Contents

Manufacturing Insight: Machining Bit

Manufacturing Insight: Machining Bit Fundamentals and Honyo’s Precision Execution

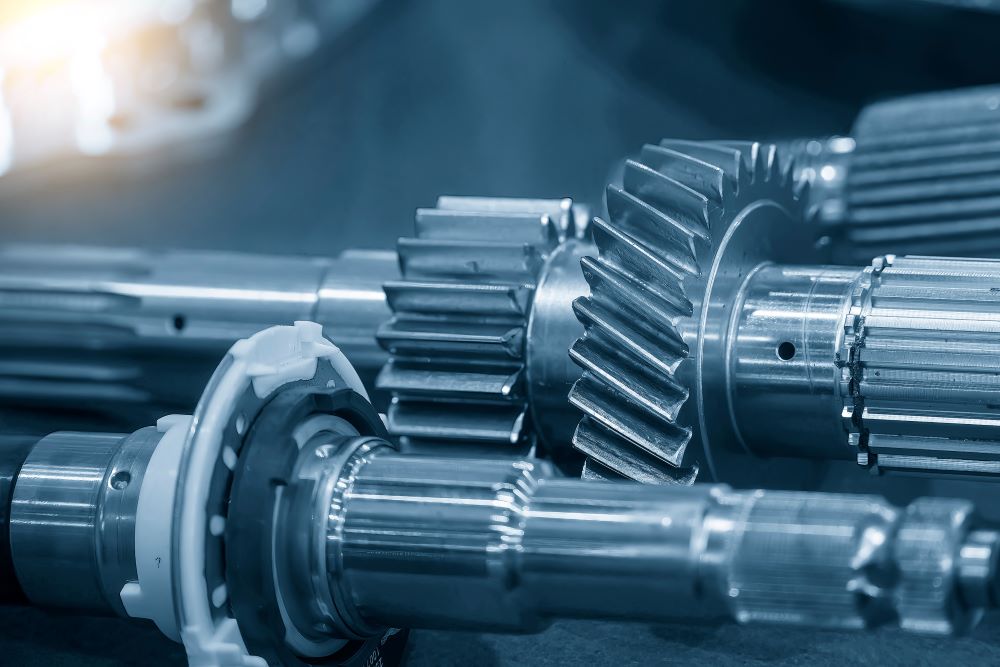

Machining bits, the critical cutting tools in CNC operations, directly determine the precision, surface finish, and structural integrity of prototype components. At Shenzhen Honyo Prototype, we recognize that bit selection transcends basic geometry—it is a strategic decision impacting material compatibility, thermal management, and feature accuracy. Unlike mass production environments where tool wear is predictable, prototyping demands adaptive tooling strategies due to diverse material batches, complex geometries, and stringent first-article requirements. An improperly selected bit introduces micro-vibrations, edge chipping, or dimensional drift, compromising the prototype’s validation purpose. Honyo’s engineering team mitigates these risks through data-driven toolpath optimization and real-time process monitoring, ensuring each bit operates within its optimal performance envelope.

Critical selection parameters include flute count, helix angle, and coating technology, which must align with the substrate’s thermal and mechanical properties. Aluminum alloys, for instance, require high-helix, polished-flute bits to evacuate chips efficiently and prevent built-up edge, while titanium necessitates rigid, low-helix geometries with AlTiN coatings to dissipate heat and resist galling. Honyo maintains an extensive in-house tooling library calibrated for exotic and standard materials, enabling rapid adaptation without client-facing delays. Our process integrates tool life tracking via machine sensors, automatically adjusting feed rates to maintain ±0.005mm tolerances even as cutting edges degrade—a non-negotiable standard for functional prototypes.

The following table outlines Honyo’s most frequently deployed bit types for prototype machining, reflecting our commitment to material-specific optimization:

| Bit Type | Primary Use | Material Compatibility | Key Advantage at Honyo |

|——————-|———————————|—————————-|——————————————-|

| Solid Carbide End Mill | 3D contouring, slotting | Aluminum, Plastics, Steels | Sub-micron precision with vibration-dampening shank designs |

| Polycrystalline Diamond (PCD) | Non-ferrous high-speed finishing | Graphite, CFRP, Copper Alloys | 10x longer life vs. carbide; eliminates fiber pull-out |

| Core Drill | Precision holemaking | Stainless Steel, Titanium | Integrated chamfering; reduces secondary operations |

| Ball Nose Mill | Organic surfaces, molds | All metals, engineering resins | Tapered shank for rigidity in deep cavities |

Honyo’s proprietary tool management system logs every bit’s performance history across 200+ client projects, feeding machine learning algorithms that predict optimal parameters for new geometries. This database, combined with our ISO 9001-certified calibration lab, ensures consistent results whether machining PEEK for medical devices or 7075-T6 aluminum for aerospace fixtures. Crucially, we avoid generic tooling recommendations—each bit specification is validated through trial cuts on client-sourced materials, eliminating assumptions that derail prototype timelines.

For clients, this translates to reduced iteration cycles and accelerated time-to-validation. When Honyo engineers select a machining bit, they balance cutting force dynamics with the prototype’s functional intent, ensuring no feature—be it a 0.2mm cooling channel or a mirror-polished optical surface—is compromised by tooling limitations. This granular control defines our prototype machining advantage: where others see a consumable, we engineer a precision instrument. Partner with Honyo to transform conceptual designs into validated, manufacturable realities through uncompromising tooling science.

Technical Capabilities

Technical Capabilities: Precision Machining of Machining Bits at Shenzhen Honyo Prototype

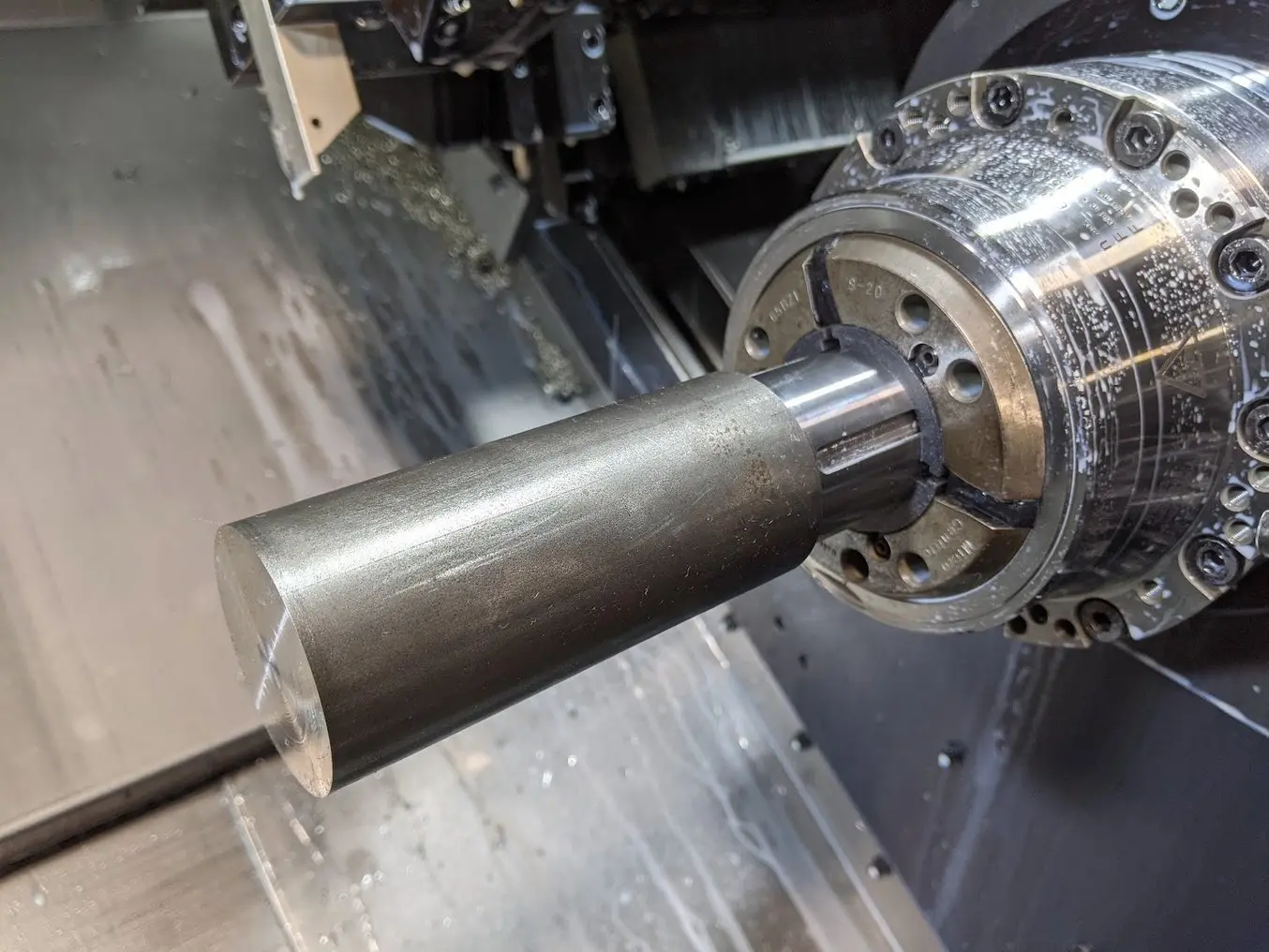

At Shenzhen Honyo Prototype, our advanced CNC machining capabilities are optimized for the production of high-performance machining bits used in industrial cutting, milling, and drilling applications. We specialize in the precision manufacturing of solid carbide, high-speed steel (HSS), and coated cutting tools, ensuring dimensional accuracy, surface integrity, and functional reliability under demanding operational conditions. Our expertise spans 3-axis, 4-axis, and 5-axis simultaneous milling, as well as multi-axis turning, enabling us to produce complex geometries including variable helix flutes, precision margins, and custom tip configurations.

Our 5-axis CNC machining centers provide full contouring capability, allowing for the accurate formation of cutting edges with minimal tool deflection and maximum repeatability. This is critical for machining bits that require asymmetric relief angles, deep flute profiles, or tapered shanks. By leveraging high-resolution probing systems and in-process inspection, we maintain tight control over critical dimensions such as diameter tolerance, concentricity, and helix angle deviation. All tool paths are verified using advanced CAM simulation software to prevent collisions and ensure surface finish consistency.

Turning operations are performed on precision Swiss-type and CNC turning centers, ideal for producing shank features, chamfers, and back-taper geometries on both straight and stepped bit designs. Our hybrid machining approach—combining milling and turning in a single setup—reduces cumulative tolerances and improves overall tool rigidity.

A cornerstone of our manufacturing excellence is our ability to achieve and verify tight tolerances. We consistently maintain tolerances down to ±0.005 mm on critical diameters and ±0.010 mm on overall length dimensions. Surface finishes are controlled to Ra ≤ 0.4 µm on functional surfaces to minimize friction and improve chip evacuation. All components undergo 100% first-article inspection using coordinate measuring machines (CMM) and optical comparators, with full traceability and material certification provided.

We support a wide range of tool materials and coatings, tailored to specific application requirements such as high-speed cutting, abrasive resistance, or elevated temperature performance. Our production process integrates post-machining treatments including edge preparation (hone/flare), cleaning, and optional PVD/DLC coatings through trusted partners.

Below is a summary of our standard machining capabilities and tolerances for machining bit components:

| Parameter | 3-Axis Milling | 4-Axis Milling | 5-Axis Milling | CNC Turning |

|—————————–|———————-|———————-|———————-|———————-|

| Positional Tolerance | ±0.010 mm | ±0.008 mm | ±0.005 mm | ±0.005 mm |

| Diameter Tolerance | ±0.010 mm | ±0.008 mm | ±0.005 mm | ±0.003 mm |

| Surface Finish (Ra) | ≤ 0.8 µm | ≤ 0.6 µm | ≤ 0.4 µm | ≤ 0.4 µm |

| Feature Complexity | Moderate | High | Very High | High (symmetrical) |

| Max Work Envelope (mm) | 500 × 400 × 300 | 500 × 400 × 300 | 450 × 350 × 250 | Ø40 × 150 length |

| Material Type | Typical Applications | Achievable Tolerance | Notes |

|—————————|——————————|———————-|——————————–|

| Solid Carbide | End mills, drills, reamers | ±0.005 mm | High wear resistance |

| High-Speed Steel (HSS) | Prototyping, low-volume bits | ±0.010 mm | Excellent toughness |

| Powdered Metal HSS | High-performance bits | ±0.008 mm | Improved uniformity |

| TiN/TiAlN Coated Tools | Extended tool life | ±0.005 mm (post-coat)| Coating thickness controlled |

Shenzhen Honyo Prototype combines cutting-edge equipment, rigorous quality control, and deep process expertise to deliver machining bits that meet the highest standards in performance and reliability.

From CAD to Part: The Process

From CAD to Part: Honyo Prototype’s CNC Machining Bit Production Workflow

At Shenzhen Honyo Prototype, our CNC machining bit production process is engineered for precision, efficiency, and seamless client collaboration. We transform digital designs into high-performance physical components through a rigorously defined three-stage workflow: AI-Powered Quoting, Collaborative Design for Manufacturability (DFM), and Precision Production. This structured approach ensures optimal outcomes while minimizing time-to-market.

The process initiates with our proprietary AI Quote Engine. Upon receiving a client’s CAD file (STEP, IGES, or native formats), the AI system performs instant geometric analysis, material identification, and complexity assessment. It cross-references Honyo’s extensive database of machine capabilities, tooling libraries, and historical production data to generate a highly accurate cost and lead time estimate within minutes. This eliminates traditional quoting delays, providing clients with immediate project feasibility insights and enabling faster decision-making. The AI output includes preliminary material cost breakdowns, machine time projections, and identified potential high-complexity features requiring DFM review.

Following client acceptance of the AI quote, the project enters the critical Collaborative DFM Phase. Our senior manufacturing engineers conduct a comprehensive geometric dimensioning and tolerancing (GD&T) analysis, scrutinizing wall thicknesses, aspect ratios, internal features, and surface finish requirements. We proactively identify manufacturability risks such as thin walls prone to deflection, deep cavities challenging tool reach, or unnecessarily tight tolerances increasing cost. Crucially, this is a dialogue; engineers provide specific, actionable feedback directly linked to the CAD model, suggesting geometric modifications or alternative processes (e.g., EDM for intricate internal features) to enhance producibility without compromising functional intent. Client approval of the DFM-optimized design is mandatory before production launch.

The Precision Production Stage leverages Honyo’s advanced CNC infrastructure. Programs are generated using Mastercam and verified via third-party simulation software to prevent collisions and ensure path accuracy. Machining occurs on our calibrated Haas and DMG MORI centers, including 3-axis vertical mills, 4-axis indexed machines, and 5-axis simultaneous milling platforms. Critical parameters are strictly controlled according to the specifications outlined below. In-process inspections using Mitutoyo CMMs and optical comparators verify critical dimensions after each major operation. Final parts undergo 100% dimensional inspection against the approved drawing and stringent surface finish verification before packaging and shipment.

Key Machining Bit Production Specifications

| Parameter | Standard Capability | High-Precision Capability | Common Materials Supported |

| :—————– | :———————— | :———————— | :—————————— |

| Tolerance (Linear) | ±0.05 mm | ±0.005 mm | Aluminum Alloys (6061, 7075) |

| Tolerance (GD&T) | ±0.1 mm Profile | ±0.01 mm Position | Stainless Steel (303, 304, 17-4)|

| Surface Finish (Ra)| 3.2 µm (125 µin) | 0.8 µm (32 µin) | Tool Steel (A2, D2, S7) |

| Max Work Envelope | 1000 x 600 x 500 mm | 500 x 400 x 300 mm | Titanium (Gr5), Brass, Plastics |

| Min Feature Size | 0.5 mm Hole Diameter | 0.1 mm Slot Width | |

This integrated workflow, underpinned by AI efficiency, expert DFM collaboration, and rigorous CNC execution, ensures Honyo Prototype consistently delivers machining bits that meet exacting performance and quality standards, directly translating client CAD data into reliable end-use components.

Start Your Project

Start Your CNC Machining Project with Honyo Prototype – Precision You Can Trust

When it comes to high-precision CNC machining, every detail matters. At Shenzhen Honyo Prototype, we specialize in delivering accurate, reliable, and repeatable results for prototypes and low-volume production runs. Whether you’re developing a new product, refining a design, or scaling up from concept to prototype, our advanced machining capabilities ensure your parts meet exact specifications—on time and within budget.

Our CNC machining services are engineered for performance, utilizing state-of-the-art 3-axis, 4-axis, and 5-axis milling centers, as well as precision turning machines. We support a wide range of materials including aluminum, stainless steel, brass, copper, titanium, and various engineering plastics such as PEEK, ABS, and polycarbonate. With tight tolerances down to ±0.005 mm and superior surface finishes, Honyo Prototype is your trusted partner for functional prototypes and end-use components.

We understand that starting a new project can be complex. That’s why our team of experienced manufacturing engineers works closely with clients from the initial design review through final delivery. We provide expert feedback on design for manufacturability (DFM), helping you optimize part geometry, reduce costs, and accelerate time-to-market.

To get started, simply share your 3D CAD model or technical drawings with us. Our team will evaluate your requirements, recommend the best material and machining strategy, and provide a fast, detailed quotation. We support common file formats including STEP, IGES, STL, and native CAD files from SolidWorks, AutoCAD, Fusion 360, and more.

| Specification | Detail |

|—————|——–|

| Machining Types | 3-axis, 4-axis, 5-axis milling, CNC turning |

| Materials | Aluminum (6061, 7075), Stainless Steel (303, 304, 316), Brass, Copper, Titanium, PEEK, ABS, PC, Nylon |

| Tolerances | Standard: ±0.05 mm; High Precision: ±0.005 mm |

| Max Work Envelope | 1200 × 600 × 500 mm |

| Surface Finishes | As-machined, Anodizing (Type II & III), Plating, Powder Coating, Bead Blasting |

| Lead Time | As fast as 3–5 days for prototypes |

At Honyo Prototype, quality is built into every process. Our facility is ISO 9001-certified, and we employ rigorous in-process inspections and final quality checks using coordinate measuring machines (CMM) and optical comparators to ensure consistency and compliance.

Ready to bring your idea to life? Contact Susan Leo, your dedicated project manager at Shenzhen Honyo Prototype. With years of experience in precision manufacturing and client solutions, Susan will guide you through every step of the process, ensuring seamless communication and outstanding results.

Email Susan Leo at info@hy-proto.com today to request a quote or discuss your project requirements. Include your CAD file or specifications, and we’ll respond with a detailed manufacturing plan and competitive pricing within 24 hours. Let Honyo Prototype be your trusted partner in innovation—where precision meets performance.

🚀 Rapid Prototyping Estimator

Get a rough estimate for CNC/3D Printing costs.