughout machining, in-process inspections using calibrated CMMs and optical comparators ensure dimensional conformity. Final parts undergo rigorous first-article inspection against the original CAD model, verifying all critical features meet the specified geometric dimensioning and tolerancing (GD&T) requirements before packaging and shipment.

This seamless integration of AI efficiency, engineering expertise in DFM, and precision execution guarantees that Shenzhen Honyo Prototype delivers complex CNC machined prototypes and low-volume production parts with exceptional accuracy, reduced lead times, and minimized risk for our clients.

Start Your Project

Start Your CNC Machining Project with Shenzhen Honyo Prototype

When precision, speed, and reliability are critical to your product development cycle, partnering with an experienced CNC machining service provider is essential. At Shenzhen Honyo Prototype, we specialize in high-accuracy CNC machining for prototypes and low-volume production runs, serving industries ranging from aerospace and medical devices to consumer electronics and automotive engineering. Our advanced 3-, 4-, and 5-axis CNC milling and turning capabilities enable us to produce complex geometries with tight tolerances, ensuring your parts meet exact design specifications.

We understand that every project begins with a vision. Whether you’re developing a first-stage prototype or preparing for small-batch manufacturing, our engineering team works closely with you from concept to completion. By leveraging state-of-the-art CNC equipment and a rigorous quality control process, we deliver machined components with superior surface finish, dimensional accuracy, and material integrity. Our facility supports a wide range of engineering materials, including aluminum, stainless steel, brass, titanium, and engineering plastics such as PEEK and Delrin.

To get started, simply upload your 3D CAD file in STEP, IGES, or STL format. Our engineers will conduct a comprehensive Design for Manufacturability (DFM) review, providing feedback on feature optimization, material selection, and cost-saving opportunities—free of charge. Once the design is finalized, we offer rapid quoting with transparent pricing and no hidden fees. Typical turnaround times range from 3 to 7 business days, depending on complexity and finishing requirements.

We pride ourselves on responsive communication, technical expertise, and on-time delivery—key factors that have made Honyo a trusted partner for global clients seeking reliable rapid prototyping solutions.

| Specification | Details |

|—————|——–|

| Machining Types | 3-axis, 4-axis, 5-axis CNC milling; CNC turning |

| Tolerances | As tight as ±0.005 mm |

| Standard Lead Time | 3–7 working days |

| Supported Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass, Titanium, PEEK, Delrin, and more |

| Finishes | As-machined, anodizing (Type II & III), powder coating, plating, polishing |

| File Formats Accepted | STEP, IGES, STL, DWG, PDF (for 2D drawings) |

Your next breakthrough begins with a single step. Contact Susan Leo today to discuss your CNC machining needs. With years of experience in international project coordination, Susan ensures seamless communication, accurate technical reviews, and timely updates throughout your project lifecycle. Send your CAD files and requirements to info@hy-proto.com for a fast, detailed quote and expert engineering feedback.

At Shenzhen Honyo Prototype, we don’t just manufacture parts—we help bring innovations to life. Let us be your trusted partner in precision manufacturing. Reach out now and experience the Honyo advantage.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.